Transcription

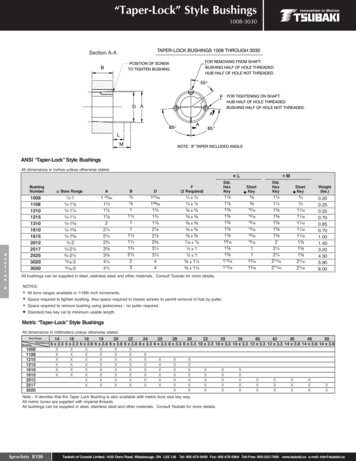

Taper LockTooling SystemTaper Lock Tooling andFor Drilling, Reaming, Countersinking, Tolerancing,THE TAPER LOCK STORY and HELPFUL TIPSThe Taper Lock Fastener System builds structurestogether and simultaneously adds greatly to theirfatigue life. Taper Lock is a complete system oftapered drills, tapered fasteners and tapered gauges.Taper Lock Fastener holes can be accomplishedquickly with a high degree of accuracy, confidence andsecurity.It is essential that the Taper Lock System beaccompanied by excellent craftsmanship. Regardlessof the higher degree of accuracy, engineering andquality, the ultimate result depends on who builds theproduct.The Taper Lock System has its own built-in qualitycontrols. Reasonable care installations will ensureproud finished products. By following this exceptionalsystem, each conscientious craftsman will receivegreat satisfaction knowing that each Fastener hasbeen installed accurately.The obvious resultsobtained from excellence isgratification.Taper Locks have changed theequations in struct ural li fecomputations.These Fastenersand Systems are composed oftapered conical shank fasteners.Tapered precision holes, togetherwith preloads and interference areall uniformly controlled.The advancement of theinterference fit effectively impactspreload. Radial compression, staticpreload and peripheral tension,effectively reduce stress andproportionately improve fatigue life.The high performance of Taper Lock Fasteners willcontinually provide structural integrity in existing andfuture designed vehicles and products.The term Taper Lock is derived from the fact thatthis tapered fastener is self-locking. When thetapered fastener is inserted into a correctly taperedhole, the interference fit secures the fastener and locksit. This prohibits it from turning, eliminating wrenches,other types of holding and special costly operations.Taper Lock Fasteners have accurately groundQ4precision shanks inserted with a mating precisiontapered hole and a mating Washernut assembly. Awasher and free turning nut make up the assembly thatprovides automatic washer centering. The “WasherNut” is extremely strong. The washer is captured tothe nut while allowing the nut to turn freely. Thesefeatures eliminate the loss of washers or handlinginventory and installations. Fumbling is eliminated.Taper Lock’s superiority is its controlledinterference fit. Preload is induced at the wall of thehole and progresses through the material, diminishingto zero at some distance from the hole’s edge.Regular Fasteners must be driven or pressed the fulllength of the hole when attempting interference fits.This procedure forces the walls outward, tending topromote seizure, galling, plating damage andbroaching the hole.The result is non-uniformpreloading. This action creates areas of concentratedand near zero stress. Thus the fastener purpose isdefeated.The Taper Lock Fastener fits freely into thegreatest portion ofthe hole and needtravel only a shortdistancetobecomefullinterference,u n i f o r m l ypreloading as thewallsexpand.CONVENTIONALThisprovidesTAPER LOCKFASTENERFASTENERlonger wear andUnbalanced StressBalanced Stressgreater strength.This allows TaperLocks to be removed without damage to thefastener or the hole.Taper Lock’s superior joint strength occursthrough even load distribution and requires fewerfasteners. Closer hole spacing than otherconventional fasteners is allowed.Nut height isreduced allowing greater wrenching freedom ininaccessible or tight places.Two types of Taper Lock Fasteners exist—threaded and non-threaded. All threaded fastenersuse the mating Washernut .Taper Lock Fasteners are available in grip lengthsof 1/16 or 1/32 increments. Charts are provided byfastener manufacturers for the ranges of thickness forUNITED Value — Taper Lock Quality!11-2-98

The Taper Lock SystemDepth Control, Guiding, Gauging & Fastener Installationseach grip length.The 100º Flush Head type fasteners are measuredfrom the top of the head to the end of the fullconical portion of the shank. The Protruding Headtype fasteners are measured from under the headto the end of the conical shank.The Taper Lock Drilling System has many qualifiedpositive feed power and motor drilling unitsavailable. Quackenbush provides In Line, Right Angleand Self Colleting tools. They compete favorably forbusiness with Cooper Tools, Rockwell, Buckeye,Gardner Denver, Peck Drill, Doler, Dotco, ChicagoPneumatic and Winslow Spacematic products.Quackenbush offers Q-Matic to Spacematiccustomers. Quackenbush has gained fairlybroad acceptance for use with drilling TaperLock holes. UNITED's Helox Shelox andNurlock Adapter Systems complementQuackenbush Positive Feed Motors.Helox Shelox assures the user drillingaccuracy and precision depth control withtotal SPC Gauging for Taper Lock drillingand installation.UNITED Taper Lock Tooling Components adapt toSpacematic, Quackenbush, Chicago Pneumatic,Rockwell, Cooper, Keller, Buckeye, Dotco, Doler, andGardner Denver drill motors.UNITED’s Helox Shelox Depth Control andSensor System designed for space saving drilling onirregular or contoured surfaces. Helox Shelox alsoadapts to these motors accurately guiding anddirecting cutters, coolant and controls to assure safe,secure and accurate Taper Lock drilling and fastenerinstallation.The Spacematic, afastpositivefeedmotor, is air operatedwith depth control. Itrequiresampleoperating room, butdoes not require pilotholes.Details areavailableinthissection.Chicago Pneumatic Power Motors are small airoperated units and have maximum capability of 3/163-18-04Taper LockDrilling Systemgroup 3 Taper Lock holes. These units can be usedwith UNITED’s Micro Controlled Countersink SuperStops, also in this section. The Chicago PneumaticUnit operates at 15000 r.p.m. Pilot holes are requiredfor reaming.Buckeye Power Units are medium size and airoperated. Their units operate at 500 r.p.m. or more.Use UNITED’s Micro Controlled Countersink SuperStop with Buckeye. They are shown in this sectionTaper Lock Coolant and Cutting Fluids wereexplained by P.F.S. Omark Applications EngineeringLaboratory as follows:“ALUMINUM cutting fluids for drilling and reamingaluminum and other soft metals with high speed steelcutters are air, air and water mist, soluble oil in eithermist or flooding forms, refrigerated air, liquefied Freonand light mixtures of mineral or lard oil. Soluble oil ismost poplar for a broad variety of applications whenmixed in a ratio of 1:30 with water. Liquefied Freonis to be used with great care in well ventilatedareas. This is due to high toxicity levels. Cetylalcohol is suitable for hand reaming.”“TITANIUM and ALLOY STEEL Drilling and Reamingwith M33 or M42 Cobalt high speed cutting uses air,air and water mist or flooding and liquefied Freon.Use liquefied Freon with great care and only in wellventilated areas. Beware of its high toxicity levels.For heavy duty drilling, sulphurized cutting oilcontaining only up to 2% active sulphur may besuccessfully used.”All types of Taper Lock Fasteners, with theexception of low interference type, do not requirewrenching, sockets or other holding tools.All Taper Locks are installed into a tapered holesimultaneously locking the fastener in the hole.Seating the Taper Lock Threaded Fastener occursthrough the transfer of torque onto the mating nut.Taper Lock Collars are swaged sealed with a rivetgun.P.B. Fastener, Deutsch, SPS, Voi Shan andBlancAero all provide full and complete Taper Locktechniques and details for their respective fastenerinstallation and removal.12200 WOODRUFF AVE. DOWNEY, CA 90241-5608 TELEPHONE (562) 803-1521 / (800) 421-3466 IN CA / (800) 486-3466 FAX (562) 803-6898 / (800) 486-3465EMAIL united@ucc-udb.com WEBSITE www.ucc-udb.comQ5

Taper LockGauging & ReamingTaper Lock Tooling andFor Drilling, Reaming, Countersinking, Tolerancing,are available to adapt Spacematic, Q-matic and otherair-powered tools to all UNITED tooling.UNITED’s commitment is to provide our industryTaper Lock quality tooling in line with our goal —FIRST - ON TIME - FASTER - LOWER COST!Taper Lock Gauges are provided by UNITED forchecking hole diameters, countersinks, bearing, finishand depth.The UTLG-5100A and -B GaugeAssembliescheck the holediameter at twopoints for 100ºcountersink holes.Sleeve and Pincheck 'B' charteddiameter(lowercheck point) in thecountersink hole.Reversethebushing sleeveUTLG-5100-AUTLG-5100-Band pin and check the upper'B' diameter.Selecting the correct Drill, Reamer, Countersinkand hole sizes for Flush Head Fasteners orProtruding Head holes requires simple efficientoperations.Taperedtoolingisprovided forevery TaperLocksizefastener.The tapered tools are relieved on backout whicheliminates chip galling and adds accuracy and smoothhole finishes. The famous Taper Lock Drill Reamerhas cutting lips at the end of the tool and reamer fluteson the sides.UNITED Taper Lock tools are manufactured to thehighest standards of quality, precision andaccuracy with the longevity required to completeyour products on time the first time.By using UNITED’s precision tapered DepthControl and Gauge tooling, operator excellencecan avoid these common pitfalls:A.The UTLG-5120 CountersinkDepth Gauge checks thedepth at countersink holes andis used in setting up all drillingequipment to accurate depths.Each Gauge is simple,accurate and a fast method ofinspecting Taper Lock holes.One advantage of the TaperUTLG-5120Lock System is that thefastener itself acts as agauge. Simply place this fastener in the hole by firmhand pressure and measure the protrusion of the headabove the material. Divide the measurement by 48.The result is the exact interference between thefastener and the hole. It is not possible to install theincorrect fastener in a Taper Lock hole.UNITED’s Taper Lock Tooling System includes AirMotors, Depth Sensors, Drills, Drill Reamers, MicroStop Cages, Guide Bushings, Fastener Installationand Removal Devices and all Product andInstallation Gauges. UNITED conversion spindlesQ6B.C.D.E.F.G.H.I.J.Eccentricity from worn power tools, spindles orcountersink cagesImproper support of the power feed toolsForced feeding and excessive tool pressureChip overload and gallingImproperly sized pilot holesIncorrect tool feeds and speedsDull tools causing crooked startsImproper drill alignmentInaccurate power feed, speed or stop adjustmentsExcessive dwell in the hole at the correct holedepth causing poor finish and oversized A. Hold the workpieces together clamped securely inplace.B. Accurately drill pilot holes through precision Blocksand Drill Bars.C. Use correct Taper Drills, Drill Reamer Tools,Countersinks, Super Stop Cages andaccurateDepth Control Units.D. Free the holes of chips and coolant before andafter reaming.E. Press the fastener head down securely by handUNITED Value — Taper Lock Quality!11-2-98

The Taper Lock SystemDepth Control, Guiding, Gauging & Fastener Installationsafter placing in the hole.Check the head protrusion with the UTLG-5130Gauge before installing the nut.G. If head protrusion is accurate, install and tightenthe nut with a rivet gun and bar.H. Seat the fastener using a rivet gun and buckingbarwith a hollow phenolic insert.I. Place the aluminum swage collar over the fullyseated grooved fastener end.J. Place the gun with a rivet set over the collar with abucking bar placed against the fastener head.K. Apply rivet driving pressure and form the collar intothe grooved end of the fastener.L. When the fastener is fully seated, trim off anyexcess material.M. The Taper Lock should now be fully swaged with atrimmed collar and tightly seated head.N. The protrusion of the Taper Lock’s fastener’sthreaded end must be within the specificprotrusion limits.F.The Taper Lock Fastener Removal Tool provides aneasy means of removing the fastener. If the collar isimproperly formed, cracked or loose, remove thefastener by first using a power tool with a hollow millcutter until the cutter is seated on the fastener’s end.Remove the fastenerwith a sharp tap onUNITED’sTaperLock Knock OutTool installed on thefastener’s threaded end without damaging the thread.(Refer to Taper Lock Knock Out Tool UDB-710255 inthis section.) Clean the hole and reseat the fastenerfollowing UNITED’s installation steps.UNITED Micro Super Stop Drill Cages haveindexing graduations which assure depthcontrol within .001 inch. A Drill Bar Foot isprovided which is placed flush to theworkpiece surface to guide this Micro SuperStop precisely. This assures straight holes onsize and normal to the workpiece.When using UNITED’s Micro ControlledCountersink Super Stop, be sure to keep thedrill cage and drill bar perfectly flat against thestructure before reaming commences.Hold the unit firmly but allow a light feedpressure. Allowing your drill to dwell after thehole is completed will cause oversized holes.Withdraw while the motor is running.11-2-98TL Installation, Removal& Final Gauge CheckWithdraw frequently to remove chips.Abnormalcutting or wobbling will also cause oversized holes.When hand reaming or drilling, the pressure is ofgreat importance. Less pressure and a “differentfeel” are required as compared to straight drilling.RECOMMENDED SPEEDS for DRILLING and REAMINGGROUPDIAMETERRPMCYCLE TIME13/16 - 1/430008 - 1215/16 - 3/8150014 - 18See the following speed recommendations in the chart.UNITED Single Flute Taper Reamer—The TaperScraper — The Final Finishing Tool — is used tocorrect any slight irregularity in shape, size or finish ofTaper Lock holes drilled in sandwiched materials andchecked with UNITED Taper Hole Gauges. The SingleFlute Taper Reamer is best used with a T-Handle andis designed to remove only a few thousandths ofmaterial and creates a fine hole finish.This tool should not be used where an actual holeenlargement is needed. If the tool needs to besharpened, send it to us for re-sharpening.Continue to check the hole with a UNITED TaperHole Gauge. If it is found to be accura

Taper Lock is a complete system of tapered drills, tapered fasteners and tapered gauges. Taper Lock Fastener holes can be accomplished quickly with a high degree of accuracy, confidence and security. It is essential that the Taper Lock System be accompanied by excellent craftsmanship. Regardless of the higher degree of accuracy, engineering and