Transcription

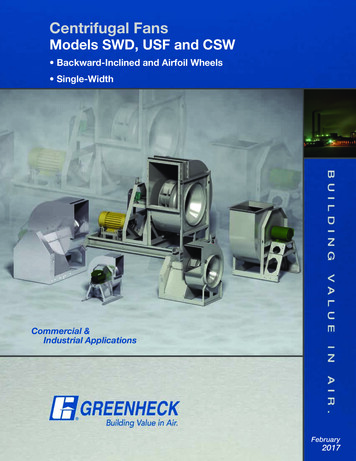

Centrifugal FansModels SWD, USF and CSW Backward-Inclined and Airfoil Wheels Single-WidthCommercial &Industrial ApplicationsFebruary2017

Centrifugal FansGreenheck's airfoil and backward-inclined centrifugal fans are designed to provide efficient and reliableoperation for commercial and industrial applications. Our products are manufactured with state-of-the-art laser,forming, spinning and welding equipment, and endure our quality control testing to ensure trouble-free start-up.Greenheck centrifugal models include industry-leading design features to ensure your ventilation equipment hasthe latest technologies available.Available with Greenheck Centrifugal Products: AMCA licensed performance PermalockTM or all welded scroll design Set screw or concentric mount bearings with theindustry’s highest cataloged bearing life Corrosion-resistant, electrostatically applied andbaked powder coatings Both belt and direct drive configurations Galvanized, coated steel, aluminum or stainlessconstruction materials UL/cUL approvals for electrical, kitchen greaseand high temperature operationMade in U.S.A.Models SWD, USF and CSW fans are designedand built in one of two manufacturing locations,Schofield, WI and Shelby, NC. Multiplemanufacturing locations enables us to build fansand get them to you, our customer, faster.MODELAMCASIZESSWDAMCA AirAll sizes (07-18)USF-BI 200AMCA Air6 - 10USF-BI 200AMCA Sound and Air12 - 22USF-BI 300AMCA Air6 - 10USF-BI 300AMCA Sound and Air12 - 24USF-BI 300AMCA Air27 - 49USF-AF 400AMCA Sound and Air18-49USF-BI 400AMCA Sound and AirAll sizes (7-49)CSW-AFAMCA Sound and AirAll sizes (18-73)CSW-BIAMCA Sound and AirAll sizes (7-73)Quick Build AvailabilityModels SWD, USF and CSW fans are availablein as little as 5 days on our Quick Build program.Quick Build offers you a number of lead times tomeet your needs.Certified data may be found in Greenheck’s Computer AidedProduct Selection program (CAPS)Quick Build ProgramModel5 Day 10 DaySWDUL/cUL 705 Listed Power VentilatorUL/cUL File E40001 (SWD, USF-200, -300, -400, CSW)UL/cUL 762 Power Ventilators for Restaurant Exhaust AppliancesUL/cUL File MH11745 (USF-300, -400, CSW)UL/cUL Power Ventilator for Smoke Control SystemsUL/cUL File MH17511 (USF-300, -400, CSW)2Standard3 3USF-200333USF-300 (6-24)333USF-300 (27-49)333USF-400333CSW333

Centrifugal FansGreenheck’s centrifugal products are specified to handle a variety of commercial andindustrial projects. General supply, return or exhaust systemsEmergency smoke exhaust (buildings, car parks, etc.)Restaurant grease exhaustStairwell pressurizationProcess heat exhaust Filter houses and dust collectorsBuilt-up or custom air handlersSpark-resistant fume exhaustCorrosive fume exhaustGrain dryingBenefits of Greenheck’s centrifugal fansGreenheck’s tiered product offering Designed, engineered and tested prior to shipment toprovide years of smooth, vibration-free operation withminimal maintenance. Centrifugal fans are more efficient at higher staticpressures and quieter than propeller fans Housing changes airflow direction efficiently withoutadding static pressure from duct turns Flexible installation locations, inside or outside Inlet cone reduces system effects when fitting intotight spaces Serviceable components at the same level as thetechnicianGreenheck’s tiered model approach gives you flexibilityin size, performance and construction matching theappropriate model to your application. Our centrifugalproduct line offers a variety of options in constructionfeatures, materials and performance by model. Quick and easy selection options along withAutoCAD and Revit models available fordownload and integration into plan drawings,custom equipment schedules and specifications. Multiple motor and control options for energyefficiency savings and exact control. eCAPS , an easy to use cloud based crossmodel selection program quickly ranks the tieredcentrifugal models based on performance, andproviding detailed estimated first cost, operatingcosts, weights, and dimensions. Enhancedconstruction requirements show only modelsmatching project requirements. CAPS selection software leads the industry inproviding selection details, options accessories andfull submittal packages. The centrifugal product filterquickly guides the user to available models meetingcriteria and offering full range of available optionsand 00 1000055000 60000 65000 70000 190000 220000Volume (CFM)SWDUSF-200USF-300USF-4005,500 (9340)2.5 (.62)333310,000 (16990)5.5 (1.4)333USF-30053,000 (90050)5.5 (1.4)33STATIC PRESSUREin. wg (kPa)BeltCAPACITIESCFM roll ssCSW-BI20DirectStatic Pressure (in. wg)243USF-40066,000 (112130)9 (2.2)333CSW-BI (7-73)231,000 (392470)21 (5.2)33333CSW-AF (18-73)195,000 (331300)14 (3.5)3333333

Centrifugal Fan ApplicationsLight Duty Commercial and Institutional:General ventilation, office space, retail space, cafeterias, break rooms,conference roomsBuilding or room with relatively clean air found in a normal work placeenvironment. Air volumes are typically below 8,000 cfm with static pressures lessthan 3 in. wg (747 Ps). Application needs a basic fan model providing good value.Galvanized housing and bolted construction are appropriate for the requirementsof this application.Models: SWD, USF-200Commercial and Institutional:Warehouse, hotels, atriums, theaters, gyms, libraryLarger volumes of air up to 20,000 cfm with low to moderate static pressuresto 5 in. wg (1245 Pa). Air quality is relatively clean; used for supply or exhaust.Fan coating available for cosmetic appearance or improved weather protection.Instances may require fan certified for use in emergency conditions.Models: SWD, USF-200, USF-300Light Industrial and Specialty Commercial:Waste water treatment, garage exhaust, restaurants, mechanical rooms, manufacturing space,dedicated exhaust hoods, emergency smoke, natatoriums, cleanroomsCategory involves a wide range of airflow volume from very low to 60,000 cfmwith moderate pressures below 8 in. wg (1990 Pa). Fans applied to dedicatedexhaust systems or combined between process and clean air. Applicationsrequiring higher efficiency can use airfoil wheel. Fans may be subjected toincreased level of chemicals or particulates in the air. Additional contaminatessuch as grease exhaust or light dusts are possible. Specialized coatings areavailable when needed. Fans may also have need for dual use in emergencyconditions or spark resistance.Models: SWD, USF-300, USF-400, CSWIndustrial:Process exhaust, fume exhaust, chemical processing, high temperatures, high humidity,vibration sensitive areasSystems having a broad airflow performance range from low to highvolumes and pressures for supply or exhaust from different processes.Application often requiring additional strength and rigidity to the unitthrough welded scroll housings and frames. Application of specializedcoatings or construction materials for spark resistance, extra protectionto resist corrosion or high temperatures. High degree of durability in thefan is critical for process operation or for safety concern. Componentsrequired are of the highest quality, durability and longest life.Models: USF-400, CSW4

Centrifugal Fan ApplicationsEmergency Smoke (UL/cUL Listed):Atriums, libraries, multi-story buildingsFan installed for emergency use on a dedicated emergency system or dualapplication use with the primary function of the fan being general air movementbut built to withstand operation seen in emergency smoke situations.Greenheck models USF-300, USF-400, and CSW are available with the UL/cULPower Ventilators for Smoke Control Systems. Listing indicates the model isdesigned and tested to exhaust heat and smoke in an emergency situation.Models: USF-300, USF-400, CSWThe emergency high temperature option is suitable for thefollowing temperatures:Operating TemperatureTime Duration500ºF (260ºC)4 hours572ºF (300ºC)2 hours752ºF (400ºC)2 hours1000ºF (538ºC)15 minutesUL/cUL 705 Listed Power VentilatorUL/cUL File E40001(SWD, USF-200, -300, -400, CSW)UL/cUL 762 Power Ventilators for Restaurant Exhaust AppliancesUL/cUL File MH11745 (USF-300, -400, CSW)UL/cUL Power Ventilator for Smoke Control SystemsUL/cUL File MH17511 (USF-300, -400, CSW)High Temperature Process Exhaust:Kilns, Dryers, FurnacesApplication involving elevated temperatures above250 F (121 C) continuously or extended periods oftime. Material and arrangement choices are limited tocomponents suitable for this application and locatedto minimize effects. Fans are manufactured with hightemperature process package that includes hightemperature shaft seal, heat slinger, high temperaturefan bearing grease, and high temperature coating onsteel fans. Heat slinger dissipates heat being transferreddown fan shaft preventing bearing grease aterial251–500ºF(121–260ºC)BI, AF1, 8, 9, 10Steel,316 Stainless Steel*501–750ºF(261–400ºC)BI1, 8316 Stainless Steel751–1000ºF(401–538ºC)BI1316 Stainless SteelNote: Aluminum construction is suitable up to 250ºF (121ºC)* AF wheels are steel construction only.Model: CSWChemical and Hazardous Exhaust:Petrochemical, Mills, Fertilizer, Poultry BarnsSpecialized type of HVAC industrial application with air containing highconcentration levels of hazardous chemicals from process exhaust or othersources. Application dictates utilizing a higher performance coating or use ofcorrosion-resistant materials (stainless steel or aluminum). Systems may alsocombine with high temperatures.Model: CSWRestaurant Grease Exhaust (UL/cUL 762 Listed):RestaurantsThe centrifugal scroll fans are designed for high pressure restaurant greaseexhaust applications. Either Permalock or welded housing are available withUL/cUL Listing of Power Ventilators for Restaurant Exhaust Appliances. Thewelded housing is suitable for indoor or outdoor mounting locations, whereasthe Permalock housing is suitable for outdoor kitchen ventilation installations.Listing tests exceed duct temperatures of 400 F (204 C) continuous operation.UL/cUL762 selections require a drain connection and access door for cleaning.Models: USF-300, USF-400, CSW5

Model ComparisonMODEL cessories6SWDUSF-200Volume (CFM max (m3/hr))5,500 (9340)10,000 (16990)Static Pressure (Ps max)2.5 in. wg (623 Pa)5.5 in. wg (1370 Pa)Sizes7-186-22Class––Wheel TypeBIBIDrive TypeDirectBeltScroll MaterialGalvanizedGalvanizedScroll ConstructionPermalock Permalock DischargesTH, UB, BH, TAU, BAU, DB, TAD, BADTH, UBArrangements410Wheel ConstructionRivetedRivetedWheel MaterialAluminumSize 6-10 AluminumSize 12-22 Coated SteelFrame ConstructionBoltedBoltedFrame MaterialGalvanized, Coated SteelGalvanizedInlet Cone MaterialAluminumCoated SteelInlet / Outlet ConnectionSlip Fit / Slip FitSlip Fit / Slip FitBearings–Set ScrewBearing Life–L10 80,000 HoursFactory Vibration Test––Welded ScrollYes–High Temperature Limit (Continuous)250 F (121 C)250 F (121 C)Stainless Airstream––Aluminum ConstructionAirstream–Spark ResistantAMCA Spark B & C–UL/cUL 705 (Electrical) ListedYesYesUL/cUL 762 (Grease Exhaust) Listed––HT-UL/cUL (Emergency Smoke) Listed––Extended Life Bearings––Quad Split Housing––Stainless Shaft––IsolationDirect Mount / RailsDirect MountAccess Door - Hinged / BoltedBoltedBoltedInlet/Outlet GuardsYesYesMotor Cover (Arr, 1, 3, 4, 8, 9) /Weatherhood (Arr 1 X/Y, 10)YesYesSure-Aire Airflow Measurement––Backdraft / Volume Control DamperWD, HB, HCDWDYesInlet / Outlet FlangeYesHeat Slinger / Shaft Seal––Coating OptionsYes–Disconnect SwitchNEMA 1, 3R, 4, 4X, 12NEMA 3R

USF-300USF-400CSWMODEL COMPARISON53,000 (90050)66,000 (112130)231,000 (392470)Volume (CFM max (m3/hr))5.5 in. wg (1370 Pa)9 in. wg (2240 Pa)21 in. wg (5230 Pa)Static Pressure (Ps max)6-497-497-73Sizes–0, I0, I, II, III (BI IV)ClassBIBI & AFBI & AFWheel TypeBeltBeltBelt / DirectDrive TypeCoated SteelCoated SteelCoated SteelScroll MaterialPermalock Permalock Permalock on Class 0, I, II & 54Welded on Class III, IV & 54Scroll ConstructionTH, UB, BH, TAU, BAUTH, UB, BH, TAU, BAUTH, UB, BH, TAU, BAU, DBDischarges10101, 3, 4, 8, 9 & 10ArrangementsSize 6-24 RivetedSize 27-49 WeldedWeldedWeldedWheel ConstructionSize 6-10 AluminumSize 12-49 Coated SteelCoated SteelCoated SteelWheel MaterialBoltedWeldedWeldedFrame ConstructionCoated SteelCoated SteelCoated SteelFrame MaterialCoated SteelCoated SteelCoated SteelInlet Cone MaterialInlet / Outlet ConnectionSlip Fit / FlangeSlip Fit / FlangeSlip Fit / FlangeSet ScrewConcentric LockingConcentric LockingBearingsL10 80,000 HoursL10 80,000 HoursL10 80,000 Hours,Bearing Life––YesFactory Vibration Test–YesYesWelded Scroll400 F (204 C)400 F (204 C)1000 F (538 C)High Temperature Limit (Continuous)––YesStainless AirstreamAluminum Construction––Airstream or Entire UnitAMCA Spark B & CAMCA Spark B & CAMCA Spark A, B & CSpark ResistantYesYesYesUL/cUL 705 (Electrical) ListedYesYesYesUL/cUL 762 (Grease Exhaust) ListedYes (excludes size 6-10")YesYesHT-UL/cUL (Emergency Smoke) Listed––L10 200,000 HoursExtended Life Bearings––YesQuad Split HousingStainless Shaft––YesDirect Mount / RailsDirect MountDirect Mount / Bases / InertiaIsolationHinged / BoltedHinged / BoltedHinged / BoltedAccess Door - Hinged / BoltedYesYesYesInlet / Outlet GuardsYesMotor Cover (Arr, 1, 3, 4, 8, 9) /Weatherhood (Arr 1 X/Y, 10)YesYes–YesYesSure-Aire Airflow MeasurementWD, HCDHB, HCDHB, HCDBackdraft / Volume Control DamperYesYesYesInlet / Outlet FlangeYesYes / YesYes / YesHeat Slinger / Shaft SealYesYesYesCoating OptionsNEMA 3RNEMA 3RNEMA 3R, 4, 4X, 7/9, 12Disconnect Switch7

SWD - Vari-Green OptionsModel SWDVari-Green AdvantagesGreenheck’s backward-inclined utility fans havemany advantages; higher operating efficiencies, nonoverloading horsepower curves and higher pressurecapabilities. You will also receive the followingbenefits with these fans: Available in seven sizes (7 through 18) capacitiesfrom 100 to 5,500 cfm (170 to 9,352 m³/hr) andstatic pressures to 2.5 in. wg (623 Pa). Model SWDis offered exclusively with Vari-Green electronicallycommutated motors for energy efficiency and easeof control.Vari-Green MotorsGreenheck’s electronically commutated (EC)Vari-Green (VG) motor combines motor technology,controllability and energy-efficiency into one singlelow maintenance unit and is the industry’s first fullycontrollable motor. When combined with Greenheck’sSWD fans, most of the CFM and static pressureranges of a belt drive can be attained with the benefitsof a direct drive.Motor 25 115/208-23021725208-230Extended RPM Single6.511.3ODPODPODPODPODPODPTEFCTEFCConstant Volume Life Cycle AnalysisThree Year Cost ComparisonAnalysis is based onoperating costs for aperiod of three yearswhere the fans operatecontinuously at 1725rpm, 24/7, with anenergy rate of 0.10/kWh. Maintenance onthe SQ-120 is estimatedat 65/yr. 200018001600140012001000800600400200 0BeltDriveVariGreen Initial CostMaintenance cost over three yearsOperating cost over three years8Note: Example is basedon a relative cost. Useand installation variablesmay produce differentresults. Initial cost is similar to abelt drive Lower operating cost No maintenance, no belts,pulleys or bearings Easy RPM adjustmentFeatures1. Dial on Motor Control - A potentiometer (dial onmotor control) is mounted on the motor for easyspeed adjustment for system balance. Simplyturn the dial; there are no belts and pulleys toadjust.2. Control Wire Inputs - the motor accepts a0-10 VDC signal from Building AutomationSystems, Vari-Green Controls or other controls toadjust motor speed.3. Consolidated Motor with Dial and 0-10 VDC Signal- Refer to greenheck.com, Vari-Green Motor andControls IOM for specific information.Vari-Green Motor BenefitsOperates on AC power that’s converted to DC—providing a more efficient motor operation ascompared to an AC operation. The motor can attain up to 85% efficiency andreduce energy consumption. Watt savings of 20-70% depending on RPM.Note: As motor speed is turned down, efficiencystays high as compared to an AC motor thatdecreases dramatically. Operates cooler than a standard AC motor at lowerRPMs. A cooler motor has longer motor life andreduces energy consumption. 80% usable RPM turndown vs. 30% on AC singlephase direct drive. SWD fans with Vari-Green motors can providemost of the CFM and static pressure ranges of acomparable belt drive. Maintenance costs are reduced as there areno belts or bearings to replace and no pulleysto adjust. Direct drive fans are often preferred wheremaintenance access is difficult. Provides a solution for demand controlledventilation applications.

SWD - Vari-Green OptionsRemote Dial - Allows for remote, manual airflowadjustments. Wall plate with dial may be mounted in astandard 2x4 inch electrical junction box.Two-Speed Control with Integral Transformer Control allows motor RPM to be set at twoindependent speeds (high or low). Meets minimumairflow requirements with the ability to bump up tohigh speed in an emergency or meet maximum airflowrequirements, or reset to low for energy conservation.Speeds are selectable via either a dry contact inputwhich utilizes an external switching device to togglebetween speeds, or an AC digital input which allowsan AC voltage signal to be used to change speeds.Constant Pressure Control - Indoor - Control VariGreen motor via static (variable volume) or velocity(constant CFM) pressure on the inlet or outlet side ofthe fan. Optional, one or two, duct or room probes foruse in: Multi-family structures - Apartments, condos, hotels;dryers, residential kitchens and bathrooms. Institutional facilities - Schools, prisons,multi-story office buildings; bathrooms.Demand Controlled Ventilation forMulti-story BuildingsApplications requiring constant pressureor variable volume can utilize SWD fans with VariGreen motors and Vari-Greencontrols. Demand controlled Variable Volumeventilation systems reduce Operating Cost AnalysisVariable Volume vs. Constant Volumethe amount of energy used 2,000by decreasing the speed1,750of the fan when demand1,500is low. This in turn lessens1,250the amount of conditioned1,000air exhausted and furtherreduces total operating750costs associated with air500conditioning and heating250in multi-storied buildings 0such as: hotels, multi-familyConstantVariableVolumeVolumecomplexes, institutionalHeating Costfacilities, and high riseCooling Costcommercial buildings.Fan Operating CostThe Vari-Green constantpressure control is preprogrammed and easy-to-Example of potential savingsbased on a northeast city inthe USA using Vari-Greencomponents for variable volume. Multi-family structures - Apartments, condos, hotels;residential kitchen, dryer facilities and bathrooms. Institutional facilities - Schools, prisons, multi-story.Air Quality – VOC - Control a Vari-Green motor viachanges in volatile organic compounds (VOC’s).VOC’s are gasses that are emitted from humans,building materials, perfumes, foods, and furnitureoff-gassing. Range is 0-2000 CO2 ppm equivalent. Institutional facilities – Schools, court house,hospitals; bathrooms, waiting rooms, cafeteria. Commercial buildings – Office space, conferencerooms, bathrooms, break room.Air Quality – Temperature and Humidity - ControlVari-Green motor via changes in temperature,humidity, or both. Range is 15 to 130 F (-10 to 55 C)and 0 to 100% relative humidity. Multi-family structures – Apartments, condos,hotels; bathrooms, utility rooms. Commercial buildings – Office buildings; officespace, conference rooms, utility rooms, bathrooms.install for applications that include: venting dryers,bathrooms, residential type kitchen space orindustrial process exhaust.Contact fans@greenheck.com for more information.Daily Operating Comparison:Variable Volume and Constant Volume% of OperationTransformer - Provides 24V power from the existingline voltage at the fan to the Vari-Green motor andcontrols. Dual voltage primary (120/240V) transformerprovided with the fan.Constant Pressure Control - Outdoor - Control VariGreen motor via static pressure on the inlet side ofthe fan. Includes one duct probe and transducer foruse in:Hypothetical (Hotel Bathroom)Variable Volume - Load Shape10080 60 40 20 0% 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24Time of DaySeries 1Demand controlled ventilation offers significant energy savings byexhausting only the necessary amount of air throughout the day.% of OperationVari-Green ControlsConstant Volume - Load Shape100806040200%1 2 3 4Series 25 67 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24Time of DayNote: A standard VFD compatible motor can also function within avariable volume system.9

ConfigurationsArrangement 10 — Belt DriveArrangement 9 — Belt DriveSingle-Width, Backward Inclined or Airfoil WheelSingle-Width, Backward Inclined or Airfoil WheelUSF-200 / 300 / 400, CSW All Sizes Recommended as first choice configuration for belt driveapplications. Bearings are mounted out of the airstream. Motor is mounted beneath the drive frame. Available with a weatherhood to cover motor, drives and bearings. Moderate dirt and heat tolerance. Compact design. Available with heat fan packages up to 500 F (260ºC).(CSW Size 33 - 73) Bearings are mounted out of the airstream. Easy access to large motors mounted on drive frame. Standard motor position is on the right side of the drive frame. Optional motor position is on the left side of the drive frame. Available with motor cover, belt guard and shaft guard. Available heat fan packages to 500 F (260ºC).Class 0, I, IIClass 0, I, II, IIIArrangement 1 — Belt DriveArrangement 3 — Belt DriveSingle-Width, Backward Inclined or *Airfoil WheelSingle-Width, Backward Inclined or Airfoil WheelFanZ(CSWSize 33 - 73)W(CSW Size 7 - 73) Bearings are mounted in the airstream. Bearings are mounted out of the airstream.YX Unlimited motor size. Unlimited motor size.FanMotor position and fan rotation areRequires an isolation base (by factory) or structural pad to mount Requires an isolation base (by factory) or structural pad to mountZ determined from driveWside the fan and motor.the fan and motor.Isolation BaseYX Choice of motor positions W, X/Y or Z (see page 11). Choice of motor positions W, X/Y or Z (see page 11).Motor position and fan rotation are Available with motor cover, belt guard. Available with motor cover.determined from drive side Recommended for clean air at ambient temperatures. Suitable for high temperatures or contaminated air.Isolation Base Available heat fan packages to 1000 F (538ºC).[*Airfoil wheel available to 500 F (260ºC)].FanZWFanZYWXYXMotor position and fan rotation aredetermined from drive sideMotor position and fan rotation areFanZ determined from driveWsideFanWFANZWYYXYosition and fan rotation areed from drive sideXMotor position and fan rotation aredetermined from drive sideClass 0, I, II, III, IVZArrangement 4 — Direct DriveIsolation BaseFANZYSingle WidthFanWXWMotorWheelposition and fan rotation areSingle-Width, Backward Inclined or Airfoildetermined from drive sideYXW(CSWSize 10 - 44) Available with partial width wheel and housing modifications forYXspecific performance.osition and fan rotation areRecommended for higher horsepower applications in lieu of belt drive.ed from drive side Limited to standard motor speeds, but are availableIsolation Basewith variablefrequency drivemotors.Single compatibleWidth Provides compact design with low maintenance. Available with motor cover.10Isolation BaseSingle WidthIsolation BaseFanIsolationBaseXClass 0, I, II, III, IVClass 0, I, II, IIIArrangement 8 — Direct DriveSingle-Width, Backward Inclined or *Airfoil Wheel(CSW Size 33 - 49)Isolation Base WidthAvailable with partial width wheel and housing modifications forSinglespecific performance. Recommended for higher horsepower applications in lieu of belt drive. Limited to standard motor speeds, but are available with variablefrequency drive compatible motors. Bearings located out of the airstream. Suitable for high temperatures or contaminated air. Available with motor cover, belt guard. Available heat fan packages to 750 F (400 C).[*Airfoil wheel available to 500 F (260ºC)].Class I, II, III, IV

ConfigurationsDischarge Positions and Rotatable HousingsAll centrifugal fans are available with clockwise (CW) or counterclockwise (CCW) rotation. See pages 6-7for available discharge positions. Rotation and discharge is always determined from the drive side ofthe fan. Rotatable housings are standard on fan sizes 30 and less; arrangements 1, 4 and 10; and Class 0,I and II.CW BAUCW UBCW TAUCW THCW DBCCW TAUCCW THCCW DBCW BHFanZCCW BAUWYCCW UBXCCW BHMotor position and fan rotation aredetermined from drive sideIsolation BaseMotor Positions — Arrangements 1 and 3 Fans (CSW)ZFanWX/YFan arrangements 1 and 3 require a structural steel base orstructural platform to support the fan and motor. The motor canbe located in any of three positions around the fan shaft to ensureproper alignment. Motor positions W and Z tend to make a longerfootprint from end to end. Positions X/Y tend to make a shorter butwider footprint.Motor position and fan rotation aredetermined from drive sideSingle Width100125200150RPMBHP% WOV3Density 0.075 lb/ftDensity 1.2 kg/m3YSTEMCURVE50% WOV5020153020151057½5750DO300070% WOV80% WOV1900HELEFT251060% WOVOFTHISS40NOTSELECTTOT40Static Pressure (in. wg)2082USF-400, CSW75150016A typical fan curve is shown with shaded classlimits. For specific certified fan data, pleaseconsult Greenheck’s Computer Aided ProductSelection program, CAPS.602717Centrifugal products are available in Class 0,I, II, III, or IV, with Class 0 being the lightestconstruction and Class IV having the heaviestconstruction and performance capacity.256020Fan class refers to a construction level designedto handle a given fan outlet velocity andpressure. As the fan performance requirementsincrease, the fan construction (material gauge,shaft diameter, motor size) must also increase tophysically handle the new work load.Double WidthStatic Pressure (Pa x 100)Class of ConstructionIsolation BaseBISW-36001390% WOV711200109005160010203040506070Volume (cfm x 1000)0204060801003Volume (m /hr x 1000)Class0ClassIClassIIClassIIIClassIV11

Construction OptionsWheelsGreenheck centrifugal fans have non-overloading backward-inclined blades. Both our flat blade backwardinclined (BI) and airfoil (AF) designs operate efficiently and quietly. All wheels are statically and dynamicallybalanced to grade G6.3 per ANSI S2.19.Backward Inclined (BI)Airfoil (AF)ApplicationGeneral purpose, clean airor severe environmentsClean air or fume exhaustTemperatureUp to 1000ºF (538ºC)Up to 500ºF (260ºC)ConstructionSteelAluminum316 Stainless SteelSteelAluminumWheel TypePermalockTM HousingsWelded HousingsPermalock housings usea mechanically fastenedseam instead of welding.This airtight and watertighthousing construction uses thesame structural support as allwelded housings. Permalockconstruction is an excellentvalue engineering option for applications up to 8.5inches wg (2.1 kPa).Optional on Class 0, I, IIand standard on larger fansizes, centrifugal fans aremanufactured with heavygauge, welded housingconstruction. All weldedconstruction is common forindustrial applications and is suitable for pressures upto 22 in. wg (5.5 kPa). Alternative housing materialssuch as aluminum or stainless steel are only availablewith CSW models.Models SWD, USF-200, USF-300, USF-400, CSWAlternative MaterialsModels USF-400, CSWGreenheck offers centrifugal models SWD and CSW in aluminum or CSW in stainless airstream construction asan alternative to coated steel. Aluminum construction provides advantages for applications with high moistureand various chemicals. Aluminum also reduces the weight of the fan if there are structural concerns. Stainlesssteel (316L) construction is used for environments subject to continuous high heat up to 1000ºF (538ºC) orsevere corrosives. Both aluminum or stainless steel construction can be applied to the entire fan (housing,wheel, inlet cone and drive frame) or the airstream components (housing, wheel and inlet cone) only.Spark-Resistant ConstructionGreenheck centrifugal fans are available with spark-resistant designs suitable for applications that involveflammable particles, fumes or vapors. Spark resistant construction options adhere to guidelines defined withinAMCA Standard 99-0401-86.WheelHousingAll parts in contact with the airstream areSpark A constructed of nonferrous material (usuallyaluminum). (CSW)The fan wheel is constructed of a nonferrousmaterial (usually aluminum). A nonferrousSpark B (aluminum) rub ring surrounds the fan shaftwhere it passes through the fan housing.(SWD, USF-300, USF-400, CSW)The inlet cone is constructed of nonferrousmaterial (usually aluminum). A nonferrousSpark C (aluminum) rub ring surrounds the fan shaftwhere it passes through the fan housing.(SWD, USF-300, USF-400, CSW)12Inlet ConePedestal

Material OptionsCSW Material Availability by Model and ConfigurationConstructionWheel Type*ConstructionSizeClassArrangementCoated SteelBI/AFPermalock /Welded7 – 730, I, II, III, IVAny—1, 3, 4, 8, 9 & 10Aluminum, entireBI/AFWelded7 – 300, I, II1, 4, 10BIWelded7 – 300, I, II, III1, 10316 Stainless, airstreamBIWelded33 – 490, I, II, III1, 8, 9, 10Spark A316 Stainless, airstreamBI/AFWelded7 – 490, I, II, III1, 10 (A

Models SWD, USF and CSW fans are available in as little as 5 days on our Quick Build program. Quick Build offers you a number of lead times to meet your needs. Quick Build Program Model 5 Day 10 Day Standard SWD 3 3 USF-200 3 3 3 USF-300 (6-24) 3 3 3 USF-300 (27-49) 3 3 3 USF-400 3 3 3 CSW 3 3 3