Transcription

UNIVERSALTESTINGMACHINES6718U n i v e r s aDl yTeg Me isnt gi n&F ianci hs hi ni ne gs

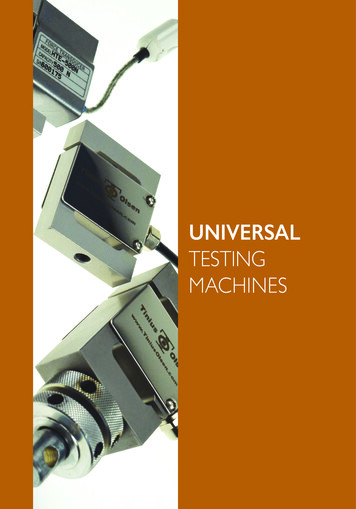

Universal Testing MachinesThe ST series of electromechanical testing machines fromTinius Olsen are designed to test a wide range of materials intensions, compression, flexure, shear, and peel.A variety of self identifying loadcells are available at differingcapacities that give precise applied load measurementsfrom the smallest test specimen to ones that go to fullmachine capacity. Test machines become complete,powerful test systems with the addition of grips to holdthe specimen, strain measurement instrumentation andTinius Olsen’s Horizon Data Analysis software.The Tinius Olsen benchtop range of ST models featureboth single and twin column frames. The single columnmodels have frame capacities of 1 kN (100 kgf / 200 lbf)and 5 kN (500 kgf / 1100 lbf), while dual column modelsare available in capacities of 10 kN (1000 kgf / 2200 lbf),25 kN (2500 kgf / 5000 lbf), and 50 kN (5000 kgf / 11000lbf), and are designed to test a vast range of materials andfinished products.New design allows rapid change of machine capacity fromas little as 0.2% of the capacity of the smallest loadcell tothe maximum frame capacity in a very simple process.Also, the machines can be operated at speeds rangingfrom a minimum of 0.001 mm/min (0.04 thousandths ofan inch per minute) to a maximum of up to 1000 mm/min(40 inches per minute), depending on frame size, whichaccommodates a wide range of material and specimens.www.sdlatlas.comUTMFeatures Test frame can be extended by up to 254 mm /10 inches (single column) or 400 mm / 16 inches(Twin column) to increase test area size Different system interface options are available:tethered handheld interface, wireless Bluetoothinterface panel, or virtual machine controller. Meets or exceeds the requirements of national andinternational standards for material testing systems (Single column) or 8 (Twin column) full lengthT slots built into machine column to allowaccessories to securely mount to the test frame Built-in pneumatic distribution ports that providelocal air supply to pneumatic gripsORDERING INFORMATION2041151ST Single Column Load Frame,1 kN / 200 lbf capacity4024445ST Single Column Load Frame, 5 kN /1100 lbf capacity20411620411710ST Twin Column Load Frame,10 kN / 2200 lbf capacity25ST Twin Column Load Frame, 25 kN / 5000 lbf capacity20411850ST Twin Column Load Frame,50 kN / 11000 lbf capacity204129HMC Handheld User Interface204130PROTERM Handheld User Interface202803Primary Platform for Horizon Software203679 /203410Textiles Library for Horizon Software79

UTMController - Proterm / HMCAll ST series can be used with selection of handheld interfaces or a virtual machine interface running on a connected PC.The PROTERM model is the familiar handheld controller which is tethered to the machine by an articulated arm.With its larger, tactile, sealed keypad, this controller is ideal for operators who use gloves to load and uploadspecimens and prefer a push button keypad. It can be used for basic operation of the tester and can initate a test,but must be used with Horizon software.Model HMC is the wireless handheld interface which is connected to the machine by a Bluetooth link. This interfacefeatures an Android-based operating platform and can be used to control the machine by itself or in conjunctionwith Horizon software. Three channel display of test machine channels and selectable multi unit display of channelvalues. Safe operating radius of a maximum of 10 m and will operate in ‘safe’ mode if the range is exceeded. Controlsmachine movement during test set up and initiates a test directly from the built-in control pad. Test procedureinvolving up to steps can be set up and run directly on the HMC interface.PROTERMRequired or OptionOption in support of testing machine corsshead positiong, specimen insertion and monitoring of machine status. ** Cannot be used to perform materials testingTactile Push Button TypeBlack elastomeric keys with epoxy capsLanguageSupports global language character setsScreenMonochrome supertwist LCD 5 lines (3 live sources, 2 status lines)Size (L x W x D)192 x 128 pixels209 mm x 104.1 mm x 29.2 mm8.25 in x 4.10 in x 1.15 inWeight340 g / 0.75 lbPROTERMHMCHMCRequired or OptionOptionTechnology PlatformAndroid v.4.1.1 (Jelly Bean)LanguageSupports global language character setsTouch ScreenColor touch screen, multi touch capacitive, rain resistant and inductive stylusDisplay141 mm diagonal super AMOLED 720 x 1280 pixelsSize (L x W x D)232 mm x 99 mm x 29 mm9.1 in x 3.9 in x 1.14 inWeight80442 g / 1 lbU n i v e r s a l Te s t i n g M a c h i n e s

Universal Testing Machines - Single Column1ST Testing MachineUTM-ST5ST Testing MachineTECHNICAL SPECIFICATIONSModel1ST5ST1 kN / 100 kg / 200 lbfNA mm / NA in5 kN / 500 kg / 1000 lbfNA mm / NA in5N, 10N, 25N, 50N, 100N, 250N,500N, 1kNNA mm / NA in755 mm / 30 in5N, 10N, 25N, 50N, 100N, 250N, 500N,1kN, 2.5kN, 5kNNA mm / NA in755 mm / 30 inmm/min0.001 to 1000in/min0.00004 to 40NA mm / NA in0.001 to 1000 to 2kN0.001 to 500 to 5kN0.00004 to 40 to 400lbf0.00004 to 20 to 1000lbNA mm / NA in0.001 to 15000.00004 to 600.001 to 15000.00004 to 600.10.000004 /- 0.005%0.10.000004 /- 0.005%511 x 467 x 1168511 x 467 x 1168CapacityMaximum Sample DiameterLoad CellsDistance between columnsMaximum Crosshead Travel(excluding grips)Testing Speed RangeJog SpeedReturn SpeedmmResolutioninmminAccuracyDimensions W x D x Hmmin20 x 18 x 4620 x 18 x 46WeightkgController InterfaceHMCProtermHorizon46 kg / 101 lbYYY46 kg / 101 lbYYYSoftware1. Load weighting system meets or exceeds the requirements of the following standards: ASTM E4, ISO7500-1, EN10002-2. It isrecommended that systems are verified at installation in accordance with ASTM E4 and ISO 75001.2. Strain measurement meets or exceeds the requirements of the following standards: ASTM E83, ISO9513 and EN 10002-4.www.sdlatlas.com81

UTM-STUniversal Testing Machines - Twin Column10ST Testing Machine25ST Testing Machine50ST Testing MachineTECHNICAL SPECIFICATIONSModelCapacityMaximum Sample DiameterLoad Cells10ST25ST50ST10 kN / 1000 kg /2000 lbfNA mm / NA in25 kN / 2500 kg / 5000 lbf50 kN / 5000 kg / 11000 lbfNA mm / NA inNA mm / NA in5N, 10N, 25N, 50N,5N, 10N, 25N, 50N, 100N, 5N, 10N, 25N, 50N, 100N,100N, 250N, 500N, 1kN, 250N, 500N, 1kN, 2.5kN, 250N, 500N, 1kN, 2.5kN,2.5kN, 5kN, 10kN5kN, 10kN, 25kN5kN, 10kN, 25kN, 50kNDistance between columns410 mm / 16 in410 mm / 16 in410 mm / 16 inMaximum Crosshead Travel(excluding grips)Testing Speed Range1090 mm / 43 in1090 mm / 43 in1090 mm / 43 in0.001 to 1000 to 10kN0.001 to 1000 to 10kN0.001 to 500 to 25kN0.00004 to 40 to 2000lbf0.00004 to 20 to 5000lbmm/minin/minJog SpeedReturn SpeedmmResolutioninmminAccuracyDimensions W x D x HmminWeightController InterfaceSoftwareHMCProtermHorizonNA mm / NA inNA mm / NA in0.001 to 500 to 20kN0.001 to 250 to 50kN0.00004 to 20 to 4000lbf0.00004 to 10 to 11000lbNA mm / NA in0.001 to 10000.00004 to 400.001 to 10000.00004 to 400.001 to 5000.00004 to 200.10.000004 /- 0.005%0.10.000004 /- 0.005%0.10.000004 /- 0.005%729 x 506 x 126529 x 20 x 64729 x 506 x 126529 x 20 x 64729 x 506 x 126529 x 20 x 64130 kg / 287 lbYYY130 kg / 287 lbYYY130 kg / 287 lbYYY0.00004 to 40 to 2000lbf1. Load weighting system meets or exceeds the requirements of the following standards: ASTM E4, ISO7500-1, EN10002-2. It isrecommended that systems are verified at installation in accordance with ASTM E4 and ISO 75001.2. Strain measurement meets or exceeds the requirements of the following standards: ASTM E83, ISO9513 and EN 10002-4.82U n i v e r s a l Te s t i n g M a c h i n e s

Single Fiber Strength TesterF012Universal Testing Machine 1ST special version is designedfor low force/extension single fiber testing. Fitted withspecial 10 N / 1000 gf loadcell and lightweight pneumaticgrips. Speed 0.001 to 1000 mm/min. Maximum 755 mmtravel (Optional Tension Clips computer testing softwareis available for oder separately). Extension resolution0.001 mm. HMC wireless Bluetooth handheld controllerincluded.Please see our Tinius Olsen Section Pages 73-75 forinformation on other grips/accessories for this device.SIZEWEIGHT46 kg / 101 lbsDIMENSIONS 511 mm (w) x 467 mm (d) x 1168 (h) /20 in (w) x 18 in (d) x 46 in (h)ORDERING INFORMATION204173F012 Single Fiber Strength Tester200982Tension Clips (Set)202803Horizon Testing Software (computer not included)STANDARDS:ISO 5070BS 3411BISFA5ST Single End Yarn Strength TesterY263ATo determine the breaking load and extension of singleyarns and threads up to 250 N, 25 kgf, 50 lbf or 100 N,10 kgf, 20 lbf load range depending on choice of load cell(one or both may be ordered). Special-purpose version of5ST single column universal tester provided with HT60manual horn-type yarn grips. Speed 0.001 to 1000 mm /min. Maximum 755 mm travel (excluded grip). Extensionresolution 0.001 mm HMC wireless Bluetooth handheldcontroller included.Optional computer testing software is available for orderseparately.SIZEWEIGHTDIMENSIONS46 kg / 101 lbs490 mm (w) x 450 mm (d) x 1140 (h) /20 in (w) x 18 in (d) x 45 in (h)ORDERING INFORMATIONY263A5ST Single End Yarn Strength Tester with HT60Grips, excludes load cell402445100 N, 10 kgf , 20 lbf load cell (ST series)402929250 N, 25 kgf, 50 lbf load cell (ST series)202803Horizon Testing Software (computer not included)STANDARDS:ASTM D2256BS 1932www.sdlatlas.comISO 206283

UTMGrips and Accessories for Universal Testing MachinesLOAD CELLS50N20057410N20057525NOrder CodeFitting200576200577100N200578M6x1 (F)M6x1 kNOrder Code200579200580200581200582200583STANDARD Z-BEAMFittingOrder CodeFitting5NM8x1.25(F) M12x1.75(F)M16x2 (F)M16x2 (F)M8x1.25(F) M12x1.75(F)SHEAR WEB1kN5kN10kNOrder rd Z BeamShear Web Load CellGENERAL PURPOSE PNEUMATIC GRIPSModel (Max Load)Order CodeHT45 (5kN)HT42 (500N)200627200617500NMinimum Load CellReplaceable Jaw Faces*25 x 25 mm rubber coated50N20061620062620061520062525 x 75 mm rubber coated20061420062425 x 100 mm rubber coatedR3 x 75 mm line contact300581200604HT 401 Pneumatic 20067820069025 x 50 mm rubber coatedSpare Rubber Sheet 150 x 150 mmN/AHT45GENERAL PURPOSE MANUAL GRIPSModel (Max Load)Order CodeHT40 (20kN)121-014(5kN)121-003(2kN)202595200617Medium Duty250N203161Light Duty50N204067Fixed Jaw Face*Includes25 x 65 mmrubber coatedTypeMinimum Load CellReplaceable Jaw Faces*25 x 25 mm rubber coated25 x 50 mm rubber coatedHeavy Duty500N25 x 75 mm rubber coatedLargest rubber300537300532(50 x 100 mm)30053530053699-1005662204066204063(50 x 80 mm)*other sizes and types of jaw face are available for selection121-01484U n i v e r s a l Te s t i n g M a c h i n e s

Grips and Accessories for Universal Testing MachinesUTMYARN/FILAMENTS GRIPS*Model (Max Load)Order CodeMinimum Load CellOperation121-013 (100N)131-007 (1kN)2031625NManual20314325NManualHT58 (100N)200603HT57 rsalФ4 x 100mmMER 150300524Ф4 x 75mm200636Ф6.5 x 80mmBS4952BS4952ASTM D4964ask for detailsФ4, 5, 6, 8,10 & 13 x120mmGeneralLOOP BARS*ModelOrder codeDimensionStandard200637BRA WIRE ATTACHMENTS & BURSTING FIXTURES*ModelOrder codeStandardBraWire (M&S)General Ball Burst Fixture200650BraWire(NEXT)202462M&SNEXTASTM D3787, D6797, D751EN 12232-1, GB/T 8878, 19976FZ/T 01030104948*other fixtures to suit specific application are available for selectionwww.sdlatlas.com85

UTMGrips and Accessories for Universal Testing MachinesATTACHMENT STRENGTH*ModelPopperLower ClampButton BoxOrder **requires insert plateModelDiamante lowerDiamante upperOrder code300438300439StandardBS7909BS7909ZIPPER TESTING*ModelS700S435HT23S415Order code300757300756300444300755Test nameElementslippageElement Pull offStop HolderSlider PullStandardBS 3084ASTM D2061BS 3084ASTM D2061BS 3084ASTM D2061BS 3084ASTM D2061FRICTION & PILLING FIXTURE*ModelFT200PT180PT190PT1000Order code20065320065520065499-1002037/1Test nameCoef. of friction180 Peel90 PeelClimbingDrumStandardISO 8295ASTM D1894BS 5350ASTM D1781*other fixtures to suit specific application are available for selection86U n i v e r s a l Te s t i n g M a c h i n e s

Horizon for Textile Software PackageBuilding on our long history of providing solutions toan enormous variety of testing problems, we offer acomprehensive software program - Horizon, that makestesting simple, precise, and efficient. Horizon softwaregoes far beyond data collection and presentation. It willhelp you automate your operations, from R&D to thecharting and analysis of QC testing. Horizon provides alibrary of standard, specific, and application focused testroutines that have been developed in close cooperationwith our customers around the world and to thestandards they are using.202803Methods LibraryAmong the many valuable features offered by Horizonare:a test routine library; simultaneous multiple machinecontrol; test, output, method, and result editors; andmultilayered securityHorizon also includes the following features: Generation of user customized reports Ability to recall, re-plot and rescale test curves User-configurable machine parameter and controlsettings Multiple layered security with individual log-ins fordifferent assigned operator access rights Networking capabilities, ensuring identical testmethods are used for multiple machine users; LIMSor EPR integrationPre-written Standard MethodsHorizon is rich with capabilities that improve productivityand enable you to build, access, and use a modern,powerful materials testing database. It employs thelatest Windows environments to create an intuitive userexperience. Built-in tutorials, on-line help, and help deskaccess provide additional user support.ORDERING INFORMATION202803Horizon for Textiles Software Packageww

interface panel, or virtual machine controller. . Y263A 5ST Single End Yarn Strength Tester with HT60 Grips, excludes load cell 402445 100 N, 0 kgf , 20 lbf load cell (ST series) 402929 250 N, 25 kgf, 50 lbf load cell (ST series) 202803 Horizon Testing Software (computer not included) STANDARDS: ISO 5070 BS 3411 BISFA STANDARDS: ASTM D2256 BS 1932 ISO 2062 5ST Single End Yarn Strength Tester .