Transcription

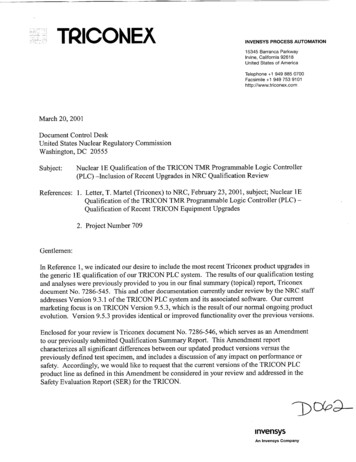

TRICONEXINVENSYS PROCESS AUTOMATION15345 Barranca ParkwayIrvine, California 92618United States of AmericaTelephone 1 949 885 0700Facsimile 1 949 753 9101http://www.triconex.comMarch 20, 2001Document Control DeskUnited States Nuclear Regulatory CommissionWashington, DC 20555Subject:Nuclear lE Qualification of the TRICON TMR Programmable Logic Controller(PLC) -Inclusion of Recent Upgrades in NRC Qualification ReviewReferences: 1. Letter, T. Martel (Triconex) to NRC, February 23, 2001, subject; Nuclear 1EQualification of the TRICON TMR Programmable Logic Controller (PLC)Qualification of Recent TRICON Equipment Upgrades2. Project Number 709Gentlemen:In Reference 1, we indicated our desire to include the most recent Triconex product upgrades inthe generic 1E qualification of our TRICON PLC system. The results of our qualification testingand analyses were previously provided to you in our final summary (topical) report, Triconexdocument No. 7286-545. This and other documentation currently under review by the NRC staffaddresses Version 9.3.1 of the TRICON PLC system and its associated software. Our currentmarketing focus is on TRICON Version 9.5.3, which is the result of our normal ongoing productevolution. Version 9.5.3 provides identical or improved functionality over the previous versions.Enclosed for your review is Triconex document No. 7286-546, which serves as an Amendmentto our previously submitted Qualification Summary Report. This Amendment reportcharacterizes all significant differences between our updated product versions versus thepreviously defined test specimen, and includes a discussion of any impact on performance orsafety. Accordingly, we would like to request that the current versions of the TRICON PLCproduct line as defined in this Amendment be considered in your review and addressed in theSafety Evaluation Report (SER) for the TRICON.invensysAn Invensys Company

Page 2NRC Document Control Desk, March 20, 2001If you have any questions pertaining to this request or wish further information, please contactme at (281) 360-6401 or Mr. Michael Phillips at (949) 885-0711.Sincerely,J. Troy Martel, P. E.Triconex Nuclear Qualification Project DirectorEnclosurecc: L. Raynard Wharton, NRCP. Loeser, NRC

N!TRICONEXProject:Purchase Order No.:Project Sales Order:NUCLEAR QUALIFICATION OF TRICON PLC SYSTEMST - 4017347286AMENDMENT 1 TOQUALIFICATION SUMMARY REPORTQualification Upgrade EvaluationDocument No.: 7286-546Revision 0March 19, 2001Author:Reviewer:Reviewer:Approvals:NameGary McDonaldGary HuftonAad FaberTroy MartelJerry McCannSigaopreC,.TitleSr. Nuclear QA EngineerDirector, Hardware DevelopmentDirector, Product AssuranceTriconex Project DirectorVP, Development

ocument Change HistoryChangeDateRevisionInitial Issue3/19/20010AMENDMENT 1 to Qualification Summary Report3/19/2001I Date:2oflOAuthorG. McDonaldI

MENDMENT 1 to Qualification Summary Report3/19/2001Date:3 of 10TABLE OF ISCUSSION44.0CONCLUSION6TABLE 11E QUALIFIED EQUIPMENT LIST7ATTACHMENT 1

AMENDMENT 1 to Qualification Summary Report4oflODate:3/19/2001INTRODUCTIONTriconex has completed a Nuclear Qualification Program for its TRICON Triple ModularRedundant (TMR) PLC for safety related (1E) applications in nuclear power plants. Thequalification program was performed and documented in accordance with NRC-approvedEPRI TR-107330, "Generic Requirements Specification for Qualifying a CommerciallyAvailable PLC for Safety-Related Applications in Nuclear Power Plants." Triconexreport 7286-545, "Qualification Summary Report," presented the final results of alltesting and analyses performed in accordance with this EPRI specification and wasprovided to the NRC for review and issuance of a Safety Evaluation Report (SER).The focus of the qualification effort was TRICON product version V9.3.1, which was theprevailing version being marketed at the time the qualification project was beingorganized. As with any high-tech product, during the extended period of qualificationtesting and evaluation, the TRICON products continued to evolve such that upgradedversions beyond V9.3.1 are now being manufactured and provided to industry. Forbusiness reasons, it is now desired to obtain NRC approval of the current TRICONproduct offering, specifically TRICON V9.5.3 and its associated support software.2.0PURPOSEAll data pertaining to testing and analysis of TRICON V9.3.1 have been provided to theNRC and are under review. The purpose of this report is to provide a listing of anypertinent differences between the product under review (V9.3.1) and the current productupgrades (represented by V9.5.3). A discussion of impact to qualification testing alreadycompleted is also provided. This additional information is provided for the NRC'sconsideration, with the express intent that the SER approval should be applied to the mostrecent TRICON product version specified herein.3.0DISCUSSIONTable 1 provides the current listing of Triconex products considered to be lE qualified asa result of the EPRI specification (& IEEE-323) qualification program. This is basicallyidentical to the hardware/software listing described in the Qualification Summary Report,with minor upgrades reflected. The routine product upgrades have not altered the criticalcharacteristics of the product, i.e., current modules have the same functional andenvironmental characteristics as the V9.3.1 Test Specimen (or better).A discussion of the software changes between V9.3.1 and V9.5.3 is provided inAttachment 1, "Evaluation of the differences between TRICON V9.3.1 and TRICONV9.5.3."

AMENDMENT 1 to Qualification Summary Report3/19/2001Date:5 of 10Routine component and board changes to maintain production needs are ongoing and arereviewed by the Configuration Control Board (CCB) in accordance with TriconexAppendix B QA procedures. This review confirms that no significant changes have beenmade to modules which would adversely affect performance specifications orqualification characteristics (seismic, environmental, electrical) as specified in the EPRITR 107330. The most significant component change, replacement of the obsolete80C451 microprocessor on most I/O boards, necessitated additional firmware upgradesand retesting as described in Attachment 1. Also, as indicated in paragraph 3.0 (2) below,component upgrades were made for four "T" (high voltage) modules; 3501TN, 3601TN,3623TN, and 3636TN. These module upgrades significantly improved the surge andisolation capabilities of these modules.In addition to evolutionary upgrades to the modules, Table 1 reflects other minor changesfrom the previous list of equipment described in the Qualification Summary Report.These equipment list changes fall into 3 categories:(1) Nuclear Model Numbers - Unique model numbers have been assigned to thesuccessfully qualified TRICON modules for marketing purposes. A trailing "N" has beenadded to each qualified module identified in 7286-545. Thus, the 3006 Main Processorwill be identified in our product literature as 3006N if it is to be provided to a nuclearpower plant for a 1E application (on a Safety Related customer purchase order). Thesemodules will receive a special faceplate overlay with the N number in lieu of the basemodel number. Only the N module will receive a Triconex Certificate of Conformanceattesting to its 1E qualification status. The commercial version of the same module willnot receive this certification. The SER should therefore reflect the N model numbersexactly as indicated in the Attachment 1 list.(2) High Voltage (T) Models - "T" modules have been substituted in place of four of theI/O modules in original test specimen. As described in paragraph 4.6 (4) of theQualification Summary Report, the 3603E module was swapped out during surge testingand replaced with the 3603T module, which was functionally identical to the originalmodule but provided a higher surge voltage withstand capability. Equivalent high voltageupgrades ("T" versions) to modules 3501E, 3601E, 3623, and 3636R are now available,and it is intended to offer these as the preferred nuclear versions. Even though theoriginal versions of these modules passed the qualification tests, the T versions provideimproved performance and are better suited to the nuclear industry.The "T" modules were introduced to comply with the latest international (IEC) productsafety and EMC standards. The high voltage modules were designed to be in compliancewith the applicable US and Canadian national standards in effect at the time of theirintroduction. As the global world economy has matured, our customers are demanding

WRTP.ICONEXDocument:7286-546Title:AMENDMENT 1 to Qualification Summary ReportRevision:0Page:6 of 10Date:3/19/2001that all Triconex products fully comply with the latest IEC standards. The requiredchanges were in 2 general categories:a)Improve the module isolation from 1500VDC to 2500VDC for compliance withIEC 61010-1: 1990, Safety Requirements for electrical equipment for measurement,control, and laboratory use, Part 1: General requirements. This required improvedvoltage ratings on field de-coupling capacitors, and modification of the per unitacceptance test procedures.b)Test and modify as required for compliance with IEC 61000-4-5, Surge Withstand.This required the installation of transient protection devices on selected modulesand/or termination panels.(3) Generic Cable Lengths - On the Table 1 equipment list, the part numbers forqualified connector cables have been generalized to indicate that, while specific lengthsof certain cables were used in the test specimen, all of the varying lengths of the samebase cable are considered qualified. Thus, while a 4000056-099 (dash number indicating99 ft length) was tested, a 25 foot length (4000056-025) would also be consideredqualified, as the base parts specification is the same. The list therefore identifies thequalified cable family part number as 4000056-xxx, consistent with our internalnomenclature standards.4.0CONCLUSIONThe TRICON V9.5.3 products indicated in Table 1 continue to meet TR 107330 andIEEE requirements for 1E service and accurately represent the TRICON QualificationTest results as presented in Qualification Summary Report 7286-545. Changes made tothe TRICON product since V9.3.1 are considered minor and evolutionary and have noadverse effect on qualification program results previously submitted for review.

m TRICONEXDocument:Revision:7286-5460TABLE 1:Title:Pa e:AMENDMENT 1 to Qualification Summary Report3/19/2001Date:7 of 10NUCLEAR 1E QUALIFIED EQUIPMENT LIST - (Hardware)QUALIFIED TRICON SYSTEM VERSION:Model No.Item DescriptionV9.5.3Triconex Part NumberPrevious Model/PN(Referenced in 7286-545)Comment(1.Module Assemblies)81 ION811IN8112NMain ChassisExpansion ChassisRemote Expansion 31 INHigh Density Power Module, 115 VHigh Density Power Module, 24 0-300(1)(1)3006NEnhanced Main Processor II, V9, 2 Mb3000348-65030067400120-500(1)4210N4211NRemote Extender ModuleRemote Extender 0176-100(1)(1)4119AN4329N4609NEICM., V9, IsolatedNetwork Communication Module, V9Advanced Communication 3701N3703EN3704ENAl Module, 0-5 VDC, 6% OverrangeAl Module, 0-10 VDCEAI Module, IsolatedHDAI Module, 0-5/0-10 7400125-110(1)(1)(1)(1)3805ENAnalog Output Module, 4-20 mA3000316-1603805E7400097-110(1)

ENDMENT 1 to Qualification Summary Report3/19/2001Date:8 of 10CommentModel No.Item DescriptionTriconex Part Number3501TN3502EN3503EN3504EN3505ENEDI Module, 115V AC/DCEDI Module, 48V AC/DCEDI Module, 24V AC/DCHDDI Module, 24/48 VDC (24V)EDI Module, 24 VDC, Low 1703000303-225Previous Model/PN(Referenced in N3604EN3607EN3623TN3624NEDO Module,EDO Module,EDO Module,EDO Module,SDO Module,SDO Module,115 VAC120 VDC24 VDC48 VDC120 VDC24 807400174-130(1) (2) (4)(1)(1)(1)(1) (2)(1)3510NPulse Input C Input ModuleITC Thermocouple Input 400112-100(1)(1)3636TNERO Module, N.O., Simplex3000314-3903636R7400123-310(1) (2) (4)8105N8107NBlank Module PanelSeismic Balance 0632-001(1)(1)Standard Chassis Mounting Bracket (for Chassis rear)2000240-001(same)Term ination Assemblies - ETA)(for use with DI 3501TN)(for use with DI 3502EN)(for use with DI 3503EN, DI 3505EN)(for use with DI 3504EN)(forusewithDO 3601TN)(for use with DO 3604EN)(for use with DO N2553-6N2554-6N2651-IN2652-IN2657-IN(2. ExternalTerm PanelTerm PanelTerm PanelTerm PanelTerm PanelTerm PanelTerm (2)(1)(1)(1)(1)

406-110Previous Model/PN(Referenced in 6-1202760-22790-310T 3000619-1007400111-1002852-19661-910 7400166-1807400166-3909662-6109753-110 7400143-510Mounting Plate for V9 ETAs9420017-070(same)(3. Signal Conditioners)Signal ConditionerSignal ConditionerSignal ConditionerSignal Conditioner(- 100/ 100) Pt(0/ 100) Pt(0/ 200) Pt(0/ 600) e)(same)(same)(same)(4. Connector Cables)1/0 Bus Cable Set(No. 9000, various lengths)--------------4000056-xxxEthernet Cable Assy(NCM, various lengths)1600010-xxx-------------4000056-099 (100ft)4000056-006 (6 ft)1600010-015 (50 ft)Model No.Item m PanelTerm PanelTerm PanelTermPanelTerm PanelTerm PanelTerm PanelTerm PanelTerm PanelTerm PanelTerm Panel-------IAMENDMENT 1 to Qualification Summary Report3/19/2001Date:9 of 10Title:Page:COMMENTS:Triconex Part Number(for use with RO 3636TN)(for use with Al 3700AN, Al 3701N)(for use with AI 3703EN)(for use with TC 3708EN)(for use with TC 3706AN)(for use with Al 3704EN)(for use with AI 3700AN/RTD)(for use with AO 3805EN)(for use with DO 3603TN, DO 3623TN)(for use with DO 3624N)(for use with PI )(3)I(1) Nuclear Model Number. "N" added to base model number. Model part number encompasses the qualified (tested) board assembly. ETA NuclearModel part number includes qualified connector cable assemblies:'(2) Indicates base module upgraded to "T" (high voltage) module.(3) Part Number for generic cable lengths.(4) Pending Release.

STRICONEXDocument:Revision:7286-5460TABLE 2:Title:Page:AMENDMENT 1 to Qualification Summary Report3/19/2001Date:10 of 10NUCLEAR IE QUALIFIED EQUIPMENT LIST- (Software)QUALIFIED TRICON SYSTEM VERSION:V9.5.3TYPEIDENTIFICATIONVERSIONUSED INApplication ProgramTriStation 1131,V3.1TriStation WorkstationDevelopment SoftwareDeveloper's Workbench 490549955305488549755023006N (MP)3006N (MP)3006N (MP)4119AN (EICM), 4329N (NCM)4609N (ACM)4329N (NCM)4119AN (EICM)4210N (RXM), 421 IN (RXM)3700AN (Al), 370IN (AI), 3706AN (TC)3703EN(AI), 3708EN (TC)351 ON (PI)3501TN (DI), 3502EN (DI), 3503EN (DI), 3505EN (DI)3704EN (AI), 3504EN (DI)3805EN (AO)3601TN (DO), 3604EN (DO), 3607E (DO)3636TN (RO)3603TN (DO), 3623TN (DO), 3624N (DO)TSXIOCCOMCommunication Modules ICMACMXNCMXIICXRXMI/O Modules AI/NITCEIAI/ITCP1EDIHDIEAOEDOEROTSDO(Bolded versions upgraded from V9.3. 1)Operating SystemFirmwareMain Processors

NDMENT 1 to Qualification Summary Report3/19/2001Date:Attachment 1ATTACHMENT 1An Evaluation of the Differences betweenTRICON V9.3.1 and TRICON V9.5.3(Nuclear Qualified Modules only)Aad FaberMarch 2001

NDMENT 1 to Qualification Summary ReportAttachment 1Date:3/19/2001TABLE OF CONTENTS1INTRODUCTION32SUMMARY AND CONCLUSIONS33TSX CHANGES43.13.2444TSX 5124TSX 5211IOC CHANGES4.14.255IOC 5106IOC 521255COM CHANGES5.15.266COM 4931COM 520666ACM CHANGES6.16.277ACM 5141ACM 520377IICX CHANGES7.17.287IICX 5148IICX 52767710 FIRMWARE iption of the changeAdditional changes madeV&V activity to support the changeEvaluation of the change9999TS 1131 CHANGES9Version 2.0Version 2.0 SP1Version 2.0 SP2Version 2.0 SP3Version 3.0Version 3.0.1Version 3.1Evaluation of the TS 1131 changes from V2.0 to V3.1Page 2 of II9991010101111

AMENDMENT 1 to Qualification Summary Report3/19/2001Date:Attachment 1IntroductionThe TRICON Nuclear Qualification project resulted in a Qualification Summary Report (7286-545) that formsthe basis for the generic qualification of the TRICON system for safety-related applications in nuclear powerplants. The basis for qualification is compliance with EPRI TR-107330. The Qualification Summary Report aswell as all testing and analysis described in that report is based on a TRICON V9.3.1 configuration. Thisdocument describes the differences between TRICON V9.3.1 and TRICON V9.5.3 and provides justificationfor the argument that the basic findings and results described in the Qualification Summary Report are alsovalid for TRICON Version 9.5.3.In order to be able to properly market and track a Nuclear Qualified TRICON System, Triconex has decided tomodify the model numbers of the qualified modules listed in Table 3-1 of the Qualification Summary Report.All Nuclear Qualified Model numbers will have an additional "N" suffix. Table 1 of this document includes alisting of the newly assigned model numbers.Following V9.3.1 TRICON Firmware and application software that were listed in the Qualification SummaryReport were changed in the V9.5.3 release.Firmware ModulePC 7548854905491549955025530V3.1Note: TS 1131 V2.0 was referenced in the qualification report.Detailed descriptions of the changes and an evaluation of the changes are provided in section 3 through 9 ofthis document.2.0Summary and Conclusions"* No changes to basic functionality were made. Updates were primarily to accommodate a new processor,recognize new module/model numbers, and bug fixes identified in Product Discrepancy Reports (PDRs)."* All changes described in this document were validated and released in accordance with current TriconexQuality Assurance procedures."* Triconex has no reason to believe that any of the changes made from V9.3.1 to V9.5.3 invalidate thefindings and results of the generic qualification of the TRICON in accordance with EPRI TR-107330.Page 3 of I I

11INTRICONEXDocument: 1 7286-5460Revision:3.0TSX Changes3.1TSX 51241 Title:Page:IAMENDMENT 1 to Qualification Summary Report3/19/2001Date:Attachment 1This version of TSX was used in the V9.3.1 qualification system.3.2TSX 5211TSX 5211 was released in version 9.5.0 (12/21/99).Supporting Documentation for this change:(1) Software Requirements Definition (SRD), 6200003-111, 12/21/1999 (E3319)(2) V9.5 SQA Validation Plan rev 1.1, 12/9/1999(3) SQA Tricon V9.5 Test Report, 3/20/20003.2.1Description of the changeThe TSX firmware was changed to support a new Pulse Totalizer module (Model number 3515). The nuclearqualification does not include this new module. The differences in the firmware are described in detail in theSRD appendix A. This description includes a source code diff., an assembly code and a binary image diff.3.2.2V&V activity to support the changeVerification of the change in TSX firmware was carried out by review of the code differences documented inthe SRD. The code differences were prepared by the responsible design Engineer and reviewed by issuer of theSRD (Director of real time software Triconex QA, and TUV).TSX 5211 was validated in accordance with the V9.5 SQA Validation Plan. This plan included therequirement to execute a number of applicable sections in the QA Validation Procedures 9600047-001 and9600038-001. The Director of Product Assurance issued a TRICON V9.5 Test Report. This report documentsthe recommendation to release V9.5.0 as specified in the SRD. TSX 5211 was released as part of V9.5.0.3.2.3Evaluation of the changeTriconex has no reason to believe that any of the changes made from TSX 5124 to TSX 5211 invalidate thefindings and results of the generic qualification of the TRICON in accordance with EPRI TR-107330. Thechanges made to TSX were minor and only affect the support of a new module. This new module is not part ofthe Qualified TRICON Module listing. The changes were fully validated both by Triconex SQA and TUV.Page 4 of ]I

WMTPRICONEXDocument:Revision:7286-54604.0IOC Changes4.1IOC 5106Title:Page:AMENDMENT 1 to Qualification Summary Report3/19/2001Date:Attachment 1This version of IOC was used in the V9.3.1 qualification system.4.2IOC 5212IOC 5212 was released in version 9.5.0 (12/21/99).Supporting Documentation for this change:(1) Software Requirements Definition (SRD), 6200003-111, 12/21/1999 (E3319)(2) V9.5 SQA Validation Plan rev 1.1, 12/9/1999(3) SQA Tricon V9.5 Test Report, 3/20/20004.2.1Description of the changeThe IOC firmware was changed to support a new Pulse Totalizer module (Model number 3515). The nuclearqualification does not include this new module. The differences in the firmware are described in detail in theSRD appendix A. This description includes a source code diff., an assembly code and a binary image diff.4.2.2V&V activity to support the changeVerification of the change in IOC firmware was carried out by review of the code differences documented inthe SRD. The code differences were prepared by the responsible design Engineer and reviewed by issuer of theSRD (Director ofreal time software Triconex QA, and TUV).IOC 5212 was validated in accordance with the V9.5 SQA Validation Plan. This plan included the requirementto execute a number of applicable sections in the QA Validation Procedures 9600047-001 and 9600038-001.The Director of Product Assurance issued a TRICON V9.5 Test Report. This report documents therecommendation to release V9.5.0 as specified in the SRD. IOC 5212 was released as part of V9.5.0.4.2.3Evaluation of the changeTriconex has no reason to believe that any of the changes made from IOC 5106 to IOC 5212 invalidate thefindings and results of the generic qualification of the TRICON in accordance with EPRI TR-107330. Thechanges made to the IOC firmware were minor and only affect the support of a new module. This new moduleis not part of the Qualified TRICON Module listing. The changes were fully validated both by Triconex SQAand TUV.Page 5 of ]]

-TRICONEXDocument:Revision:7286-54605.0COM Changes5.1COM 4931Title:Page:AMENDMENT 1 to Qualification Summary Report3/19/2001Date:Attachment 1This version of IOC was used in the V9.3.1 qualification system.5.2COM 5206COM 5206 was released in version 9.5.0 (12/21/99).Supporting Documentation for this change:(1)(2)(3)(4)(5)Software Requirements Definition (SRD), 6200003-111, 12/21/1999 (E3319)V9.5 SQA Validation Plan rev 1.1, 12/9/1999SQA Tricon V9.5 Test Report, 3/20/2000Product Discrepancy Report (PDR) 2446, 11/20/1998Technical Advisory Bulletin (TAB) 96, 1/27/19995.2.1Description of the changeThe COM firmware was modified to fix PDR 2446 / TAB 96.5.2.2V&V activity to support the changeThe validation of changes to the COM firmware as a result of the PDR 2446 fix are documented in the SQAValidation report in section 6.2.16.5.2.3Evaluation of the changeTriconex has no reason to believe that any of the changes made from COM 4931 to COM 5206 invalidate thefindings and results of the generic qualification of the TRICON in accordance with EPRI TR-107330. Thechange made to the COM firmware was a fix for a problem that was discovered during Triconex InternalValidation testing. The changes were fully validated both by Triconex SQA and TUV.Page 6 of 11

STR.ICONEXDocument:Revision:7286-54606.0ACM Changes6.1ACM 5141Title:Page:AMENDMENT 1 to Qualification Summary Report3/19/2001Date:Attachment 1This version of ACM was used in the V9.3.1 qualification system.6.2ACM 5203ACM 5203 was released in version 9.4.0 (1/15/99).Supporting Documentation for this change:(1)(2)(3)(4)Software Requirements Definition (SRD), 6200003-104, 12/21/1999 (E3319)V9.5 SQA Validation Plan rev 1.1, 12/9/1999SQA Tricon V9.4 Test Report, 3/20/2000Product Discrepancy Report (PDR) 7286.2.1Description of the changeThe ACM Firmware was modified to improve fault insertion behavior of the module. This change wastriggered by TRICON PDR 728.6.2.3V&V activity to support the changeThe ACM 5203 Firmware was validated as part the V9.4 validation effort. This validation included a fullfunctional validation of the V9.4 TRICON system including a validation and manual fault insertion of the ACMmodule. The results of this validation are reported in the V9.4 SQA validation report.6.2.3Evaluation of the changeTriconex has no reason to believe that any of the changes made from ACM 5141 to ACM 5203 invalidate thefindings and results of the generic qualification of the TRICON in accordance with EPRI TR-107330. Thechanges were fully validated both by Triconex SQA and TUV.7.0IICX Changes7.1IICX 5148This version of IOC was used in the V9.3.1 qualification system.7.2IICX 5276IICX 5276 was released in version 9.5.2 (8/8/2000).Page 7 of II

STP.ICONEXTitle:Page:Document: 1 7286-5460Revision:AMENDMENT 1 to Qualification Summary Report3/19/2001Date:Attachment 1Supporting Documentation for this change:& E3471)(1) Software Requirements Definition (SRD), 6200003-118, 8/8/2000 (E3445(2) V9.5.2 SQA Validation Plan rev 1.0, 3/17/2000(3) SQA Tricon V9.5.2 Test Report(4) Product Discrepancy Reports (PDRs) 2418, 688, 689, 6907.2.1Description of the change7.2.2V&V activity to support the change7.2.3Evaluation of the changeIICX 5148 to IICX 5276 invalidate theTriconex has no reason to believe that any of the changes made fromwith EPRI TR-107330. Thefindings and results of the generic qualification of the TRICON in accordancechanges were fully validated both by Triconex SQA and TUV.8.0I/O Firmware changesa number of PDRs were generatedAs a result of an investigation into a problem report from one customer,the these problems.correcttomodifiedwas(PDR 2418, 688, 689, 690). The IICX Firmwarerelease. The results of the validation areThe changes to the IICX firmware were validated as part of the V9.5.2documented in the SQA V9.5.2 Validation report.modules. The following tableTRICON Version 9.5.3 includes changes to most of the I/O firmwareaffected by this change.wasthatsummarizes the Firmware Meta numbers for each 1/O moduleChanges made other thenV9.5.3I V9.3.1I 1TvA tn Mnd1Irequired to support the mNone549735683636R, 3636TNEROEDOEDIEIAI/ITCHDI3601E, 3601T,3601TN,3604E 36(04EN,3607E, 3607EN3501E, 3501T,350ITN3502E, 3502EN3503E, 3503EN3505E, 3505EN3703E, 3703EN3708E, 3708EN3504E, 3504EN3704E, 3704EN46215488Yes, PDR 71642995490None50871 5491None48435499NonePage 8 of I I

STRICONEXDocument:Revision:7286-5460TSDOEAO8.11 Title:Page:3603E,3603T, 3603TN3623,3623T,3623TN3624, 3624N3805E, 3805ENf AMENDMENT 1 to Qualification Summary ReportAttachment 1Date:3/19/200150665502None45325530Yes, PDR 849Description of the changeThe 80C451 chip used in the 1/0 boards went out of production, necessitating replacement. The firmwarechanges that were required to replace the 80C451 microprocessor with the 80C515 microprocessor were verylocalized in the code. The only change required between the new and old firnmware was identified as a changein the port assignments (constants) that are used at multiple locations in the code. The port assignments aredone in code header files.8.2Additional changes madeIn addition to the changes made to support the new microprocessor, the EAO firmware and the EDO firmwarewere modified to fix two outstanding PDRs (PDR 849, 716). PDR 849 was fixed in EAO 5530 firmware.PDR 716 was fixed in EDO 5488 firmware.8.3V&V activity to support the changeAll changes to the 1/O firmware listed in the table above were validated as part of the TRICON V9.5.3validation effort. In addition, the differences between the old firmware and the new firmware were analyzed byEngineering to ensure that only the port assignment numbers were changed. The validation was carried out inaccordance with the TRICON I/O processor replacement Validation plan (rev 1.0). The plan included a fullfunctional validation per the I/O Modules Functional Validation Procedure (9600038-001). The plan alsoincluded fault insertion testing of the 3805E Module. Both PDR 849 and PDR 716 were fixed and validated inTRICON V9.5.3. The results of the validation are documented in the SQA V9.5.2 Validation report.8

Subject: Nuclear lE Qualification of the TRICON TMR Programmable Logic Controller (PLC) -Inclusion of Recent Upgrades in NRC Qualification Review References: 1. Letter, T. Martel (Triconex) to NRC, February 23, 2001, subject; Nuclear 1E Qualification of the TRICON TMR Programmable Logic Controller (PLC)