Transcription

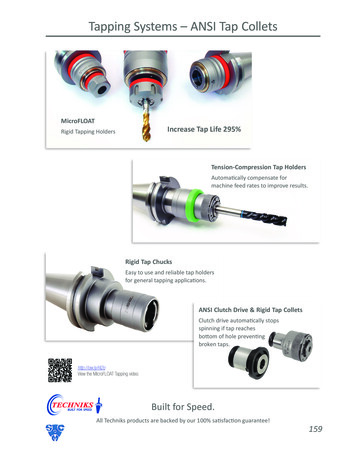

Tapping Systems – ANSI Tap ColletsMicroFLOATIncrease Tap Life 295%Rigid Tapping HoldersTension-Compression Tap HoldersAutomatically compensate formachine feed rates to improve results.Rigid Tap ChucksEasy to use and reliable tap holdersfor general tapping applications.ANSI Clutch Drive & Rigid Tap ColletsClutch drive automatically stopsspinning if tap reachesbottom of hole preventingbroken taps.http://ow.ly/rIi2oView the MicroFLOAT Tapping video.Built for Speed.All Techniks products are backed by our 100% satisfaction guarantee!159

Synchronous Feed Holders for Rigid Tap CyclesMicroFLOAT Tap Holders prevent broken taps increase tap life 295% improve thread qualityStop breaking so many tapsThis graph shows how MicroFLOAT reduces stress on the tap during tapping cycle.Inserti ng Tap300 –without250 –MicroFLOAT150 –100 –B a c ki n g Ou t Ta ptap breakageoccursREVERSAL350 –without MicroFLOATtaps break, damaged threads50 –0 –Force (N)MicroFLOAT 3X less forceSynchronous feed eases the tap through the whole cycle, preventing breakage.160Call 800.597.3921 or 317.803.8000 for a fast friendly quote. Fax: 317.803.8001

Synchronous Feed Holders for Rigid Tap CyclesMicroFLOAT improves CNC Rigid TappingKey Technology FeaturesNo matter how good your machine's tapping cycleis, there are always small mechanical variances thatproduce path inaccuracies during tapping. These variances cause wear on the tap, leading to prematuretap failure and poor thread quality.1. Synchronous Feed – In and OutInternal steel springs ensure maximumstability during tapping cycle.MicroFLOAT synchronous feed holders cushion thesudden shocks taps are subject to, minimizing damage to the tap. MicroFLOAT’s ability to compensatefor feed variances provides unmatched stability.MicroFLOAT is the recommended solution for improving rigid tapping performance and extending tap life.MicroFLOAT Test: 295% more holes per tap!You canexpect similar results500450400350300250During the tapping cycle MicroFLOAT's synchronousfeed technology automatically corrects formechanical variances such as ballscrew play, spindlewear, or material irregularities to produce the truestpossible threads. Internal steel spring compensationallows 0.008" (.2mm) of compression and 0.040"(1mm) of tension, effectively compensating for pathinaccuracies and protecting the tap from metal fatigueand breaking. Because the tap follows the exact samepath both in and out of the hole, optimum threadquality is achieved.2. Quick-change Tap Adapters200150Adapters make tap changes fast and easy. Changetaps in spindle without presetting equipment.100500Machine: Mori Seiki SH403Material: AISI 304Coolant: 7% concentrationCutting speed: 12m/minThread: M6; 12 mm depthTap: UFS, K82M6X-TXC3. Modular extensions achieve lengths up to 9"Quickly combine adapters and extensions to createlengths up to 9 inches without sacrificing accuracy.On a machining center we compared an ER rigidtap holder to a MicroFLOAT holder. The onlydifference was the tool holder. As you can see,the savings are significant. MicroFLOAT yields337 more threaded holes per tap!See MicroFLOAT in action 4. Coolant-thru technologyHigh-pressure (50 Bar) coolant through is standard.http://bit.ly/29e85vZWe stand behind all our CNC tooling solutions from spindle to workpiece.www.techniksusa.com161

How to Order – MicroFLOAT Synchronous Feed HoldersToolholderMicroFLOAT ComponentsMicroFLOAT is an easy to use system that can be expanded to achievelengths of 9" using extensions. Quick-change connection makes tapreplacement fast and easy even in-spindle.Refer to the diagram (right) to identify system components.MicroFLOAT tap holders can be configured three ways:A using a holder with a quick-change tap adapterB holder with a modular body and modular tap adapterC holder with a modular body, extensions, and tap adapterModular BodyATap AdapterBExtensionModular Body2" extension1" extensionCModularTap AdapterModularTap AdapterHow to OrderSelect the MicroFLOAT holder required for your machinespindle and tap size from the table (right).LNOTE: #1 holders fit our #1 ER16 tap adapters, whichcan hold tap sizes up to 3/8".NOTE: #2 holders fit our #2 ER25 tap adapters, whichcan hold tap sizes up to 11/16".For configuration A, (using a holder with a quickchange tap adapter) select the correct quick-changetap adapter from the table below.For configurations B or C, select a modular body, extensionsif needed, (1" or 2" available) and modular quick-changetap adapter from the tables on the next page.Quick-Change Tap Adapter(use for configuration A)ER16 fits taps up to 3/8"ER25 fits taps up to 11/16"Part AT Toolholders#1 holders fit #1 ER16 tap adapters and #1 components.#2 holders fit #2 ER25 tap adapters and #2 components.Part No.DescriptionLDd23400-40CATCAT40 holder #12.75"1.7"0.79"23600-40CATCAT40 holder #23.54"2.36"1.26"23400-50CATCAT50 holder #12.75"1.7"0.79"23600-50CATCAT50 holder #23.54"2.36"1.26"23400-30BTBT30 holder #12.09"1.7"0.79"23400-40BTBT40 holder #12.40"1.7"1.26"23600-40BTBT40 holder #23.22"2.36"1.26"d23400-H63AHSK63A holder #12.52"1.7".79"1.10".79"23400-INC11" Straight Shank holder # 11.3"1.7"0.79"1.65"1.27"23600-INC11" Straight Shank holder # 22.13"2.36"1.26"LDER16 tap adapter #12.16"ER25 tap adapter #23.39"Call 800.597.3921 or 317.803.8000 for a fast friendly quote. Fax: 317.803.8001

MicroFLOAT Components and ER Rigid Tap ColletsLDModular ExtensionsPart No.Modular components are sized #1 and #2#1 holders fit #1 modular components#2 holders fit #2 modular componentsPart No.DescriptionDChuck1" Mod. Extension #1.98".91"23400-.42150-502" Mod. Extension #11.97".91"23400-.42250-502" Mod. Extension #21.97"1.38"23600-.42250-1004" Mod. Extension #23.94"1.38"23600-.LLDdModular BodyL42150-25DescriptionLDdER Modular Tap AdaptersPart No.DdDescriptionLDd23411-MODModular Body MicroFLOAT #1.20".91".79"42147-ER16ER16 Mod. Adapter #11.97"1.10".91"23611-MODModular Body MicroFLOAT #2.28"1.38"1.26"42247-ER25ER25 Mod. Adapter #23.11"1.65"1.38" Square drive prevents spinning the tap High-carbon steel, heat treated for long life Precision ground and polishedER16, ER25 Rigid Tap Collets (metric)ER16, ER25 Rigid Tap Collets (inch)Part No.SizedSQTap Size (d2)Part No.SizedSQTap Size (d2)05320-141ER16.141".110"1/8" or " or " or 2" or 6ER166.25M805510-141ER25.141".110"1/8" or #60538505510-168ER25.168".131"5/32" or 94ER25.194".152"3/16" or #1005534-DIN05510-220ER25.220".165"7/32" or R25.437".328"1/8" 06"11/16"We stand behind all our CNC tooling solutions from spindle to workpiece.www.techniksusa.com163

CAT, BT Tension / Compression Tap HoldersTechniks Quality Features Adjustible compression helps start difficult taps Taper ground to AT3 accuracy or better Quick-Change StyleldANSI TapColletspg. 169TighteningStandspg. 234RetentionKnobspg. 228Wrenchespg. 232AdjustableCompressionCAT Tension / Compression Tap HoldersTapPart mpression32400/40CATCAT40 T/C Holder, Size 10.748"1.5"2.36"10 – 9/16"0.35"0.35"32400/50CATCAT50 T/C Holder, Size 10.748"1.5"2.44"10 – 9/16"0.35"0.35"32600/40CATCAT40 T/C Holder, Size 21.220"2.17"3.94"25/16 – 7/8"0.59"0.59"32600/50CATCAT50 T/C Holder, Size 21.220"2.17"3.27"25/16 – 7/8"0.59"0.59"32800/40CATCAT40 T/C Holder, Size 31.890"3.11"5.43"31/2 – 1-3/8"0.94"0.94"32800/50CATCAT50 T/C Holder, Size 31.890"3.11"5.24"31/2 – 1 3/8"0.94"0.94"32900/40CATCAT40 T/C Holder, Size 42.362"3.86"6.06"41-7/16 – 1-7/8"1.02"1.02"32900/50CATCAT50 T/C Holder, Size 42.362"3.86"5.79"41-7/16 – 1-7/8"1.02"1.02"BT Tension / Compression Tap HoldersTapPart yTensionCompressionBT30 T/C Holder, Size 10.748"1.5"2.48"10 – 9/16"0.35"0.35"32400/40BTBT40 T/C Holder, Size 10.748"1.5"2.68"10 – 9/16"0.35"0.35"32400/50BTBT50 T/C Holder, Size 10.748"1.5"3.15"10 – 9/16"0.35"0.35"32600/30BTBT30 T/C Holder, Size 21.220"2.17"3.78"25/16 – 7/8"0.59"0.59"32600/40BTBT40 T/C Holder, Size 21.220"2.17"3.66"25/16 – 7/8"0.59"0.59"32600/50BTBT50 T/C Holder, Size 21.220"2.17"4.02"25/16 – 7/8"0.59"0.59"32800/40BTBT40 T/C Holder, Size 31.890"3.11"5.43"31/2 – 1-3/8"0.94"0.94"32800/50BTBT50 T/C Holder, Size 31.890"3.11"5.31"31/2 – 1-3/8"0.94"0.94"32900/40BTBT40 T/C Holder, Size 42.362"3.86"6.18"41-7/16 – 1-7/8"1.02"1.02"32900/50BTBT50 T/C Holder, Size 42.362"3.86"5.79"41-7/16 – 1-7/8"1.02"1.02"164Call 800.597.3921 or 317.803.8000 for a fast friendly quote. Fax: 317.803.8001D

HSK & Straight Shank Tension / Compression Tap HoldersTechniks Quality Features Adjustible compression helps start difficult taps Quick-Change StylelDdAdjustableCompressionHSK A Tension / Compression Tap HoldersTapPart izeCapacityTensionCompressionHSK40A T/C Holder, Size 10.748"1.5"3.14"10 – 9/16"0.295"0.295"HSK50A T/C Holder, Size 10.748"1.5"2.83"10 – 9/16"0.295"0.295"34400/H63AHSK63A T/C Holder, Size 10.748"1.5"2.83"10 – 9/16"0.295"0.295"34400/H100AHSK100A T/C Holder, Size 10.748"1.5"3.14"10 – 9/16"0.295"0.295"34600/H50AHSK50A T/C Holder, Size 21.22"2.17"4.33"25/16 – 7/8"0.393"0.393"34600/H63AHSK63A T/C Holder, Size 21.22"2.17"4.33"25/16 – 7/8"0.393"0.393"34600/H100AHSK100A T/C Holder, Size 21.22"2.17"3.94"25/16 – t Shank Tapping ChucksTapCompensationPart /INC11" shank T/C Holder, Size 11.00"1.5"1.76"1.95"0 – 9/16"0.35"0.35"32600/INC11" shank T/C Holder, Size 21.00"2.17"2.52"2.00"5/16 – 7/8"0.59"0.59"32600/INC1-1/21 1/2" shank T/C Holder, Size 21.50"2.17"2.52"3.50"5/16 – 7/8"0.59"0.59"32800/INC1-1/21 1/2" shank T/C Holder, Size 31.50"3.38"3.85"3.50"1/2 – 1 3/8"0.94"0.94"We stand behind all our CNC tooling solutions from spindle to workpiece.www.techniksusa.com165

CAT, BT Rigid Tap HoldersTechniks Quality Features Taper ground to AT3 accuracy or better Quick-Change StylelANSI TapColletspg. 169TighteningStandspg. 234RetentionKnobspg. 228dWrenchespg. 232DCAT Rigid Tap HoldersPart No.DescriptionlDdSizeTap Capacity21480/40CAT21480/50CATCAT40 Rigid Tap Holder, Size 12.59"1.31"0.748"10 – 9/16"CAT50 Rigid Tap Holder, Size 12.95"1.31"0.748"10 – 9/16"21680/40CATCAT40 Rigid Tap Holder, Size 23.23"1.97"1.22"25/16 – 7/8"21680/50CATCAT50 Rigid Tap Holder, Size 23.86"1.97"1.22"25/16 – 7/8"21880/40CATCAT40 Rigid Tap Holder, Size 34.80"2.83"1.89"31/2 – 1 3/8"21880/50CATCAT50 Rigid Tap Holder, Size 34.80"2.83"1.89"31/2 – 1-3/8"lDdSizeTap CapacityBT Rigid Tap HoldersPart No.Description21480/30BTBT30 Rigid Tap Holder, Size 12.80"1.31"0.748"10 - 9/16"21480/40BTBT40 Rigid Tap Holder, Size 12.63"1.31"0.748"10 - 9/16"21480/50BTBT50 Rigid Tap Holder, Size 13.07"1.31"0.748"10 - 9/16"21680/30BTBT30 Rigid Tap Holder, Size 23.70"1.97"1.22"25/16 - 7/8"21680/40BTBT40 Rigid Tap Holder, Size 23.54"1.97"1.22"25/16 - 7/8"21680/50BTBT50 Rigid Tap Holder, Size 23.97"1.97"1.22"25/16 - 7/8"21880/40BTBT40 Rigid Tap Holder, Size 34.61"2.83"1.89"31/2 - 1 3/8"21880/50BTBT50 Rigid Tap Holder, Size 34.80"2.83"1.89"31/2 - 1 3/8"166Call 800.597.3921 or 317.803.8000 for a fast friendly quote. Fax: 317.803.8001

HSK and Straight Shank Rigid Tap HoldersTechniks Quality Features Quick-Change StylelDdHSK Rigid Tap HoldersPart No.DescriptionlDdSizeTap Capacity21480/H50AHSK50A Rigid Tap Holder, Size 12.30"1.31"0.748"10 - 9/16"21480/H63AHSK63A Rigid Tap Holder, Size 12.32"1.31"0.748"10 - 9/16"21480/H100AHSK100A Rigid Tap Holder, Size 12.95"1.31"0.748"10 - 9/16"21680/H50AHSK50A Rigid Tap Holder, Size 23.23"1.97"1.22"25/16 - 7/8"21680/H63AHSK63A Rigid Tap Holder, Size 23.23"1.97"1.22"25/16 - 7/8"21680/H100AHSK100A Rigid Tap Holder, Size 23.86"1.97"1.22"25/16 - 7/8"21880/H63AHSK63A Rigid Tap Holder, Size 34.80"2.83"1.89"31/2 - 1 3/8"21880/H100AHSK100A Rigid Tap Holder, Size 34.80"2.83"1.89"31/2 - 1 3/8"lLDdd1Straight Shank Rigid Tap HoldersPart No.Descriptiond1LlDdTap Capacity21480/INC11" shank, Rigid Tap Holder, Size 11.00"1.95"1.60"1.31".748"0 – 9/16"21680/INC11" shank, Rigid Tap Holder, Size 21.00"2.00"2.50"1.97"1.22"3/8 – 7/8"21880/INC1-1/21 1/2" shank, Rigid Tap Holder, Size 31.50"3.50"3.44"2.83"1.89"1/2 – 1 3/8"We stand behind all our CNC tooling solutions from spindle to workpiece.www.techniksusa.com167

ANSI Clutch Drive Tap ColletsANSI Clutch Drive Tap Collet Features Prevents broken taps Automatically stops spinning whenbottom is reached Change worn taps in secondsDimensionsNote: Metric tap collets availableon request. Please verify shankdiameter when ordering metrictap collets.ABCDESize 0.51".77".83".91".24"Size 1.75".85".98"1.26".31"Size 21.22"1.38"1.34"1.97".16"Size 31.89"2.19"1.77"2.83".04"Collet SetPart No.Description48/3-SETSize 3, 16 piece set – 1/2" thru 1" NPTANSI Clutch Drive Tap ColletsANSIMetric Tap / ANSI ShankShankSQSize 0Size 10-6"M1.6-M3.50.141"0.110"13/0-403619/1-40368, 5/32"M40.168"0.131"13/0-404119/1-404110, 3/16"M4.5, 05419/1-405413/0-406319/1-406312, 7/32"Size 2Size 31/4"M6, M6.30.255"0.191"5/16"M7, /2-41111/2"M12, /3-42381"M250.800"0.600"48/3-42541 1/8, 1 1/16"M270.896"0.672"48/3-42861 1/4, 1 3/16"M301.021"0.766"48/3-43171 3/8, 1 5/16"M331.108"0.831"48/3-43491/8" NPT0.437"0.328"1/4" NPT0.562"0.421"31/2-4131C3/8" NPT0.700"0.531"31/2-4166C48/3-4166C1/2" NPT0.687"0.515"31/2-4209C48/3-4209C3/4" NPT0.906"0.678"48/3-4264C1" NPT1.125"0.843"48/3-4332C16819/1 - 4097Call 800.597.3921 or 317.803.8000 for a fast friendly quote. Fax: 317.803.8001

ANSI Rigid Tap Collets Change worn taps in seconds Quick-Change StyleDimensionsABCDESize 1.75".85".28"1.18".39"Size 21.22"1.38".43"1.81".75"Size 31.89"2.19".55"2.68"1.18"Size 42.36"2.48"1.65"3.27"1.14"Collet SetsPart No.19/11-SETANSI Rigid Tap ColletsDescriptionSize 1, 11 piece set – 0-6" thru 9/16" & 1/8" NPT31/12-SETSize 2, 13 piece set – 5/16" thru 1/2" NPT48/13-SETSize 3, 16 piece set – 1/2" thru 1" NPTANSIMetric Tap / ANSI ShankShankSQSize 10-6"M1.6-M3.50.141"0.110"19/11-40368, 5/32"M40.168"0.131"19/11-404110, 3/16"M4.5, M50.194"0.152"19/11-40480.220"0.165"19/11-405412, 7/32"Size 21/4"M6, M6.30.255"0.191"19/11-40635/16"M7, 11131/12-4111Size 31/2"M12, "0.406"31/12-417448/13-41743/4"Size 250.800"0.600"48/13-42541 1/8, 1 1/16"M270.896"0.672"48/13-42861 1/4, 1 3/16"M301.021"0.766"48/13-43171 3/8, 1 5/16"M331.108"0.831"48/13-43491 1/2, 1 7/16"M361.233"0.925"60/14-4381C1 5/8"M391.305"0.979"60/14-4412C1 3/4"M421.430"1.072"60/14-4444C1 7/8"1.520"1.139"60/14-4476C1/8" NPT0.437"0.328"1/4" NPT0.562"0.421"31/12-4131C3/8" NPT0.700"0.531"31/12-4166C48/13-4166C1/2" NPT0.687"0.515"31/12-4209C48/13-4209C3/4" NPT0.906"0.678"48/13-4264C1" NPT1.125"0.843"48/13-4332C19/11-4097We stand behind all our CNC tooling solutions from spindle to workpiece.www.techniksusa.com169

Tightening Torque Specifications ChartRecommended Collet & Retention Knob Tightening TorqueColletNut TypeCollets I.D.OVER 1/16"(2mm)ER16slotted42 ft/lbs30 ft/lbs04580-16ER16hex42 ft/lbs30 ft/lbs04601-16ER20slotted59 ft/lbs24 ft/lbs04580-20ER20hex59 ft/lbs24 ft/lbs04602-20ER25slotted77 ft/lbs77 ft/lbs04503-25ER25mini nut25 ft/lbs25 ft/lbs04587ER32slotted100 ft/lbs100 ft/lbs04604-32ER40slotted130 ft/lbs130 ft/lbs04605-40SYOZ 25hook90 ft/lbs90 ft/lbs03690-25TG 75slotted90 ft/lbs90 ft/lbs04604-32TG 100hook90 ft/lbs90 ft/lbs03690-25Retention Knobs Wrench FlatsCollets I.D.UNDER 1/16"(2mm)Order TorqueWrench AdapterDriveTorqueOrder SocketBT30 Taper0.535"1/4"36 ft/lbsPSS-30BTISO 30 Taper0.535"3/8"36 ft/lbsPSS-30ISOAny 40 Taper0.750"3/8"76 ft/lbsPSS-40BT50 Taper1.187"1/2"99 ft/lbsPSC-50CAT50 Taper1.250"1/2"99 ft/lbsPSC-50170For maximum holding power fill the collet allthe way with the tool shank (left) and use aPowerCOAT nut.DIRECTIONS1. Snap collet into nut.2. Insert cutting tool into collet.Make sure shank extends to thebottom of the collet.3. Hand tighten collet nutassembly into toolholder.4. Insert toolholder assembly intotightening fixture and secure it.5. Tighten collet nut torecommended torque using atorque wrench andadapter.Call 800.597.3921 or 317.803.8000 for a fast friendly quote. Fax: 317.803.8001

We stand behind all our CNC tooling solutions from spindle to workpiece. wwwtechniksusacom 161 Synchronous Feed Holders for Rigid Tap Cycles Internal steel springs ensure maximum stability during tapping cycle. Key Technology Features 1. Synchronous Feed – In and Out During th