Transcription

HARDI ISO NOZZLESNozzle product guide

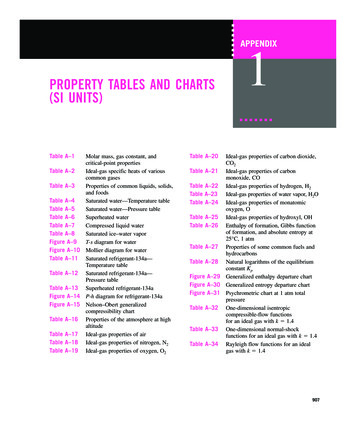

Table of contentsHARDI nozzle supremacy. . . . . . . . . . . .3Nozzle technology . . . . . . . . . . . . . . . .4Field sprayingChoosing nozzles for arable crops . . . . . . . . .6HARDI nozzles on all liquid systems. . . . . . .7. . . . . . . . .8HARDI ISO F 110 – Standard Flat Fan nozzles . . .10HARDI ISO LD 110 – Low Drift nozzles . . . . . .11ISO MINIDRIFT Air Inclusion nozzles . . . . .12HARDI ISO INJET Air Inclusion nozzles . . . . . .13HARDI ISO F 80 Flat Fan nozzles . . . . . . . . . .14HARDI QUINTASTREAM 5 hole fertilizer nozzles . . .151553 Solid stream nozzle . . . . . . . . . . . . . .16Large drop flat spray nozzle . . . . . . . . . . . . .16V ineyard and orchard sprayingCalibration of mistblowers . . . . . . . . . . . . . . .171299 Ceramic hollow cone nozzles . . . . . . . . . . .181099 Solid stream nozzle - CERAMIC . . . . . . . . . . .18Calibration of field crop sprayersHARDI 1553 Cone nozzles. . . . . . . . . . . . . . . . . . .19Hand operated sprayingCalibration of hand operated sprayers . . . . . . . . . . . . .20HC – Hollow cone nozzle – SYNTAL . . . . . . . . . . . . . . .21REFLEX nozzle – SYNTAL . . . . . . . . . . . . . . . .21HARDI Adjustable nozzle - SYNTAL. . . . . . . . . . . . . . . . . . .21Band sprayingCalibration for band spraying . . . . . . . . . . . . . . . . . . . .22HARDI 4680E 80 Even spray nozzlesISO ISO ISOSpecial nozzlesISO ISO ISOEnd nozzles . . . . . . . . . . . . .ISO ISO ISO4665 65 Flat spray nozzle – SYNTAL .SO ISO ISO ISOISO ISO ISO4625 25 Flat spray nozzle – SYNTAL .SO ISO ISO ISO5131 Misting nozzle – SYNTAL . . . .ISO ISO ISOSO ISO ISO ISO3600 Deflector spray nozzle – SYNTALISO ISO ISO ISMulti-hole rinsing nozzle – SYNTAL . .SO ISO ISO ISO IISO ISO ISO ISO5066 Agitation nozzle - SYNTAL . .SO ISO ISO ISO ISOTank cleaning nozzle . . . . . .ISO ISO ISO ISO ISOHARDI DUOCAP . . . . .SO ISO ISO ISO ISO ISO2ISO ISO ISO ISO ISO ISOFilter & Fittings . .SO ISO ISO ISO ISO ISO ISOSO. . . . . . . . . . . . . . .22. . . . . . . . . . . . . . . .23. . . . . . . . . . . . . . . .24. . . . . . . . . . . . . . . .24. . . . . . . . . . . . . . . .24. . . . . . . . . . . . . . . .24. . . . . . . . . . . . . . . .25. . . . . . . . . . . . . . . .25. . . . . . . . . . . . . . . .25. . . . . . . . . . . . . . . .26. . . . . . . . . . . . . . . .27

HARDI nozzle supremacyPrecise, dependable and accountableHARDI has produced sprayers since 1957 - meetingthe needs of all farmers and crops worldwide - a keygoal that has demanded the world’s best nozzles.Today the same basic HARDI philosophy promotesthe efficient, effective and responsible plant care thatensures quality food production.The nozzle can dominate the sprayer performance.All of the sprayer components are important for safeand effective use, but it is the nozzle that can have themajor influence on the performance of the plant protecting product that it will apply.HARDI quality nozzle production in Nørre Alslev, DenmarkHARDI 's modern production facilities and technical abilities have resulted in the superior precision and durabilityof HARDI nozzles.The nozzle controls: The throughput [and therefore the dose] Quality of distribution Drop spectrum and coverage Distribution over the target Drop retention or reflection The degree of drift and downwind falloutQuality control includes not just laboratory measurements but the use of HARDI nozzles in the field, undercommercial conditions.Every drop of spray needs to be both accounted for- and documented - in order to ensure the quality offood delivered onto the dining table, and it meets thedemands of the public today.HARDI quality nozzles meet these increasing demandswith world leading research and development.All these functions are considered by HARDI to ensurethat the spray liquid is deposited exactly where it isneeded, in its most effective form, and is not wasted.HARDI has combined both design and material selection to produce a range of nozzles that suit the broaddemands of both crops and the vast array of agrochemical products available today. This has been the basis forHARDI ’s worldwide success.Close co-operation between farmers, advisers, chemical companies, independent and regulatory bodies withHARDI ’s agronomists has beenthe backbone of this continuingsuccess.Quality in production ensuresoptimal field performance.The application of plant protection products to cropsinvolves issues now, which go beyond traditional considerations such as economy and efficiency. Now nozzlechoice and performance also relates to broad issuesof drift such as airborne losses, downwind fallout anddeposits on non-target surfaces within the treated areaitself. All of these issues need to be carefully considered.HARDI is a world leader in understanding the conceptof spray accountability and it is this knowledge thatunderpins its world leadership in today's spraying.Today, HARDI has developed the world’s largest ISOnozzle programs for agriculture, horticulture [including most vegetables], viticulture as well as many morespecialist needs. This nozzle guide will help you selectthe best nozzle for your needs, consider environmentalaspects, and help you calibrateit for optimal use to ensure thatyou meet all of today’s needswhen using crop protectionproducts.HARDI INTERNATIONAL A/S Nørre Alslev3

Nozzle technologyFundamental research with nozzles by HARDI agro-scientistsis conducted in their own dedicated laboratories and thoseof independent research centers at many key institutionsthroughout the world. Sites where field research is conductedare very diverse - ranging from the temperate conditions ofNorthern Europe to the tropical crops of Australia.Instrumentation used in HARDI ’s laboratories is at the leading edge in droplet size analysis studies.It is this broad, but intensive, approach combined with stateof the art manufacturing techniques and computerized qualitycontrol programs, that guarantees HARDI nozzles will meetthe demands of better crop protection.Measuring droplet sizesThe droplet spectrum is characterized by the average dropletsize based on volume (VMD) and the range that indicates the uniformity of the atomization. Alaser Phase Doppler Particle Analyser (Aerometrics, PDPA) supplies this information instantaneously and is used to constantly monitor the spray quality of our nozzles in our laboratory.HARDI Flat fan nozzlesHARDI LD LowDrift nozzlesxx33F-02-110 50 PSI 13 GPA 5 MPHLD-02-110 50 PSI 13 GPA 5 MPHHARDI MINIDRIFT nozzlesHARDI INJET nozzlesxxMINIDRIFT-02-110 50 PSI 13 GPA 5 MPH334INJET-02-110 50 PSI 13 GPA 5 MPH

Nozzle technologyNozzle developmentChanges in cropping practices, regulatory restraints andthe introduction of new agrochemicals are just someof the forces that ensure new nozzle developments,which have and will continue to take place at HARDI .This activity closely involves our agronomists, engineersand specialist tool makers. Farmer's needs are recognized and metwith HARDI nozzles designedto provide theprecision theydemand today.Wind Tunnel StudiesQuality controlSamples of all HARDI nozzles are constantly monitoredby Quality Control - using devices such as this state ofthe art nozzle distribution table.Airborne drift and downwind fallout are tested anddocumented in the controlled conditions of a wind tunnelfor all HARDI nozzles. This leads to approvals as driftreducing equipment for buffer zones in many countries.Together with field research this has given the HARDI nozzle range approvals in the UK, Holland and Germanyto be used closer to waterways than previously allowedwith traditional nozzles.High Speed VideoModern high-speed video techniques are used to investigate the droplets behaviour on their way to the targetand when impacting on a leaf. These tests are done withclean water and with actives to simulate in-field spraying.High Quality MaterialsHARDI nozzles are produced from high qualitySYNTAL plastic that ensures both precision anddurability. Where highly abrasive compounds are tobe sprayed, the selection of HARDI CERAMIC nozzleswill maintain this same level of superior durability.Deposit testsFluorescent UV dye is used to test the exact amount ofliquid that stays on the leaf after spraying. This is the keyfactor for the biological efficacy of the plant protectionproducts.43210BrassStainless steelSYNTALDurability relative to brass flat spray nozzle at themanufacturer’s recommended pressure(Kim Sintorn, Swedish University).5Efficacy trialsSpecialist field equipment is used at the Danish WeedResearch Institute to test the efficacy of herbicide performance when using HARDI nozzles.5

F ie ldsp r a y i n gChoosing nozzles for arable cropsA nozzle for every spray jobChoosing nozzlesChoice of nozzle type and size may have to balance theneed to ensure optimal biological effect with a consideration for wind drift, sprayer capacity – that influencesfield work rates – as well as forward speed.The tables below can be used when choosing the rightnozzle for a spray job. Important precondition for thetables: Always follow label recommendation for spray quality and volume rate– if nothing is stated the tables can be used as a guideline. To minimize wind drift and maintain even liquid distribution, sprayingpressure between 20 to 70 PSI is recommended (INJET: 40 to 120PSI). Higher pressures with TWIN air assistance are also acceptable. Spraying against grass weeds or on other vertical targets – it isimportant to use a relative fine spray.1-415-255-830-379-1139-80LowDriftINJETDrift reduction / Spraying capacityThe reduced number of very small droplets producedby LowDrift nozzles makes them less sensitive to wind.Therefore they can be used on conventional sprayersunder sub-optimal conditions. In particular, they are usedwhen spraying lower water volumes. MINIDRIFT andINJET nozzles mix air with the spray liquid to coarsenthe atomization. Drift is substantially reduced with thesenozzles so that field delays – due to high wind speeds– are minimized and timing is improved. The biologicaladvantage gained through this better field timing maymask the use of coarser sprays. Their use has becomecritical to conventional spraying practice which has to tryand meet both environmental needs without risking theeffectiveness of the product to be applied.CoarseMediumFine200 micronsStandardVery Coarse400 micronsTWIN100 micronsBilological efficiencyGrowth stageFeekesDecimal (Zadox)Fine droplets improved coverageDrift/Biological efficiency index50 micronsSmall droplets from STANDARD Flat Fan nozzles mayoffer an unsurpassed liquid distribution and an effectivecoverage of the target surface. HARDI TWIN sprayers can safelyuse theseWater volumes10GPAsmall standard15nozzles evenGPA20-3015 GPAwhen weatherGPA20 GPAconditions are25 GPAnot optimal.25 GPA Small dicot weeds need good coverage either through fine dropletsor – if using a coarser spray – by compensating with a higher volumerate. For large dicot weeds – coarse atomization can be used. Fungicide treatments are often less sensitive to spray quality;medium drops can be recommended. Remember that the volumerate must be adjusted to crop density and needs for penetration tomore basal parts. Generally the water rate for conventional spraying should not beless than 15 GPA and for TWIN not less than 8.5 – 10.5 GPA foroptimum efficacy at lower doses. When mixing products or using products with more than one modeof action adjust to the most demanding component of that productmix.Spray quality and capacity for HARDI ISO 110 flat fan nozzlesPSIISO size/color620HARDI ISO F-110HARDI ISO LD-110HARDI ISO MINIDRIFTHARDI ISO INJETStandardflat fan nozzlesLowDriftnozzlesAir inclusionnozzlesAir inclusionnozzles3040506070GPMPSI2030ISO size/color40506070GPMPSIISO size/color203040506070GPMPSIISO size/color40607080100120GPM0075-Pink0.053 0.065 0.075 0.084 0.092 0.09901-Orange0.071 0.087 0.100 0.112 0.122 0.13201-Orange0.071 0.087 0.100 0.112 0.122 0.13201-Orange0.100 0.122 0.132 0.141 0.158 0.173015-Green0.106 0.130 0.150 0.168 0.184 0.198015-Green0.106 0.130 0.150 0.168 0.184 0.198015-Green0.106 0.130 0.150 0.168 0.184 0.198015-Green0.150 0.184 0.198 0.212 0.237 0.26002-Yellow0.141 0.173 0.200 0.224 0.245 0.26502-Yellow0.141 0.173 0.200 0.224 0.245 0.26502-Yellow0.141 0.173 0.200 0.224 0.245 0.26502-Yellow0.200 0.245 0.265 0.283 0.316 0.346025-Lilac0.177 0.217 0.250 0.280 0.306 0.331025-Lilac0.177 0.217 0.250 0.280 0.306 0.331025-Lilac0.177 0.217 0.250 0.280 0.306 0.331025-Lilac0.250 0.306 0.331 0.354 0.395 0.43303-Blue0.212 0.260 0.300 0.335 0.367 0.39703-Blue0.212 0.260 0.300 0.335 0.367 0.39703-Blue0.212 0.260 0.300 0.335 0.367 0.39703-Blue0.300 0.367 0.397 0.424 0.474 0.52004-Red0.283 0.346 0.400 0.447 0.490 0.52904-Red0.283 0.346 0.400 0.447 0.490 0.52904-Red0.283 0.346 0.400 0.447 0.490 0.52904-Red0.400 0.490 0.529 0.566 0.632 0.69305-Brown0.354 0.433 0.500 0.559 0.612 0.66105-Brown0.354 0.433 0.500 0.559 0.612 0.66105-Brown0.354 0.433 0.500 0.559 0.612 0.66105-Brown0.500 0.612 0.661 0.707 0.791 0.86606-Grey0.424 0.520 0.600 0.671 0.735 0.79406-Grey0.600 0.735 0.794 0.849 0.949 1.03908-White0.566 0.693 0.800 0.894 0.980 1.05808-White0.800 0.980 1.058 1.131 1.265 1.38610-Light blue0.707 0.866 1.000 1.118 1.225 1.323Spray quality:FineCoarseMediumVery coarse

Fi elds pra y i n gHARDI nozzles on all liquid systemsHARDI ISO nozzles fulfill ISO (International Standards Organization) standards regardingflow, numbers, colors and outer dimensions. This ensures that it is easy to fit HARDI ISO nozzles on all sprayer brands. You can see the fittings below, which allow you to adaptHARDI ISO nozzles to your sprayer.On sprayers with HARDI SNAP-FITsystems, the HARDI COLOR TIPS (CT) are recommended for safe andeasy handling. For INJET nozzlesuse the 334083 black nozzle cap.HARDI part 10423503 Nitril O-ringfor HARDI nozzles (Between Capand Nozzle Body ).On sprayers with TeeJet or compatible systems, use Single nozzles(S) and the 334862 black cap.The same cap is used for INJET nozzles. (gasket: 242222).On all other systems, use the ISO capdelivered with your sprayer togetherwith Single nozzles (S) or INJET s(INJET s require a special 0.4" cap).Conversion table for old HARDI 4110 and HARDI ISO nozzlesl/min1.4 GPM5.01.24.5361.0104.0Flows atpressure from20 to 70 PSI(1.5 to 5 bar)70PSI5.0bar103.5HARDI 4110-0.8HARDI 15020253.02.520PSI1.5bar2.01.51.00.50.0You can use these figuresto check the new HARDI ISO nozzles that mayreplace your old 4110nozzles.7

F ie ldsp r a y i n gCalibration offield crop sprayersPrecise and safe applications in the field demand that the sprayer is effectively calibrated. Calibration must always be done with clean water and before the use of anycrop protection product. Follow these three steps to calibrate your sprayer.2 Select volume rate, nozzle andpressure1 Check driving speedHalf fill the spray tank with water.For easy selection of nozzles and pressure, use theHARDI calibration disk (order no. 285721 - US or285802 - metric).ExamplePressureNozzle flowVolume rate 15 GPADriving speed 8 MPHNozzleISO F-04-110300 ftMark out 300 ft – note time to drive the distance.40 PSI0.40 GPMHARDI ISO oV.Cears ytCom u a liqd iuMe prayFFerseS06 0504502020035015100250814018 1624 20 125030psi 1520 30 50U100110paSg236121041US gpm3LDF inFF.05LDMDINJETMINJETLD8.164 If actual output is not equal to desired output:Readjust pressure.(alternatively: changenozzle or driving speed) If output has increasedmore than 10% fromtable value: change allnozzles.2FF53 Check nozzle output.550.7815.4402.5120 189 MPH.3.23031.5151025203.51.5Distance driven (ft) x 0.68Time (sec.)1012Driving speed formula95 4.5 46780075 -110If it takes 10 seconds to drive 300 ft then the spraying speedis 2.3 MPH.0010USpsi 15203015ISO50Nozzle flowIf your water volume rate and spraying speed are known then use this table to identify the flow rate that will berequired by the nozzle. The nozzle flow rate [GPM] selected from this table, can then be used together with thenozzle tables on the following pages, to identify a suitable 9431.1781.414

Fi elds pra y i n gCalibration offield crop sprayersWhen calibrating, it is the perfect time to check the distribution of spray across yourboom. Here you have clean water in the whole system and a great opportunity to inspectyour sprayer for any leaks, blockages, etc.Calibration formulasSpeed checkDistance (ft) 0.68Time (sec.)Nozzle outputNozzle spacing (in.) GPA x MPH5940 MPHApplication volume5940 x GPM (per nozzle)Nozzle spacing (in.) MPHPressure adjustment( GPA)New output (GPA) 2 Known pressure (PSI) New pressure (PSI)Known output (GPA)Cleaning of nozzlesAn even distribution across your boom is critical to theperformance of the product you are applying. Dirty and/or blocked nozzles are the most frequently reportedproblem affecting distribution. Cleaning nozzles is bestdone using water and a soft brush suchas a toothbrush. Never use tools likescrewdrivers or nails - they will certainlydamage the nozzle and its ability to evenlydistribute the sprayed liquid.A soft brush for nozzle cleaning is included as a part ofthe HARDI calibration set(81624503).When did you last check the outputfrom your nozzles?Liquid fertilizerLiquid fertilizers may be of a higher liquid density thanwater and almost all, normal spray solutions. The density correction table below states the increased pressure that will be needed to reach the required outputwith such liquids.ExampleThe nozzle has an output of 0.5 GPM at 40 PSI. If the densityof the liquid fertilizer is 10.65 lbs/gal you have to multiply thecalibration pressure – found when checking the nozzle flow withwater – with the density factor. This gives an adjusted pressureof 45 PSI. The value can be found in the table at 40 PSI (calibrated pressure) and a density of 10.65 lbs/gal.Density (lbs/gal)9.00Conversion factors 1.04 GPM (per nozzle)10.001.10PSI10.6511.001.131.15Adjusted 648505255575860606266686972HARDI recommends:1. Check water volume rates afterevery week.2. Change your nozzleswhen the water volumerate they should deliveris exceeded by 10% inorder to ensure accuracy of distribution anddrop size.Water sensitive paperAn important toolto check the sprayquality and deposition in the field. Buy itat your HARDI dealer.1" x 3"50 pcs. no: 8932119

F ie ldsp r a y e rHARDI ISO nozzlesHARDI ISO F-110 - standard Flat Fan nozzlesISO: Flow, color, coding and outer dimensionsWorking pressure: 20 to 70 PSIRecommended for TWIN sprayersSYNTAL – precision molded thermoplasticCERAMIC – extremely high durabilityCOLOR TIPS (CT) – (unibody tips and caps) for safeand easy handling0.0530.0650.0750.0840.0920.099371964 (12 pcs 94.22.02.42.83.13.43.7371764 (12 pcs. .03.74.24.75.25.62.63.23.74.24.54.9SYNTAL-CT 371765 (12 pcs. 755628)CERAMIC-CT 371772 (12 pcs. 755635)2030405060700.1060.1300.1500.1680.1840.198M 6.3F 7.7F 8.9F 10.0F 10.9F .26.87.4SYNTAL-CT 371766 (12 pcs 755629)CERAMIC-CT 371773 (12 pcs .3060.3318.4 7.0 6.010.3 8.6 7.311.9 9.9 8.513.3 11.1 9.514.5 12.1 10.415.7 13.1 11.25.36.47.48.39.19.8371950 (12 pcs .815.216.4GPA at 6371706 (12 pcs. TAL-S 371707 (12 pcs. 755646)CERAMIC-S 371738 (12 pcs. 2.42.83.13.43.71.82.12.52.83.03.3SYNTAL-S 371708 (12 pcs 755649)CERAMIC-S 371739 (12 pcs S7.5 6.6 5.89.2 8.0 7.110.6 9.3 8.311.9 10.4 9.213.0 11.4 10.114.0 12.3 3.33.74.04.4371946 (12 pcs 750628)4.85.86.87.58.38.9 Spray quality: Very Fine (VF), Fine (F), Medium (M),Coarse (C), Very Coarse CT 371769 (12 pcs. 755632)CERAMIC-CT 371776 (12 pcs. 6SYNTAL-CT 371770 (12 pcs 755633)CERAMIC-CT 371777 (12 pcs 27.329.5371771 (12 pcs 439.3371970 (12 pcs. 9.555.360.665.530.036.742.447.452.056.1GPA at MPH910111226.332.237.141.545.549.1141618SYNTAL-S 371709 (12 pcs 755652)CERAMIC-S 371740 (12 pcs 755673)7.9 7.0 6.3 5.79.6 8.6 7.7 7.011.1 9.9 8.9 8.112.5 11.1 10.0 9.113.6 12.1 10.9 9.914.7 13.1 11.8 10.7SYNTAL-CT 371768 (12 pcs. 755631)CERAMIC-CT 371775 (12 pcs. 755638)371963 (12 pcs CT606-Grey55SYNTAL-CT 371767 (12 pcs 755630)CERAMIC-CT 371774 (12 pcs 755637)08-WhitePSI GPMPSI GPM10-Light blue 14 - 28"Traditional flat fan nozzle. Recommended for all types of pesticide application whereoptimum coverage is demanded. This nozzle will giveyou excellent and uniform liquid distribution at boom20"heights from 14" to 28" (20" recommended to takecare of uneven terrain or boom movements).HARDI part 10423503 Nitril O-ring for HARDI nozzles (Between Cap and Nozzle Body .87.43.54.35.05.56.16.5SYNTAL-S 371710 (12 pcs. 755655)CERAMIC-S 371741 (12 pcs. 5.77.6 7.0 6.09.4 8.6 7.310.8 9.9 8.512.1 11.1 9.513.2 12.1 10.414.3 13.1 11.25.36.47.48.39.19.84.75.76.67.48.18.7SYNTAL-S 371711 (12 pcs. 755658)CERAMIC-S 371742 (12 pcs. 47.5 6.6 5.89.2 8.0 7.110.6 9.3 8.311.9 10.4 9.213.0 11.4 10.114.0 12.3 10.9SYNTAL-S 371712 (12 pcs 755661)CERAMIC-S 371743 (12 pcs .616.87.9 7.09.6 8.611.1 9.912.5 11.113.6 12.114.7 13.1371713 (12 pcs 16.217.5371966 (12 pcs. 4.6The nozzles are available both as single nozzles (S) and as COLOR TIPS (CT),where the nozzle is integrated in the SNAP-FIT cap.11.714.316.518.420.221.8

Fi elds pra y i n gHARDI ISO nozzlesHARDI ISO LD-110 - Low Drift nozzlesLow Drift nozzles are recommended when optimum spraying conditions cannot beachieved (risk of drift) and spraying cannot be postponed. This nozzle will give you excellent and uniform liquiddistribution at boom heights from 14" to 28"(20" recommended to take care of uneven terrain orboom movements).ISO: Flow, color, coding and outer dimensionsWorking pressure: 20 to 70 PSIRestrictor designed for minimum chemical residuesSYNTAL – precision molded thermoplasticCERAMIC – extremely high durabilityCOLOR TIPS (CT) – (unibody tips and caps) for safeand easy handling12HARDI part 10423503 Nitril O-ring for HARDI nozzles(Between Cap and Nozzle Body )3To ensure that the boom distribution is not disturbed by interference, the nozzles are set at an angle of 8 to the boom. Thisfeature is built into all HARDI COLOR TIP and SNAP-FIT caps.This angle has to be set manually if single nozzles are used.20"Turn-&-Clean with the HARDI key – easily removable 74.24.75.25.62.63.23.74.24.54.9SYNTAL-CT 371838 (12 pcs 755709)CERAMIC-CT 371843 (12 pcs 755714)2030405060700.1060.1300.1500.1680.1840.198M 6.3M 7.7M 8.9M 10.0M 10.9M .26.87.4SYNTAL-CT 371839 (12 pcs 755710)CERAMIC-CT 371844 (12 pcs MMMMM2030405060700.1770.2170.2500.2800.3060.3318.4 7.0 6.010.3 8.6 7.311.9 9.9 8.513.3 11.1 9.514.5 12.1 10.415.7 13.1 11.25.36.47.48.39.19.8371958 (12 pcs .815.216.4GPA at MPH9101112141618SYNTAL-S 371817 (12 pcs 755698)CERAMIC-S 371822 (12 pcs 1.61.92.12.32.51.21.41.71.82.02.2PSI TAL-S7.5 6.6 5.89.2 8.0 7.110.6 9.3 8.311.9 10.4 9.213.0 11.4 10.114.0 12.3 3.33.74.04.4 Spray quality: Very Fine (VF), Fine (F), Medium (M),Coarse (C), Very Coarse .827.730.332.715.018.421.223.726.028.1GPA at .724.612141618SYNTAL-S 371820 (12 pcs. 755701)CERAMIC-S 371825 (12 pcs. 755706)7.9 7.0 6.3 5.79.6 8.6 7.7 7.011.1 9.9 8.9 8.112.5 11.1 10.0 9.113.6 12.1 10.9 9.914.7 13.1 11.8 10.7SYNTAL-CT 371894 (12 pcs. 755815)CERAMIC-CT 371897 (12 pcs. 755816)371957 (12 pcs 750632)4.85.86.87.58.38.96SYNTAL-CT 371841 (12 pcs. 755712)CERAMIC-CT 371846 (12 pcs. 755717)SYNTAL-S 371819 (12 pcs 755700)CERAMIC-S 371824 (12 pcs 755705)4.75.76.67.48.18.75SYNTAL-CT 371840 (12 pcs. 755711)CERAMIC-CT 371845 (12 pcs. 755716)SYNTAL-S 371818 (12 pcs 755699)CERAMIC-S 371823 (12 pcs 755704)03-Blue804-Red7SYNTAL-CT 371837 (12 pcs 755708)CERAMIC-CT 371842 (12 pcs en02-Yellow514 - 28"PSI 26.87.43.54.35.05.56.16.5SYNTAL-S 371821 (12 pcs. 755702)CERAMIC-S 371826 (12 pcs. 5.77.6 7.0 6.09.4 8.6 7.310.8 9.9 8.512.1 11.1 9.513.2 12.1 10.414.3 13.1 11.25.36.47.48.39.19.84.75.76.67.48.18.7SYNTAL-S 371893 (12 pcs. 755817)CERAMIC-S 371896 (12 pcs. 47.5 6.6 5.89.2 8.0 7.110.6 9.3 8.311.9 10.4 9.213.0 11.4 10.114.0 12.3 10.9The nozzles are available both as single nozzles (S) and as COLOR TIPS (CT),where the nozzle is integrated in the SNAP-FIT cap.11

F ie ldsp r a y i n gHARDI ISO MINIDRIFTHARDI ISO MINIDRIFT air inclusion nozzlesThe HARDI MINIDRIFT nozzle can be used for spraying at sub-optimal weatherconditions, when spraying cannot be postponed. The MINIDRIFT nozzle will, atlow pressures, reduce drift to a minimum. HARDI part 10423503 Nitril O-ringfor HARDI nozzles (Between Cap and Nozzle Body ).Spray liquid Air inclusion nozzleWorking pressure: 20 to 70 PSIISO flow, colors, sizes and nomenclatureApplication rates from 6 to 40 GPA (at 5 mph)SYNTAL – precision moulded thermoplasticTwo big air inlets reducethe risk of clogging.AirCompact design reducesimpact damage.This nozzle will give you excellent and uniform liquiddistribution at boom heights from 16" to 35".Meets full ISO specifications.The drop

06-Grey 0.424 0.520 0.600 0.671 0.735 0.794 08-White 0.566 0.693 0.800 0.894 0.980 1.058 10-Light blue 0.707 0.866 1.000 1.118 1.225 1.323 PSI 20 30 40 50 60 70 ISO size/color GPM PSI 20 30 40 50 60 70 ISO size/color GPM PSI 20 30 40 50 60 70 ISO size/color GPM PSI 40 60 70 80 100 120 ISO size/color GPM