Transcription

Taper-Lok Connectors

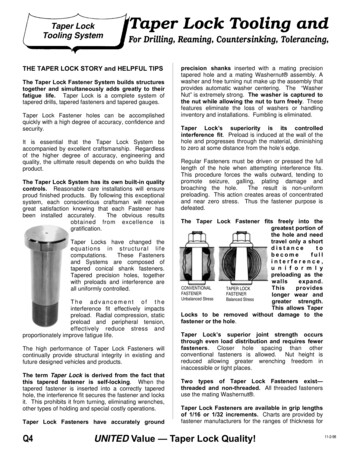

Table of ContentsTaper-Lok Overview. 3AFGlobal Connector Applications and Solutions. 4-5Taper-Lok Seal Ring - How it works. 6Taper-Lok FEA and Seal Ring Contact Pressure. 7Taper-Lok Misalignment Capability. 8Taper-Lok Configurations. 9-10Offshore Topsides Applications. 11Offshore Riser Applications. 12Subsea Applications. 13Taper-Lok Additional Features. 14Taper-Lok Ball Misalignment Flange and 3 Bolt Quick Assembly. 15Taper-Lok Heat Exchanger Retrofits. 16-18Downstream Applications. 19Taper-Lok Relationship to Codes and Standards.BackTaper-Lok Products Engineered to OutperformTaper-Lok pressure energized and enhanced connectors are engineered to provide the safest, most reliable seal of anybolted connection while offering unequaled design flexibility and engineered advantages. Sizes start at 3/4" to 85".Pressure-EnergizedSeal RingSmaller Stud Diameter,Lower Torque RequirementsReusable Metal Seal RingSupplied with Baked-OnMolybdenum CoatingFor LubricationStandard Pipe SchedulesWide Area SealSelf-AligningSelf-CenteringTaper-Lok Service CommitmentOur clients deserve a servicecommitment that does not endwith installation. Taper-Lok notonly provides complete producttraining, installation and field repairinstructions, but also projectmanagement support, product designand design calculations. All whileproviding leak-free service for the lifeof your connector. Taper Lok's oldestconnectors have been in operationmore that 40 years with combinedleak-free service of over 1 billionhours without failure.Visible Seal Provides forQuick, Visual Inspectionof Proper Make-upSeal Ring is Self-Retainingin Female Pocket2 2018 AFGlobal Corporation. All rights reserved.

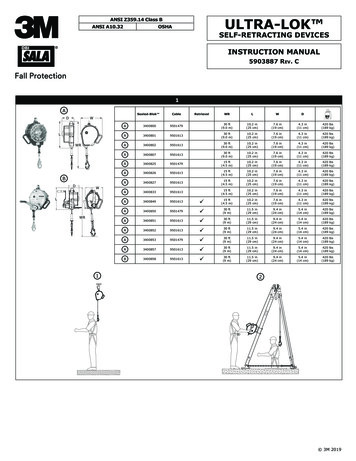

Taper-Lok Connectors——Over 40 years and thousands of connections withleak-free service——Consists of a male and female flange that aidswith misalignment——Reusable metal-to-metal wide area seal withconverging angles——Sizes ¾-in. – 85-in.*——Pressures from vacuum to 20,000 psi *——Services of -350 F to 1500 F *——Field repairable——Designed to withstand high external loads——Visual seal aids with make-up——Available in all material grades——Taper-Lok connectors are subsea diver-friendly withadditional features that provide ease of assembly anddiver safety during the installation processThese benefits significantly decrease installation time and cost.*Special designs �Topsides, risers and subsea——Petrochemical and refinery——Spool tie-ins, production risers, manifolds and flow lines——Pipeline transmission and distribution8-in. – 2500# ANSI Class Comparison——Heat exchanger body and channel flanges 2018 AFGlobal Corporation. All rights reserved.Taper-Lok Connector246 kgANSI B16.5628 kgFemaleWeld NeckSeal RingMaleWeld Neck3

Taper-Lok and CofferLok Connection SystemsOur process piping, pipeline, riser and exchanger connection systems provide the solutions tochronic problems associated with standard ANSI and API flange connections.Leak-Free ReliabilityAFGlobal’s metal-to-metal seal ring technology offers leak-free reliability over traditionalANSI and API gaskets. Our seal rings offer the equivalency of welded joint integrity andcan be used in critical and chronic leak areas.Weight SavingsWith weight savings of up to 80% in comparison to ANSI flanges, our connection systemscan typically save up to 1 million lbs. of weight on an offshore floating platform.Space SavingsSpace savings of up to 82% with smaller O.D. and length dimensions comparedto ANSI/API flanges. Pipe runs are closer together to create more room for processequipment and future tie-backs. Ideal for small O.D. pull-in-head requirements.External LoadsOur connectors are able to handle high fatigue and high bending moments. We canoptimize the design of the connector as needed to meet project requirements.Quick AssemblyOur connection systems typically use fewer and smaller bolts in comparison to ANSIor API flanges. Our catalog of connectors include clamps that only require four boltsand connectors that are self aligning.Cost SavingsIn many cases, our connector assemblies are less expensive to purchase than thecorresponding ANSI or API flange assembly. Our leak-free seal rings save operational costs.Misalignment CapabilityAFGlobal offers connection systems that are self-aligning and offer up to 20º ofmisalignment capability.High Pressure/TemperatureOur connector systems have applications in high pressure and/or high temperaturewhere they out perform ANSI and API flanges in terms of reliability and leak free service.Connector ApplicationsTOPSIDES4RISERSSUBSEAREFINERY &PETROCHEMICALHEAT EXCHANGERRETROFITS 2018 AFGlobal Corporation. All rights reserved.

CofferLokCompactFlange(Economy) ANSI / APIFlangesCofferLok CompactFlange(NORSOKL-005)ISO 27509CofferLok CompactFlange(Standard)CofferLok ClampConnectorTaper-Lok lityHigh Pressure/TemperatureICONRANK 1 2018 AFGlobal Corporation. All rights reserved.OK6Superior5

Taper-Lok Seal Rings - How They WorkThe Taper-Lok connection uses theMECHANICAL ADVANTAGE of theinclined plane and generates up toTHREE TIMES the gasket force on theseal ring. It also requires less bolt loadand less bolting. As this pressureincreases it enhances sealing capability.Taper-Lok incorporates a wide area seal that has up to 20 times the contact area of other metal to metal seals. Thisensures a robust connection that can easily withstand the rigors of repeated job site connections in tough conditions.In Comparison to Other ConnectorsMany metal to metal ring type connections rely on a narrow band of contact. In principle, this will be sufficient, but inpractice, in field conditions they are easily damaged. Due to the wide area sealing surface, the Taper-Lok Seal Ringdesign is more forgiving when dealing with harsh field conditions and potential installation damage.Lip type metal seal found on hub/clampand compact flange connectors6RTJ type seal found in ANSI / API flanges 2018 AFGlobal Corporation. All rights reserved.

Taper-Lok FEA Contact PressureContact Pressure Example - 2,545 psi (per ASME BPVC Section VIII)Taper-Lok has very high contact pressure and the largest surface area of any metal-seated connector in the industry. Our FEAexample below proves that we have more than enough contact pressure required by the ASME Code to maintain a leak free seal.35,000 to 55,000 psi contact pressureis more than enough required (14,000 psi)to maintain a leak free seal. (Green, Blueand Yellow colors)Internal Pressure, P 2,545 psiMaintenance Factor, m 5.5Min Contact Pressure m P 14,000 psiContact Pressure Example - 20,000 psi1-1/4"In this example at 20,000 psi any contactpressure that is not gray color is sufficientto maintain a leak free sealContact pressure:m P (min) 2.5 20,000 50,000 psim P (min) 5.5 20,000 110,000 psi 2018 AFGlobal Corporation. All rights reserved.7

Taper-Lok Seal Rings - Misalignment CapabilityTaper-Lok can make connectors with a spherical nose and seal ring on the male end which allows for 2 to 3 degreesof misalignment as standard.——Perfect installation solution for misalignment of heavy wall pipe during fabrication——Great for diver installed pipelines, flow lines and risers.——If the bolting can be inserted through the bolt-holes the joint can come together!Taper-Lok Swivel Assembly with Spherical NoseTestingAfter 10 years of subsea service, thisspherical nose and sealring are still doingthe job of keeping this pipeline leakfree.8 2018 AFGlobal Corporation. All rights reserved.

Taper-Lok Flange ConfigurationsWeld Neck AssemblySwivel Flange AssemblyBlind Closure AssemblyThe Weld Neck Assembly is a compactflange comprised of a male flange, afemale flange, a seal ring, and a completeset of studs and nuts. Weld neckassemblies are typically used for both newpiping construction and replacement ofexisting flanges.The Swivel Assembly is comprised of afemale weld neck flange, a seal ring, amale fitting, a swivel ring flange, and acomplete set of studs and nuts. In swivelflanges greater than 12", ball bearing racesare included to greatly ease the rotationof the swivel ring during installation.This connection encompasses all of thefeatures of a weld neck assembly but givesthe ability to align bolt holes with a simplerotation of the swivel ring.The Blind Assembly is comprised of amale or female weld neck flange, a maleor female blind flange, a seal ring, and afull set of studs and nuts. Blind assembliesare frequently used for both manwaysand containment connections on pressurevessels, heat exchangers, pipelines, andskid packages.Double Male AdapterBall Misalignment FlangeSwivel and Ball MisalignmentThe Misalignment Assembly is comprised ofa weld neck flange with a spherical recessin the face, a ball joint, a spherical seal ring,a swivel ring flange, and a complete set ofstuds and nuts. The standard misalignmentassembly (shown) allows up to 10-degreesof both axial and angular misalignment ofpiping. When 10-degrees of misalignmentis not enough, then this assembly canbe modified to include a second ball jointthat would allow for up to 20- degrees ofmisalignment of piping.The MVL Assembly (Misalignment/ SwivelAssembly) is a combination of a Swivelassembly and a Misalignment assembly.The two assemblies are connected togetherby an intermediate adapter flange that holdsboth the seal ring for the misalignment andthe swivel flanges. This assembly allows forup to a 10-degree misalignment of pipingwhile also allowing for ease of bolt holealignment during installation. This productis typically used in subsea applicationbetween the flow line and riser piping.The Double Male Adapter is an individualcomponent that has two opposing malenoses and is inserted in between twofemale flanges. The double male adaptercan serve many purposes based on thedesired configuration. It can be designedto accommodate instrumentation, serveas a double block and bleed and evenwork as a strainer. However, it is mostcommonly used when converting anexisting flange set up to the Taper-Lok sealing technology. 2018 AFGlobal Corporation. All rights reserved.9

Taper-Lok Flange ConfigurationsLong Weld Neck AssemblySkillet BlindSphericalDouble Male AssemblyThe Long Weld Neck Assembly iscomprised of a male or female flange withan extra long reinforced neck, a seal ring, amale or female blind flange, and a completeset of studs and nuts. The long weldneck is typically used in pressure vesselapplications where the reinforced neckthickness is required to match or replacethe material that was removed from the shellof the pressure vessel. The blind flange canalso be replaced with a weld neck flange ifcontinuous piping is required.The Taper-Lok Skillet Blind is an individualcomponent that is comparable to apancake blind for an ANSI flange. The skilletblind is a pancake blind with a Taper-Lok seal ring integrated into the design. Skilletblinds are rated for hydro-test pressureand can be inserted into any Taper-Lok connection when blinding is required.The Spherical Misalignment Assembly iscomprised of two misalignment-femaleweld neck flanges, two spherical seal rings,a spherical male adapter, and a completeset of studs and nuts. Because of theallowable misalignment, spherical washersare installed to reduce stress on the studs.This technology is based on the "doubleball joint" shape of the spherical maleadapter, which allows for both axial andangular misalignment of piping.Heat Exchangers and VesselsChannel or big body flanges on heat exchangers and vessels. New build construction or retrofits10 2018 AFGlobal Corporation. All rights reserved.

Taper-Lok for Offshore Topsides Applications——Weight and space savings of up to 80% in comparisonto ANSI / API of flanges——Misalignment for heavy wall pipe and connectingmodular skid packages——Facilities / process piping runs can be closer togethersaving valuable deck space——Valves——Vessels——Heat Exchangers——Manifolds——Membrane Systems——Compressors——Injection Systems——Separation Systems——Numerous Other ApplicationsManifold Skids8-in. – 2500# ANSI Class ComparisonValves 2018 AFGlobal Corporation. All rights reserved.Membrane SystemsTaper-LokConnector246 kg ANSI B16.5628 kg11

Taper-Lok for Offshore Riser Applications——Small outside diameters for pull-ins——High fatigue an

Taper-Lok Seal Rings - How They Work The Taper-Lok connection uses the MECHANICAL ADVANTAGE of the inclined plane and generates up to THREE TIMES the gasket force on the seal ring. It also requires less bolt load and less bolting. As this pressure increases it enhances sealing capability.