Transcription

Master Keying Table of ContentsMaster Keying Kwikset Locks2Cylinder Preparation4Using a Deep Master Key6Using a Shallow Master Key8Using a Random Master Key10

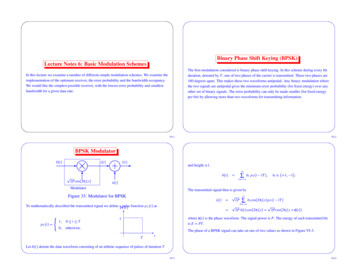

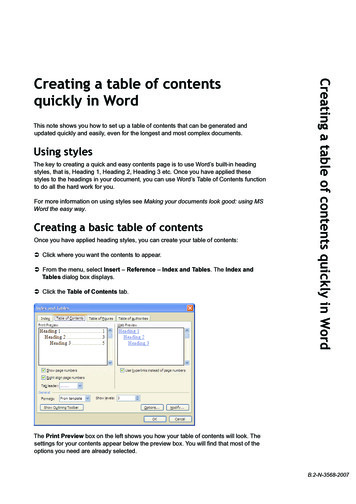

Master Keying Kwikset LocksMaster keying refers to the keying procedurethat makes one lock work with two or more keycut combinations. The master key will be able toopen all locks in a complex, and the other key (thetenant key) will only be able to open one lock in thecomplex. The right combination of bottom pins andmaster pins will produce a shear line for both keys.Next, find the difference between each cut. Thesenumbers will be the required master pins.Note: a “0” means that no master pin is used in thatposition.Master key3 4 2 5 2Tenant key5 4 6 3 5Master pins 2 0 4 2 3Shear lineSpringsFigure 4. Finding the difference between cutsTop pinsDeep and Shallow Master KeyingMaster pinsAny key can be used as a master key. Often, masterkeys are ordered with only shallow cuts or only deepcuts. See Figure 5.Note: A #7 cut is reserved only for builders’ keys.Bottom pinsFigure 1. Master keyed Lock6 7 7 6 6The first step in master keying is to gauge both keysand write down both combinations. See the examplein Figure 2.Master key3 4 2 5 2Tenant key5 4 6 3 5Deep master key1 2 2 1 2Figure 2. Gauging both keysShallow master keyCircle the smallest number of each cut. Thesenumbers will be the bottom pins required in the lock.Master key3 4 2 5 2Tenant key5 4 6 3 5Figure 5. Deep and Shallow Master KeysFigure 3. Determining bottom pins2

Protecto Keying — Protecto Keying is a two levelkeying procedure that is used for new construction. Thelock will work with a builder’s key during constructionand will become invalid after construction once thehomeowner’s key is used in the lock. To accomplishthis type of keying, three steel PK balls (located in thekeying kit) must be used in place of a #2 master pin.The builder’s key will have a cut two increments deeperthan the homeowner’s key for the chamber in whichthe PK balls are located. When the homeowner’s keyis inserted, it will raise the PK balls above the shearline. As the key rotates in the plug, the balls fall intoa pocket on the side of the plug. This changes thecombination of the lock and locks out the builder’s key.By using a deep master key where all cuts are 6’sand 7’s, all the bottom pins will match the key cutsof the tenant key. See Figure 6.Master key6 7 7 6 6Tenant key3 5 4 4 4Figure 6. Deep master keying bottom pinsUsing a shallow master key where all cuts are 1’sand 2’s will require that the bottom pins match themaster key’s cuts.Bottom pinsMaster key1 2 2 1 2Tenant key3 5 4 4 4Grand Master Keying — Grand Master Keyinginvolves three or more levels of keying. Tenant keysoperate individual locks, master keys operate lockswithin a group, and the grand master key operatesall units in the group.Figure 7. Shallow master keying bottom pinsOnce the bottom pins and master pins have beendetermined, the lock will need to be disassembledand all of the top pins and springs will need to bereplaced. See the master keying procedures on thefollowing pages for more complete instructions.Protecto-Grand Master Keying — This procedureis similar to Grand Master Keying, with the additionof a builder’s key and three PK balls in place of a #2master pin.Levels and Types of KeyingThe basic master keying procedure describedpreviously provides two levels of keying becausetwo different key cut combinations open the lock. Alock with one level of keying will only allow one keycut combination to open it. These two types are theprimary focus in this manual, but several more aredescribed below.Maison Keying — This procedure, also referred toas “Keyed Common” or “Keyed to Pass,” is usedwhen several tenant keys must pass through acommon entrance, like a lobby or laundry room.3

MASTER KEYINGCylinder PreparationThis procedure should be performedbefore master keying a lock. Theillustrations below show a standardknob cylinder after it has beenremoved from the knob’s chassis.ABcurrent key1A2Caution: Plug contentsare spring loaded.B4

3SpringsTop pinsBottom pins4B5Use small screwdriver topry up the spring cover5

MASTER KEYINGUsing a Deep Master KeyDeep master keying requiresthe use of a master key withkey cuts that are all deeperthan those of the tenant key.Note: The key cut combinationsused here are examples only.A71652346766MT017MDeep master keyTenant keyMeasure both keys and writedown key cut combinations.Note: The key cut combinations usedhere are examples only.Circle the smallest number of each cut.765432A10Master6 7 7 6 6Tenant3 5 4 4 4The circled numbers are the requiredbottom pins. In deep master keying, thesmallest numbers will be all the cuts ofthe tenant key.TNow, find the difference of each cut.MMaster6 7 7 6 6Tenant3 5 4 4 43 2 3 2 2The difference refers to therequired master pins.6

2Insert required bottom pins, startingwith the one closest to the key bow.Performprocedure onpage 4 ifyou have notdone so already.3M5444Mkey bow3Insert required master pins, startingwith the one closest to the key bow.3232 2Check for shear lineMMkey bow4Reinstall the plug intothe cylinder housing.A standard knob cylinderhousing is illustrated here.newtop pins(.160")newspringsInstall new springcover. Press downfirmly and becareful not todeform springs.Do not use.180" top pins.5If the correct pins were used to master key the lock,the tenant key will produce a shear line by pushingthe master pins above the plug.Install new clip.Do not use old clip.shear lineTKeep key in place whileinstalling clip.Test operation ofboth keys.Cylinder housing has been simplified here.7

MASTER KEYINGUsing a Shallow Master KeyShallow master keying requiresthe use of a master key with keycuts that are all more shallowthan those of the tenant key.1Note: The key cut combinationsused here are examples only.A7165234212MT012MShallow master keyTenant keyMeasure both keys and writedown key cut combinations.Note: The key cut combinations usedhere are examples only.Circle the smallest number of each cut.765432A10Master1 2 2 1 2Tenant3 5 4 4 4The circled numbers are the requiredbottom pins. In shallow master keying,the smallest numbers will be all the cutsof the master key.TNow, find the difference of each cut.MMaster1 2 2 1 2Tenant3 5 4 4 42 3 2 3 2The difference refers to therequired master pins.8

2Insert required bottom pins, startingwith the one closest to the key bow.Performprocedure onpage 4 ifyou have notdone so already.1T2212TMkey bow3Insert required master pins, startingwith the one closest to the key bow.2323 2Check for shear lineMTMTkey bow4Reinstall the plug intothe cylinder housing.A standard knob cylinderhousing is illustrated here.newtop pins(.160")newspringsInstall new springcover. Press downfirmly and becareful not todeform springs.Do not use.180" top pins.5If the correct pins were used to master key the lock,the master key will produce a shear line by pushingthe master pins above the plug.Install new clip.Do not use old clip.shear lineMKeep key in place whileinstalling clip.Test operation ofboth keys.Cylinder housing has been simplified here.9

MASTER KEYINGUsing a Random Master KeyUsing a random master key (notshallow or deep) will require theplug to be repinned without akey inserted.3Note: The key cut combinationsused here are examples only.A7165234252MT014MTenant keyMeasure both keys and writedown key cut combinations.Shallow master keyNote: The key cut combinations usedhere are examples only.Circle the smallest number of each cut.765432A10Master3 4 2 5 2Tenant5 4 6 3 5The circled numbers arethe required bottom pins.TNow, find the difference of each cut.MMaster3 4 2 5 2Tenant5 4 6 3 52 0 4 2 3The difference refers to therequired master pins. A “0”means that a master pin isnot put in that chamber.10

2Insert required bottom pins, starting with theone closest to the face of the cylinder plug.Perform procedure on page 4and isolate the cylinder plug ifyou have not done so already.3Do not insert key.304232faceInsert required master pins, starting withthe one closest to the face of the cylinder.24A shear line will not be visible until one ofthe keys is inserted later on. It is vital thatthe bottom pins and master pins arecorrect before proceeding further.2 3face4Reinstall the plug intothe cylinder housing.A standard knob cylinderhousing is illustrated here.newtop pins(.160")Install new springcover. Press downfirmly and becareful not todeform springs.newspringsDo not use.180" top pins.5Install new clip.Do not use old clip.If the correct pins were used to master key the lock, both keys will produce ashear line by shifting the master pins above or down into the plug. Testoperation of both keys.shearlineMshearlineTCylinder housing has been simplified here.11

By using a deep master key where all cuts are 6's and 7's, all the bottom pins will match the key cuts of the tenant key. See Figure 6. Figure 6. Tenant key Master key 35444 67766 Deep master keying bottom pins Using a shallow master key where all cuts are 1's and 2's will require that the bottom pins match the master key's cuts .