Transcription

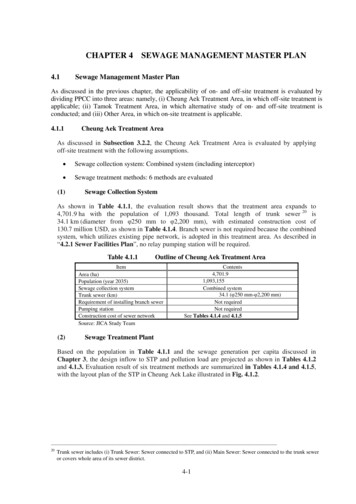

CHAPTER 44.1SEWAGE MANAGEMENT MASTER PLANSewage Management Master PlanAs discussed in the previous chapter, the applicability of on- and off-site treatment is evaluated bydividing PPCC into three areas: namely, (i) Cheung Aek Treatment Area, in which off-site treatment isapplicable; (ii) Tamok Treatment Area, in which alternative study of on- and off-site treatment isconducted; and (iii) Other Area, in which on-site treatment is applicable.4.1.1Cheung Aek Treatment AreaAs discussed in Subsection 3.2.2, the Cheung Aek Treatment Area is evaluated by applyingoff-site treatment with the following assumptions. Sewage collection system: Combined system (including interceptor) Sewage treatment methods: 6 methods are evaluated(1)Sewage Collection SystemAs shown in Table 4.1.1, the evaluation result shows that the treatment area expands to4,701.9 ha with the population of 1,093 thousand. Total length of trunk sewer 20 is34.1 km (diameter from φ250 mm to φ2,200 mm), with estimated construction cost of130.7 million USD, as shown in Table 4.1.4. Branch sewer is not required because the combinedsystem, which utilizes existing pipe network, is adopted in this treatment area. As described in“4.2.1 Sewer Facilities Plan”, no relay pumping station will be required.Table 4.1.1Outline of Cheung Aek Treatment AreaItemArea (ha)Population (year 2035)Sewage collection systemTrunk sewer (km)Requirement of installing branch sewerPumping stationConstruction cost of sewer networkSource: JICA Study Team(2)Contents4,701.91,093,155Combined system34.1 (φ250 mm-φ2,200 mm)Not requiredNot requiredSee Tables 4.1.4 and 4.1.5Sewage Treatment PlantBased on the population in Table 4.1.1 and the sewage generation per capita discussed inChapter 3, the design inflow to STP and pollution load are projected as shown in Tables 4.1.2and 4.1.3. Evaluation result of six treatment methods are summarized in Tables 4.1.4 and 4.1.5,with the layout plan of the STP in Cheung Aek Lake illustrated in Fig. ��――――――――――20Trunk sewer includes (i) Trunk Sewer: Sewer connected to STP, and (ii) Main Sewer: Sewer connected to the trunk seweror covers whole area of its sewer district.4-1

Table 4.1.2Design Inflow to Cheung Aek STPItemsSewageGround waterTotalDesign inflow(m3/day)(m3/day)(m3/day)(m3/day)Daily average224,09735,264259,361260,000Daily maximum245,96035,264281,224282,000Hourly maximum371,67335,264406,937407,000Note: (Groundwater estimate 1) 4,701.9 ha 7.5 m3/day/ha 35,264 m3/day .(1)(Groundwater estimate 2) Population (160 95)L/capita/day 0.85 15% 35,541 m3/day.(2)The results show that (1) (2). Therefore, (Groundwater estimate 1) is adopted.Source: JICA Study TeamTable 4.1.3ItemsDaily averageinflow(m3/day)Design Water Quality of Cheung Aek STPConcentrationcalculated(mg/L)Design waterquality(mg/L)RemarksTotal BOD load:49,935 kg/dayOf whichBOD260,000192195 domestic and commercial:49,192 kg/dayIndustrial:743 kg/dayTSS260,000202205 BOD 1.05Note: (Domestic and commercial BOD load) (Population) 45 g/capita/day 10-3(Industrial BOD load) (Population) 8.5 L/capita/day (amount of water use) 80 mg/L 10-6Source: JICA Study TeamStudy results on STP are defined briefly below. Land requirement: Land requirements of PTF and SBR are almost the same and smallestamong the six methods (PTF:13.0 ha, SBR:13.4 ha). Maximum is Lagoon with 262.4 ha.OD is second-ranked with the area of 43.1 ha. Construction cost: OD has the highest (397.9 million USD), followed by TF. Lowest oneis 214.2 million USD of Lagoon. O&M cost: Lagoon’s cost is the lowest (about 1.9 million USD/year) and OD’s is highest(about 18.0 million USD/year). EIRR: EIRRs in Tables 4.1.4 and 4.1.5 are estimated as reference, in consideration of lossof social value with the reclamation of Cheung Aek Lake, which is surrounded by largedevelopment and housing areas. The tables show that the EIRR of Lagoon is smallestbecause its reclamation area amounts to more than 10 times of those of the other methods. Environmental and social aspects: If applying Lagoon, large-scale resettlement (about100 households) will be required and almost all Cheung Aek Lake will be reclaimed, asshown in Fig. 4.1.1, in which land requirements of the lagoon and typical mechanicalmethod of CASP are depicted for comparison. In addition, control of offensive odour isdifficult. As a result, Lagoon will much affect the surrounding environment.4-2

Source: JICA Study TeamFig. 4.1.1Comparison of Land Requirement of Lagoon and CASPIn addition to the above discussion, result of quantitative evaluation, focusing on constructioncost, O&M cost, easiness of O&M, number of application in large-scale STP and environmentaland social aspects due to reclamation and offensive odour, are summarized in the tables. Based onthe evaluation, Lagoon is the best option in terms of low construction and O&M cost, as well aseasiness of O&M. On the other hand, Lagoon has such disadvantages as (i) social impact due tolarge-scale resettlement and reclamation is quite large, (ii) the reclaimed land will no longer beused for protected or cultivation area for aquatic plants and (iii) it has a lot of negativeenvironmental impacts such as uncontrolled offensive odour. In consideration of thedisadvantages of Lagoon, the application of CASP is recommendable and PTF will also be a goodoption, although the method has so far not applied to large-scale STP.4-3

Table 4.1.4ItemsComparison of Wastewater Treatment Method applied to Cheung Aek STP(1/2)LagoonLand requirement (ha)Construction cost (million USD)STP in totalCivil (reclamation)Civil ludge dumping siteTotalO&M cost (million USD/year)STP in totalCivil (reclamation)Civil ludge dumping siteTotalEIRRNumber of resettlementsanticipatedPros and consEvaluation1)Construction costO&M costEasiness of O&MNumber ofapplications inlarge-scale STP2)Number ofTrickling ated .17410.1849.4%12.1% About 100 households No resettlement No resettlement Large-scale resettlement isrequired and adverse socialimpact due to large-scalereclamation is anticipated. Construction and O&Mcosts are lowest. O&M is easy but control ofoffensive odour bycovering is difficult due tothe reason that the systemhas to introduce sunshineinto the lagoons forprovision of oxidizationand disinfection. This method has strength incoping with fluctuation ofwater quality but periodicalremoval of sludge isrequired so as not to reducecapacity. Land requirement is 2ndlargest, which is twice aslarge as that of PTF. 3rd lowest of O&M costdue to low energyconsumption. Control of offensive odorand outbreak of filter bedflies are difficult. Application to large-scaleSTP is small in number. Land requirement is theminimum among 6treatment methods. 2nd lowest of O&M costdue to low energyconsumption. Periodical mixing of mediakeeps filter bed clean andthus prevent from out-breakof filter flies. This method has strengthin coping with first flushand hence this method isapplicable to combinedsystem. At present, there is noapplication to large-scaleSTP. Only in operation in:1. Demo plant in Da Nang,300 m3/day2. Under construction plantin Hoi An,2,000 m3/day3. Demo plant in Japan,6,750 m3/day 4-4

ItemsLagoonTrickling Filter(TF)Pre-treated TricklingFiltration(PTF)resettlementsEnvironmental and social aspectsTotal 19 20Note1: Scores in “Evaluation” are on a five-level descending system of “ ” to “ ”.Note2: Large-scale STP in the table is defined as the STP with capacity of more than 100,000 m3/day.Source: JICA Study TeamTable 4.1.5ItemsOxidation Ditch (OD)Sludge dumping siteTotalO&M cost (million USD/year)STP in totalCivil (reclamation)Civil ludge dumping siteEIRRNumber of resettlementsanticipatedPros and consEvaluation1)Construction costO&M costEasiness of O&MNumber ofapplications inlarge-scale STP2) 23Comparison of Wastewater Treatment Method applied to Cheung Aek STP(2/2)Land requirement (ha)Construction cost (million USD)STP in totalCivil (reclamation)Civil otal 43.1Conventional Activated SludgeProcess al Batch 10.5%11.7% No resettlement No resettlement No resettlement O&M is easy because ofits simplified structure.On the other hand, landrequirement of ODreaches 2.5 times ofCASP's. In general, this method isapplicable to STP withcapacity of less than10 thousand m3/day. Application of thismethod to large-scaleplant tends to berelatively high in cost. Construction cost is higherbut O&M is lower than thoseof SBR. In addition, O&M iseasier compared to SBR. Large in number ofapplication to large-scaleplants and operation methodsare well-established. Construction cost is lowerthan that of CASP.O&M cost is higher than thatof CASP. Skilled techniques includingformulation of appropriatesequence are required,because this method treatwastewater in one reactor.This method is as a wholeapplicable to a site in whichavailable land is limited. 4-5

ItemsOxidation Ditch (OD)Conventional Activated SludgeProcess (CASP) Sequential Batch Reactor(SBR) Number of resettlementsEnvironmental and social aspectsTotal 18 23Note1: Scores in “Evaluation” are on a five-level descending system of “ ” to “ ”.Note2: Large-scale STP in the table is defined as the STP with capacity of more than 100,000 m3/day.Source: JICA Study Team4-6 21

4-7Source: JICA Study TeamFig. 4.1.2Layout Plan of Cheung Aek STP

(3)Financial AnalysisFinancial analysis is performed based on the result described above, targeting CASP and PTF,which are first-ranked in the quantitative evaluation, as well as Lagoon which has strength interms of low-cost.The financial analysis figures out: (i) sewerage fee and (ii) charge on vacuum truck dumpingon-site facilities’ sludge to the proposed sludge dumping site as detailed in Subsection 4.3.2, inorder to cover O&M cost only or to cover both O&M and construction cost. The analysis result issummarized in Table 4.1.6 and the transition of estimated total charge (expressed in percent) ispresented in Fig. 4.1.3.As shown in Table 4.1.6, for example, current sewerage fee of 10% to water tariff can coverO&M cost of Lagoon system. In contrast, sewerage fee of 10% up to year 2025 will be requiredto cover O&M cost of the CASP system, and then 20% from year 2026 to 2039 and 55% from2040, are required.Table 4.1.6Summary of Financial Analysis for Cheung Aek Treatment AreaCaseCheung Aek Treatment Areais serviced applying LagoonCheung Aek Treatment Areais serviced applying PTFCheung Aek Treatment Areais serviced applying CASPTargetO&M costonlyO&M costonlyO&M costonlySource of revenueSewerage fee(ratio to watercharge)O&M andconstructioncostO&M andconstructioncostO&M andconstructioncost10%10%10%10%10%10%(entire period)(up to year2025) (up to year2030) (up to year2025) (up to year2025) (up to year2025) (from year2026)(up to year2039) (from year2026)(up to year2039) (from year2026)20%15%50%35%20%60%55%(from year2040)(from year2040)(Adding topresent sewerageand drainagecharge of 10%)(-)(-)(up to year2025) 10%(from year2026)(-)(up to year2030) 5%(up to year2039) 25%(from year2040)(-)(up to year2025) 40%(from year2026)(-)(up to year2025) 10%(up to year2039) 45%(from year2040)(-)(up to year2025) 50%(from year2026)Charge onvacuum truckdumping sludgeto the sludgedumping site(USD/truck)555555Source: JICA Study Team4-8

Cheung Aek Treatment AreaCheung Aek Treatment Area(Covering O&M and Initial Cost)(Covering O&M cost)70%60%LagoonLagoonPTFCASP50%PTFCASP60%% of Water Supply Charge30%40%30%20%20%10% ofWaterSupplyCharge10%10% 203220332034203520362037203820392040% of Water Supply Charge50%40%YearYearSource: JICA Study TeamFig. 4.1.3(4)Transition of Sewerage Fee to cover Cost of Cheung Aek Treatment AreaConclusionBased on the above discussion, the Lagoon system is not preferable in consideration of social andenvironmental negative impacts due to extensive land reclamation. Rather, a typical mechanicaltreatment system of CASP or PTF, which is a new Japanese treatment system being advantageousto O&M cost reduction and minimization of land acquisition, are recommendable. However,when applying the PTF, careful attention should be paid on the risks of the method because themethod is not yet applied to large-scale STPs. Additionally, more attention should be paid toPPCC’s strategies and priorities for sustainable sewage management when selecting andfinalizing wastewater treatment method. Therefore, the selection of wastewater treatment methodis finalized through the discussion in T/C and S/C meetings.In response, CASP was selected for M/P and Pre-F/S for Cheung Aek STP in the discussions ofT/C and S/C with PPCC, held in September 2016, because it is too early to apply PTF due to thefact that the method is not yet applied to large-scale STPs.4-9

4.1.2Tamok Treatment AreaAlternative study on (i) Alternative-1, off-site and (ii) Alternative-2, on-site, are carried out,targeting the area in Tamok basin having the population density of more than 50 persons/ha in theyear 2035, as schematically illustrated in Fig. 4.1.421.Source: JICA Study TeamFig. 4.1.4(1)Alternative Study on Tamok Treatment AreaStudy Result of Off-Site Treatment (Alternative 1)As discussed in Subsection 3.2.2, study on off-site treatment is conducted with the followingassumptions. Sewage collection system: Separate system Sewage treatment methods: 6 methods are evaluated(a) Sewage Collection SystemAs shown in Table 4.1.7, the evaluation result shows that treatment area amounts to 6,019.2 hawith population of 481 thousand. Total length of trunk sewer is 66.1 km (diameter fromφ200 mm to φ1,650 mm). Pumping station should be installed at nine locations, of which sevenpumping stations are manhole type. Construction cost of sewer system is estimated at 397.7million USD, higher than that of Cheung Aek Area, as shown in Tables 4.1.10 and 4.1.11,because branch sewers are required in entire Tamok Treatment Area, unlike the Cheung AekTreatment �――――――――――21Thus, area in Tamok basin with population density of less than 50 persons/ha is integrated into “Other Area”4-10

Table 4.1.7Outline of Tamok Treatment AreaItemsArea (ha)Population (year 2035)Sewage collection systemTrunk sewer (km)Requirement of installing branch sewerPumping stationContents6,019.2481,423Separate system66.1 (φ200 mm-φ1,650 mm)RequiredLarge-scale 2 locationsManhole type 7 locationsSee Tables 4.1.10 and 4.1.11Construction cost of sewer networkSource: JICA Study Team(b) Sewage Treatment PlantBased on the population in Tables 4.1.7 and sewage generation per capita discussed inChapter 3, design inflow to STP and pollution load are projected as shown in Tables 4.1.8 and4.1.9. In addition, evaluation results of six treatment methods are summarized in Tables 4.1.10and 4.1.11, and the layout plan of STP in Tamok Lake is illustrated in Fig. 4.1.5.Table 4.1.8Design Inflow to Tamok STPGround waterTotalDesign inflowSewage(m3/day)(m3/day)(m3/day)(m3/day)Daily average98,69215,652114,344115,000Daily maximum108,32015,652123,972124,000Hourly maximum163,68415,652179,336180,000Note: (Groundwater estimate 1) 6,019.2 ha 7.5 m3/day/ha 45,144 m3/day .(1)(Groundwater estimate 2) Population (160 95)L/capita/day 0.85 15% 15,562 m3/day.(2)The results show that (2) (1). Therefore, (Groundwater estimate 2) is adopted.Source: JICA Study TeamItemsTable 4.1.9ItemsDaily averageinflow(m3/day)Design Water Quality of Cheung Aek STPConcentrationcalculated(mg/L)Design waterquality(mg/L)RemarksTotal BOD load:21,991 kg/dayof whichBOD115,000191195 domestic and commercial:21,664 kg/dayIndustrial:327 kg/dayTSS115,000201205 BOD 1.05Note: (Domestic and commercial BOD load) (Population) 45 g/capita/day 10-3(Industrial BOD load) (Population) 8.5 L/capita/day (amount of water use) 80 mg/L 10-6Source: JICA Study TeamEvaluation results show that Lagoon is the best option in terms of lowest construction and O&Mcost. Unlike Cheung Aek Lake, Lagoon requires largest land requirement but negativeenvironmental impact to Tamok Lake is limited because the lake has a considerably largesurface area. In addition, resettlement will not be required.Based on the quantitative evaluation in terms of construction cost, O&M cost, easiness of O&M,number of application in large-scale STP and environmental and social aspects, Lagoon, PTFand CASP are given the highest scores in the evaluation.4-11

Table 4.1.10Comparison of Wastewater Treatment Method applied to Tamok STP (1/2)ItemsLagoonLand requirement (ha)Construction cost (million USD)STP in totalCivil (reclamation)Civil )Pumping stationSludge disposal site2)TotalO&M cost (million USD/year)STP in totalCivil (reclamation)Civil umping stationSludge disposal site1)TotalEIRRNumber of resettlementsanticipatedPros and consEvaluation3)Construction costO&M costEasiness of O&MNumber ofapplications inlarge-scale STP4)Number ofresettlementsEnvironmental and115.0Trickling 01.318.356.815.965.245.1397.71.7600.7Pre-treated Trickling 70.1781.7370.3810.2261.4920.0756.1164.3%3.2%3.5% No resettlement No resettlement No resettlement Large-scale resettlement isnot required and socialimpact due to large-scalereclamation is limited,compared to Cheung AekLake. Construction and O&Mcosts are lowest. O&M is easy but control ofoffensive odour by coveringis difficult due to the reasonthat the system has tointroduce sunshine into thelagoons for provision ofoxidation and disinfection. This method has strength incoping with fluctuation ofwater quality but periodicalremoval of sludge isrequired so as not to reducecapacity. Land requirement is 2ndlargest, which is twice aslarge as that of PTF. 3rd lowest of O&M cost dueto low energy consumption. Control of offensive odourand outbreak of filter bedflies is difficult. Adoption in large-scale STPis small in number. Land requirement is lessthan half of TF's. 2nd lowest of O&M cost dueto low energy consumption. Periodical mixing of mediakeeps filter bed clean andthus prevent from out-breakof filter flies. This method has strength incoping with first flush, andhence applicable tocombined system. At present, there is noapplication to large-scaleSTP. Only in operation in1. Demo plant in Da Nang,300 m3/day2. Under construction plantin Hoi An,2,000 m3/day3. Demo plant in Japan,6,750 m3/day 4-12

ItemsLagoonTrickling Filter(TF)Pre-treated Trickling Filtration(PTF)social aspectsTotal 23 20Note 1: Construction cost includes cost of branch sewer installation.Note 2: Construction and O&M cost is included in sludge dumping site in Table 4.1.4 and Table 4.1.5.Note 3: Scores in “Evaluation” are on a five-level descending system of “ ” to “ ”.Note 4: Large-scale STP in the table is defined as the STP with capacity of more than 100,000 m3/day.Source: JICA Study TeamTable 4.1.11ItemsComparison of Wastewater Treatment Method applied to Tamok STP (2/2)Oxidation Ditch (OD)Land requirement (ha)Construction cost (million USD)STP in totalCivil (reclamation)Civil )Pumping stationSludge disposal site2)TotalO&M cost (million USD/year)STP in totalCivil (reclamation)Civil umping stationSludge disposal site1)TotalEIRRNumber of resettlementanticipatedPros and consEvaluation3)Construction costO&M costEasiness of O&MNumber ofapplications in 2324.1Conventional Activated SludgeProcess 8.812.545.219.874.646.7397.71.7598.2Sequential Batch 480.2301.8160.3240.2451.4920.0759.0303.8%2.8%3.1% No resettlement No resettlement No resettlement O&M is easy because of itssimplified structure. On theother hand, land requirementof OD reaches 2.5 times ofCASP's. In general, this method isapplicable to STP withcapacity of less than10 thousand m3/day. Application of this methodto large-scale plant tends tobe relatively high in cost. Construction cost is higherbut O&M is lower than thatof SBR. In addition, O&M iseasier compared to SBR Large in number ofapplication to large-scaleplants and operationmethods arewell-established. Construction cost is lowerthan that of CASP. O&M cost is higher thanthat of CASP. Skilled techniques includingformulation of appropriatesequence are requiredbecause this method treatwastewater in one reactor.This method is as wholeapplicable to the site inwhich available land islimited. 4-13

ItemsOxidation Ditch (OD)Conventional Activated SludgeProcess (CASP)Sequential Batch Reactor(SBR)large-scale STP4)Number of resettlementsEnvironmental and social aspectsTotal 18 23Note 1: Construction cost includes cost of branch sewer installation.Note 2: Construction and O&M cost is included in sludge dumping site in Table 4.1.4 and Table 4.1.5.Note 3: Scores in “Evaluation” are on a five-level descending system of “ ” to “ ”.Note 4: Large-scale STP in the table is defined as the STP with capacity of more than 100,000 m3/day.Source: JICA Study Team4-14 21

4-15Source: JICA Study TeamFig. 4.1.5Layout Plan of Tamok STP

(2)Study Result of On-Site Treatment (Alternative 2)As shown in Table 2.4.2, more than 90% of households in Phnom Penh have the pit latrine orseptic tank. Most probably, therefore, roughly 90% households in Tamok treatment area havethe pit latrine or septic tank.In order to select the appropriate on-site treatment method for Tamok treatment area, on-sitetreatment methods of pit latrine, septic tank, Johkasou and community plant are evaluated asshown in Table 4.1.12. As the result, Johkasou is selected as the appropriate on-site treatmentmethod in Tamok treatment area with the following reasons. In this evaluation, domestic andcommercial wastewater is treated by the facilities but industrial wastewater is treated by eachowner of factory to the level of BOD of 80 mg/L. On-site treatment facilities, which exceed the capacity of septic tank, is appropriate inconsideration of the present deterioration of water environment in Tamok basin under thecondition that most of the households install septic tank or pit latrine, and estimatedincrease in population as well as pollution load generated Johkasou and community plant are candidates for the facilities exceeding the septic tank,but in particular Johkasou has advantages over community plant that (i) it can be fabricatedin factory and be easily installed on the site; (ii) it has in principle functionality equivalentto community plant; and (iii) it has a wide range of line-up covering community based size.4-16

Table 4.1.12MethodPit latrineSeptic tankComparison of On-Site Treatment Methods applicable to Tamok TreatmentAreaSalient features This method is equipped with a pit andcover plate. Structure is very simple but it cannotcontrol offensive odour and outbreak offlies because it only deposit faeces andurine. Electricity is not required. This method consists of flush toilet andunderground tank in which faeces andurine are partially decomposed byanaerobic digestion. This method is widely used in PhnomPenh. Electricity is not required.Evaluation This method is very simple and it can be easilyinstalled with low-cost. However, more advancedmethod of septic tank are widely installed in PhnomPenn and thus this method is no longer applicablefor newly installed facilities in Phnom Penh.Evaluation : This method is widely used in Phnom Penh.Nevertheless water environment in Phnom Penh isdeteriorating. It is therefore recommendable tointroduce facilities exceeding septic tankEvaluation : This device is applicable as alternative of septictank because (i) the device has advantages ineasiness of installation compared with communityplant, (ii) phased installation is easy and (iii) it haswide variety of line-up ranging from a householdsize to community based size equivalent to severalhundred to a thousand people. Recently, community-based Johkasou has beendeveloped and it becomes alternative of communityplant due to the reason of easiness of installation atlower cost. Further cost reduction is expected if this device iswidely installed in PPCC in the future.Evaluation : Community This is a system consisting of sewer The system treats wastewater at the same level ofplantnetwork in the community and small-scalemechanical off-site treatment system but on theSTP.other hand the system is not simple and costly Electricity is required and removal rate ofcompared to Johkasou because it requires samethe system is the same as that ofconfiguration of off-site treatment system.mechanical off-site treatment system.Evaluation : Scores in “Evaluation” are on a three-level descending system of “ ” :good; “ ”:fair; and “ ” :not good.Source: JICA Study TeamJohkasou This is an on-site treatment facility devicedeveloped in Japan. This device has widerange of line-up, covering a householdsize to community-based size withcapacity for several hundred to severalthousand. This devise is in principle fabricated infactory and easily installed on site. Electricity is required, but, the electricconsumption of household size is forexample several dozen Wh. Removal rate of the device is same as thatof mechanical off-site treatment system.Evaluation results applying Johkasou are described briefly as below. Construction and O&M cost: Construction and O&M cost is estimated at 396 million USDand 15.8 million USD/year. This construction cost is more than 100 million USD lowerthan that of Lagoon, which is lowest in construction cost (509 million USD) of off-sitetreatment system. This result arises from the reason that Tamok basin needs branch sewerinstallation, unlike Cheung Aek treatment area. On the other hand, O&M cost (14.3 millionUSD/year) is 1.9 times of CASP’s (8.3 million USD/year). However, total cost includingconstruction cost and O&M is lower than that of CASP. Others: Johkasou have advantages that phased construction and commission is easybecause it is generally installed individually. Moreover, unlike off-site treatment system,reclamation of Tamok Lake is not required and EIRR is higher than those of the other sixoff-site treatment methods.Table 4.1.13Outline of On-Site Treatment System applied to Tamok Treatment AreaItemTitle of facilitiesTarget populationQuantities of facilities1)ContentsOn-site treatment (Johkasou481,423Small scale (for 5 persons):48,085 unitsCommunity-based scale (for 300 persons):805 units4-17

ItemConstruction cost (million USD)Total O&M cost (million USD/year)ElectricityInspectionDesludge and disposal of sludgeSpare parts and IRRPros and cons Construction cost is lower than any other off-sitetreatment method (6 methods). O&M cost is higher than that of typical off-site treatmentmethod of CASP. Phased construction is easy because Johkasou can becommissioned individually. Reclamation of Tamok Lake is not required.Evaluation2)Construction cost O&M cost Easiness of O&M Number of application Number of resettlement Environmental and social aspectTotal 23Note 1: Number of Johkasou is computed under assumption that 50% of population usessmall-scale Johkasou, while others use community-based Johkasou.Note 2: Scores in “Evaluation” are on a five-level descending system of “ ” to “ ”, as with inTables 4.1.10 and 4.1.11.Source: JICA Study TeamBased on the discussion in Tables 4.1.10 and 4.1.11, which summarise the quantitative evaluationof six off-site treatment methods, as well as Table 4.1.13, which outlines quantitative evaluationof on-site treatment, off-site treatment applying Lagoon, CASP and PTF or on-site treatmentapplying Johkasou are preferable as a whole.(3)Financial AnalysisBased on the discussion above, financial evaluation is performed focusing on the off-sitetreatment by Lagoon, CASP and PTF, as well as the on-site treatment by Johkasou, because thefour methods obtained the same score. It is noted that the financial analysis is performed tocompute sewerage fee and sludge dumping fee posed to vacuum truck, in order to cover cost ofTamok as well as Cheung Aek Treatment areas, since Cheung Aek Treatment Area is covered bysewerage fee, regardless of selection of treatment method in Tamok Treatment Area. There is acase that investment cost as well as O&M cost in Tamok area is borne only by users in Tamokarea but this case is not studied because the financial burden to Tamok Area is

Source: JICA Study Team Table 4.1.5 Comparison of Wastewater Treatment Method applied to Cheung Aek STP (2/2) Items Oxidation Ditch (OD) Conventional Activated Sludge Process (CASP) Sequential Batch Reactor (SBR) Land requirement (ha) 43.1 16.3 13.4 Construction cost (million USD) STP in total 397.9 302.9 260.9