Transcription

BOWEN - QUEENSLAND - AUSTRALIARTM ENGINEERING PTY LTDCOMPANY PROFILEDESIGNING-FABRICATION-INSTALLATIONGENERAL ENGINEERING INDUSTRIAL AND AGRICULTURAL SUPPLIES

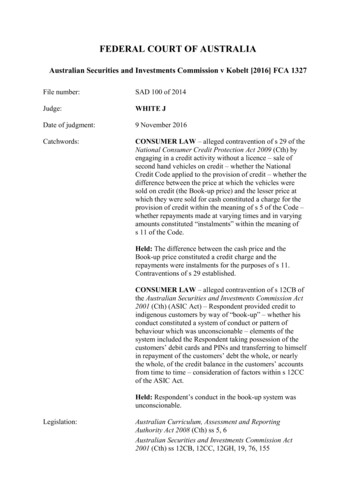

CO N T E N T SMessage from the Managing Director . . . . . 1Company Overview . . . . . . . . . . . . . . . . . . 2Company Structure . . . . . . . . . . . . . . . . . . . 3Our Mission Statement . . . . . . . . . . . . . . . . 4Values Statement . . . . . . . . . . . . . . . . . . . . . 4Russell Mayhew - Managing DirectorSafety Statement . . . . . . . . . . . . . . . . . . . . . 5Design and Drafting Department . . . . . . . . . 6Service Department . . . . . . . . . . . . . . . . . . . 7Workshop Services . . . . . . . . . . . . . . . . . 7On-Site Services . . . . . . . . . . . . . . . . . . . 7Our Experienced Team . . . . . . . . . . . . . . . . 8Retail Sales Department. . . . . . . . . . . . . . . 10Business Planning . . . . . . . . . . . . . . . . . . . 11Therese Mayhew - DirectorFuture Expansion . . . . . . . . . . . . . . . . . . . . 12Project Summaries . . . . . . . . . . . . . . . . . . . 13Contact Us . . . . . . . . . . . . . . . . . . . . . . . . 16

M E S S AG E F R O MT H E M A N AG I N G D I R E C TO RSince 1990 we have been a family owned and operated business committed to being a serviceprovider of choice to owners, developers and clients throughout the region. Our first and foremostcommitment is to our local community, using a local workforce. As we continued to experienceservice demands from the local community our small business expanded into what it is today, a‘multi-faceted’ engineering company. From our original scope of repairs and maintenance we nowprovide a full range of engineering services.Today we operate from our original location offeringa modern facility with a design and draftingdepartment, fitting and machine shop, welding bays,fabrication and assembly areas, industrial blastingand painting, hydraulic hose manufacture, hydrauliccomponent repairs, retail sales store and corporateservices office.We respond very quickly to the needs of our widercommunity and industries. Over the years weidentified a need to stock materials and componentsfor the manufacturing of our equipment. Today weoperate a retail sales shop which offers modern spareparts, materials and equipment to our clients. Thisapproach allows us to remain competitive in ourmarket as we are able to maintain our stock levelsthrough a streamlined ordering system resulting intimely production and service to our clients.Our diverse client base now includes, coal handlingand power generation industries, transport,construction and agricultural industries. We willcontinue to work with our local community andthese industries and provide innovative and effectivesolutions in our production and provision of service.Our keys to successProviding a professional quality service on timeand on budget.Working honestly by developing a follow-upstrategy to gauge performance and build trustwith all our clients.Our staffOver the years we have built a stable workforce witha large number of our employees being ‘long termemployees’. Loyalty and commitment are values wepromote amongst all our employees, fromapprentices and trainees through to seniormanagement. We support our local community byproviding career opportunities for local people. Eachyear we offer two apprenticeships and or traineeshipsin the trades we require. I am proud of our ability tobe able to offer these career opportunities for ouryoung people. Today, a number of our qualified andexperienced tradespeople in fact commencedemployment with the Company as an apprenticetradesperson.Our communityWe play an active role in our community, inparticular providing financial and sponsorshipsupport to local fundraising activities, sporting groupsand community organisations.I am committed to building a sustainable future forour company and the staff we employ by continuingto work with and in our local community to achievesuccess in all we do.Thank you for considering RTM Engineering Pty Ltdas a business partner and a provider of engineeringservices.Developing an end to end engineering productand services capability.Working closely with our customers andproviding a transparent line of communication.Russell MayhewManaging Director“o u r e n g i n e e r i n g - y o u r s o l u t i o n”1

CO M PA N Y O V E R V I E WWith a staff of over 60, our experienced team isembedded with a wide range of skills and abilities,enabling us to meet any challenge in our field.systems which facilitate the management ofquality on our projects by implementing thefollowing principals:As our region continues to prosper and grow inrich resources such as coal, power and agricultureso to do the products and services we provide. Wehave the capabilities, facilities and equipment todo small, medium and large jobs in any one of theindustries we work within. Comply with all relevant statutory andcontractual obligations. Conform to recognised standards. Maintain excellent communications withclients. Continually improve our services throughreview of our goals and objectives. Continually improve the skills andcompetencies of our workforce.Our mission statement ‘working togethersuccessfully’ encompasses our relationships withour clients, subcontractors and staff, highlightingour desire to build relationships whilst workingtowards a successful outcome for all involved.We strive for excellence in client relationships andprovision of services. We undertake projects in amanner that provides value to our clients by at alltimes trying to exceed their expectations. To reachour objectives we plan, implement and controlThese principals are incorporated into ourbusiness planning process to provide theframework for the delivery of a quality service toour clients.RTM Engineering Pty Ltd structure is organisedaround 4 internal departments – Design andDrafting, Service, Sales and Corporate Services.LOCATIONBowen is centrally located between the largercentres of Townsville and Mackay.RTM Engineering Pty Ltd’s main workshop islocated 10km from the heart of the Bowenbusiness centre, 30 minutes drive from exportcoal terminal of Abbot Point and one hourfrom the nearest Bowen Basin mine sites towhich we continue to provide an ongoingservice.A second workshop is located in Bowen’stownship industrial area.AyrHome HillFrom this ideal location we are able toprovide services to clients within the regionincluding, Bowen, Collinsville, Sonoma,Newlands and as far reaching as Moranbah.Port of Abbot PointAbbot Point Coal TerminalBOWENCollinsvilleMackay2“o u r e n g i n e e r i n g - y o u r s o l u t i o n”

CO M PA N Y S T R U C T U R EO R G A N I S AT I O NCHARTManaging DirectorRussell MayhewDirectorTherese MayhewDesign and DraftingDepartmentService DepartmentRetail SalesDepartmentCorporate ServicesDepartmentMachine ShopProject EngineerRetail SalesHuman ResourcesFreight &LogisticsAdministrationMechanic ShopDraftspersonsWorkshop 1Paint ShopFabricationShopProject Estimator/PlannerWorkshop 2FabricationShopOnsiteProjects“o u r e n g i n e e r i n g - y o u r s o l u t i o n”3

O U R M I S S I O NS TAT E M E N T“ Work ing together successfully ”VA LU E SS TAT E M E N TQUALITY – we are committed toproviding the highest quality service andproducts to our clients and to add valueRTM Engineering Pty Ltd strives to be theclient’s choice for engineering servicesbased upon our ongoing record of meetingor exceeding their expectations.to their investment. Our end to endengineering processes and systemsprovide the means by which we candeliver our service and commitments.VALUE – we treat our clients business asWe are committed to:our business by providing value forproviding long-term commitment andmoney and obtaining the mostsupport to our clients.competitive pricing.remaining at the cutting edge ofINTEGRITY – we will be honest andmanufacturing (fabrication andopen in all our dealings to ensure wemachining) services and combining thisobtain the trust of our clients.knowledge with the highest standards ofTEAMWORK – we actively promoteengineering practice.teamwork and expect each person toachieving the highest level oftake responsibility for their work, andinnovation, skill and competence in ourtreat others with respect.field.INNOVATION – we aspire to provideour clients with innovative and effectivesolutions in our production andprovision of service.4“o u r e n g i n e e r i n g - y o u r s o l u t i o n”

S A F E T Y S TAT E M E N TAt RTM Engineering Pty Ltd our Occupational Health andcommitted to providing and maintaining a safe andSafety Policy is based on the belief that the wellbeing ofhealthy working environment.our people at work, or people affected by our work, is thehighest priority and must be considered during all workperformed.Through our established safety committees andrepresentatives we consult with our employees abouthealth and safety. Our health and safety policies are theOur staff are our most important asset and their health anddocumented principles, objectives, obligations andsafety is our greatest responsibility.commitments that guide our decision making withinThe management of RTM Engineering Pty Ltd is totallyour business.ENVIRONMENTAL STATEMENTRTM Engineering Pty Ltd is committed to minimising the impact on theenvironment as a result of our working activities. We will strive for continualimprovement in this area so that we minimise our impact on the communityand other groups who may be affected by our work.As such RTM Engineering Pty Ltd will carry out all activities in a manner thatprovides consideration of the environment and the health and wellbeing ofthose involved.We will cooperate with relevant authorities and clients to meet statutory andcontractual requirements.At RTM Engineering Pty Ltd every individual is responsible for providing ahealthy, safe and environmentally clean work place.“o u r e n g i n e e r i n g - y o u r s o l u t i o n”5

D E S I G N A N D D R A F T I N GD E PA R T M E N Tservice from concept drawings to detailedworkshop drawings).Our project engineering group is a team ofprofessionals who design products for, andprovide services to a diverse range of clientsin our region.o2D AutoCAD.o3D Inventor Solid modeling.Our project engineering team consists of: A professional Mechanical Engineer. An experienced Planner and Estimator. Experienced Draftspersons.We believe our multi disciplinary team offers ourclients highly skilled professionals and the cuttingedge in technology, systems and equipment.Our expertise extends to, but is not limited to: Consultation and preparation ofspecifications. Project management and site supervision. Site measurement and surveying. Drafting (we offer a complete drafting6 General arrangement and layoutdrawings. Fabrication drawing. DXF files for laser cutting. Full solid model properties, centreof gravity, mass, etc.Mechanical EngineeringoOnsite trouble shooting.oSite supervision of projects.oDesign and certification as needed.oProject specifications, work methodstatements and manufacturers datareports.oWeld procedures and weld qualifications.“o u r e n g i n e e r i n g - y o u r s o l u t i o n”

S E R V I C E D E PA R T M E N TWorkshop Ser vicesRTM Engineering Pty Ltd offers in-house sheetmetal, welding, fabrication, machining andpainting facilities and workshops that producecustom designed products and services, including: Light and heavy fabricationGeneral engineering and machiningoAll lathe work (5 lathes)oAll milling work (3 machines)All classes of welding, including aluminiumand stainless steelSheet metal workSandblasting and protective coatings, IndustrialTiling and wear resistingPoly pipe weldingGuillotine - 3m x 12mm capacityGuillotine – 1.8m x 3mm capacityPress brake - 3.6m x 155 tonnePress brake – 3.6m x 120 tonne Hydraulic hoses, fittings and componentsHydraulic fault finding and circuit designPneumatic sales and serviceConveyor belts and joinersElectrical repairWe provide an end to end production facility withdirect access to stock, parts and equipment for thejob at hand. In our workshop we complete jobs ofall sizes and complexity. Our clients’ needs aremeticulously designed, drafted and specificationsdetailed. These are provided direct to our ServiceManager who is instrumental in facilitating thesedrawings and specifications from material requisitionto production and subsequently through to siteinstallation and quality testing.Our highly skilled and trained tradespeople andsupervisors offer our clients a one stop shopensuring the most cost effective outcome for theclient and the Company.S E R V I C E D E PA R T M E N TOn-Site Ser vices Onsite labour Mobile welding Poly pipe welding Sandblasting and protective coatings (mobileunit as well as stationary plant at workshop) On-site tool trailers fully equippedOur staff are trained and competent in all onsiterequirements and specifications. On-site tool containers fully equipped 400 cfm mobile compressorsSome of the onsite services we provide include,but are not limited to the following: 150 cfm mobile compressor Manitou 4 tonne telehandler c/w jib, forks,4 in 1 bucket Two 12 tonne mobile cranesAt RTM Engineering Pty Ltd we have theresources to ensure successful project completionand client satisfaction. Our goal is to be sure thatour clients project progresses smoothly and thatall project time frames and resources aremanaged as efficiently and effectively as possible.“o u r e n g i n e e r i n g - y o u r s o l u t i o n”7

O U R E X P E R I E N C E D T E A M“Our people are our most important asset”Fitter and TurnerOur fitters are fully qualified and areexperienced with all equipment associatedwith mining, wash plant and coal portoperations, in particular Abbot Point bulkcoal facility. The type and use of equipmentvaries from plant to plant therefore all our sitespecific inductions, competencies and trainingare maintained and current.Our Machine Shop is fully equipped andserviced by our highly skilled team ofmachinists. In addition, our machinists arecompetent in supporting the repair andmanufacture process of any of our projects.BoilermakersOur boilermakers are fully qualified andexperienced with the interpretation of drawings,and the repairs and maintenance of mining andcrushing equipment and structural steelfabrication. They are competent in the use of allequipment necessary for both workshop and onsiteworks including the use of aluminium, stainlesssteel and carbon steel. Our workshop and sitemachinery includes all the latest and up to dateequipment necessary to perform these tasks.PaintersOur painters are competent in the use of abrasiveblasting equipment, airless and conventional spraypainting, paint testing equipment and atmospheretesting equipment. They are trained in the use of allthis equipment for both on site and workshop projects.Our team of highly skilled painters maintain daily logsto monitor ambient conditions and completespecification sheets with accuracy on a daily basis.MechanicsOur motor mechanic services and maintains allcompany vehicles, cranes, forklifts and small engines.An equipment monitoring and asset maintenance systemis utilised to ensure all company equipment, vehicles andassets are registered, maintained and serviced as permanufacturer’s specifications.8Sheetmetal WorkersOur sheetmetal workers are experienced in the use ofstainless steel sheeting, aluminium sheeting and zincsheeting. They are competent in the use of guillotines,press brakes and tube bending machines. Our Sheetmetalworkers are responsible for light fabrication projectsincluding frames, guards and walkways. The diversity ofthe projects they undertake ranges from the simplestbracket to a complete commercial kitchen or a foodprocessing plant.ElectriciansOur electricians are experienced in various aspects ofthe trade including workshop repairs and maintenance,appliance tag and testing, mine site repairs andmaintenance, power station repairs and maintenanceand coal port repairs and maintenance. In addition,electronic control systems, PLC programming andcomputerised fruit grading equipment is designed,installed and maintained by our electricians.Trades AssistantsOur trade assistants specialise as boilermakers'assistants, fitters' assistants, mechanic’s assistants andindustrial painter’s assistants. They are experienced inassembly and dismantling operations, welding,operating power tools, presses and a variety ofcutting and shaping tools. They are competent inassisting with workshop fabrication and onsitemaintenance and shutdown work. We have tradeassistants who are highly skilled in poly pipewelding, the operation of light and heavy vehiclesand mobile cranes, working at heights and inconfined spaces. They are physically andmedically fit and are team players.Apprentices and TraineesOur apprentice fitters, boilermakers, electriciansand trainees continue to add value to the serviceprovided by our company to our valued clients.They are trained by our skilled trades people inall aspects of their relative trades including workskills and ethics. We have a 100% success ratewith our apprentices. We offer our clientsapprentices and trainees who are competent,hard working and are equipped with the tools,safety training, inductions and supervisionrequired for workshop fabrication and onsitemaintenance repair work.“o u r e n g i n e e r i n g - y o u r s o l u t i o n”

Our tradespeople are fully qualified and highly skilledwith the majority holding one or more competenciesand tickets for workshop and onsite environments. For“We are committed to continuousimprovement processes andproviding our staff with the skillsand experiences they need toexample, crane, forklift, elevated work platform,scaffolding, rigging and dogging, heavy rigid and lightvehicle licences.We provide our clients with motivated tradespeoplewilling to perform any task or project within theirfurther develop and enhancetheir own individual portfolios.”recognised skill sets and trade. We have a number oftradespeople who are holders of 2 or more trades - ‘dualtrades’, making them extremely versatile in the projects theycan be assigned to.9

R E TA I L S A L E S D E PA R T M E N T“ We have the materials for all projec ts”Our Retail Sales Department specialises in the supplyand sale of industry specific equipment and products Bearings, seals, V belts and sprockets CRC products and industrial paints Welding products and abrasives Loctite adhesives and ceramic wear compounds Lifting and safety equipment Hand and power tools Pneumatic tools and pneumatic quick fit fittings Drills, taps and dies Brass and stainless steel fittings Bolts – metric, UNC, UNF, zinc and stainless steel Conveyor belts Batteries Ripper points and agricultural tips Agricultural tractor accessories and trailer spares Pressure cleaners and generators Gearboxes and electric & hydraulic motors Oils, greases and lubricants Industrial gases Filters – hydraulic, engine and air Plate, sheet and merchant bars 10SteelStainless steelAluminiumBisalloy4140 barRTM Engineering Pty Ltd are distributors for: CBC Motion IndustriesMobil LubricantsBOC Gas & BOC Equipment PartnerCelli Rotary Hoes & MulchersBareco & Sparex after Market Agricultural SparesSilvan Agricultural ProductsSuper Charge BatteriesDonaldson FiltersKincrome ToolsHitachi Power ToolsSP ToolsTradequip toolsCompair and Pilot Air CompressorsSpitwater Pressure WashersQMN Hydraulic CylindersTitan Axles & WheelsBonfigioli Gearboxes & MotorsRapid Spray Diesel & Spray tanksBeaver Lifting & Height Safety ProductsCigweld Welding ProductsEutectic Welding ProductsWIA Welding ProductsRyco Hydraulics, Hose & FittingsPferd AbrasivesIrwin ToolsMacnaught LubricationGessner IndustriesRocca IndustriesAshdown’s ElectricalTonkin Steel“o u r e n g i n e e r i n g - y o u r s o l u t i o n”

B U S I N E S S P L A N N I N G“Continue to enhance our end to end engineering product and services capability”Delivering a solution to a recognised needProfessional Engineering.ExperienceConsultation - Information collection,organisation, storage and retrieval.Diverse industry and sitespecific experience.Methodical approach to problem solving.Machinery, equipment andtools owned and operated byCompany staff.Project managers andsupervisors.Conformance with Australian Standards.Design Certification.InstallationDesignOn-site assembly.Complete Drafting ServiceRigging and crane capabilities.TestingEngineeringFrom concept drawings to detailedworkshop drawings.2D AutoCAD.DraftingAnalysis3D Inventor Solid Modeling.General arrangement and layoutdrawings.Quality Assurance process.Compliance with sitespecifications.ManufactureDXF files for laser cutting.On-site testing.Workshop and SiteFitting and Machining.Welding.Fabrication and assembly.Industrial blasting and painting.Hydraulic hose manufacture.Hydraulic component repairs.Spare parts, materials and equipment.OUR STRENGTHSOUR GOALSLocation of business.1.Maintain solid financial growth Increase gross revenue. Increase asset utilisation. Improve cost structure.2.Increase product competitiveness Work closely with clients to understand industry demands. Continue improving design, drafting, production and deliveryprocesses to maintain competitive pricing of products andservices. Integrate Finite Element Analysis computer program withcurrent Inventor package. Extend workshop and machining capabilities.3.Promote Excellence Strengthen client loyalty and brand image. Continue to invest in information capital – systems, networksand databases. Increase employee satisfaction.Quality processes and procedures.Diverse profitable products andservices.Solid leadership.Investment in human capital andtechnical skills.Direct access to and timely deliveryof parts materials and equipment.“o u r e n g i n e e r i n g - y o u r s o l u t i o n”11

F U T U R E E X PA N S I O NAs industry demands and expectations increase so towill the investment in our capabilities, facilities andservices.Our future workshop expansion plans are reliant on oursuccess in securing ongoing and repeat business withnew and existing clients.A large number of our clients are repeat clients who havecomplete confidence in the quality and service weprovide. We will continue to invest time, energy andmoney into increasing our capabilities in order tobroaden our client base.Our plan for future expansions include:We will work with our clients to ensure ongoing andrepetitive business transactions. By meeting all ourclients expectations the first time around we will securetheir trust and confidence to complete (end to end) theirnext project. Additional 1800m2 of workshop floor at completion 2 x 10t Overhead Cranes Dedicated mechanic maintenance workshop New sandblast pit with grit recovery system Large industrial painting facility New amenities buildings Increased car parkingFUTURE SITE PLAN“to be the preferred supplier for all engineering and manufacturing services in our region”12“o u r e n g i n e e r i n g - y o u r s o l u t i o n”

P R O J E C T S U M M A R I E SProject Title:Client:Duration:Project Value:Project Scope:Out loader 1 Guard Package – Abbot PointAdaniJuly 2011 to December 2011 200k to 300kDesign, fabricate and install all associated guards to Adani specification for the OL1guard packageProject Title:Client:Duration:Project Value:Project Scope:Design and fabricate conveyor and screen deck systemsFynbatApril 2012 to October 2012 300k to 400kDesign and fabricate portable 1.2m wide x 15m long conveyors and a screen decksystemProject Title:Client:Duration:Project Value:Project Scope:Fabricate berth 1 fender facesAbbot Point bulk CoalJuly 2012 to December 2012 400k to 500kFabricate 5 fender faces to Abbot Point specificationProject Title:Client:Duration:Project Value:Project Scope:Remove and replace deslime screen and underpansThiess – Collinsville CHPPAugust 2012 to September 2012 200k to 300kFabricate modified deslime 1 and 2 underpans, remove and replace deslime screens 1and 2 and clarifier screenProject Title:Client:Duration:Project Value:SR2A, SR4, SR5, SR6 Stacker / Reclaimer construction,FAMQ - Abbot Point X50 Expansion2009 – 2011 3m to 4m“o u r e n g i n e e r i n g - y o u r s o l u t i o n”13

P R O J E C T S U M M A R I E SProject Title:Client:Duration:Project Value:SR3 Stacker / Reclaimer constructionSandvik - Abbot Point X21 Expansion2007 – 2009 2m to 3mProject Title:Client:Duration:Project Value:Project Scope:Dump Station #1 rail receiver hoppersSun Engineering – Abbot Point X50 Expansion2009 – 2010 (9 months) 1m to 2mFabricate, Blast, Paint, Transport & Install 5 new Dump Hoppers – complete with fullMDR documentationProject Title:Client:Duration:Project Value:Project Scope:Refurbishment of Spare TelechuteXstrataongoing 100k to 200kRefurbish as required to conform with Abbot Point specificationsProject Title:Client:Duration:Project Value:Project Scope:SR2 Stacker / Reclaimer demolitionCMA- Abbot Point X50 Expansion2011 (2 weeks) 35k Full engineering service for demolition of substructure portal, C Frame and slew deckof SR2. Full 3D model for centre of mass. Welding and certification of lifting points and bracing structure14“o u r e n g i n e e r i n g - y o u r s o l u t i o n”

P R O J E C T S U M M A R I E SProject Title:Client:Duration:Project Value:Project Scope:Replace damaged Grizzly and steel surround, Sonoma mine Wash PlantSedgman Sonoma2010 (5 day shift and 4 night shift) 300k to 400kDesign, draft, fabricate and install replacement upgraded Grizzly: Design new alternative that could be fitted in a 5 day shutdown Fabricate new components Remove damaged Grizzly Install new steel surround ware plates Install new Grizzly (completed in the required on time)Project Title:Client:Duration:Project Value:Project Scope:Re-line reject bin, Collinsville mine Wash PlantThiess Collinsville2009 (5 day shift and 4 night shift) 200k to 300kDesign, draft, fabricate liner plates and stiffening rings: Re-line Reject bin with 5mm 3CR12 Stainless steel Rolled plates and pressed cone Removal of remaining poly coating in bin. Site installation of all S/S sections including stiffening rings (5 day shut 2 x 12hr shifts per day) Completed on time Designed and Drafted several stairs and access ways for the wash plant to AS1657. (Lime silo,reject bin, cyclone access platform). Designed, Drafted, Fabricated and installed guarding on several conveyors as the result of amajor safety upgrade. (CC3,CC4, St2,ST3,RC2,ST6,ST8,ST9) Designed, Drafted, Fabricated and installed guarding on Drag lines. (Aluminium sliding guards)Project Title:Client:Duration:Project Value:Project Scope:Structural Steel project, Coral Cove ApartmentsDavid Harney Constructions2008 (10 months) 600k to 700kDesign, draft, fabricate and install structural steel and roof at Coral Cove Apartments.“o u r e n g i n e e r i n g - y o u r s o l u t i o n”15

CO N TAC T U SRTM Engineering Pty LtdPostal:PO Box 991, BOWEN QLD 4805Business:18 Hermans Road, BOWEN QLD 4805Phone:(07) 4791 2800General hop EnquiriesEmail:service@rtmeng.com.auQuote RequestsEmail:quotes@rtmeng.com.auRetail Sales EnquiriesEmail:retail@rtmeng.com.auRecruitment EnquiriesEmail:16recruitment@rtmeng.com.au

“o u r e n g i n e e r i n g - y o u r s o l u t i o n”

BOWEN - QUEENSLAND - AUSTRALIA

Abbot Point Coal Terminal Ayr Home Hill LOCATION RTM Engineering Pty Ltd's main workshop is located 10km from the heart of the Bowen business centre, 30 minutes drive from export coal terminal of Abbot Point and one hour from the nearest Bowen Basin mine sites to which we continue to provide an ongoing service. A second workshop is located in .