Transcription

PRODUCT CATALOGVolume 1www.tweco.com

Air Carbon Arc Gouging TorchesAngle-Arc Gouging TorchesNew & Improved Air Flow and FourBarrel Air Nozzle Gives OptimumMetal RemovalCheck out these exciting features of the new Extreme Gouging Torch from Arcair :Improved Torch Air FlowMore efficient use of air supply. Improved metal removal.K-SeriesGouging TorchesNew Four Barrel Air NozzleOptimizes air flow to the arc. Efficiently cleans slag fromgroove edge.Optimized Air Flow to Control NoiseAllows usage in areas where noise cannot exceed 115 decibels.Able to use torch at lower air pressure and flow to obtainacceptable grooves.Air Assist Positive Air Shut-OffMinimizes air supply unit cycling on and off. Allows torch usagewhen air supply is marginal.Improved Cable Electrical ConductionTri-Arc Gouging TorchesImproves cable service life. Decreases heat build up in cableand torch.Superior Outer Cable CoverDurable cover for improved cable life in a harsh environment.Resist breakdown due to exposure to heat produced by gouging.Insulated Connection Boot & Hook-Up KitMakes for easy torch hook-up. Virtually eliminates the possibilityof arcing when contacting electrically hot parts.U.S. Customer Care: 800-426-1888 /page 2FAX800-535-0557

Air Carbon Arc Gouging TorchesAngle-Arc Manual Gouging TorchesOnly Arcair – the inventor of the original air carbon arc process and the industry leader for 50 years – could bring you the superbmarriage of proven technology and improved design. Only Angle-Arc Torches work efficiently with the natural angles and movementsof the arm and wrist. This major advance in gouging and cutting equipment delivers rugged reliability. The addition of superb supportand complete technical backup makes Arcair the number one name in air carbon arc manual torches.Arcair Angle-Arc Torches are highly efficient metal removal tools for fabrication jobs in steel fabrication plants, shipyards, railroads,farms . . . anywhere people want to save time and money. They speed up weld removal, backgouging, edge preparation, defectrepair and many other metal removal jobs. They are ideal for almost all metals – with little or no deformation – because the heatinput is so low.Now a complete family of Angle-Arc Torches to meet your everyday needs. Just pick the best torch to fit your gouging applications.K2000K3000K4000K5000Light DutyMedium DutyHeavy DutyExtra Heavy DutyAccepts:Pointed Carbons:1/8” (3mm) to 1/4” (6mm)Flat Carbons:3/8” (10mm)Accepts:Pointed Carbons:1/8” (3mm) to 3/8” (10mm)Flat Carbons:3/8” (10mm) & 5/8” (16mm)Accepts:Pointed Carbons:5/32” (4mm) to 1/2” (13mm)Flat Carbons:3/8” (10mm) & 5/8” (16mm)Accepts:Pointed Carbons:5/32” (4mm) to 5/8” (16mm)Flat Carbons:3/8” (10mm) & 5/8” (16mm)Maximum 450 AmpsMaximum 600 AmpsMaximum 1000 AmpsMaximum 1250 AmpsCompressed air:Pressure:40 psi (2.8kg/cm2)Flow Rate:8 cfm (0.23m3/min)Compressed air:Pressure:80 psi (5.6kg/cm2)Flow Rate:21 cfm (0.60m3/min)Compressed air:Pressure:80 psi(5.6kg/cm2)Flow Rate:28 cfm (0.79m3/min)Compressed air:Pressure:80 psi(5.6kg/cm2)Flow Rate:30 cfm(0.85m3/min)Torch & Cable Weight:3.6 lbs. (1.6kg)Torch & Cable Weight:4.0 lbs. (1.8kg)Torch & Cable Weight:5.4 lbs. (2.4kg)Torch & Cable Weight:6.8 lbs. (3.1kg)ORDERING INFORMATIONK2000K3000K4000K5000Torch OnlyTorch w/ 7ft. CableTorch w/ 7ft. Cable &Insulated Hook-Up KitTorch w/ 10ft. CableTorch w/ 10ft. Cable &Insulated Hook-Up 00701-105-00161-105-002N/A61-105-003N/AFEATURES & BENEFITSNatural 15 Torch AngleGreater operator comfortReduced WeightOptimum cable and torch weightto minimize fatigue360 Swivel CableLess cable twistLess strain on operatorHigh Quality Cable HoseBest quality cable hose offershigh heat and abrasion resistancePositive Grip HandleGreater operator feel and ease inpositioning the torchRugged ConstructionOverall rugged construction forthe harsh environmentInternational Customer Care: 905-827-9777 /www.tweco.comFAX905-827-9797page 3

Air Carbon Arc Gouging TorchesAngle-Arc Manual Gouging Torch PartsK5000 TorchK2000, K3000and K4000 Torch(K4000 Shown)Torch Assembly Replacement 0111213141516Complete TorchInsulators & ScrewsUpper InsulatorLower InsulatorLever & ScrewValve BonnetBonnet WrenchBonnet OnlySpool & O-RingsO-Ring (2 Reqd.)Spool OnlyUpper ArmHead & ScrewTorch BodyHinge -Up Kit & PartsItemDescriptionCat No.1234Complete Hook-Up KitMale Gouging ConnectorCable Boot Cap4-WPC-R ConnectorPigtail Air Supply 205Cable Assembly Replacement K50007’ (2.1m) Cable ’ (3m) Cable AssemblyRetainer ScrewO-RingConnectorSpring WasherFlat WasherSwivel SleeveClamp (2 Required)7’ (2.1m) Conductor10’ (3m) Conductor7’ (2.1m) Cover10’ (3m) CoverInsulating BootFemale 1-27494-105-01494-170-15070-084-21094-170-182SEE ABOVESEE 0 and K3000 CableU.S. Customer Care: 800-426-1888 /page 4K4000 CableK5000 CableFAX800-535-0557

Air Carbon Arc Gouging TorchesStraight Handle Manual Gouging TorchesOnly Arcair – the inventor of the original air carbon arc process and the industry leader for 50 years – could bring you the superbmarriage of proven technology and improved design. The K-3 and K-5 are just two torches in a line of gouging and cutting equipmentthat delivers rugged reliability. The addition of superb support and complete technical backup makes Arcair the number one name inair carbon arc manual torches.The K-Model Manual Torches are an essential part of the money-saving air carbon arc metal removal process, which melts metal withan electric arc, then blows it away with a jet of ordinary shop compressed air.These torches are highly efficient metal removal tools for fabrication jobs in steel fabrication plants, shipyards, railroads, farms . . .anywhere people want to save time and money. They speed up weld removal, backgouging, edge preparation, defect repair and manyother metal removal jobs. They are ideal for almost all metals – with little or no deformation – because the heat input is so low.The K-Model Torches offer the reliable and rugged design users expect from Arcair Torches, just pick the best torch to fit yourgouging applications.K-3K-5Medium DutyExtra Heavy DutyAccepts:Pointed Carbons:1/8” (3mm) to 3/8” (10mm)Flat Carbons:3/8” (10mm) & 5/8” (16mm)Accepts:Pointed Carbons:5/32” (4mm) to 5/8” (16mm)Flat Carbons:3/8” (10mm) & 5/8” (16mm)Maximum 600 AmpsMaximum 1250 AmpsCompressed air:Pressure:80 psi (5.6kg/cm2)Flow Rate:21 cfm (0.60m3/min)Compressed air:Pressure:80 psi (5.6kg/cm2)Flow Rate:30 cfm (0.85m3/min)Torch & Cable Weight:4.0 lbs. (1.8kg)Torch & Cable Weight:6.8 lbs. (3.1kg)ORDERING INFORMATIONK-3K-5Torch OnlyTorch w/ 7ft. CableTorch w/ 7ft. Cable &Insulated Hook-Up KitTorch w/ 10ft. CableTorch w/ 10ft. Cable &Insulated Hook-Up 01301-104-00361-104-007N/A61-104-008N/AFEATURES & BENEFITSReliable Torch DesignGreater operator comfortReduced WeightOptimum cable and torch weightto minimize fatigueSwivel CableLess cable twistLess strain on operatorHigh Quality Cable HoseBest quality cable hose offershigh heat and abrasion resistancePositive Grip HandleGreater operator feel and ease inpositioning the torchRugged ConstructionOverall rugged construction forthe harsh environmentInternational Customer Care: 905-827-9777 /www.tweco.comFAX905-827-9797page 5

Air Carbon Arc Gouging TorchesK-Series and Tri-Arc Manual Gouging Torch PartsK-3 and K-5 Torch(K-5 Shown)Tri-Arc TorchHook-Up Kit & PartsTorch Assembly Replacement 1415Complete TorchInsulators & ScrewsHead & ScrewUpper ArmSpringTorch BodyHandleLever & ScrewHinge PinValve & Bonet AssemblySpool & O-RingsO-RingValve BonnetSpanner WrenchAlways ON Valve Assy.Torch E PAGE 794-433-118SEE PAGE 294-960-00194-638-08294-784-045ItemDescriptionCat No.1234Complete Hook-Up KitMale Gouging ConnectorCable Boot Cap4-WPC-R ConnectorPigtail Air Supply 205Cable Assembly Replacement PartsItem123456788991011K-5Tri-Arc STDDescriptionK-37’ (2.1m) Cable ’ (3m) Cable AssemblyRetainer ScrewO-RingMale ConnectorSpring WasherBrass WasherSwivel SleeveClamp (2 Reqd.)7’ (2.1m) Conductor10’ (3m) Conductor7’ (2.1m) Cover10’ (3m) CoverInsulating BootFemale 130-286N/A94-171-284N/A94-105-01994-170-174Tri-Arc EXHDU.S. Customer Care: 800-426-1888 /page 6K-3 CableK-5 CableTri-Arc CableFAX800-535-0557

Air Carbon Arc Gouging TorchesTri-Arc Foundry Gouging TorchesOnly Arcair – the inventor of the original air carbon arc process and the industry leader for 50 years – could bring you the superbmarriage of proven technology and improved design. The Tri-Arc Foundry Torch delivers the rugged reliability. The addition of superbsupport and complete technical backup makes Arcair the number one name in air carbon arc manual torches.The original triple purpose torch is an essential part of the money-saving air carbon arc metal removal process, which melts metalwith an electric arc, then blows it away with a jet of ordinary shop compressed air.This torch is a highly efficient metal removal tool for all the heavy foundry applications . . . anywhere people want to save time andmoney. It speeds up padwashing, removes defects in castings and generally cleans castings of fins, nails and other unnecessarymetal. This process is ideal for almost all metals – with little or no deformation – because the heat input is so low.The Tri-Arc Torch offers one torch body that accepts three types of heads that can be tailored to fit your application best. Need severaltorch types for different applications? No problem the Tri-Arc offers different heads to fit in the same torch body to fit all your needs.No need for maintenance shops and distributors to stock several torches and confuse parts. Again the Tri-Arc gives you the reliableand rugged design users expect from Arcair Torches, just pick the best torch/head combination to fit your gouging applications.Tri-ArcTri-ArcDefect Removal HeadsTri-ArcPadwashing HeadsGeneral Purpose Cleaning HeadsAccepts:Pointed or Jointed Carbons:5/16” (6mm) to 3/4” (20mm)Maximum 2200 AmpsAccepts:Pointed or Jointed Carbons:1/2” (13mm) to 1” (25mm)Maximum 2200 AmpsAccepts:Pointed or Jointed Carbons:5/16” (6mm) to 3/4” (20mm)Maximum 2200 AmpsCompressed air:Pressure:80 psi (5.6kg/cm2)Flow Rate:36 cfm (1.0m3/min)Compressed air:Pressure:80 psi (5.6kg/cm2)Flow Rate:37 cfm (1.0m3/min)Compressed air:Pressure:80 psi(5.6kg/cm2)Flow Rate:40 cfm (1.1m3/min)Torch Weight:2.4 lbs. (1.1kg)Torch Weight:2.4 lbs. (1.1kg)Torch Weight:2.4 lbs. (1.1kg)ORDERING INFORMATIONNo Heads in Torch1/2” (13mm) Electrodes1/2” (13mm) ElectrodesTorch Only02-991-411Torch Only02-991-413Torch OnlyTorch & 7’ (2.1m) Cable62-991-417Torch & 7’ (2.1m) Cable62-991-419Torch & 7’ (2.1m) Cable62-991-422Replacement Heads94-378-286Replacement Heads94-378-2675/8” (16mm) Electrodes02-991-4165/8” (16mm) ElectrodesTorch Only02-991-414Torch Only02-991-417Torch & 7’ (2.1m) Cable62-991-420Torch & 7’ (2.1m) Cable62-991-423Replacement Heads94-378-289Replacement Heads94-378-2705/16” (6mm) to 3/4” (19mm)3/4” (19mm) Electrodes3/4” (19mm) ElectrodesTorch Only02-991-425Torch Only02-991-415Torch OnlyTorch & 7’ (2.1m) Cable62-991-435Torch & 7’ (2.1m) Cable62-991-421Torch & 7’ (2.1m) Cable02-991-41862-991-424Replacement Heads94-378-370Replacement Heads94-378-283Replacement Heads94-378-2731” (25mm) ElectrodesInternational Customer Care: 905-827-9777 /www.tweco.comFAXTorch Only02-991-424Replacement Heads94-378-344905-827-9797page 7

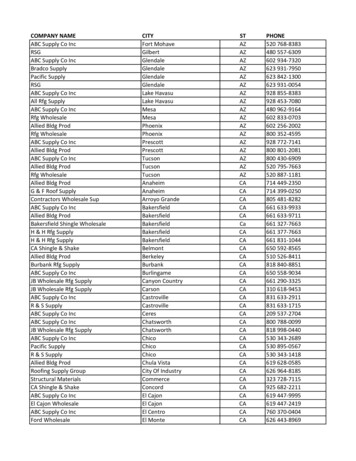

Air Carbon Arc Gouging TorchesCurrent RequirementsCarbonDiameter1/8”3mm5/32”4mmMin. Amps6090Max. hniques for Specific Materials5/8”16mmElectrode TypesDC Copperclad PointedCarbon SteelThis material can be easily gouged or cut using DCEP (reversepolarity). Normal conditions use a 35 electrode to work anglewith a maximum of 7” (17.8cm) electrode stickout. The airblast is always positioned between the electrode and workpiece.Stainless SteelThese alloys can be easily gouged using the same techniquesas described in carbon steel.AluminumThe electrode stickout should be no more than 3” (7.6cm).Be careful not to touch the electrode to the work surface,as a carbon deposit will occur. The finish of the groove/cutwill require a stainless steel brush to remove the black oxide(oxides not carbon) from the area. Recommend using DCCopperclad electrodes on DCEP (reverse polarity). If thisdoesn’t work well, then switch to DCEN (straight polarity).Standard all purposegouging electrode.Controlled coppercoating improvesconductivity providingmore efficient, cooleroperation and helpsmaintain electrodediameter at the pointof the arc.Specially designedfor close tolerancemetal removal.Excellent for removing weld crowns, rivetheads and cladding.Standard all purposegouging electrode.Controlled coppercoating improvesconductivity providingmore efficient, cooleroperation and helpsmaintain electrodediameter at the pointof the arc.Copper Base AlloysHeat dissipation due to high conductivity of these materialsmakes them more difficult to cut or gouge than carbonsteel. Use DC electrodes with DCEN (straight polarity) atthe maximum amperage rating of the electrode or use ACelectrodes with AC.4.0mm x 30.5cm3/16” x 12”4.8mm x 30.5cm1/4” x 12”6.4mm x 30.5cm5/16” x 12”7.9mm x 30.5cm3/8” x 12”9.5mm x 30.5cm1/2” x 14”12.7mm x 35.6cm3/8” x 5/32”x 12”9.5mm x 4.0mmx 30.5cm5/8” x 3/16”x 12”15.9mm x 4.8mmx 30.5cm5/32” x 12”4.0mm x 30.5cm3/16” x 12”4.8mm x 30.5cm1/4” x 12”6.4mm x 30.5cm5/16” x 12”7.9mm x 30.5cm3/8” x 12”9.5mm x 30.5cm1/2” x 14”12.7mm x 35.6cmAC Copperclad PointedSpecially blended,with an added rareearth arc stabilizer, foruse with AC powersupplies.High Nickel AlloysThe higher the nickel content the harder the material is togouge. Use AC electrode on DCEP (straight polarity) or useAC electrodes on AC.800-535-05575/32” x 12”DC Plain PointedThese materials require a special operating procedure whenattempting to gouge with CAC-A. It is recommended that thecurrent range for gouging be 1000 amps or higher. This alsorequires using 1/2” (12.7 mm) diameter carbons or larger.Attempts to gouge with smaller carbons will deposit refractoryslag (gray crystalline surface) resulting in little or no gougingprogress while burning up carbons.FAX3.2mm x 30.5cmDC Copperclad FlatGray, Ductile & Malleable Cast IronU.S. Customer Care: 800-426-1888 /1/8” x 12” 3/16” x 12”4.8mm x 30.5cm1/4” x 12”6.4mm x 30.5cm3/8” x 12”9.5mm x 30.5cmInternational Customer Care: 905-827-9777 /905-827-9797www.tweco.comFAXA Global Cutting & Welding Market Leader WO R L D H E A D Q UA RT E R S :16052 Swingley Ridge Road, Suite 300THE AMERICASDenton, TX USAU.S. Customer CarePh: (1) 800-426-1888Fax: (1) 800-535-0557Miami, FL USASales Office, Latin AmericaPh: (1) 954-727-8371Fax: (1) 954-727-8376West Lebanon, NH USACustomer Care, PlasmaPh: (1) 800-752-7621Fax: (1) 800-221-4401Form No. 89-2200 (12/20/06)EUROPEASIA/PACIFICOakville, Ontario, CanadaInternational Customer CarePh: (1) 905-827-9777Fax: (1) 905-827-9797Chorley, United KingdomCustomer CarePh: (44) 1257-261755Fax: (44) 1257-224800Cikarang, IndonesiaCustomer CarePh: 62 21 8983-0011 / 0012Fax: 62 21 893-6067Rio de Janeiro, BrazilCustomer CarePh: (55) 21-2485-8998Fax: (55) 21-2485-8866Milan, ItalySales OfficePh: (39) 02-98-80320Fax: (39) 02-98-281773Osaka, JapanSales OfficePh: 816-4809-8411Fax: 816-4809-8412 Thermadyne Industries, Inc., 2006 St. Louis, Missouri 63017Melbourne, AustraliaCustomer Care:Ph: 1300-654-674Fax: 613 9474-7391International:Ph: 613 9474-7508Fax: 613 9474-7488www.thermadyne.comRawang, MalaysiaCustomer CarePh: 603 6092-2988Fax: 603 6092-1085U. S. A .Shanghai, ChinaSales OfficePh: 86 21 6280-1273Fax: 86 21 3226-0955SingaporeSales OfficePh: 65 6832-8066Fax: 65 6763-5812Printed in U.S.A.

Hook-Up Kit & Parts Item Description Cat No. Complete Hook-Up Kit 94-463-045 1 Male Gouging Connector 94-170-181 2 Cable Boot Cap 94-105-027 3 4-WPC-R Connector 9425-1427 4 Pigtail Air Supply Hose 94-396-205 K2000, K3000 and K4000 Torch (K4000 Shown) K2000 and K3000 Cable K4000 Cab