Transcription

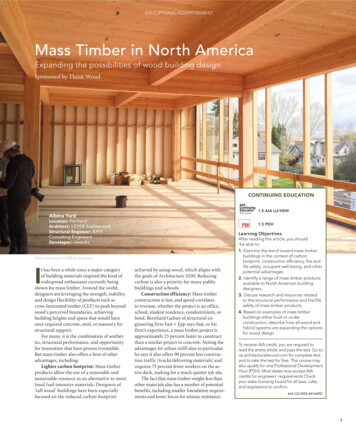

CONTINUING EDUCATIONMass Timber in North AmericaExpanding the possibilities of wood building designSponsored by Think WoodCONTINUING EDUCATION1.5 AIA LU/HSWAlbina YardLocation: PortlandArchitect: LEVER ArchitectureStructural Engineer: KPFFConsulting EngineersDeveloper: reworks1.5 PDHPhoto courtesy of LEVER ArchitectureIt has been a while since a major categoryof building materials inspired the kind ofwidespread enthusiasm currently beingshown for mass timber. Around the world,designers are leveraging the strength, stability,and design flexibility of products such ascross-laminated timber (CLT) to push beyondwood’s perceived boundaries, achievingbuilding heights and spans that would haveonce required concrete, steel, or masonry forstructural support.For many, it is the combination of aesthetics, structural performance, and opportunityfor innovation that have proven irresistible.But mass timber also offers a host of otheradvantages, including:Lighter carbon footprint: Mass timberproducts allow the use of a renewable andsustainable resource as an alternative to morefossil fuel-intensive materials. Designers of‘tall wood’ buildings have been especiallyfocused on the reduced carbon footprintachieved by using wood, which aligns withthe goals of Architecture 2030. Reducingcarbon is also a priority for many publicbuildings and schools.Construction efficiency: Mass timberconstruction is fast, and speed correlatesto revenue, whether the project is an office,school, student residence, condominium, orhotel. Bernhard Gafner of structural engineering firm Fast Epp says that, in hisfirm’s experience, a mass timber project isapproximately 25 percent faster to constructthan a similar project in concrete. Noting theadvantages for urban infill sites in particular,he says it also offers 90 percent less construction traffic (trucks delivering materials) andrequires 75 percent fewer workers on the active deck, making for a much quieter job site.The fact that mass timber weighs less thanother materials also has a number of potentialbenefits, including smaller foundation requirements and lower forces for seismic resistance.Learning ObjectivesAfter reading this article, you shouldbe able to:1. Examine the trend toward mass timberbuildings in the context of carbonfootprint, construction efficiency, fire andlife safety, occupant well-being, and otherpotential advantages.2. Identify a range of mass timber productsavailable to North American buildingdesigners.3. Discuss research and resources relatedto the structural performance and fire/lifesafety of mass timber products.4. Based on examples of mass timberbuildings either built or underconstruction, describe how all-wood andhybrid systems are expanding the optionsfor wood design.To receive AIA credit, you are required toread the entire article and pass the test. Go toce.architecturalrecord.com for complete textand to take the test for free. This course mayalso qualify for one Professional DevelopmentHour (PDH). Most states now accept AIAcredits for engineers’ requirements Checkyour state licensing board for all laws, rules,and regulations to confirm.AIA COURSE #K1609D1

EDUCATIONAL-ADVERTISEMENTImage courtesy of Fast EppCONTINUING EDUCATIONPhoto courtesy of StructureCraftMass timber systems are a complement to light wood-frame and post-and-beam construction.Discussing the new Design Building at theUniversity of Massachusetts, for example,structural engineer Robert Malczyk of Equilibrium Consulting says, “The seismic force isproportionate to the weight of the building. Ifthis building were designed in concrete, whichwas considered, the weight would be six timesmore than the mass timber design.”Fire and life safety: Structurally, masstimber offers the kind of proven performance—including fire protection and seismicresistance—that allows its use in larger buildings. It also expands the options for exposedwood structure in smaller projects.Occupant well-being: An increasingnumber of studies focused on wood’s biophilicaspects have linked the use of exposed woodin buildings with improved occupant healthand well-being.1,2This course is intended for architects andengineers seeking current information on masstimber, including products, research relatedto structural performance and life safety, andavailable resources. It answers common questions regarding strength, fire protection, anddurability, and highlights examples of masstimber buildings in different occupancy groupsto illustrate both design trends and the extentto which mass timber has captured the imagination of North American building designers.WHAT IS MASS TIMBER?Mass timber is a category of framing stylestypically characterized by the use of largesolid wood panels for wall, floor, and roofconstruction. It also includes innovativeforms of sculptural buildings, as well as nonbuilding structures formed from solid woodpanel or framing systems of 6 feet or more inwidth or depth. Products in the mass timberfamily include the following.2ARCHITECTURAL RECORDAU G U S T 2 0 2 0Cross-Laminated Timber (CLT)CLT consists of layers of dimension lumber(typically three, five, or seven) oriented atright angles to one another and then gluedto form structural panels with exceptionalstrength, dimensional stability, and rigidity.Panels are particularly cost-effective formultistory and large building applications.Some designers view CLT as both a standalone system and product that can be usedtogether with other wood products; it can alsobe used in hybrid and composite applications.CLT is well-suited to floors, walls, and roofs,and may be left exposed on the interior foraesthetics. Because of the cross-lamination,CLT also offers two-way span capabilities.CLT can be manufactured in customdimensions, with panel sizes varying bymanufacturer. There are several CLT suppliersin North America, with more anticipated. Thespecies of wood used depends on the manufacturing plant location.The 2015 International Building Code(IBC) and 2015 International ResidentialCode recognize CLT products manufactured according to the ANSI/APA PRG-320:Standard for Performance Rated CrossLaminated Timber. Under the 2015 IBC,CLT at the required size is specifically statedfor prescribed use in Type IV buildings.However, CLT can be used in all types ofcombustible construction (i.e., wherevercombustible framing or heavy timbermaterials are allowed). The National DesignSpecification (NDS) for Wood Construction is referenced throughout the IBC asthe standard for structural wood design,including CLT. The 2012 IBC does notexplicitly recognize CLT, but the 2015 IBCprovisions for CLT can be a basis for its useunder alternative method provisions.Designed by MGA, the seven-story T3building in Minneapolis includes glulamcolumns and beams, and NLT floors.For more information on CLT, the U.S.CLT Handbook is available as a free download at www.thinkwood.com.Nail-Laminated Timber (NLT)Nail-laminated timber (NLT) is createdfrom individual dimension lumber members (2-by-4, 2-by-6, 2-by-8, etc.), stackedon edge, and fastened with nails or screws tocreate a larger structural element.NLT is far from new—it has been usedfor more than a century—but is undergoing a resurgence as part of the modern masstimber movement. Commonly used infloors, decks, and roofs, it offers the potential for a variety of textured appearances inexposed applications, and wood structuralpanels can be added to provide a structuraldiaphragm. NLT has also been used tocreate elevator and stair shafts in midrisewood-frame buildings.NLT naturally lends itself to the creationof unique roof forms. Because panels arecomprised of individual boards spanningin a single direction, both singly curved andfreeform panels can be created by slightlyoffsetting and rotating each board relative tothe others. This allows the complex geometryof curved roof and canopy structures to berealised with a simple system.Advantages of NLT include the ability touse locally available wood species and thefact that specialized equipment generally isn’tnecessary. An NLT system can be created viagood on-site carpentry, though some suppliersdo offer prefabrication, and this can have benefits depending on the scale and complexity ofthe project. Prefabricated NLT panels typicallycome in sizes up to 10 feet wide and 60 feet

EDUCATIONAL-ADVERTISEMENTPhoto courtesy of LEVER ArchitectureGlued-Laminated Timber (Glulam)Glulam is composed of individual woodlaminations (dimension lumber), selectedand positioned based on their performancecharacteristics, and then bonded togetherwith durable, moisture-resistant adhesives.The grain of all laminations runs parallel withthe length of the member.Glulam has excellent strength and stiffnessproperties, and is available in a range of appearance grades for structural or architecturalapplications. While typically used as beamsand columns, designers can use glulam in theplank orientation for floor or roof decking.With careful specification and design thatconsiders the flatwise structural properties (see APA reference below), deep glulamsections can be placed flatwise as deckingsimilar to NLT. With the flexibility of glulammanufacturing, glulam ‘panels’ can be used tocreate complex curvature and unique geometry. When used in such innovative floor androof panel configurations, glulam is seen as anextension of the mass timber product familyand sometimes referred to as GLT.The IBC recognizes glulam productsmanufactured in conformance with ANSIStandard A190.1-2012: Standard for WoodProducts—Structural Glued LaminatedTimber. For more information, consult theGlulam Product Guide available at www.apawood.org/glulam.Dowel-Laminated Timber (DLT)Dowel-laminated timber panels are a nextgeneration mass timber product commonlyused in Europe. Panels are made from softwood lumber boards (2-by-4, 2-by-6, 2-by-8,etc.) stacked like the boards of NLT andfriction-fit together with dowels. Typicallymade from hardwood lumber, the dowels holdeach board side-by-side, similar to how nailswork in an NLT panel, and the friction fitlends some dimensional stability to the panel.There isn’t a prescriptive code path for theuse of DLT under the current IBC, and theNDS doesn’t provide published design valuesor equations for calculating capacities of woodCONTINUING EDUCATIONlong, with wood sheathing preinstalled. Whendetailing NLT systems, designers need to account for moisture movement.The IBC recognizes NLT and providesguidance for structural and fire design. Noproduct-specific ANSI standard is required, asthe structural design of each element is covered by the NDS and applicable grading rules.NLT can be used in all types of combustibleconstruction.ALBINA YARD & FRAMEWORKLocation: Portland, OregonArchitect: LEVER ArchitectureStructural Engineer: KPFF Consulting EngineersDesign Assist Build (Framework): StructureCraftDeveloper (Albina Yard): reworksThe four-story, 16,000-square-foot Albina Yard is noteworthy for being the first commercial building in the United States to use domestically fabricated CLT as a structuralelement. A Type III project designed under the 2014 Oregon Structural Specialty Code, itis also interesting as a precursor to another LEVER-designed office project—Framework,the 12-story winner of the U.S. Tall Wood Building Prize Competition.“We were very interested in exploring a mass timber/CLT project on a smaller scaleprior to building the larger high-rise project, so it was a very fortunate coincidence,” saysDesign Principal Thomas Robinson. Asked about lessons learned, he emphasized the needfor early collaboration between architectural, structural, mechanical, and installation.“Each discipline had a role to play; input and problem solving needed to happen together.As the building was essentially prefabricated off-site, the coordination and problemsolving that often occurs in the field needed to be accounted for beforehand. After wewere off the ground-floor slab, Albina Yard was built to a 1 8 -inch tolerance, and it wenttogether perfectly.”Currently in design, Framework will consist of ground-floor retail, five levels of officespace, five levels of housing, and a rooftop community space. It is expected to include CLTfloor panels as well as a new system of post-tensioned rocking wall panels.Developed for use in high seismic regions, rocking mass timber shear walls were testedby the Network for Earthquake Engineering (NEES) as part of its CLT Planning Project.Seismic activity was simulated by cyclic loading that pushed and pulled the top of a 16-by4-foot CLT panel with an embedded vertical pretensioned rod into a rocking motion. Thewall was able to reach 18 inches of displacement, while maintaining its ability to self-centerback to a vertical position.Framework, which is scheduled for completion in 2018, is expected to be the firstapplication of a rocking mass timber shear wall system in the United States.3

EDUCATIONAL-ADVERTISEMENTCONTINUING EDUCATIONPhoto courtesy of StructureCraftPictured is a dowel-laminated timber panelwith an acoustic profile integrated into theexposed surface.dowel joints. To calculate capacities, the Timber Framers Guild provides some information. However, because nothing is referencedin the code, the use of DLT would requireapproval by the Authority Having Jurisdictionon a case-by-case basis.Among the advantages of DLT, acousticstrips can be integrated directly into thebottom surface of a panel. This can help adesigner achieve acoustic objectives, whilekeeping the wood exposed and allowing for awide variety of surface finishes.With growing interest in DLT, continuedproduct innovation is likely, along with increased availability to U.S. building designers.Structural Composite Lumber (SCL)SCL is a family of wood products createdby layering dried and graded wood veneers,strands, or flakes with moisture-resistantadhesive into blocks of material, which aresubsequently re-sawn into specified sizes.Two SCL products—laminated veneerlumber (LVL) and laminated strand lumber(LSL)—are relevant to the mass timbercategory, as they can be manufactured aspanels in sizes up to 8 feet wide, with varying thicknesses and lengths, dependingon the product and manufacturer. Parallelstrand lumber (PSL) columns are also commonly used in conjunction with other masstimber products.The manufacture of SCL is standardized.However, while SCL is included in the NDS,design values are provided by the manufacturers. International Code Council Evaluation Service (ICC-ES) evaluation reportsand APA product reports are available toassist with structural design capacities andspecifications.4ARCHITECTURAL RECORDAU G U S T 2 0 2 0Wood-Concrete CompositesMass timber systems vary widely, and hybrids are an option for wood high-rises, verylong spans, or other project-specific requirements. No material is perfect for every job,and it’s important for designers to choosea combination of materials that effectivelymeets the performance objectives.At a product level, most of the panelsdescribed above can be made into a woodconcrete composite by applying a concretetopping in such a way that the two materialsact as one.One example is the University of Massachusetts Design Building described laterin this course (see Schools), which includesCLT/concrete composite floors. According toarchitect Tom Chung of Leers Weinzapfel Associates, the team relied on the CLT panels forthe building load requirements. However, thecomposite action between the CLT and concrete provided extreme stiffness and minimaldeflection which, along with an insulationlayer between the materials, provided goodacoustic separation between floors.WHEN IS MASS TIMBER APPROPRIATE?Because of its strength and dimensionalstability, mass timber offers a low-carbonalternative to steel, concrete, and masonryfor many applications. A complement toother wood framing systems, it can be usedon its own, in conjunction with other woodsystems such as post-and-beam, or in hybridstructures with steel or concrete. Mass timber is not necessarily a good substitute forlight wood-frame construction, only becausedimension lumber framing offers such acompelling combination of performanceand cost where permitted by code. For thisreason, building types where designers typically default to forms of construction otherthan light wood-frame—including offices,public/institutional buildings, schools, andtaller mixed-use occupancies—may offergreater appeal for mass timber than low-risecommercial or residential buildings, thoughexamples of the latter do exist.“We’re seeing a lot of interest in masstimber for midrise buildings such as hotelsand high-end offices that would have typicallyused concrete or steel,” said Lucas Epp ofStructureCraft, a specialty timber engineering and construction company known forinnovative wood structures. “In additionto the warmth of exposed wood, people arediscovering that it’s a viable option for creating high-performing and cost-competitivestructures.”Thomas Robinson, whose firm is designing three mass timber projects in addition toAlbina Yard and Framework, sees particularpotential in multifamily housing and otherbuilding types that lend themselves to modular prefabrication. “The time spent upfrontdesigning and perfecting a building systemcan be leveraged in projects where you haverepeatable elements,” he says.Office/Mixed-UseFor office environments, the aesthetic of masstimber can be a particular draw, resulting inhigher rents and longer-term tenants.The Radiator in Portland, Oregon—afive-story, Type IIIA project completed in2015—is part of a surge of mass timber officesin the Pacific Northwest. Designed by PATHArchitecture for the Kaiser Group, gravityloads for the 36,000-square-foot structure arehandled through a system of glulam beamsand columns, while a mass timber deck withwood structural panels creates the structuralfloor diaphragm, and dimension lumber wallssheathed with wood structural panels provideshear capacity. Beams, columns, and the underside of the floor decking are all left exposed,contributing to the interior’s contemporaryindustrial character.MASS TIMBER:AN EFFICIENT SOLUTIONIn addition to the structural, aesthetic,and environmental advantages, masstimber can be an efficient and practicalsolution to design challenges.With prefabricated panels,mass timber construction is fast—approximately 25 percent faster thanconcrete, according to BernhardGafner of Fast Epp, based on hisfirm’s experience. Gafner says it alsoresults in 90 percent less constructiontraffic and 75 percent fewer workers onthe active deck, making it well-suitedto urban infill sites.Because mass timber is lighter thansteel and concrete, it can be a goodsolution for sites where poor soil is anissue.There is also a trend towardthe integration of services intoprefabricated elements, such as panelsand trusses. The fact that the labor isdone off-site means greater qualitycontrol and a less hectic job site.

EDUCATIONAL-ADVERTISEMENTImage courtesy of Michael Green ArchitectureFurther expanding the possibilities, theseven-story, 220,000-square-foot T3 buildingin Minneapolis, Minnesota, includes a mix ofglulam columns and beams, NLT floors, and aconcrete core. Architect Michael Green, a longtime advocate of using wood to reduce thecarbon footprint of buildings, calls the TypeIV project “a game changer for the commercialbuilding industry and a milestone for masstimber construction in the United States.” Inaddition to its carbon benefits, Green citesthe ability of modern wood products to bringwarmth and beauty to the interior, while promoting a healthy indoor environment.Demonstrating some of the efficiencies associated with mass timber, the woodstructure of T3 took an average of nine daysto erect per 30,000-square-foot floor. Morethan 100 truckloads of glulam and NLT panels arrived as they were needed at the projectsite, with steel connections preinstalled,allowing the structural components to be assembled quickly. The project team estimatesthat it is 30 percent lighter than a comparable steel design and 60 percent lighter thanpost-tension concrete.footprint, and wood’s biophilic effects. Theaesthetic possibilities are also exciting tomany designers.In the United States, examples includeChicago Horizon, a Type IV public paviliondesigned by Ultramoderne for the ChicagoArchitecture Biennial. Elegantly crafted, thisaward-winning structure includes a CLT roofsupported on 13 glulam columns distributedin a radial pattern to address lateral loads anduplift. The pavilion represents the first use ofexposed CLT in the city of Chicago, providinglocal precedent for the approval and use ofmass timber for government and public assembly applications. In addition, the two-wayslab roof is the first of its kind, suggesting newopportunities for open-layout buildings madefrom CLT. The planned long-term use of thebuilding as a commercial vendor and publicassembly space is a significant and sustainabledeparture from the typical design exhibitionmodel of temporary installations.With a growing body of research supporting the positive impacts of wood on occupantwell-being, there is also a trend toward the useof mass timber in healing environments.Public and InstitutionalReasons to use mass timber in public andinstitutional buildings are similar to thosefor offices and schools, including carbonSchoolsMass timber has a number of characteristics that make it attractive for schools anduniversities—from the ability to construct anCONTINUING EDUCATIONT3Location: Minneapolis, MinnesotaDesign Architect: Michael Green ArchitectureArchitect of Record: DLR GroupStructural Consultant: MKADesign Assist Build: StructureCraftentire project over the summer while studentsare off campus, to the potential efficiencies ofreplicable modular designs, a lighter carbonfootprint, and the positive impacts of exposedwood on student well-being.For a 14,000-square-foot addition to Common Ground High School in New Haven,Connecticut, for example, Gray OrganschiArchitecture and engineering partner Bensonwood chose a combination of CLT and glulam.CLT panels provide the tension surface (andfinal ceiling finish) in a system of prefabricated stressed skin assemblies that span theupper classrooms and circulation spaces.Vertical CLT panels form bearing and shearwalls throughout the building, while glulamrafters and heavy timber trusses span a largeground-floor multipurpose space. A treatedglulam bridge deck on laminated timber piersprovides access from the upper campus.Discussing some of the advantages of masstimber, Design Principal Alan Organschi says,“CLT and glulam can serve as both primarystructure and finished interior surface at thesame time. This creates efficiencies in deploying trades and sequencing construction, whichhas very real monetary implications. As theconstruction industry, accustomed to building institutional buildings like schools usingconventional wall, roof, and floor assemblies,gains more experience with these versatile new5

EDUCATIONAL-ADVERTISEMENTCONTINUING EDUCATIONPhoto courtesy of David SundbergCommon Ground High SchoolLocation: New Haven, ConnecticutArchitect: Gray Organschi ArchitectureTimber Engineer: Bensonwoodtimber products, greater production economies will accrue and more of timber’s potential benefits—light weight, high strength,workability, etc.—will be captured.”Organschi also stressed constructionspeed. Assisted only by a mobile crane, afive-person assembly crew installed theentire primary structure and enclosure injust four weeks.Regarding the impact of wood on studentsand teachers, he adds, “It’s well-known that,as a hygroscopic material (cellular plantstructure), wood surfaces serve as moisture buffers, moderating swings in interiorhumidity and thereby improving air quality.It’s worth mentioning that during the firstfew weeks the new building was being used,a teacher commented to me that people wereremarking on the freshness of the air in theclassrooms. Anecdotal, I know, but it squareswith the scientific predictions of healthbenefits of using wood (especially unfinishedwood) in building interiors.”Common Ground High School is TypeVB Construction, fully sprinklered, and wasdesigned under the 2005 Connecticut StateBuilding Code.6ARCHITECTURAL RECORDAU G U S T 2 0 2 0Another example, the DesignBuilding at theUniversity of Massachusetts – Amherst(UMass), featuresan exposed glulampost-and-beamstructure, CLT decking and shear walls,CLT/concrete floors(rigidly connectedby glued-in steel fasteners), and a ‘zippertruss’ roof spanninga two-story-highcommon space.One challengingaspect of this projectwas that it startedas a steel design.Keen to make thebuilding a showcasefor sustainability, theuniversity made thedecision to use woodpart way through thedesign process.Noting that hemay have madedifferent choiceshad he started withwood, architect Tom Chung of Leers Weinzapfel Associates said, “Generally, mass timberdoesn’t have to radically change the designconcepts we already use; we can accomplishwhat we are already familiar with in steel andconcrete. Steel post-and-beam can be done asglulam post-and-beam. Concrete/masonryshafts can be done in CLT. Steel/concretefloors can be CLT/concrete floors. A steeldeck roof can be a CLT roof. Steel braces canbe glulam braces. For the UMass project, wewent step by step, asked ourselves what theprecedents were and how we could go aboutmaximizing the use of timber.“If the project started out in wood and theprimary objective was to design the most efficient mass timber building, then the shapeand massing may have been more along thelines of a conventional ‘box,’ which is theshape of most of the mass timber structuresbuilt so far. But since there were other important design objectives, the UMass building has unique angles and cantilevers thatrequired steel in addition to wood. Our goalwas to use the most appropriate materials tomeet the structural objectives at hand.”Chung also said that educating code of-ficials is an important part of the process.The UMass project team was in constantcommunication with a Massachusetts statebuilding inspector and, because the buildingrepresented a new type of construction, alsowent before the Massachusetts state board ofappeals for official approval. The project wasapproved after the team was able to demonstrate its performance capabilities as well asthe long history of mass timber structures inEurope and Canada.Scheduled for completion in 2017, theUMass project is a combination of Type IVand IIB Construction.Multifamily and HospitalityIn the United States, a recent example of amulti-story mass timber building is a four-story CLT hotel, Candlewood Suites at RedstoneArsenal, an Army base near Huntsville, Alabama. Developed and designed by Lendlease,the hotel is part of the Privatization of ArmyLodging (PAL) program, created to providequality private-sector lodging for soldiers andtheir guests. Compared to typical PAL hotelof 54,891 square feet, Lendlease says the new62,688-square-foot CLT hotel was erected in37 percent less time, with a 44 percent reduction in structural person hours. In terms ofstructural performance, the hotel’s location ona military base meant it also had to meet AntiTerrorism and Force Protection standards.Another project at the preconstructionstage is a 70,000-square-foot hotel/condominium complex in Austin, Texas. Knownas a leader in sustainable design, architecturefirm Lake Flato was interested in whethermass timber could meet both structural andenvironmental objectives for a multistorybuilding. The project includes five buildings,three of which use mass timber construction, with a combination of NLT, glulam, andprefabricated wood-frame walls.Tall WoodWhile most of this course focuses on structures that can be built under current U.S.building codes, a discussion of mass timberis incomplete without reference to woodhigh-rises. Many examples exist worldwide,illustrating the potential of mass timber tobring environmental and other advantagesto higher-density projects. A recent ThinkWood infographic (www.thinkwood.com)highlights 17 tall wood buildings built in thepast five years, including: Treet – Norway – 14 stories, 2014 Trafalgar Place – United Kingdom – 10stories, 2015

EDUCATIONAL-ADVERTISEMENTImage courtesy atelierjones, LLCCONTINUING EDUCATION Forté – Australia – 10 stories, 2012 Banyan Wharf – United Kingdom – 10stories, 2015Closer to home, architect Michael Greenforeshadowed his work on the T3 projectwith the 96-foot-tall Wood Innovation andDesign Centre in British Columbia, Canada.Completed in 2014, it is made from aninnovative combination of glulam postand-beam construction and built-up CLTfloor panels. It includes six stories, plus apenthouse and mezzanine.An 18-story student residence—oneof the tallest mass timber buildings in theworld—is also under construction at theUniversity of British Columbia (UBC). Thestructure, Brock Commons, is a hybridsystem comprised of CLT floor slabs, glulamcolumns, steel connectors, and concretecores. Scheduled for completion in 2017, ithas been designed to achieve LEED Goldcertification.UBC is a strong proponent of utilizingwood for its carbon benefits, and BrockCommons is just the latest of several masstimber buildings on its campuses.In the United States, a number of tallwood buildings are in design, includingthe winners of the U.S. Tall Wood BuildingPrize Competition. Established by the U.S.Department of Agriculture (USDA), Softwood Lumber Board (SLB), and BinationalSoftwood Lumber Council (BSLC), thecompetition was the first step in a processto showcase the safe application, practicality,and sustainability of tall wood structures(minimum 80 feet in height) using masstimber, composite wood technologies, andinnovative building techniques. It was created to provide scientific and technical support for the design and construction of tallwood buildings, and the winners re

for innovation that have proven irresistible. But mass timber also offers a host of other advantages, including: Lighter carbon footprint: Mass timber products allow the use of a renewable and sustainable resource as an alternative to more fossil fuel-intensive materials. Designers of 'tall wood' buildings have been especially