Transcription

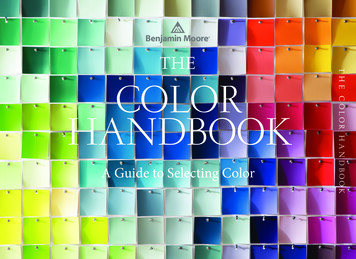

Boat Paint Guide& Color CardUS Edition

Topsides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .08Undercoats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14No matter where you are, in whichever waters around the globe, you’ll find highperformance coatings backed by meticulously researched knowledge and supportfrom Interlux.Varnishes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10Why do I need a Thinner? . . . . . . . . . . . . . . . . . . .15Whether we’re in the lab researching and developing new products, or out on the waterputting our products to the test, we’re in our element. Getting the chemistry right iscritical to us, as is knowing the subtle differences between people and water all overthe world. Wherever there are boats, we’re right at the heart of the matter, makingconnections, solving problems, sharing knowledge Health & Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16Our World is WaterAt Interlux, we recognize the importance of providing high-quality technical supportand advice to all our customers. Whether you’re a novice or a more experiencedDIY’er, you’re sure to have a question for us – and we’d love to help – here’s howyou can reach us Don CampbellTechnical Manager,North American ‘Step-by-Step’ Project GuidesHow to prepare bare substrates . . . . . . . . . . . . . .17Painting your bilge . . . . . . . . . . . . . . . . . . . . . . . . .26Always check the weather! . . . . . . . . . . . . . . . . . .18Preparing a non-skid deck . . . . . . . . . . . . . . . . . .27Making small repairs to fiberglass . . . . . . . . . . . . .20Applying varnishes . . . . . . . . . . . . . . . . . . . . . . . .30Removing aged finishes or varnishes . . . . . . . . . .21Applying antifouling . . . . . . . . . . . . . . . . . . . . . . . .32Removing antifouling . . . . . . . . . . . . . . . . . . . . . . .22Applying antifouling to an aluminum pontoon boat 34Applying finishes . . . . . . . . . . . . . . . . . . . . . . . . . .24Painting outdrives, stern gear, propellers & keels . . .35n AntifoulingIs my new antifouling compatible? . . . . . . . . . . . .36Below water systems . . . . . . . . . . . . . . . . . . . . . .38Technical data sheetsn Topsides1 800 468-7589Material safety data sheetsinterluxtechnicalservice@akzonobel.comJoin the discussion atwww.yachtpaintforum.comTopsidesHow much antifouling paint do I need? . . . . . . . . .37yachtpaint.comProduct labelsHave a question? Our experts have the answers!Two-part premium paint systems . . . . . . . . . . . . .42Varnish systems . . . . . . . . . . . . . . . . . . . . . . . . . .44One-part conventional paint systems . . . . . . . . . . .43Sikkens Cetol Marine . . . . . . . . . . . . . . . . . . . . . .45n Blister Repair and PreventionHow to protect against osmosis . . . . . . . . . . . . . .46How to treat osmosis . . . . . . . . . . . . . . . . . . . . . .47Osmosis protection systems . . . . . . . . . . . . . . . . .47Interlux and the environment: We have many products and systems designed to help you reduce yourboating environmental footprint. Call us or see the appropriate sections on yachtpaint.com for more information.Blister Repairand PreventionAsk the Expertsn Before You StartBeforeYou StartPrimers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12‘Step-by-Step’Project GuidesAntifoulings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .04Antifoulingn Quick Reference GuideFor over a century we’ve been creating the most innovative paint solutions to protect,beautify and improve the performance of all types of boats.Quick ReferenceGuideContentsn The Echo Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48The EchoProgramBoat Paint Guide & Color Cardn Color CardAntifoulings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52ColorCardTopside Finishes . . . . . . . . . . . . . . . . . . . . . . . . . .490203

Quick Reference GuideBoat Paint GuideAntifoulingsUse this guide to our antifoulingproducts to help you choose theperfect product for your project.Micron Technology Polishing AntifoulingsMicron 66 Key attributes Micron Extra Top of the Micron rangePatented self polishing copolymertechnology with Biolux Best antifouling performance inthe harshest fouling conditionsMaximum protection even duringstationary periods at the dock Biolux technology boostsperformance by controlling slimeExcellent for use on all boats*in all watersNot suitable for use infresh water 433433 or216Thinners216Micron CFMicron CSC Controlled polishing –gets smoother with timemaximizing fuel efficiencyAdditional High Performance Products Proven performancefor 20 yearsHaul & relaunchwithout repainting Wears down like abar of soap Suitable for powerand sailboats In VOC regulated areasplease use Micron CSC HS433216 Ultra All the benefits ofMicron technology ina copper-free formula Multi-season antifoulingprotection Uses Biolux slimeblocking technology Bright colors includingShell White as well asa crisp blackPacifica Plus Ultra strong formula forhigh fouling areasFast dry – paint and launchthe same dayBiolux increases antifoulingperformance Use wherever the foulingchallenge is severe Copper-free ablativeantifouling Contains Econea to control barnaclesand shell fouling High solids, lowsolvent emissionsFiberglassBottomkote NTACT Contains Slime Fighterto combat slimeBest value ablativeantifouling availableDesigned to erodeaway with useOvercoats existingantifoulingsEliminates paint build-upand sanding Dual Resin Technologyoptimizes the benefitsof hard and ablativepaintsSlow polishing actionminimizes paint build-upand prevents prematurewear-throughFiberglassBottomkote Aqua Solid protection againstall types of fouling,including zebra mussels Colorfast durable finish Easy clean-up with water Reduced emissions,low odorTrilux 33 Fast dry – paint andlaunch the same dayAvailable in 5 brightclean colors includingWhiteIdeal for use on allsubstrates, includingaluminumBiolux blocks slimeSlow polishing, avoidsseasonal paintbuild-upSuitable for use on all boats433216433216433433 or216216433216433 or216WaterPractical coverage (ft2/gallon)320440440518455528430400407440Number of coats2-32-32-32-32 (3 on bare wood)2 (3 on bare wood)2 (3 on bare wood)2 (3 on bare wood)2 (3 on bare wood)2 (3 on bare wood) SubstratesSafe for use on aluminumApplication method‘* Not for use on aluminum hulls.Use antifouling paints safely. Always read the label and product information before use.Econea is a trademark of Johnson & Johnson.Trilux 33 AerosolInterested in the relative environmental impact* of your chosen product? For more information go to echoprogram.com * When compared to the largest selling product in OUR range.FRP04WOODSTEELALUMINUMLEADGALV.STEEL BRUSHROLLERSPRAYTechnical Service Helpline: 1 800 468-7589 Open Monday to Friday, 9am-4pm Eastern timeAEROSOLFor comprehensive application and scheme information, always read the technical data sheet before you start.Visit our website for more information – yachtpaint.com0506Effective antifouling in a convenient aerosolBiolux technology reduces slime andincreases antifouling performanceFor all outdrives and underwater metalsBlack YBA063ASTEELGray YBA064AALUMINUMWhite YBA068ALEADTechnical Service Helpline: 1 800 468-7589 Open Monday to Friday, 9am-4pm Eastern timeGALV.STEEL

Quick Reference Guide Fluoro microadditive providesa low friction surface for ahigh performance finish Hard, smooth finish canbe burnishedHard, smooth, thin filmantifouling for a highperformance finish With fluoro microadditivefor a low friction surface Quick drying for fastre-launchProfessional-quality resultsmade easyHighest gloss and highestabrasion resistanceUnique UV protection forlongest-lasting color and glossSuitable for salt andfresh waterThinners216Thinners216 Ideal for use anywhere abovethe true waterlineFull range of bright, crisp colors3332333N216 Contains fine mineral additivefor hard wearing, non-slipsurface Suitable for all substratesLow sheen finish preventssunlight glare Hard wearing coating forbilges and bulkheadsChemical resistance to fumes,fuel and oilHigh opacity for thoroughcoverage Cleans easily for reducedupkeepApply straight from the canwith brush or roller 333333Instant scratch repairfor gelcoat and paint216489495396321 2-3 (3-4 coats if wet sanding)2-3Number of coats2-32-31-21-2 Offers aconvenientand easyway to repairscratchesand chips fastCreates analmostinvisible repairNo hassle removal when apermanent repair is madeQuick repair to keep yourboat looking its bestAvailable in 12 colors to easilymatch gelcoat and paintSubstrates ColorCodeApplication methodVC Performance EpoxyVC Offshore Regatta BaltoplateBiocide-free bottom coatingAntifouling for the serious racer A bright white hard, abrasion resistant epoxyIdeal for boats stored on racks andlifts as well as trailered boatsContains a fluoro microadditiveto reduce frictionCan be applied by spray, roller orbrush and wet sanded for extra smoothness A long heritage of use by winning sailorsCan be burnished to a smooth, shinymetallic finishCan be used in fresh, salt andbrackish watersFor use on fiberglass, wood andprimed underwater metals (except aluminum)FlatteningAgent YZM914FlatteningAgent YMA715Intergrip No SkidCompound 2398CIntergrip No SkidCompound 2398CLEADGALV.STEELBRUSHFor a no-skid finish add:Interested in the relative environmental impact* of your chosen product?* When compared to the largest selling product in OUR range.ROLLERSPRAYVisit our website for more information – yachtpaint.comWhite 011 White / Blu-Glo White /Mediterranean WhiteWhite 012 Snow WhiteWhite 013 Ivory / Hatteras Off-WhiteFRP0708–FlatteningAgent YMA715–Intergrip No SkidCompound 2398CWhite 015 Off WhiteBlack 111 BlackBlue 211For more information go to echoprogram.comSTEELEpoxyPrimekote or Pre-KoteSimilar toPerfection / BrightsideWhite 014 Matterhorn WhiteFor a satin finish add:Use antifouling paints safely. Always read the label and product information before use.WOODEpoxyPrimekote or Pre-Kote Additives EpoxyPrimekote or Pre-KoteEpoxyPrimekote Recommended undercoatFRP Practical coverage (ft2/gallon)Application method Excellent flow and levelingcharacteristics yield that‘sprayed on’ look whenbrush appliedSlip resistant polyurethanedeck paint340Suitable for high speed craft Hard, high gloss one-partpolyurethane finish Substrates 300Practical coverage (ft2/gallon)Number of coats Ultimate performance, two-partpolyurethane finishBeforeYou Start For racing, sailing andpower boats Key attributesBilgekote WOODSTEELALUMINUMBRUSHROLLERTechnical Service Helpline: 1 800 468-7589 Open Monday to Friday, 9am-4pm Eastern timeSPRAYFurther information on Flattening Agents for one and two-partfinishes and Intergrip No Skid Compound and their uses canbe found on the product label or on the technical data sheets,which are available at yachtpaint.comMauritius Blue / Flag BlueBlue 212Oxford Blue / Dark BlueBlue 213Sapphire Blue /Lauderdale BlueBlue 214Largo Blue / Ocean BlueThe EchoProgram Key attributesVC 17m ExtraInterdeckBrightside Green 311 Sea Green /Jade Mist GreenRed 411Rochelle RedColorCardVC OffshorePerfection ‘Step-by-Step’Project GuidesHigh PerformanceAntifoulingUse this guide to our topside products tohelp you choose the perfect product foryour project.TopsidesTopsidesUse this guide to our antifoulingproducts to help you choose theperfect product for your project.Blister Repairand PreventionAntifoulingsQuick ReferenceGuideBoat Paint Guide09

Quick Reference Guide Exceptional deep gloss and colorare retained over the lifetime ofthe coatingSuperior gloss lasts four timeslonger than conventional one-partvarnishes Professional-quality results made easy 2:1 mix ratio: Easy to measureand mix* Based on the results of our trials.Thinners Sand between every other coat Traditional amber colorDesigned for the experiencedvarnish enthusiast or professional3332333NCoverage (ft2/gallon)216 Premium quality,traditional tung oil varnish Rich golden color anddeep glossExcellent UV protectionGood flow-out and self-levelingcharacteristics for easierapplicationSuitable for interiors, exteriorsand over existing varnish333 High durability, high glosspolyurethane varnishA bright, clear, high gloss finishlets the natural color of thewood show throughContains a unique combinationof UV additives, HALS, surfacestabilizers and antioxidants forlong-term gloss and clarity216333 A satin finish polyurethanevarnish for interior useResistant to hot water, mildacids, alcohol and alkalisFast-dry formulation minimizesdust -6 Number of coatsWill vary depending on usage.Please check product label/data sheet.Suitable for use direct tooily wood (e.g. teak or iroko)Application methodAdditivesUV protection/gloss retentionFor interior use onlyFlatteningAgent YZM914For a satin finish add:Original 10Thinners333Traditional, general purpose gloss varnishGood flow, flexibility and gloss retentionHigh clarity finish for light color woodsInterior, exterior and over existing varnishBRUSHROLLERFlatteningAgent YMA715216SPRAYGOOD‘FlatteningAgent YMA715Coverage476ft2/gallonJet SpeedNumber of coats4-6 UV protectionOUTSTANDINGTechnical Service Helpline: 1 800 468-7589 Open Monday to Friday, 9am-4pm Eastern time Fast dry varnish for quick overcoatingUse whenever speed of dry isimportantNot recommended as an exterior finishFlatteningAgent YMA715BeforeYou Start ‘Step-by-Step’Project Guides Chemical cure for the hardestfinish & highest abrasion resistanceAdvanced UV technology in ourlongest-lasting one-part varnishGoldspar SatinAntifouling Ultimate performance, clear,two-part polyurethane varnishCompass ClearSchooner Topsides Key attributesSchooner Gold–Thinners333216Coverage500ft2/gallonNumber of coatsInterior: 4-6 / Exterior: 2-3*The EchoProgramPerfection PlusBlister Repairand PreventionGloss retentionoutperforms otherleading 1-partvarnishes *Use this guide to our varnish products tohelp you choose the perfect product foryour project.* Finish with varnish that has UV filtersUV protection–For a no-skid finish, use Intergrip No Skid Compound with your chosen varnish.Visit our website for more information – yachtpaint.comColorCardVarnishesQuick ReferenceGuideBoat Paint Guide11

Quick Reference GuideNEW Typically used For prevention and repairof gelcoat blisteringExcellent for use on underwatermetals, hulls and keelsEasy to apply – dries quickly –no sandingUse as part of a no sand systemExcellent anti-corrosiveprotection above & belowthe waterline A high solids epoxy barrier coatingthat protects hulls from waterabsorption and osmotic blisteringApply a full barrier coat in1-3 coatsContains Micro-Plates to increaseprotection from water absorptionVOC compliantProtects metals from rustand oxidationUniversal primer for aboveand below the waterlineUniversal primer for aboveand below the waterline Primocon AerosolConventional one-part primer foruse below waterQuick drying, with anticorrosivepropertiesCan be used under all majorantifoulings* or as a conversioncoat over incompatible orunknown antifoulings2333N2316N2333NBelow water, under antifoulingsor to seal unknown antifoulings2316N A non bleeding, anticorrosiveprimer for use on outdrives andoutboards, prior to application ofTrilux 33 , Trilux 33 Aerosol,Pacifica Plus or Micron CF Eliminates the need to sandfiberglass prior to applyingantifouling paintUsed on epoxy primers to improvethe adhesion of antifouling paintReduces galvanic corrosionon metal surfaces* Over suitable primerDo not use with VC-17M Extra,VC Offshore or Baltoplate.Thinners Fiberglass No Sand Primer433216Below water, under Trilux 33 ,Trilux 33 Aerosol, Pacifica Plusor Micron CFBelow water, under antifoulings–Do not thinPractical coverage (ft2/gallon)24015130022 sq.ft per can535Number of coats1-51-32-321SubstratesAll metalsAntifouling Key attributesPrimocon InterProtect HSTopsidesInterProtect 2000EBlister Repairand PreventionUse this guide to our primers andundercoats to help you choose theperfect product for your project.‘Step-by-Step’Project GuidesPrimersBeforeYou StartQuick ReferenceGuideBoat Paint GuideSuitable for above waterline Suitable for below waterline The EchoProgramApplication methodInterested in the relative environmental impact* of your chosen product?For more information go to ERTechnical Service Helpline: 1 800 468-7589 Open Monday to Friday, 9am-4pm Eastern timeSPRAYFor comprehensive application and scheme information, always read the technical data sheet before you start.Visit our website for more information – yachtpaint.comColorCard* When compared to the largest selling product in OUR range.GALV.STEEL13

Quick Reference GuideUndercoatsWhy do I need a Thinner?Use this guide to our undercoatsto help you choose the perfectproduct for your project.Thinners are solvents which are usually the same, or very similar, to those used within the product they arerecommended with. Thinners can be used as an additive to ease application, or to clean brushes and equipment.To find out which thinner you need to use refer to the chart below:Typically usedThinnersAbove the waterline underInterlux two-part finishes andin some underwater systems2333N2316N 450BeforeYou StartProductAbove the waterline underInterlux one-part finishesDo not use under two-partproducts333216Epoxy Primekote mustbe thinned prior to usePractical coverage (ft2/gallon)2161-21-214 Technical Service Helpline: 1 800 468-7589 Open Monday to Friday, 9am-4pm Eastern time2333N% Thinner requiredBrushSpraySprayPerfectionPerfection Plus2333N2316NAs required5-10%As required25-35% max.BrightsideYacht EnamelVarnishes333216As required10% max.10-15%Pre-Kote333216As required10% max.10-15%Bottom Paints(Conventional)21621610%1st coat wood onlyAs required10% max.Micron 66 , Micron ExtraMicron CSC, Micron CFACT433216As required10% max.As required20-30% max.Trilux 33 Pacifica Plus21621610%1st coat wood onlyAs required10% max.VC 17m Extra21621610-15% max.10-15% max.21610%1st coat wood onlyAs required10% max.216InterProtect 2000E2333N2316N5-10%10-15%Epoxy Primekote2333N2316N25-30%25-30%VC Performance nApplication methodSuitable for below waterline2316N420SubstratesSuitable for above waterline433BrushVC OffshoreNumber of coats333Fiberglass Surface Prep YMA601VFiberglass Surface Prep YMA601V is a low VOC contamination/mold release agent remover usedfor preparing fiberglass bottoms of new boats or unpainted hulls before applying primers orantifouling paints. Removing contaminants from fiberglass is extremely important if full adhesivequalities of primers and/or antifouling paint are to be realized. It can also be used for the removal of amine blushfrom clear epoxy and cleaning previously painted surfaces prior to sanding before repainting topside finishes.Fiberglass Surface Prep YMA601V is ideal for preparing inflatable boats for a compatible antifouling system.Visit our website for more information – yachtpaint.com‘Step-by-Step’Project Guides Undercoat for one-partfinishesContains Microspheresfor superior build andhide, while improvingflow and sandabilityLong-lasting, easy toapply and rub downAntifouling Topsides A multi-purpose epoxy primerfor use with two-part finishesUse as part of a systemto resurface cracked andcrazed gelcoatEliminates the effects ofamine blush of clear epoxiesBright white color makes itideal for priming bilge andlocker areasBlister Repairand Prevention The EchoProgramKey attributesPre-KoteColorCardEpoxy Primekote Quick ReferenceGuideBoat Paint Guide15

Before You Start‘Step-by-Step’ Project GuidesHealth & safetyHow to prepare bare substrates Personal healthAvoid ingestionFood and drink should not be prepared or consumedin areas where paint is stored or used. In cases ofaccidental paint ingestion seek immediate medicalattention. Keep the patient at rest, do NOTinduce vomiting.Avoid inhalationBreathing solvent fumes can make you dizzyand could result in collapse.The inhalation of solvent vapor from paint orsanding dust, can be reduced with adequateventilation or extraction but may not be sufficient,suitable respiratory protection should always beused. In badly ventilated areas wear an air-fedhood or cartridge respirator with an organic vaporfilter. Wear a cartridge type respirator whenabrading old antifoulings – never burn off ordry-sand antifoulings as this may create harmfulfumes or dust. Spray painting creates additionalhealth hazards and respiratory protection shouldalways be used. Air-fed hoods provide the bestprotection but read the label carefully and ensurerecommended protection is worn. Do not smokeStore paint in a well-ventilated, dry placeaway from sources of heat and direct sunlightKeep the tin tightly closedAvoid sparks from metals, electrical appliances beingswitched on and off, or faulty electrical connectionsDo not leave paint soaked rags lying around,in the pockets of overalls or in waste bins. Sometypes of paint can dry out and auto-ignite.Avoid eye contactEye protection should be used during paintapplication and when there is any risk of paintsplashing on the face. Safety glasses that complywith ANSIZ871-1989 Standard are inexpensive, easilyavailable and are well worth wearing. If material doescontaminate the eye, flush the eye with clean freshwater for at least 15 minutes, holding the eyelidsapart, and seek medical attention.Avoid skin contactTo avoid skin irritation always wear protectivegloves and clothing to cover the body and a barriertype skin cream to cover the face. Do NOT usepetroleum jelly as this can help the absorption ofpaint into the body. Remove rings and watches thatcan trap paint particles next to the skin. Removepaint that does get on skin with warm water andsoap or an approved skin cleanser. Never usesolvent to clean the skin. For Material Safety Data Sheets go towww.yachtpaint.comFor medical emergency, spill, leak, exposureor accident, call toll free – day or night –CHEMTREC 1-800-424-9300.Medical Advisory Number: Contact your localpoison control center or call 1-800-854-6813.Steel/Cast Iron/LeadBare Wood/PlywoodSand smooth with 80-180 grit paper and then280 grit paper. Remove sanding dust by brushingor dusting. Wipe down thoroughly with solvent andallow to dry completely, to ensure any residualsanding dust is removed, before applying productsrecommended for application direct to wood(see paint systems guides).Degrease with Fiberglass Solvent Wash 202.Thoroughly grit blast, or sand with a 36 grit abrasivedisc to a uniform, clean bright metal surface.Remove abrasion residue by brushing, vacuumingor blowing down with a clean air compressor line.Immediately prime with Interlux InterProtect 2000E/2001E thinned 15-20% with recommendedsolvents. Refer to the paint systems guides onPages 38-43 for more information.Oily woods e.g. teakEnsure that the surface is thoroughly degreasedusing a recommended solvent to ensure all oilsare removed. Sand smooth with 80-180 grit paperand then 280 grit paper. Remove sanding dustby wiping with solvent, to ensure any residualdust is removed. Ensure the surface is completelydry before applying products recommended forapplication direct to wood (see paint systemsguides).Stainless Steel/BronzeDegrease with Fiberglass Solvent Wash 202. Lightlygrit blast or sand with 60-80 grit sandpaper to bringthe metal to a uniform, shiny appearance. Removeabrasion residue by brushing, vacuuming or blowingdown with a clean air compressor line. Immediatelyprime with InterProtect 2000E/2001E thinned15-20% with recommended solvents. Refer to thepaint systems guides on Pages 38-43 for moreinformation.AluminumDegrease with Fiberglass Solvent Wash 202. Sandwell using 60-80 grit (aluminum compatible) paper.Interstrip 299E Paint Remover:Interstrip 299E paint remover utilizes a new technology that delivers an effective paintremover system that does not require methylene chloride, a suspected human carcinogen.Interstrip 299E is safe for fiberglass surfaces and has a low odor. Interstrip 299Eformulation incorporates special sealing agents that allow the stripper to stay wet longer,thereby lengthening working time. Interstrip 299E can be used to remove antifouling paint,varnishes, and topside paints.For further information on Personal Protective Equipment, visit yachtpaint.com16Technical Service Helpline: 1 800 468-7589 Open Monday to Friday, 9am-4pm Eastern time‘Step-by-Step’Project Guides Antifouling Avoid naked flames where paint is being stored,opened or appliedRemove abrasion residue by brushing, vacuumingor with a clean air compressor line. Immediatelyprime with InterProtect 2000E/2001E thinned15-20% with recommended solvents. Refer tothe paint systems guides on Pages 38-43 formore information.Topsides FiberglassDewax with Interlux Fiberglass Surface Prep YMA601V.Sand well (using 80-220 grit below water/180-220grit above water) sandpaper. Clean thoroughly andallow to dry completely. Prime using an Interluxprimer following the product recommendationsprovided in the paint systems guide onPages 38-47.Blister Repairand PreventionMost paints contain organic solvents – some of whichevaporate into the air upon opening the container.Any dangers can be reduced if a few simpleprecautions are taken:All surfaces should be thoroughly degreased and free from any sanding debris prior to the application ofany paint to the surface.The EchoProgramRisk of fire or explosionColorCardHealth and safety precautions for paint productsare a legal requirement and form a specificsection on our labels and is often difficult tounderstand. This section is intended to help youunderstand the information in our literature andon our product label to make applying paint asafer job. Before starting work always read thelabel which will indicate those areas whereparticular care should be taken. Other generalsafety precautions are detailed below and willhelp should any problem occur while usingour paints.Visit our website for more information – yachtpaint.com17

‘Step-by-Step’ Project GuidesBoat Paint GuideAlways check the weather! 18Dew point is important when applying paint toa surface, as the evaporation of the solvent fromthe paint draws heat and/or energy from thatsurface, cooling it down. If conditions are rightcondensation may form on the surface of thepaint resulting in various problems.Relative humidity is important as air can onlyhold so much water or solvent vapor at any onetime. So, as the relative humidity increases, thelevel of solvent vapor the air can hold reduces,meaning paint will effectively dry more slowly. Air and substrate temperature will affect thedrying properties of any paint. Failing to observethe recommended drying times can result incoating failure, including improper drying,wrinkling and loss of adhesion.Always avoid extreme air or temperatureconditions; Interlux products are tested acrossa range of temperatures, to ascertain the dryingtimes and application characteristics of eachproduct. Drying time recommendations areprovided on our products labels; furtherinformation relating to weather considerationscan be found on our product data sheets,available on our web site.Low temperatures will increase drying times;always check the ‘through-dry’ of each interimcoat, before sanding or overcoating.Sanding too early can cause the paint towrinkle under the sand paper, in some caseseven tearing or gouging into the paint filmmaking refurbishment difficult. Sanding beforethe paint film is ‘through-dry’ can also clog thesand paper, meaning more sheets are neededto complete the task. Overcoating too early can cause wrinkling,blistering and loss of gloss in the finishedpaint job.High temperatures will reduce drying times,but can make application more difficult, asproduct flow and leveling can be compromised –particularly when applying finishes or varnishes.Where appropriate, thinning recommendationsto help with higher temperature application areprovided on labels and data sheet. When applying two-part products in highertemperatures the pot life of the product will alsobe affected, reducing your work time window. Do not paint in direct sunlight, or when thesubstrate itself is excessively warm, as theresidual heat of the substrate can adverselyaffect the application and drying properties ofany paint product; this can result in poor flowand leveling, rapid drying, cracking and loss ofgloss. Surface temperature can be measuredusing a surface thermometer.Technical Service Helpline: 1 800 468-7589 Open Monday to Friday, 9am-4pm Eastern timeDry, well ventilated conditions are preferablewhen applying finishes or varnishes. While gentleair movement will assist the drying process,a dust-free environment is critical to achievinga good quality gloss finish; always avoid paintingin windy conditions.Choosing a faster drying product or system,where available, will help to minimize the windowfor dust contamination. The effects of dust contamination may be furtherreduced by sanding lightly between each coat,removing residual dust by wiping down with asuitable solvent and allowing to dry beforeapplying the next coat. This will also helpimprove the initial aesthetics.Avoid applying two-part finishes or varnisheslate in the afternoon or when relative humidityexceeds 80% as these products are particularlysensitive to moisture. Condensation duringapplication or due to overnight ambienttemperature changes can affect the chemicalcure of these products resulting in loss of gloss.When painting orvarnishing woodavoid applying if theambient temperatureis increasing (orpredicted to increase)significantly. When curing i

Copper-free ablative antifouling Contains Econea to control barnacles a ndshe lfoui g High solids, low solvent emissions Visit our website for more information - yachtpaint.com Boat Paint Guide 2-3 2-3 2 (3 on bare wood) 2 (3 on bare wood) 440 518 455 528 Micron CSC Micron CF Ultra ACT Proven performance for 20 years Haul & relaunch