Transcription

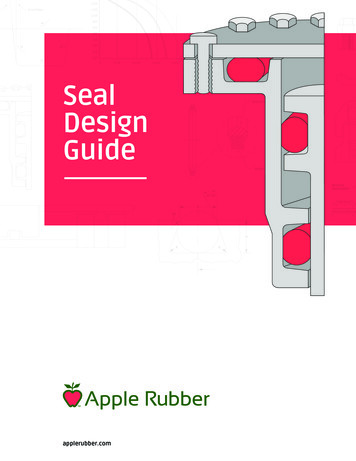

SealDesignGuideapplerubber.com

Welcome toApple RubberThe Apple Rubber Seal Design Guide was first published in 1989 and quicklybecame more popular and successful than we could have ever hoped,with thousands of copies distributed.This guide reflects the dynamic growth of Apple Rubber and our commitmentto continually bring you new ideas and technologies in seals and otherelastomeric products.So much has happened since our first catalog. In fact, we’re not really sure“catalog” is a fitting name for this edition. It will be used in many different waysby many different people – as a design guide, a reference, a handbook, a manual,a textbook, a research tool, and certainly, at times, a catalog.Whatever you call it, however you may use it, this book is dedicated to helping youdesign a successful sealing solution. We hope you turn to it often and we thank youfor your confidence in Apple Rubber.Sincerely,Steven L. ApplePresident

Table of Contents1Introduction. 4 - 5Explains how to use and take advantage of the Seal Design Guide.2Products and Services. 6 - 8Overview of complete products and services available at Apple Rubber.3O-Ring Basics. 9 - 13Defines an o-ring and methods of seal squeeze. Provides informationon cross section and inside diameter calculations.4Seal Types and Gland Design. 14 - 56Defines all types of static and dynamic seals and seal glands.5Critical Operating Environmental Factors. 57 - 62Discusses the details of critical environmental factors.6Material Selection Guide. 63 - 84Provides comprehensive descriptions of elastomers.7Special Elastomer Applications. 85 - 93Provides a listing of numerous troublesome applications callingfor the use of specific o-ring materials.8Troubleshooting. 94 - 98Presents a number of common reasons for o-ring/seal failure.9Sizes and How to Order. 99 - 105You will find a listing of all Apple Rubber o-rings, including ascendingAS568 dash numbers.10Glossary of Terms. 106 - 112Lists terms commonly used throughout the Seal Design Guide.11Technical Summary. 113 - 117Includes Rules of Thumb summary, formulas, Visual Seal Glossaryand Engineering Assistance Request (EAR) form.12Index, Bibliography and Trademarks. 118 - 121Copyrights 2020 Apple Rubber, Inc. All rights reserved.Expanded Seal Design Guide Available OnlineWe encourage you to visit our expanded online adaptation of the Seal Design Guide. Located atapplerubber.com, the online version offers exclusive and comprehensive seal content, including allof our standard and non-standard sizes. Let our online tools and calculators help you create theexact sealing solution for your needs.

Introduction1WHERE TO STARTEvery day we are partners in seal design and troubleshooting with engineers in industries as diverse asautomotive, computer and medical devices. This experience has taught us that most successful seal designsare the result of what we call “Seal Thinking, ” the careful application of sealing concepts that are basic,but not obvious or intuitive.The Apple Rubber Seal Design Guide makes “Seal Thinking ” even more accessible. The Rules of Thumbfeature is the product of hundreds of conversations with engineers about what must be emphasized toachieve a successful design. We have been very fortunate in the many opportunities we have had to workwith dedicated and gifted engineers. In a very real sense, they are contributors as well.THE O-RING EXAMPLETHE VISUAL SEAL GLOSSARYThroughout this guide, the o-ring is used as anexample in our discussion of seal design principles.Apple Rubber’s Visual Seal Glossary is notable forcolor illustrations that let you see an array of sealingproducts at a glance. It can help you connect theproper terminology with a variety of sealing devicesand related components, which may even spark anidea for your application. The Visual Seal Glossary isincluded in Section 11.We have made this choice for these reasons:1. It is the most common and most widely knowntype of seal in use today.2. It is used in all types of applications and by abroad range of industries.3. In most new designs, the o-ring is the first typeof seal to be considered.Also, as a practical matter, a discussion of themany types of seals would overwhelm our primarypurpose, which is to illustrate the general principlesof seal design.RULES OF THUMB PUT INFORMATION ATYOUR FINGERTIPSApple Rubber’s Rules of Thumb feature providesbasic information anyone working with seals shouldknow and understand. We think you’ll find that asmall investment of your time in reading these ruleswill yield a greater understanding and knowledgeof sealing principles. These rules are distributedthroughout the book and summarized in Section 11.4APPLE RUBBER INTRODUCTIONHOW THIS BOOK WORKSThis edition is organized into 12 sections. You canstart wherever you like, but we recommend you atleast go over the Rules of Thumb.In this guide you will find information on basicconcepts of o-ring design; seal types and glanddesign, critical operating environmental factors, amaterial selection guide, troubleshooting, orderingprocedures, o-ring size charts, and much more. Ourgoal is to offer you the most comprehensive guide inthe seal industry today.

BEYOND THESE PAGESAs noted, there are so many types and variationsof seals that it is impossible to cover them all inthis book. Also, space limitations made it difficultto fully address a number of our many capabilitiessuch as Liquid Silicone Molding (LSR), compositeseals, custom engineering, and complete qualityassurance. If you don’t see what you need here,don’t hesitate to contact Apple Rubber, at:(1-800) 828-7745P (716) 684-6560info@applerubber.comFor more information, including our completelist of available products and literature, visit usonline at applerubber.com.ACKNOWLEDGMENTSAs a leading designer and manufacturer of seals andsealing devices, Apple Rubber is in a unique positionto bring you this new edition. The informationpresented comes from our extensive experiencewith sealing products since our founding in 1971, aswell as the most up-to-date sealing industry sourcessuch as: Elastomeric material suppliersTechnical societies and associationsTechnical books, magazines and journalsYou’ll find a list of these source materials andorganizations in the bibliography at the back ofthis book.We also wish to extend sincere appreciation toeveryone associated with Apple Rubber who madethis book possible – our experienced engineers,our technical and manufacturing personnel, ourquality control people, our customer service staff,and most importantly, customers like you whoseneeds for better sealing solutions drive what wedo. Specifically, thanks go out to our editorial staff,including:John Tranquilli, Senior EditorDavid Meehan, Associate EditorKevin Oberholzer, Associate EditorFEEDBACK, PLEASEApple Rubber created our first catalog and thisedition in great part by listening to our customers.We welcome your comments and suggestionson this edition so that future issues meet yourchanging needs.To give us your feedback, contact ourMarketing Director at:(1-800) 828-7745P (716) 684-6560info@applerubber.comPLEASE NOTE THE FOLLOWINGThe applications, suggestions and recommendationscontained in this book are meant to be used as aprofessional guide only. Because no two situationsor installations are the same, these comments,sug gestions, and recommendations are necessarilygeneral and should not be relied upon by any purchaserwithout independent verification based on the particularinstallation or use. We strongly recom mend that the sealyou select be rigorously tested in the actual applicationprior to production use.Reproduction in whole or in part of this Seal Design Guidewithout written authorization from Apple Rubber is strictlyprohibited. Apple Rubber reserves the right to change ordiscontinue specifications at any time without incurringany obligations.5

Products and Services2THE INDUSTRY’S BROADEST RANGE OF PRODUCTS AND SERVICESAs a leading designer and manufacturer of seals and sealing devices, Apple Rubber offers the industry’sbroadest range of products to meet your seal requirements. We also have an unparalleled range of services andcapabilities, and continually implement new technologies to meet the changing needs of our customers. Thiscombination makes Apple Rubber an exceptional resource for your sealing solutions.An overview of our products and services follows. As always, if you don’t see what you need, give us a call at(1-800) 828-7745 or visit our website at applerubber.com. Experienced, knowledgeable sealing professionals areready to assist you.of sizes from 5” I.D. to 500” I.D. and in crosssections from .063” to 1”. Available in the mostpopular materials.PRODUCTS»O-RingsThe widest size range of o-rings in the sealindustry, including standard AS568 and ISO 3601;most metrics; and a wide variety of non-standardsizes. Available in all common and many specialmaterials and durometers.»Innovative FilterSeals are custom designedas a combination elastomer and fabric devicethat operates as both a seal and a filter. A widevariety of elastomers can be bonded to a varietyof filter materials (TeflonTM Membrane, Nylon,stainless steel, etc.). Provide cost and timesavings - one part to purchase instead of two;one part to install.CUSTOM PRODUCTS»MicrOringTM SealsThe largest selection of microminiature o-ringsanywhere. A MicrOringTM seal is any o-ringthat measures less than 1 mm in either insidediameter (I.D.) or cross section (C.S.). Over 2,000sizes of MicrOringTM seals, from .039" I.D. or C.S.down to .008" I.D. Microminiature compositeseals and custom-engineered microminiatureseals also available on special order.»MacrOringTM SealsMacrOringTM seals are manufactured byproprietary processes for greater strength andtighter tolerances than conventional, large sizedbonded o-rings. Available in a broad range6APPLE RUBBER PRODUCTS AND SERVICESFilterSeals »Composite SealsCustom-engineered composite seals incorporatethe seal and another component in one part:increasing performance and reducing assemblycosts. Com posite seals include complicated partssuch as rubber bonded to metal and plastic.»LSR (Liquid Silicone Rubber) Partsand SealsLSR parts and seals exhibit a wide tempera turerange (-85 F to 437 F), low compression set, and

»»resistance to the damaging effects of sunlightand ozone. Available in a durometer range of10-80 Shore A and custom color for virtually anytype seal or part including o-rings, gaskets,face seals, housing seals, FilterSeals and custom shapes.»Custom Molded ShapesSERVICESCustom designed all-rubber shaped sealsto meet exact specifications, includingmicrominiature shapes. Examples includegrommets, molded inserts, bushings, poppets,connector seals and piston seals. Customshapes and seals are available in a widevariety of materials.Whether you require design engineering assistance,a fast prototype or a customized quality assuranceprogram, this is where you’ll find information onall the services Apple Rubber can provide for yoursealing solution.ExpresSeal EMI Shielded O-Rings and SealsCustom designed, EMI-shielded o-rings andseals for a variety of electronic applicationsprovide an alternative to metallic coatings andother methods.»Design EngineeringOur engineers have a broad range of experienceand knowledge in seal design acquired overAdvanced, computerized manufacturingtechnology which produces hydraulic andpneumatic seals in minutes for emergencyreplacements, hard-to-find parts, prototypesand more. U-cups, wipers, piston rings,bushings, back-up rings, wear rings and o-ringsalso available from inventory.»Housing SealsSuperior seals custom designed to fit specifichousings. Ideal for a variety of applications, theyoutperform flat gaskets and other gasketingmethods. Silicone housing (face) seals aregenerally reusable after disassembly, unlike RTVgaskets. Available in a range of hardnesses forplastic or metal housing requirements.7

more than 30 years of solving problems fordiverse industries and applications. Capabilitiesinclude concurrent engineering, completeproject management, computer aided design,expertise in polymer technology and othermaterials and prototyping to drastically reducedevelopment cycle time.»Research and DevelopmentIt is our obligation to provide the best sealingsolutions of tomorrow as well as today.Confronted continually by the challenges ofnew applications from industries as diverse asmedical, electronics and automotive, we arealways exploring new designs, new materials andnew processes.»Customer ServiceWith direct access to Apple Rubber’sknowledgeable sales team, design engineers andQC staff, you have the “source” working for you.No middlemen – no confusion – no games.»Comprehensive ManufacturingTechnologiesAn unparalleled range of capabilities and fullyintegrated manufacturing facilities includingtransfer molding, compression molding, liquidsilicone molding, plastic injection molding,rubber injection, CNC machining and proprietarybonding processes. Manufacturing is performedin our US plant located in Lancaster, NY.»ISO 9001 RegistrationApple Rubber earned ISO 9001 Registration.The scope of our ISO 9001 Registration, themost comprehensive standard of the ISO 9000series, covers the design and manufacture ofsealing components for various applicationsincluding aerospace, automotive and medical8»APPLE RUBBER PRODUCTS AND SERVICESAS9100Apple Rubber’s quality managementsystem meets the requirements of AS9100,Quality Management Systems - Aerospace- Requirements. AS9100 incorporatesthe requirements of ISO 9001 and addsrequirements specific to the aerospace industry.PrototypingWe have the experience and advanced processesto respond quickly to prototype requirements,helping you to drastically reduce design anddevelopment time.»products. ISO 9001 Registration is testimonyto Apple Rubber’s commitment to offeringthe highest quality seals and sealing devicesavailable. Apple Rubber actively participates inongoing certification updates. Check our websitefor the most current certification listings anddocumentation.»Quality Assurance and TestingApple Rubber’s advanced testing laboratoryoffers one of the most stringent qualityassurance programs in the industry. Materialand dimensional certifications are available.We can customize a quality program to meetyour specific testing requirements and supplydocumentation with shipments.

3O-Ring BasicsSEAL THINKINGTMElastomer seals are unlike any other materials thatdesign engineers confront. Metal or plastic parts, forinstance, are probably failing if visibly distorted. But,an o-ring must be deformed to function properly. Infact, an o-ring that is not squeezed and stretched in itsapplication is the wrong o-ring.DEFINITIONAn o-ring is a doughnut-shaped object, or torus. Theopposite sides of an o-ring are squeezed between thewalls of the cavity or “gland” into which the o-ring isinstalled. The resulting zero clearance within the glandprovides an effective seal, blocking the flow of liquidsor gases through the gland’s internal passage.An o-ring is defined by its dimensions (based oninside diameter and cross section), durometer(Shore A hardness), and material composition.Illustration 3.1 demonstrates three applicationsshowing the two basic categories of o-rings: static,contained within a non-moving gland as in a face seal,and dynamice, contained within a moving gland as ina piston or rod seal.WHY AN O-RING WORKSAs Illustration 3.1 shows, a properly designed sealingsystem incorporates some degree of initial o-ringcompression. At atmospheric pressure, only theresiliency of the compressed o-ring provides the seal.However, as system pressure activates the seal, theo-ring is forced to the low pressure side of the gland.Designed to deform, the o-ring “flows” to fill thediametrical clearance and blocks any further leakage.Illustration 5.1 in section 5 shows a progressiveapplication of pressure and the effect it has onthe seal. Pressure, as well as many otherconsiderations, determine the effectivenessof a seal. These consid erations are highlightedthroughout this design guide.DIMENSIONAL CONSIDERATIONS»Inside DiameterTo provide an effective seal, the o-ring’s insidediameter (I.D.) must be smaller than the pistongroove diameter, so that the o-ring is slightlystretched, fitting snugly in the groove. This stretchshould be between 1% - 5% with 2% as the idealin most applications. A stretch greater than 5%is not recommended. The resulting stress onthe o-ring will cause accelerated aging and crosssection reduction.Exception to this rule is a floating seal. These areo-rings that are allowed to sit in grooves freelyor “float”. These are typically used in pneumaticpiston applications, where some leakage can betolerated for the benefit of lower friction.Calculate the o-ring I.D. according to the followingformula:O-RING I.D. Groove Diameter% of stretch desired 1(1% - 5%)EXAMPLEIf Groove Diameter .231Then O-Ring I.D. .231 .229 to .2201.01 to 1.05Depending on % of stretch desired9

»Cross SectionWhen calculating the cross section (C.S.) ofan o-ring, you need to consider the size ofthe gland to be filled as well as the amount ofsqueeze needed to create a good seal. Virtuallyevery gland has a slight gap between the twomating surfaces, termed “diametrical clearance.”Therefore, it is important for the o-ringcross-section to be greater than the gland depth.The resulting o-ring squeeze prevents leakage byblocking the diametrical gap.Illustration 3.1 demonstrates that in “static”face seals or “dynamic” piston and rod seals, theo-ring is being squeezed slightly within the gland.Squeeze may occur in one of two possible ways.If the squeeze occurs on the top and bottomsurfaces of the o-ring, as in face seals,it is referred to as axial squeeze. If the squeezeis on the inner and outer surfaces of the o-ring,as in piston or rod seals, it is referred to as radialsqueeze.To obtain the correct amount of squeeze foroptimum o-ring sealing, careful considerationmust be given to the size of the o-ring in relationto the size of the glandular space into which theo-ring is being installed. The actual calculationfor the cross section needed in an o-ring variesdepending on whether it will be used in adynamic or static application. In a dynamicsituation, lower squeeze is recommended toreduce friction.10APPLE RUBBER O-RING BASICSFaceAxialSeals(C 0)ABDABPiston (Radial)SealC2AA - Gland DepthB - Groove WidthC - Diametrical ClearanceD - Groove DepthBRod (Radial)SealC/2Illustration 3.1, Common ApplicationsRule ofThumbA stretch greater than 5% on the o-ringI.D. is not recommended because it canlead to a loss of seal compression dueto reduced cross-section.Rule ofThumbA groove depth is the machined depthinto one surface, whereas a glanddepth consists of the groove depth plusdiametrical clearance. The gland depthis used to calculate seal compression.

ximumRING CS»Calculation of Minimum O-Ring Cross SectionDynamic (Moving) Radial SealCross Section CalculationReferring to Illustration 3.2 for term definition,and Illustration 3.3 for sample dimensions,calculating the correct o-ring cross section for aspecific gland depth is illustrated to the right. Inthe case of the dynamic piston seal shown, thecross section is calculated as follows:Calculation of Maximum O-Ring Cross Section1. Enter the bore diameter2. Subtract the bore tolerance from thebore diameter3. Enter the groove diameter4. Add the groove tolerance to thegroove diameter5. Subtract line 4 from line 26. Divide line 5 by 27. Enter the maximum % compression8. Divide line 7 by 1009. Subtract line 8 from the number 110. Divide line 6 by line 911. Enter o-ring C.S. tolerance12. Subtract line 11 from line 10for the answer1.2.3.4.5.6.7.8.9.10.11.12.Enter the bore diameterAdd the bore tolerance to the bore diameterEnter the groove diameterSubtract the groove tolerance from thegroove diameterSubtract line 4 from line 2Divide line 5 by 2Enter the minimum % compressionDivide line 7 by 100Subtract line 8 from the number 1Divide line 6 by line 9Enter o-ring C.S. toleranceAdd line 11 to line 10 for the answerStatic (Non-moving) Axial Seal CalculationMax Bore Diameter - Min Groove DiameterMinimumO-RING CS21-Min % Compression O-Ring CS Tolerance100Min Bore Diameter - Max Groove Diameter2MaximumO-RING CS1-Max % Compression– O-Ring CS Tolerance100CrossSectionDiametrical ClearanceGrooveDiameterBoreDiameterIllustration 3.2, Radial SealRule ofThumbTo create seal squeeze, the gland depthmust be less than the seal cross section.Min Bore Diameter - Max Groove Diameter21-Max % Compression100InsideDiameterIllustration 3.3, O-ring ProfileTo calculate the cross section of an axialseal, determine the gland depth and thenmultiply by the maximum and minimumsqueeze requirements, noting to add 1.00 tothe recommended squeeze. For example, arecommended squeeze of 30% would translateto a multiplied factor of 1.3.The o-ring I.D. is determined by the presenceof pressure, whether from the I.D. or the O.D. Ifpressure forces the o-ring towards the inside, asshown in Illustration 4.2, then the o-ring shouldbe designed with the I.D. close to the grooveI.D. However, if pressure forces the seal to theoutside, as shown in Illustration 4.1, then theseal should incorporate some inference onthe O.D.– O-Ring CS Tolerance11

MATERIAL CONSIDERATIONSFRICTIONAfter you have determined the o-ring size, you willthen have to select the appropriate o-ring material.Listed in Section 6, “Material Selection Guide,”are various elastomers including statements ofdescription, key uses, temperature ranges, featuresand limitations. Prior to seal purchase, make sure totake into account all of the factors discussed below.In addition, you might want to consider availabilityand cost (see Section 6). If a material is not shown,contact Apple Rubber for availability.There are two types of friction, both of which areimportant considerations in dynamic (moving)applications. When part movement is intermittent,the effects of breakout friction can cause excessivelyhigh pressures to develop. This pressure can tearportions of the seal that adhered to the gland wallcausing seal failure.CHEMICAL ATTACKA major consideration for o-ring material selectionis resistance of specific elastomers to degradationby exposure to certain chemicals. Therefore, thefirst step in material selection is to match yourapplication’s chemicals with the o-ring material thatoffers the best resistance. To do this, refer to the“Chemical Compatibility” table and the “GeneralProperties” table found on our website or Section 6of this guide.TEMPERATUREThe range of temperature experienced duringoperation is an important factor when consideringefficient sealing. It is particularly important tomeasure temperature in the immediate o-ringenvironment, not just the system temperature. Youmust also consider the length of exposure to anyhigh temperature, whether it involves short bursts orlong, sustained levels.The temperature ranges for various o-ring materialsare listed in Section 6, “Materials Selection Guide,”as well as graphed in Section 5, “Critical OperatingEnvironmental Factors.” The Material Selection Guideon our website allows users to enter a range to findthe correct material.12APPLE RUBBER O-RING BASICSIn continuously moving applications, excessiveo-ring running friction can cause heat to build upwithin the o-ring material itself. This causes swelling,which causes more heat to develop, and eventuallyresults in material degradation and failure. For moreinformation, consult Section 5.DUROMETERDurometer (Shore A) is a measurement of thehardness of an elastomeric compound. Thenumerical ratings for hardness run from lowernumbered (less than 70) softer materials to highernumbered (greater than 70) harder materials,noting that fluorocarbon has a base rating of 75.This classification system is designed to work withina 5 point range. All materials are not available inall hardnesses. Please refer to Section 6, “MaterialSelection Guide,” for the range of individualelastomers.PRESSUREThe presence of high pressure on an o-ring canjeopardize its ability to seal. For correct o-ring designin high pressure situations, see Section 5, “ExtrusionLimit” chart.However, low pressure can present a problem aswell. If the system pressure is below 100 psi, it isclassified as low pressure. Because system pressureis not great enough to “activate” the seal, the designmust rely solely on the resiliency of the elastomerRule ofThumbThe maximum volume of the o-ringshould never surpass the minimumvolume of the gland.Rule ofThumbStatic applications are more tolerantof material and design limitationsthan dynamic applications.

to retain its original compressive force. Over time,the elastomer may not resist compression as muchand take a compression “set,” resulting in possibleseal failure. However, by proper component designwhich may include lowering the seal durometeror increasing the o-ring cross section, maximumseal utility is achieved. For an illustration of thisrelationship, see Section 5.005”(.13mm)Max.003”(.08mm)MaxSUMMARYFor optimum sealing performance, correct o-ringselection is the direct result of a number of designconsiderations. These considerations include: size,squeeze, stretch, chemical compatibility and theability to resist pressure, temperature and friction.All of these points of o-ring design are covered indetail within the sections of this Design Guide. Formore information on any of these points, see theappropriate sections. Often, there are a numberof materials that are appropriate for a particularapplication. Consideration should be given to the fullrange of environmental and cost factors. Your finalselection will usually be a compromise in the sensethat you have to balance all of these considerations.Illustration 3.4, O-ring ProfilePARTING LINE PROJECTIONParting line projection is a continuous ridge ofmaterial located on the parting line at the ID andOD of the o-ring. This is often caused by mold wearcreating enlarged radii from the mold cavity to the flatplane of the tool.EXCESSIVE FLASHExcessive flash is a thin, film-like layer of materialextending from the parting line projection, oftencaused by mold separation or inadequate de-flashing.The standard acceptable flash shown in Illustration3.4 is .005” thick and .003” extension.PLEASE NOTE THE FOLLOWINGThe applications, suggestions and recommendationscontained in this book are meant to be used as aprofessional guide only. Because no two situationsor installations are the same, these comments,sug gestions, and recommendations are necessarilygeneral and should not be relied upon by any purchaserwithout independent verification based on the particularinstallation or use. We strongly recom mend that the sealyou select be rigorously tested in the actual applicationprior to production use.13

Seal Types and Gland Design4MAJOR CLASSIFICATIONSAll o-ring seal applications are categorized in terms of relative motion. In situations involving little or nomotion relative to the seal, the o-ring application is static. In situations involving reciprocating, rotating,or oscillating motion relative to the seal, the o-ring application is dynamic.ASTATIC SEAL TYPESStatic seals are categorized as either axial or radial,depending upon the direction in which squeeze isapplied to the o-ring’s cross section.» Static Axial SealA static axial seal acts similar to a gasket in thatit is squeezed on both the top and bottom of theo-ring’s cross section. This type of seal is typicallyemployed in the face (flange) type applications,depicted in Illustration 4.1.PWhen used as a face seal involving eitherinternal or external pressure, the o-ring shouldalways be seated against the low pressure sideof the groove (as shown in Illustration 4.1 andIllustration 4.2) so the o-ring is already where itneeds to be as a result of the pressure.Static axial seals tend to be easier to design thanstatic radial seals. Since there is no extrusiongap, there are fewer design steps and you cancontrol the tolerances easier.Illustration 4.1, Internal PressureBPPstatic axial seal gland dimensionsTable B lists SAE recommended dimensionsfor static axial seal glands by ascending AS568o-ring numbers.Illustration 4.2, External Pressure14APPLE RUBBER SEAL TYPES AND GLAND DESIGN

» Static Radial SealsStatic Radial Seals are squeezed between theinner and outer surfaces of the o-ring. Theyare typically employed in cap and plug typeapplications, as depicted in Illustration 4.3.45 static radial seal gland dimensionsTable C (p. 30-44) lists SAE recommendeddimensions for static radial seal glands byascending AS568 numbers.NOTE: Recommended dimensions for static radial sealglands listed in Table C are based on an applicationpressure limit of 1500 psi. For higher pressurerequirements, reference Section 5, Illustration 5.1or contact Apple Rubber for technical assistance.Illustration 4.4, Static Crush Seal»Static Seals with Dovetail GlandsO

The Apple Rubber Seal Design Guide was first published in 1989 and quickly became more popular and successful than we could have ever hoped, with thousands of copies distributed. This guide reflects the dynamic growth of Apple Rubber and our commitment to continually bring you new ideas and technologies in seals and other elastomeric products.