Transcription

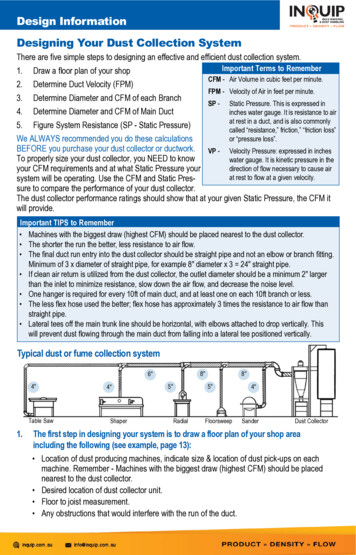

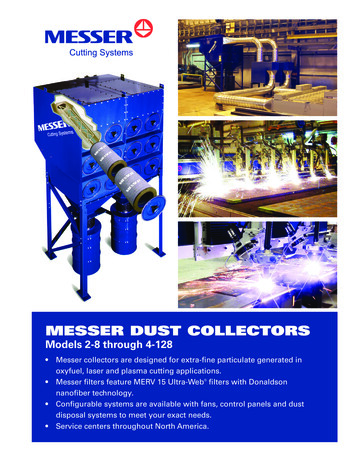

MESSER DUST COLLECTORSModels 2-8 through 4-128 Messer collectors are designed for extra-fine particulate generated inoxyfuel, laser and plasma cutting applications.Messer filters feature MERV 15 Ultra-Web filters with Donaldsonnanofiber technology.Configurable systems are available with fans, control panels and dustdisposal systems to meet your exact needs.Service centers throughout North America.

MESSER CUTTING SYSTEMS, INC.DONALDSON COMPANY, INC.CARTRIDGE FILTER TECHNOLOGYULTRA-WEB NANOFIBER FILTER MEDIADonaldson leverages almost 100 years of air filtration experience in the development of filtration media,providing tremendous value to our customers. Ultra-Web media incorporates a durable layer of premiumnanofiber designed to intercept the smallest dust particles at the surface of the media.Independent laboratory testing determined that Ultra-Web media has a Minimum Efficiency ReportingValue (MERV) of 15 based on the ASHRAE 52.2-2007 test standard. Ultra-Web media rated MERV15 is themost optimized, balanced and cost-effective media in the marketplace, providing higher efficiency withoutcompromising pressure drop or filter life. For more information on Ultra-Web and MERV ratings,please visit www.ultrawebisalwaysbetter.com.10 micron10 micronNanofiber Media(600x)Nanofiber surface loading technology is availablein all Ultra-Web and Fibra-Web cartridge filters.Commodity Filter Media(600x)Conventional media has spaces of up to 60 µm betweenfibers, allowing dust to become deeply embedded.SYSTEM ENERGY EFFICIENCY, SAVINGSAND NOISE CONTROLSurface loading is a key characteristic of Donaldson's Ultra-Web media. This surface loading capabilityimproves the effectiveness of pulse cleaning, which minimizes system pressure differential, thereby conservingcompressed air usage and brake horsepower requirements of the system fan.Clean Ultra-Web FilterSurface-Loaded Ultra-Web Filter(substrate still clean)Ultra-Web nanofiber media is loaded with ISO fine dust. Dust particles collect on the surface of the media and clean off easily while the substratestays clean. A depth-loading filter would allow dust particles to penetrate deeply into the substrate where they build up and choke off the airflow.

MESSER CUTTING SYSTEMS, INC.DONALDSON COMPANY, INC.OPERATING EXPLANATIONClean AirOutletDiaphragmValveContaminatedAir InletFilterElementsClean AirPlenumExtraLifeFilter CleaningSystemNormal OperationFilter Cleaning CyclePULSE CLEANING TECHNOLOGYExtraLife Filter Cleaning System uses proprietary, computer-modeled pulse cleaning technology to easily“pulse off” dust from the surface of the filter, improving filtration efficiency and prolonging filter life. Thered lines in the illustration show the increased pressure at the front of the Downflo filter generated by theExtraLife system. The blue line shows the pulse signature of a standard cartridge collector.Pulse gradients produced by thestandard Downflo during pulsecleaning compared to gradientsproduced by a Downflo with theExtraLife Cleaning System (red).Compressed AirCleaning PulsesVenturiTubesheetCartridgeFiltersDOWNFLO PULSE PRESSURE GRADIENTS

MESSER CUTTING SYSTEMSSYSTEMS, INC.DONALDSON COMPANY, INC.KNOW YOUR CUTTING DUSTSThe U.S. Occupational Safety and Health Administration (OSHA) has issued a National Emphasis Programand continues to communicate with most industries on the hazards of combustible dust. The agency'sfocused effort is targeted at reducing combustible dust risks in industrial plant settings. Is your planteffectively managing the risks associated with combustible dust in its processes?For decades Donaldson Torit has been providing quality dust collectors that have become an integral part ofmany plant’s combustible dust compliance strategies. Donaldson remains active in supplying dust collectorsto support your combustible dust control strategy by interfacing with you and your experts on fire andexplosion protection equipment and strategies.These pages are intended to increase your understanding of typical combustible dust management strategiesand some of the components involved.WHERE TO START?A Messer representative can review your operational challenges to help you better understand how to integrate dustcollection into your combustible dust management strategy. The following considerations are designed to help youdecide how you want Messer to support your combustible dust management strategy:DO YOU HAVECOMBUSTIBLEMATERIALS?*ARE THERE SPARKS?NOHAS THE PROCESSEXPERIENCED FIRES?YESNODO YOU HAVE TESTRESULTS CONFIRMINGNO COMBUSTIBLEMATERIALS?YESYESNOObtain test data oncombustible propertiesKst, Pmax, MIE, MEC.YESDO YOU WANTDONALDSON TORITTO INCLUDE OPTIONSTO SUPPORT YOURCOMBUSTIBLE MATERIALSMANAGEMENTSTRATEGIES?NOCollector selectionscould be made withoutoptions for combustiblematerial risk management.NOMATERIALS MAYNOT BE COMBUSTIBLE.GET VERIFICATION OFMATERIAL PROPERTIES.DO TEST RESULTSCONFIRMCOMBUSTIBLEMATERIALS?NOOPTIONS FORCOMBUSTIBLEMATERIALS MAY NOTBE NECESSARYFOR YOUR COLLECTOR.YESOptions for yourcombustible material risksmanagement strategiesare provided by others.DOCUMENTED PROCESSHAZARD ASSESSMENTMAY SUGGEST OPTIONSTO CONSIDER DURINGCOLLECTOR SELECTION.YESMesser will include optionsto support your combustiblematerial risk managementstrategies.Additional options may beprovided by others.

MESSER CUTTING SYSTEMS, INC.As a manufacturer and supplier of Industrial Filtration Products,Donaldson can assist process owners/operators in the selectionof filtration technologies.Compliance with applicable codes and standards remains theresponsibility of the process owner/operator. Among otherconsiderations, the current National Fire Protection Association(NFPA) standards require owners/operators whose processesinvolve potentially combustible materials to have a currentHazard Analysis, which can serve as the foundation for theprocess owners/operators hazard mitigation strategies.Upon request, Messer can assist owners/operators toincorporate Donaldson Filtration Product into a comprehensivefire and/or explosion mitigation strategy. Messer requirescomplete and accurate information on all potentiallycombustible contaminants and fire and/or explosion mitigationstrategies that process owners/operators intend to pursue.Visit www.nfpa.org for more information.STANDARDS, CODES, ANDGUIDELINES THAT IMPACT DUSTCOLLECTOR DECISIONSMany standards and codes may influence your decisions ondust control, including local, state and federal regulations.Knowing the codes that apply to your facility is critical, andwe recommend research of code requirements in your area.A few commonly referenced standards for combustible dustrisk management strategies include those issued by: NFPA,the International Mechanical Code, the International Fire Code,Factory Mutual Property Loss, and OSHA (federal).Since each Authority Having Jurisdiction may have a specificset of codes it references, you should have general knowledgeof more than one standard or code. Standards are published byNFPA, including both design and operational standards focusedon combustible dust (see above).FIRE TRIANGLEFire management strategies traditionallyfocus on the control or elimination ofone of the three key elements necessaryfor a fire — often represented by the“fire triangle." Managing one or moreof the elements in the triangle candecrease the fire risk.EXPLOSIONPENTAGONExplosion risk management strategiesconsider a slightly expanded set ofelements often represented as an“explosion pentagon.” In addition tothe key elements from the fire triangle —fuel, heat and oxygen.The explosionpentagon includes two additionalelements necessary for an explosion:“Dispersion of Dust” and “Confinementof Dust.” As with fire managementstrategies, the management or removalof one or more of the elements in theexplosion pentagon can reducethe explosion risk. While many explosionmanagement strategies focus oncontrolling the same elements in thefire triangle, explosion risk managementstrategies that focus on the dispersionof dust, or the containment of dust alone,may require a separate strategy toaddress any remaining fire risks.IGIRGYXOIONRS TPESDIS F DUOSince these standards are often cited by OSHA and havebeen adopted as code in many areas of the country, they area good starting point for developing your combustible dustmanagement strategy.NE/ANITIO[H NE SOAT U]RCDUSTEXPLOSIONECONFIOF NEMDU ENTSTCOMBUSTIBLE DUST STATEMENTDONALDSON COMPANY, INC.COMBUSTIBLEDUST/FUME[FUEL]To be compliant with OSHA regulations, you must meet other requirements and all applicable standards or codes.Visit www.osha.gov to find OSHA regulations.

MESSER CUTTING SYSTEMS, INC.DONALDSON COMPANY, INC.COMBUSTIBLE DUSTSGUIDE TO EXPLOSION PROTECTIONOPTIONS FOR MESSER DUST COLLECTORSOPTION 1 - CHEMICAL SUPPRESSION AND ISOLATIONab3ITEM #DESCRIPTIONDetector / Sensor – Chemical or Actuated System Devices5Rotary Valve / AirlockChemical Suppressant Delivery Device6Chemical Isolation Device - Inlet [NOT SHOWN]3Suppression System Control Panel7Chemical Isolation Device - Outlet [NOT SHOWN]4Fire Extinguisher/Fire Suppression/Sprinkler Coupling12a, 2b

MESSER CUTTING SYSTEMS, INC.DONALDSON COMPANY, INC.OPTION 2 - EXPLOSION VENTING AND MECHANICALISOLATION (OUTDOOR APPLICATIONS ONLY - AIRCANNOT BE RETURNED INTO BUILDING)3ITEM #DESCRIPTION1Explosion Vents with Weather Cover2Rotary Airlock3Inlet Isolation Device (integrated into ductwork)

MESSER CUTTING SYSTEMS, INC.DONALDSON COMPANY, INC.FANSDIRECT DRIVEBackward Inclined (TBI) Fans provide a convenient, cost-effective method of integrating a high efficiency fanwith a Messer dust collector. ounts directly to the clean-air plenum of the dust collector,Meliminating costly transition ducting, and reducing footprint ofthe system Sizes range from 3 to 50 hp Capacities from 1,400 to 15,000 cfm Backward inclined fan wheel provides high efficiency operation irect-drive operation eliminates maintenance of fan bearingsDand belts omputer balanced fan and motor assembly ensures vibrationCfree operation All hardware is included for quick installation All 60 Hz motors are Energy Independence and Security Act of2007 (EISA) compliant and meet or exceed NEMA Premium Efficiency StandardsTBI-15 (60 Cycle)PERFORMANCE CURVES FOR 60 CYCLE TBI FAN22201816Static Pressure -5TBI-20TBI-25TBI-7.52002000400060008000Airflow (scfm)100001200014000160001800020000

MESSER CUTTING SYSTEMS, INC.DONALDSON COMPANY, INC.FANSFLOOR MOUNTED The floor mounted fan selections deliver the specified cfm and static pressure at standard conditions (70 Fsea level). Contact Messer for non-standard conditions. Designed for clean air only. Arrangement 9 has motor mounted on side of fan/bearing pedestal. Motors are 1800 rpm, TEFC 1.15 SF, EISA compliant, NEMA Premium per Table 12-12, general purpose,60 cycle. Voltage is 230/460/575/3/60 thru 75 hp; 460/575/3/60 only for 100 hp. Fan include: Arrangement 9 or 1 design as needed, slip fit inlet, flanged outlet with punched holes, quickclamp or bolted style housing inspection door located same side as motor, housing drain coupling, OSHAshaft and bearing guard, OSHA belt guard with expanded metal front, constant speed 1.3 SF V-belt drive,TEFC motor, adjustable slide base, static and dynamic balanced, and shipped assembled. Guards will bepainted OSHA yellow. Outlet dampers will be painted the same as the fan. Standard Damper is parallel blade construction with manual handle and locking quadrant. Standard Silencers are constructed of minimum 14 gauge steel.

MESSER CUTTING SYSTEMS, INC.DONALDSON COMPANY, INC.MESSER CONTROL PANELSTANDARD MESSER CONTROLLERSolid-state product provides pressure drop measurement, digital display, and pressure drop control with an alarmfunction. A pulse-cleaning timer provides accurate and dependable control of starting and stopping the cleaningprocess at the limits you choose. Delta P Plus offers three cleaning options:1. Differential pressure cleaning (DFF)2. Down-time cleaning (DTC)3. Combined differential and down-time cleaning (ALL) Digital 3 character display, 0.6-inch (15.2mm), in red for high visibility Solid-state electronics for reliability and long-term accuracy High, low and alarm setpoints programmable from front panel User selected lockout feature to prevent unauthorized adjustment of setpoints Accuracy 1% full scale No battery backup required UL and CUL ApprovedDelta P Plus ControlsOPTIONAL AIRFLOW CONTROLLERThe Electrical Control System: Airflow Controller with Variable Frequency Drive (VFD) maintains airflow in yourdust collection system and works to maximize filter performance, minimize system downtime, and saves energy.How does the Airflow Control System work?Three components work hand in hand for maximum results.1.Donaldson’s filter media provides lower pressure drop due to superiorsurface-loading and better dust-shedding capabilities throughout theentire filter life. Lower pressure drop during the life of a filter eases theworkload on the fan.2. The Airflow Controller with VFD monitors the fan speed andautomatically maintains the design airflow by either slowing down (atstart-up) or speeding up the motor (at the end of the filter's useful life)based on system static pressure drop.3.The control system is most effective in combination with PremiumEfficiency Motors which are designed to boost efficiency with less heat.Since less heat is generated, less energy is needed to cool the motor witha fan.The Airflow Control System Benefits: Programs only once during the collector start-up No manual adjustments No need to adjust a fan damper or ductwork damper Maintains design capture velocity at the duct system hoods aintains design duct conveying velocity regardless of theMdifferential pressureGo to DSIREUSA.org for additional information. Federal, State, and local programs may issue rebates for theuse of a VFD and/or Premium Efficie

For decades Donaldson Torit has been providing quality dust collectors that have become an integral part of many plant’s combustible dust compliance strategies. Donaldson remains active in supplying dust collectors to support your combustible dust control strategy by interfacing with you and your experts on fire and explosion protection equipment and strategies. These pages are intended to .