Transcription

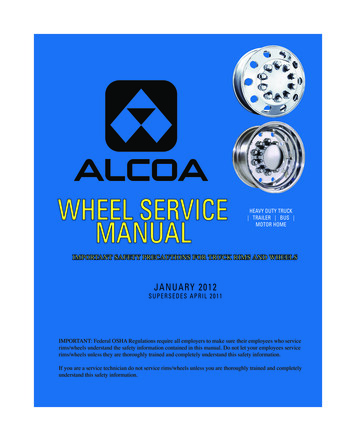

WHEEL SERVICEMANUALHEAVY DUTY TRUCK TRAILER BUS MOTOR HOMEIMPORTANT SAFETY PRECAUTIONS FOR TRUCK RIMS AND WHEELSJANUARY 2012SUPERSEDES APRIL 2011IMPORTANT: Federal OSHA Regulations require all employers to make sure their employees who servicerims/wheels understand the safety information contained in this manual. Do not let your employees servicerims/wheels unless they are thoroughly trained and completely understand this safety information.If you are a service technician do not service rims/wheels unless you are thoroughly trained and completelyunderstand this safety information.01ALC ServiceManual2012 rem.indd 011/28/12 7:06 AM

ALCOALIMITED WARRANTYFOR HEAVY DUTY TRUCKS, TRUCK TRAILERS,BUSES, RV and MOTORHOME WHEELSThis limited warranty applies to Alcoa forged aluminum wheels with bead seatdiameters measured in .5 inch increments ("Wheels") and the surface of rim flangetreatments applied to the Wheels. "Transit Wheels" means Wheels used on transitvehicles, such as buses and vans, whose primary purpose is to transport people.Alcoa warrants to the original purchaser, from Alcoa or its authorized distributor, thata new Alcoa truck, truck trailer, bus, RV or motorhome Wheel is free from defects inmaterial and workmanship for the applicable time period set below:WARNING Wheels that are not properlyinstalled or maintained may not be safe.WARNINGFailure to follow proper wheel installation ormaintenance practices may result in injury ordeath.Follow the proper wheel installation andmaintenance practices as contained in this Alcoa ServiceManual. For additional copies of the manual and other usefulitems listed below, available free of charge, or for the mostrecent updates, contact Alcoa Wheel and TransportationProducts at 1-800-242-9898 or on the web atwww.alcoawheels.com.HtTstTwlinon3senin(a) Except as stated in (b) of this section, Wheels are warranted for 60 monthsfrom the date of manufacture as shown on the Wheel.(b) Transit Wheels and RV and motorhome Wheels are warranted for 120 monthsfrom the date of manufacture as shown on the Wheel.Alcoa agrees, without charge, to repair or replace a Wheel that fails in normal use(see the qualifications section below) because of defects in material and workmanship.Alcoa warrants to the original purchaser from Alcoa or its authorized distributor theDura-Flange rim flange treatment against sharp edges for 24 months from the dateof manufacture as shown on the Wheel. Alcoa warrants to the original purchaser fromAlcoa or its authorized distributor the Dura-Bright surface treatment against (i)filiform corrosion (worm or hair like lines, generally milky in appearance, underneathsurface protective treatment and emanating from damage to the surface treatmentsuch as nicks, scratches, or damage from the mounting hardware or wheel weights),(ii) blistering due to loss of adhesion of the surface treatment and (iii) lift off of thesurface treatment due to physical damage (nicks, scratches, gouges). The foregoingDura-Bright surface treatment warranty is applied for the application period of timeset forth below:(a) Except as stated in (b) of this section, Dura-Bright surface treatment onWheels is warranted for 60 months from the date of manufacture as shown onthe Wheel.(b) Dura-Bright surface treatment for RV and motorhome Wheels is warranted for120 months from the date of manufacture as shown on the Wheel.If the Dura-Flange rim flange treatment or Dura-Bright surface treatment failsin normal use or service (see the qualifications section below) to meet the foregoingwarranties on any Wheel, Alcoa agrees, without charge, to replace the Wheel.Qualifications: Alcoa does not warrant, and will not repair or replace or makeadjustment, with respect to any Wheel or surface or rim flange treatment on suchWheel that has been subjected to misuse or abuse or any of the following:(a) Using a tire which is oversized according to standards recommended by theTire and Rim Association, Inc. or other recognized tire and rim agencies such asETRTO (Europe);(b) Loading the Wheel beyond the applicable maximum wheel load as specified byAlcoa;(c) Inflating tires beyond the applicable maximum as specified by Alcoa;To obtain information on free training on proper installation andmaintenance procedures, contact Alcoa Wheel Products at (800)242-9898 or on the web at www.alcoawheels.com.Important information available free from Alcoa:Alcoa Wheel Service Manuals Disc Wheel Service ManualVideos/CD Safe Wheel and Tire Changing Practices for Heavy DutyTrucks and Buses Maintaining Your Edge Rim Flange Maintenance Simple Facts about Hub-Piloted Wheel SystemMaintenance Disc Wheel Inspection CD published by the TIAMaintenance Charts Zipper RupturePublished by RMA Tire Information Service BulletinPublished by RMA Heavy & Medium Truck & Trailer Torque SpecificationsPublished by WRIS Demounting & Mounting Procedures for Truck/Bus TiresPublished by RMA(d) Changing the original condition of the Wheel by alteration or by subjecting it toany processing such as welding or straightening. Multipiece Rim Matching Chart(e) Accidents; or abnormal or severe operating conditions including, withoutlimitation, tire fires, brake fires, severe brake system drags or seizures orrunning with a flat tire; Mounting/Demounting Instructions for Alcoa Aluminum19.5" RW(f) Failure to follow maintenance instructions or warnings set forth in the AlcoaWheel Service Manual ("Service Manual"), Alcoa Technical Bulletins or otherAlcoa literature. Recommended maintenance includes, without limitation, usingproper torque, periodic cleaning, polishing, valve replacement, periodic inspectionfor damage, and loose lug nuts and rim flange wear inspections and procedures.(g) Nicks, scratches and other surface blemishes resulting from improper maintenance,cleaning, road debris, curbing, accident.(h) Rim flange wear (unless the rim has been treated with Dura-Flange ); or(i) Damage due to cleaning with abrasives, abrasive brushes, steel wool, scouringpads, or strong chemicals (acids or alkaline).Alcoa's liability and purchasers' exclusive remedy for a Wheel or surface or rimtreatment on such Wheel that does not comply with the foregoing warranties is limitedto repair of replacement of the Wheel.Alcoa shall not be liable for any incidental, consequential, indirector special damages for any breach of warranty. There is no warrantythat a Wheel or surface or rim treatment of such Wheel shall bemerchantable or fit for any particular purpose. Nor is there anyother warranty, express or implied, except such as is expressly setforth in this limited warranty.This limited warranty should be used in conjunction with the Service Manual and theAlcoa Dura-Bright Wheel Finish Care and Maintenance manual. The Service Manualcontains important safety information and warnings, and failure to read and understandthis information may result in serious injury or death.Published by OSHAPublished by Alcoa Wheel and Transportation Products Wheels and Steel Disc 19.5" WheelsPublished by Alcoa Wheel and Transportation ProductsAlcoa Rim Flange Safety Material Maintaining Alcoa Aluminum Wheels Rim FlangeWear Instructions Rim Flange Wear GaugeTechnical Bulletins available at www.alcoawheels.com. Welding Rim Flange or otherwise heating AlcoaAluminum Wheels Altering Alcoa Wheels from original design and useof adaptor plates Tire Balancers/Sealants Wheel balancing weights Mounting/demounting tires on Alcoa 22.5non-symmetrical wide base wheels Rim Flange Wear02ALC ServiceManual2012 rem.indd 021/28/12 7:07 AM

Table of ContentsHow to usethis manualThis manual is written in astyle called structured text.Throughout the manual youwill find numbers which looklike this (See Section 3-1). Thesenumbers are cross references toother sections of the manual. Thenumbers (3-1) refer to section3, subtopic 1. You will find thesection number and subtopicnumber under the headingin each section.Section Number1Page Number1 Safety .22 Inspection and Maintenance -152Inspect thoroughly and frequently .3Wheel alteration .3Heat damage .4Dimension checks .5Cracked or damaged wheel checks.6Mounting area .7Corrosion.8Bolt holes .9Disc area .9Rim area .10Bead Seat area.10Rim flange wear .11Dura-Flange maintenance .16Maintenance against corrosion (non Dura-Bright surface treated wheels) .16Dura-Bright surface treated wheels cleaning and maintenance .163453 Mounting Alcoa Wheels with Tubeless Tires .173-13-23-33-43-53-6Recommendations for mounting tubeless tires.17Mounting tubeless tires .18Mounting tires on non-symmetricial drop well wheels .19Rim width to tire matching .20Recommendations for demounting tubeless tires .20Demounting of tubeless tires .21674 Wheel Installation .224-14-24-34-44-54-64-74-84-9Recommendations for proper installation of wheels .22Wheel cap nuts .23How to measure stud standout .24Stud located ball seats are spherical .24Stud-Piloted Mounting System (Single and wide base wheel, stud located, ball seat mounting) .24Dualed wheels, stud located, ball seat mounting.25Dualed wheels, steel inner/aluminum outer stud located, ball seat mounting .27Tightening stud located, ball seat cap nuts .28Hub-Piloted Mounting System (Single, dualed and wide base wheels, hub piloted mounting,two-piece flange nuts).304-10 Tightening hub piloted mounting, two-piece flange nuts.314-11 Incorrect assemblies .3385 Proper Torque, Wheel Identification and Valves .345-15-25-35-45-55-6Avoid abuse.34Keep wheel nuts tight .34Balance weights .35Owner/in-service identification .35Valves .35Identification .366 OSHA Regulations.376-1OSHA Regulations.377 Glossary of Common Terms .427-17-2Glossary of Common Terms .42Wheel measurement .448 Conversion Tables.458-18-2Inch Fraction, Decimal and Millimeter Equivalents Chart (Up to 1 Inch) .45Conversion Factors .461ALC ServiceManual2012 rem.indd 11/28/12 7:07 AM

11Safe servicepractices are amatter of lifeand death.SafetyWARNING An inflated wheel and tire assembly contains enough air pressure to causean explosive separation.WARNINGUnsafe handling or failure to follow approved mounting and demounting procedurescan lead to serious injury or death.Study, understand and follow the procedures contained in this manual.Safety is serious business. All tire shops must know and follow OSHA work regulations. no matter howsmall the shop. Under U.S. federal law any individual handling tire/wheel assemblies must be trainedin OSHA regulations as mentioned in section 6.Safety is everybody’s business. Do not attempt to service any wheel assembly without proper training.Proper equipment is important. Be sure you have the recommended tools and equipment on hand anduse them according to manufacturer’s instructions.Tubeless wheels and tires require equal care. Even though tubeless assemblies have fewer parts thanmulti-piece wheels, they still require respect and proper handling.Pay particular attention during crucial steps: Removal of tire and wheel assemblies from vehicles Demounting tire from wheel Wheel inspections Inflation of tire Handling and storing of inflated assemblySafety and service information is readily available. Wheel, tire and service equipment manufacturersoffer service manuals and other training materials. Stay up to date on proper procedures and keepcurrent instructional materials handy in the shop. Study safety and service information and use it onthe job.2ALC ServiceManual2012 rem.indd 21/28/12 7:07 AM

2Inspect thoroughlyand frequentlyInspection and MaintenanceSafe operation requires thorough examination of wheels and attaching hardware, at frequent intervals,both on and off the vehicle.Wheels that have been in service need to be inspected at regular intervals to assure proper and safeperformance.2-12It is not always possible to predict the useful life of a wheel. Wheels will eventually wear out. Butgenerally, older wheels and wheels operating in extreme conditions should be examined more frequentlyfor obvious signs that they should be removed from service.Examine all exposed areas frequently. Clean wheels and look for cracks, corrosion, wear or other damage.Also check the inner dualed wheel when the outer wheel is removed.During tire changes, thoroughly examine the entire wheel. Pay particular attention to the rim contour andthe surfaces of the rim.Hidden DamageDo not exceed maximum wheel load. Customer must compare OEM vehicle load rating to maximumwheel load rating and inflation pressure which is roll-stamped onto wheel per Section 5-6.Do not overinflate. Use the tire manufacturer’s recommended pressure, but under no circumstances exceedcold tire pressures as listed in Alcoa Wheels Product Spec Guide. Before mounting the tire, perform awheel fitment check to insure proper clearance from any obstructions.Some forms of wheel damage can be hidden beneath the tire, so whenever a tire is removed, thoroughlyexamine the complete wheel. Remove all grease and road dirt. Use a wire brush or steel wool to removerubber from the bead seats.Check mounting holes for enlargement and elongation which can occur if the cap nuts are not kept tight(see Section 2-8). Dirt streaks radiating from stud holes may indicate loose cap nuts.Wheel alteration2-2Alcoa does not approve any form of alteration to wheels except minor cosmetic buffing for appearancepurposes or sanding in the rim flange area (see Section 2-12).Wheels should not be altered by welding, brazing or other heat application in an attempt to repairor straighten a wheel. Use of adapter plates or bead-locks is not approved on Alcoa wheels.Wheels should not be painted or otherwise coated in any way that may interfere with the mountingsurfaces.Any wheels that show signs of alteration should be removed from service and scrapped.Wheel identification must be legible. Wheels should be taken out of service if such identificationdoes not meet federal requirements.WARNING Welding, brazing or otherwise heating any area of an Alcoa aluminumwheel will weaken the wheel. Weakened or damaged wheels can lead to an explosiveseparation of tires and wheels or wheel failure on the vehicle.WARNINGExplosive separations of tires and wheels or wheel failure on the vehicle could causeserious injuries or death.Never attempt to weld, braze or heat any surface of an Alcoa aluminum wheel.3ALC ServiceManual2012 rem.indd 31/28/12 7:07 AM

Heat damageWARNING Excessive heat from fire, brake malfunction, wheel bearing failure, tirefailure or other sources may weaken the metal and cause the wheel/tire assembly toseparate explosively.2-3Exploding wheel/tire assembly can cause serious injury or death.WARNING2Immediately and permanently remove from service any wheel that has been exposedto excessive heat.Inspect for exposure to excessive heat. A wheel that has been subjected to excessive heat mayappear charred or burned. A wheel that has been exposed to excessive heat may appear to be ingood condition if it has been cleaned. Do not use any wheel that has been overheated regardless ofappearance. Even if a wheel does not appear to be obviously burned, inspect the labels, tire bead,brake drum and high temperature nylon spacer for evidence of charring, melting, blistering orburning.A wheel may discolor from excessive heat. It can appear a dull grayish color and will not polish toa bright finish as a typical wheel would.Any wheel run with a flat tire longer than the time necessary to immediately pull off the roadshould be checked for excessive heat damage.After January 2009 the new Alcoa Logo maynot show heat damage.A blistered, charred, blackened or crackedlooking logo decal on an Alcoa wheel mayindicate that the wheel has been exposed toexcessive heat as shown in picture to the left,or discoloration as shown in picture to the rightCharred Sticker (prior to 2009)Inspect all axle end components for signs ofexposure to excessive heat. Pay particularattention to brake drums (or discs), hightemperature nylon spacer wheel liners and tirebeads. If these components show signs of overheating, the entire assembly, including thewheel, should be replaced.Charred High TemperatureNylon SpacerDiscoloration of WheelCharred RubberCharred Heat Indicator Drop Center(2009 and after)Wheels manufactured starting in January 2009will have a 1 inch clear round heat indicatorlocated next to the roll stamp on the insideshown on the left and right, along with the same1 inch clear round heat indicator located on thetire side drop well as shown in the photo above.Charred Heat Indicator(2009 and after)If either of these round labels show signs ofblistering, or have a charred, blackened, orcracked look, this may indicate that wheel hasbeen exposed to excessive heat.Charred Heat Indicator(2009 and after)IF ANY OF THE ABOVE CONDITIONS ARE SEEN, REMOVE THE WHEEL FROM SERVICE IMMEDIATELY. THISINCLUDES ANY HEAT DAMAGE TO THE TIRE, DISCOLORATION TO THE WHEEL, AND OR BRAKE DRUM, ANDANY BURNT OR CHARRED LABELS.4ALC ServiceManual2012 rem.indd 41/28/12 7:07 AM

DimensionchecksOpen Side Circumference CheckWARNING Wheels that have been subjected to high pressure tire and rim separationor excessive heat damage may no longer have sufficient dimension and contour toretain the tire bead while under pressure.2-4Exploding wheel/tire assembly can cause serious injury or death.WARNING Immediately and permanently remove from service any wheel that has been exposedto high pressure tire and rim separation or excessive heat.2WARNING Wheels that have been run flat or have other physical damage may no longerhave sufficient dimension and contour to retain the tire bead while under pressure.Rims that lack proper dimension and contour can lead to explosive separation of the tireand rim, causing serious injury or death.WARNINGAny wheel that has been in service must be inspected prior to mounting. Follow dimensioncheck procedures described in this section during each wheel inspection.Best InspectionMethodMeasure the circumference of the bead seat on the open side(see illustration to left) with a ball tape.Photo to the rightshows the TRA BallTapeThe circumference of the bead seat on the open side of the wheel shouldbe checked at each tire change. The open side is the side opposite the discface. In the case of center flange wide base wheels, or wheels with insetsless than 3 inches, both rim flanges should be checked. Any wheel shouldbe inspected prior to mounting. If the circumference of the bead seat doesnot match the required dimension as indicated by the TRA certified balltape, immediately and permanently remove the wheel from service.Ball tapes used for measuring wheel circumference can be purchased from the Tire and Rim Association, Inc.,175 Montrose West Avenue, Copley, Ohio 44321. (330) 666-8121 or at www.rma.org. For instructions onproper use of ball tape, reference the current Tire and Rim Association yearbook.2nd Best InspectionMethodIf a ball tape isunavailableDual wheelACCEPTABLEPhoto above shows carpenter square evenon both bead seats.UNACCEPTABLEPhoto above shows an undersized wheel that youcan clearly place a credit card (approximately .030in.or .76mm) between the square and the wheel.THIS INSPECTION TECHNIQUE ONLY APPLIES TO DUAL OR DISC FACED WHEELSNon-Dual wheelCheck all wheels at each tire change for proper contour of the open side of the rim. Place the long leg of acarpenter square across the center of the disc side of the wheel. Extend the short leg across both rim flangesof the wheel as shown above. Repeat this process at four equidistant points around the wheel.The short leg should touch both rim flanges at each point. If a distance greater than the thickness of a creditcard (or .030 in. or .76mm feeler gauge) appears between the short leg and the rim flange, the wheel shouldbe removed from service and scrapped.3rd Best InspectionMethodRolling wheel asdescribed on thispageIf a ball tape or carpenter square is unavailable, roll the unmounted wheel without a tire a minimum of 10 feetover a smooth, flat, level, clean surface such as asphalt or concrete pavement. Any deviation from rolling in astraight line is an indication of a potential lack of proper dimension and contour. Remove the wheel fromservice until it can be properly checked with a ball tape.IF YOU DO NOT FULLY UNDERSTAND ANY OF THESE INSPECTION METHODS ASDESCRIBED IN THIS SECTION CONTACT ALCOA AT 800-242-9898 FOR CLARIFICATION.5ALC ServiceManual2012 rem.indd 51/28/12 7:07 AM

Dimension checks(continued)Tire Wear or Ride ProblemsIf you experience tire wear or ride problems it may be helpful to check radial run out. Removethe wheel from the vehicle, deflate and remove the tire (see Section 3-5 for recommendations andinstructions for demounting tubeless tires).1Remount the wheel on the vehicle without the tire. Be sure to follow proper mounting proceduresto assure the wheel is well centered on the hub. Place a dial indicator as illustrated below to trace thebead seats of the wheel. Rotate the wheel, noting the amount of variation shown on the dial indicator.Note: Alcoa aluminum wheels should be tested for radial run out only at the bead seat surface.A total indicator reading of .030 inches or less is acceptable.234567Tire wear can also be caused by improperly seated tires. Inspect the tire for proper seating on the wheel.The tire beads may not be seated properly. If so, remove the wheel from the vehicle, deflate and breakthe bead seats (see Section 3-5 for recommendations and instructions for demounting tubeless tires).Adequately lubricate the bead seats and properly re-seat the tire beads. Reinflate the wheel in a safetycage or other suitable restraint (refer to OSHA rule 1910.177, paragraph b, see Section 6).8Cracked ordamaged wheelchecksWARNING Cracked or damaged wheels may fail or come off the vehicle.Wheels that fail or come off the vehicle while it is moving can cause serious injuryor death.WARNINGImmediately and permanently remove cracked or damaged wheels from service.Visually inspect wheels for cracks or damage. Remove wheels from service with known or suspecteddamage.6ALC ServiceManual2012 rem.indd 61/28/12 7:07 AM

Mounting area2-6Stud hole cracks are usually caused by improper torquing (see Sections 4-8 and 5-2),excessive loading or insufficient mounting flange support by the hub or brake drum.Remove wheel from service.123456Shown below are stud hole cracks emanating from bolt hole to bolt hole. Causes are:undersized diameter of wheel support surface (see specifications on next page), supportsurface not flat, incorrect attachment parts (see Section 4-2) and insufficient torque(see Sections 4-8, 4-11, 5-2). Remove wheel from service.7Support surface should be flat to the diameter recommended on the chart on thefollowing page.8Inspect the hub/drum contact area thoroughly or cracks or other damage.7ALC ServiceManual2012 rem.indd 71/28/12 7:07 AM

Mounting area(continued)Support Surface DiametersSupport surface should be flat to the diameter recommended per SAE J694:NumberofNumberof BoltsBolt CircleBoltCircleMounting TypeMountingTypeBackupBackupDiameter1011.25 inchU.S. Stud pilot13.2-13.5 in.750/1.125 in.10285.75mmHub pilot13.2-13.4 in.22mm10335mmHub pilot15.0-15.2 in.22mm8275mmU.S. Stud pilot13.2-13.5 in.22mm8275mmISO Hub pilot12.4-12.6 Certain environments can lead to corrosion. Some of the more common corrosive materials are: salt,magnesium chloride and calcium chloride compounds used for snow removal and highly alkalinematerials. If the air used to fill tubeless tires, or the tire itself, is not dry, the areas of the wheelunder the tire can corrode severely.2-7Bead seat and valve stem corrosion often are caused by entrapped moisture. Mild corrosion as shownin pictures to left should be removed thoroughly by wire brush and the rim protected with non-waterbased tire lubricant (see Section 3-1). Remove any severely corroded (0.125 inches deep) wheel fromservice.ACCEPTABLEHub bore gauge does not fit.!CAUTIONUNACCEPTABLEHub bore gauge with severe corrosion. Removeany severely corroded wheel from service.CAUTION The use of liquid tire balancers or sealants in Alcoa wheels maycause extremely rapid corrosion of the wheel rim surface. Alcoa wheels corrodedby the use of liquid tire balancers or sealants will not be replaced under theAlcoa limited warranty.Severely corroded wheels are unsuitable for service.8ALC ServiceManual2012 rem.indd 81/28/12 7:07 AM

Bolt holesIf wheels are run loose, both stud located wheels and hub piloted wheels can be damaged. Look forwallow

BUSES, RV and MOTORHOME WHEELS This limited warranty applies to Alcoa forged aluminum wheels with bead seat diameters measured in .5 inch increments ("Wheels") and the surface of rim flange treatments applied to the Wheels. "Transit Wheels" means Wheels used on transit vehicles, such as buse