Transcription

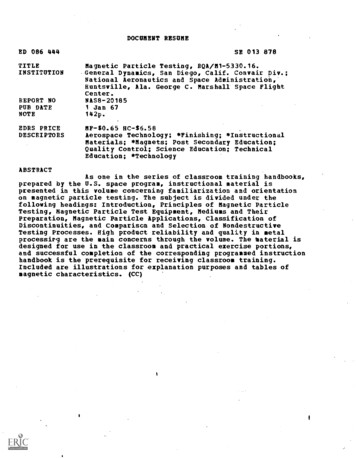

DOCUMENT RESUMEED 086 444TITLEINSTITUTIONREPORT NOPUB DATENOTEEDRS PRICEDESCRIPTORSSE 013 878Magnetic Particle Testing, RQA/P11-5330.16.General Dynamics, San Diego, Calif. Convair Div.;National Aeronautics and Space Administration,Huntsville, Ala. George C. Marshall Space FlightCenter.NAS8-201851 Jan 67142p.MF- 0.65 HC- 6.58Aerospace Technology; *Finishing; *InstructionalMaterials; *Magnets; Post Secondary Education;Quality Control; Science Education; TechnicalEducation; *TechnologyABSTRACTAs one in the series of classroom training handbooks,prepared by the U.S. space program, instructional material ispresented in this volume concerning familiarization and orientationon magnetic particle testing. The subject is divided under thefollowing headings: Introduction, Principles of Magnetic ParticleTesting, Magnetic Particle Test Equipment, Mediums and TheirPreparation, Magnetic Particle Applications, Classification ofDiscontinuities, and Comparison and Selection of NondestructiveTesting Processes. High product reliability and quality in metalprocessirg are the main concerns through the volume. The Material isdesigned for use in the classroom and practical exercise portions,and successful completion of the corresponding programmed instructionhandbook is the prerequisite for receiving classroom training.Included are illustrations for explanation purposes and tables ofmagnetic characteristics. (CC)

JanuaryQUALITY ANDI ,U S DEPARTMENT OF HEALTH.EDUCATION 8 WELFARENATIONAL INSTITUTE OFEDUCATIONRELIABILITY ASSURANCELABORATORYTHIS DOCUMENT HAS fIEFN REPROOUCED EXACTLY AS RECEIVED FROMTHE PERSON OR ORGANIZATION ORIGINATiNG IT POINTS OF VIEW ON OPINIONSSTATED DO NOT NECESSARILY REPRESENT OFFICIAL NATIONAL INSTITUTE OFEDUCATION POSITION OR POL ICYMAGNETIC PARTICLE TESTINGRQA/M1 - 5330 .16sameAlARRIALLNOWINVILM ALABAMANATIONAL AERONAUTICS AND SPACE ADMINISTRATIONMSFt - Form 1262 (September 1961)1967

5330. 16PREFACEClassroom Training Handbook - Magnetic Pakic le Testing (5330. 16) is one of aseries of training handbooks designed for use in the classroom and practical exerciseportions of Nondestructive Testing. It is intended that this handbook be used in theinstruction of those persons who have successfully completed Programmed InstructionHandbook - Magnetic Particle Testing (5330. 11).Although formal classroom training ii -not scheduled at the present time, this handbook contains material that is beneficial to personnel engaged in Nondestructive Testing.NASA's programs involve tightly scheduled procurement of only small quantities ofspace vehicles and ground support equipment, requiring the extreme in reliability forthe first as well as later models. The failure of one article could result in missionfailure. This requirement for complete reliability necessitates a thoroughly disciplined approach to Nondestructive Testing.,A major share of the responsibility for assuring such high levels of reliability lieswith NASA, other Government agencies, and contractor Nondestructive Testing personnel. These are the people who conduct or monitor the tests that ultimately confirmor reject each piece of hardware before it is committed to its mission. There is noroom for error no chance for reexamination. The decision must be rightunquestionablythe first time.General technical questions concerning this publication should be referred to theGeorge C. Marshall Space Flight Center, Quality and Reliability Assurance Laboratory, Huntsville, Alabama 35812.The recipient of this handbook is encouraged to submit recommendations for updatingand comments for correction of errors in this initial compilation to George C.Marshall Space Flight Center, Quality and Reliability Assurance Laboratory(R-QUAL-OT), Huntsville, Alabama 35812.1

5330.16ACKNOWLEDGMENTSThis handbook was prepared by the Convair Division of General Dynamics Corporationunder NASA Contract NAS8-20185. Assistance in the form of process data, technicalreviews, and technical advice was provided by a great many companies and individuals.The following listing is an attempt to acknowledge this assistance and to express ourgratitude for the high degree of interest exhibited by the firms, their representatives,and other individuals who, in many cases, gave considerable time and effort to theproject.Aerojet-General Corp.; Automation Industries, Inc., Sperry Products Division;AVCO Corporation; The Boeing Company; Douglas Aircraft Co., Inc.; Grumman Aircraft; Lockheed Aircraft Co.; Magnaflux Corp.; The Martin Co. (Denver); McDonnellAircraft Corp.; North American Aviation, Inc.; Rohr Corporation; Southwest ResearchInstitute; St. Louis Testing Laboratories, Inc.; Uresco, Inc.; X-Ray Products Corp.ii

5330.16CLASSROOM TRAINING HANDBOOKMAGNETIC PARTICLE TESTINGCHAPTER 1INTRODUCTIONCHAPTER 2PRINCIPLES OF MAGNETIC PARTICLE TESTINGCHAPTER 3MAGNETIC PARTICLE TEST EQUIPMENTCHAPTER 4MEDIUMS AND THEIR PREPARATIONCHAPTER 5MAGNETIC PARTICLE APPLICATIONSCHAPTER 6CLASSIFICATION OF DISCONTINUITIESCHAPTER 7COMPARISON AND SELECTION OF NDT PROCESSES

5330.16CHAPTER 1: INTRODUCTIONTABLE OF ERALPURPOSEDESCRIPTION OF CONTENT1. Arrangement2. LocatorsINDUSTRIAL APPLICATIONS OF MAGNETIC PARTICLE TESTINGTESTING PHILOSOPHYPERSONNELTESTING CRITERIATEST PROCEDURESTEST OBJECTIVEPage1-31-31-31-31-31-41-41-41-41-41-5

5330.16CHAPTER 1:100INTRODUCTIONGENERALThe complexity and expense of space programs dictate fabrication and testing procedures that insure reliability of space vehicles and associated ground support equipment. Nondestructive testing (testing without destroying) provides many of theseprocedures. Of the number of nondestructive test procedures available, the magneticparticle tests, with which this handbook is concerned, is one of the oldest nondestructive test methods and a proven tool.s101PURPOSEThe purpose of this handbook is to provide the fundamental knowledge of magneticparticle testing required by quality assurance and tes', personnel to enable them to:ascertain that the proper test technique, or combination of techniques, is used toassure the quality of the finished product; interpret, evaluate, and make a sound decision as to the results of test; and recognize .those areas of doubtful test results thatrequire either retest or assistance in interpretation and evaluation.1021.DESCRIPTION OF CONTENTSARRANGEMENTThe material contained in this handbook is presented in a logical sequence and consistsof:2.a.Chapter 1:Introduction and testing philosophyb.ChapterPrinciples of magnetic particle testing, describing theory,fields, current and demagnetizationc.Chapter3:Magnetic particle test equipment, equipment and accessoriesconsideration, and their operationd.Chapter 4:Mediums, their characteristics, application, and preparatione.Chapter5:Magnetic particle applications, classification of magnetizationmethods, surface preparation, and demagnetization requirementf.Chapter6:Magnetic particle indications, their characteristics, classification by origin, and preservation0.Chapter7:Comparison and selection of NDT processesLOCATORSThe first page ,3f each chapter consists of a table of contents for the chapter. Majorparagraphs, figures, and tables are listed in each table of contents.1-3

5330.16103INDUSTRIAL APPLICATIONS OF MAGNETIC PARTICLE TESTINGBecause magnetization of certain metals is possible, a medium having magnetic attraction is applied to the surface of the test object Ater or during induction of a magneticfield, thereby detecting certain discontinuities which are present in the material. Sincemagnetic particle testing is capable of revealing discontinuities (variations in materialcomposition) economically, it is one of the most used nondestructive test methods.104TESTING PHILOSOPHYThe basic reason for use-of nondestructive testing is to assure maximum reliabilityof space and associated ground supporting hardware, fabricated of many materials. Toaccomplish such reliability, standards have been set and test results must meet theserigid NASA standards.105PERSONNELIt is imperative that personnel responsible for magnetic particle testing be trained andhighly qualified with a technical understanding of the test equipment, the item undertest (specimen), and the test proceddres. Quality assurance personnel must beequally qualified. To make optimum use of magnetic particle testing, personnel conducting tests must continually keep abreast of new developments. There is no substitute for knowledge.106TESTING CRITERIAWhen required by appropriate documentation, .every vehicle and support articlemust be tested using applicable Nondestructive Testing techniques. The criteria is part of a building block test philosophy which dictates that each itemmust be tested individually before it is required to perform in sub-assemblieswhich are in turn tested individually before they are required to perform inassemblies. Using this approach, unsatisfactory and faulty articles are discovered at the earliest possible time, resulting in higher system reliabilityand reduced cost.107TEST PROCEDURESApproved procedures for magnetic particle testing are formulated from analysis of thetest specimen, review of past history, experience on like or similar specimens, andinformation available concerning similar specimen discontinuities. It is the responsibility of personnel conducting or checking test to insure that test procedures areadequately performed, and that the test objective is accomplished. Procedures foundincorrect or inadequate must be brought to the attention of responsible supervisiOnfor correction and incorporation into revised procedures.1-4

5330.16108TEST OBJECTIVEThe objective of magnetic particle testing is to insure product reliability by providing a means of:1.a.Obtaining a visual image of an indication related to a discontinuity in or onthe surface of a material.b.Disclosing the nature of discontinuities without impairing the material.c.Separating acceptable and unacceptable material in accordance with predetermined standards.2. No test is successfully completed until an evaluation of the test results is made.Evaluation of test procedures and results requires understanding of the test objective.1-5

5330.16CHAPTER 2:PRINCIPLES OF MAGNETIC PARTICLE TESTINGTABLE OF CONTENTSParagraph2002011GENERALTHEORY OF MAGNETISM1. General2. Magnetic Poles3. Magnetic Field4. Lines of Force5. Longitudinal Magnetization6. Horseshoe MagnetVector FieldConsequent Poles9. Distorted Fields10. Leakage Fields7.g.202203MAGNETIC MATERIALSELECTRICALLY INDUCED MAGNETIC FIELDS1. General2.Right-Hand Rule3.4.Coil5.Magnetic FluxFlux DensityPermeabilityReluctanceResidual MagnetismRetentivity10. Coercive Force6.7.8.9.204HYSTERESIS. LOOP1.2.3.205GeneralVirgin CurveResidual MagnetismCoercive ForceReversed Polarity4.5.6. Curve CharacteristicsCIRCULAR. AND LONGITUDINAL MAGNETIZATION1. GeneraLMagnetization3. Longitudinal MagnetizationPage2-52-52-52 -52-62 -62-72-72-72-82-82-92-102-102-102 -112 -112-112 -122-122-122-122 62-1

5330.16TABLE OF CONTENTS (CONT)Paragraph200PageFIELD DISTRIBUTION IN MAGNETIC ANDNONMAGNETIC CONDUCTOR S1.2.3.4.5.GeneralSolid Nonmagnetic ConductorSolid Magnetic ConductorHollow Nonmagnetic ConductorHollow Magnetic Conductor(3.Alternating Current Field DistributionDirect Current Residual FieldsAlternating Current Field Distributio,-7.8.207MAGNETIZING CURRENT CHARACT1AISTICS2 -172 -172 -192 -192 -219 912 -2293.4Penetration Characteristics2-242.CURRENT REQUIREMENTS1.2.342099 -1 {2GeneralAlternating CurrentHalf-Wave Rectifie.1 Current.1.2082 -16GeneralCircular MagnetizationLongitudinal MagnetizationProd MagnetizationTHEORY OF DEMAGNETIZATION1.2.3.4.Figure 2-1Figure 2-2Figure 2-3Figure 2-4Figure 2-5Figure 2-6Figure 2-7Figure 2-8Figure 2-9Figure 2-10Figure 2 -11Figure 2-12Figure 2-132 -292 -239 9,12 -242 -952-962-282-28GeneralAlternating Current DemagnetizationDirect Current DemagnetizationEfficiency of Demagnetization2 -282 -28Orientation of MoleculesAttraction and RepulsionMagnetic Field Surrounding Bar MagnetPoles in Straight Bar, Horseshoe, and Broken MagnetVector Field DiagramConsequent PolesCut and Fused Bar-Magnet Illustrating Opposite PolarityLeakage Fields Around DiscontinuitiesRight-Hand RuleLongitudinal Field Around CoilThe Hysteresis Curve2-5,,Hysteresis Loop CharacteristicsCircular Magnetization by Direct andIndirect Current 2-142-152-2

5330.16TABLE OF CONTENTS (CONT)ParagraphFigure 2-14Figure 2-15Figure 2-16Figure 2-17PageLongitudinal MagnetizationField Distribution In and Around a Nonmagnetic ConductorField Distribution In and Around a Solid Magnetic ConductorField Distribution In and Around a Hollow NonMagneticConductorField Distribution In and Around a Hollow Magnetic Conductor .Field Distribution In and Around a Hollow Magnetic CylinderWith Central ConductorField Distribution In and Around Solid Magnetic Conductor2-162-172-182-20Figure 2-26Figure 2-27Carrying Alternating CurrentField Distribution In and Around a Hollow Magnetic ConductorCarrying Alternating CurrentSingle Phase Alternating Current Wave-FormRectification of Alternating Current to Half-WaveDirect CurrentThreshold Sensitivities of Various MetalsCircular Magnetization of Typical Specimens Using Head-Shotor Central ConductorDemagnetization Flux-Curve Projected from Hysteresis CurveDemagnetization CoilTable 2-1Table 2-2Magnetic Characteristics of, MaterialsMagnetizing Current for Sdlid and Tubular ArticlesFigure 2-18Figure 2-19Figure 2-20Figure 2-21Figure 2-22Figure 2:-23Figure 2-24Figure 2-254,2-3

5330.16CHAPTER 2:200PRINCIPLES OF MAGNETIC PARTICLE TESTINGGENERALMagnetic particle testing is a relatively easy and simple test method that can be appliedto finished articles, billets, hot rolled bars, and forgings. It can also be used tocheck processing operations, such as heat treat, machining, and grinding. Magneticparticle testing consists of magnetization of the article, application of a magneticmedium, and interpretation of the magnetic medium patterns.2011.THEORY OF MAGNETISMGENERALAn object is magnetized when part or all of its molecules have their north and southpoles oriented. (See Figure 2-1.)sicilVsNepIssoNeoQNeSeNeSeNeSeNeSe e&ebG01)G00eeeeeeeee o eRANDOM ORIENTATION OF MOLECULESALIGNED MOLECULESFigure 2-1. Orientation of Molecules2.MAGNETIC POLESA body which possesses the ability to attract iron pieces is called a magnet. Magnetsmay be permanent, retaining their magnetism more or less permanently; or temporary, retaining their magnetism only as long as a magnetizing force is being applied.The ability of the magnet to attract or repel is not uniform over its surface, but isconcentrated at local areas called poles. Each magnet has at least two opposite poles,which are attracted by the earth's magnetic poles; hence, the poles are respectivelycalled the north and south poles. The attraction and repulsion of poles are illustratedin Figure 2-2.2-5

5330.16NREPELNATTRACTNNFigure 2-2. Attraction and Repulsion3.MAGNETIC FIELDA magnetic field exists within and around a permanent magnet or around a conductorcarrying an electric current. The magnetic field surrounding a permanent bar magnet has polarity, but the magnetic field surrounding a conductor does not. As anexample, the earth itself can be thought of as a bar magnet because of its two poles.Quite frequently the field surrounding the earth strongly magnetizes large ferromagnetic objects that lie aligned with the earth's poles for periods of time.4.LINES OF FORCEThe concept of lines of force is useful for describing a magnetic field. As illustratedin Figure 2-3, a bar magnet is covered with a sheet of paper and iron filings are- - .,. .N. \\\ il/ / /i\\ \ \\ N\\\\N,/ 4, z//J /1///////!///I\ \,,,. \\\\\.\\\\,,\iiii,///, y,////:/z'-,/,':z'1 /1I''/2-----.:---.;-:\,a\I\i'.\\IiiiiiVii,i.t1,-!% --1*v .%1--.f.7 - ----- ------------: ------w-'----'------. -"--fromIrrv\\: -- --//- ,,,-;,/,/,7- ---- -%.,I, I,---,---,.,,,/filifi\li // '//7 1/II\\.,., ,\\\\\\///,/,11\II\\Figure 2-3. Magnetic Field Surrounding Bar Magnet2-6-----1.4 ;--------:--- ----\\ \\ \

5330.16scattered over the paper. The Lines of force arrange themselves in characteristicpatterns. They never cross; they seek the path of least resistance; they are mostdenSely packed at the poles of the magnet; and they flow from north to south outsidethe magnet, but from south to north within the magnet.5.LONGITUDINAL MAGNETIZATIONA permanent bar magnet is the Aimplest example of longitudinal magnetization. Sincethe direction of the magnetic flux is axial, it usually has two poles. Longitudinalmagnetization is said to exist in an object when the flux lines traverse in a directionessentially parallel to one of its axes.G.HORSESHOE MAGNETIf a straight bar magnet is bent, it becomes a horseshoe magnet. When the magnet isbent further to make a complete loop and the ends are fused together, the polesdisappear; i, e. a closed magnetic circuit is formed. If the circle is cut, eitherpartially or all the way through, the poles reappear as shown in Figure 2-4.WILL LIFT OR DRAW A NAILTO THE MAGNETFIELD IS ENTIRELYWITHIN, THUS NOEXTERNAL FORCELEAKAGE FIELD WILLATTRACT MAGNETICPARTICLESFigure 2-4. Poles in Straight Bar, Horseshoe, and Broken Magnet7,VECTOR FIELDTwo magnetizing fr.-ces may be imposed simultaneously upon the area of a magnetizable object. When this occurs, the two fields do not exist independently; that is, theobject is not magnetized in two directions at once, but a vector field is formed whichis the esultant in direction and strength of the two imposed fields. This phenomenonis illustrated in Figure 2-5, where Fa is the first magnetizing force, Fb, the secondmagnetizing force, and Fab equals the resultant magnetizing force.2-7

5330.16Figure 2-5. Vector Field Diagram8.CONSEQUENT POLESConsequent poles exist when more than two poles are present simultaneously in amagnetized object. For example, there may be two north poles and one south pole.Figure 2-6 illustrates a series of poles along the length of an article. Herein lies theprinciple of magnetic particle testing, since under test particle build-up occurs ateach of the poles.9.DISTORTED FIELDWhile it is normal to conceive of magnetic fields as being either circular or longitudinal in many cases the actual field is a combination of the two. This is known as adistorted field. Distorted fields may be produced intentionally, or they may beFigure 2-6. Consequent Poles2-8

5330. 16unavoidable. When produced intentionally, they are of great value in accomplishingthe desired result, which is to produce a magnetic field at an angle to the direction ofa possible discontinuity. Distorted fields are often helpful and, in some instancesessential to the success of certain magnetic particle test procedures.10.LEAKAGE FIELDThe magnetic field around a bar magnet is shown in Figure 2-2. If a bar magnet isbroken in two, making two shorter bars, each immediately becomes a separate barmagnet with a north and a south pole. If the two bars are again fused together, withopposite magnetic poles adjacent, the poles will not completely disappear. A smallconcentrated leakage field will remain in the fusion area. (See Figure 2-7.) Similarly, if the bar is cut only Partially through two opposite poles will appear, and aleakage field will exist in the area of the cut. From Figure 2-8 it can be seen thatNSSNSSNSNNFigure 2-7. Cut and Fused Bar-magnet Illustrating Opposite PolaritySLOTMAGNETIC PARTICLEBUILD-UPFigure 2-8, Leakage Fields Around Discontinuities2- 9

5330.16leakage fields are actually magnetic lines of force that leave the bar and pass throughthe air from one pole to the other of opposite polarity Since the new opposite poleswere created by the interruption of the paths of the lines of force within the magnet;it follows then that nonmetallic inclusions in a magnetized article, or changes in thematerial of the article, will also cause the creation of two opposite poles and a resultant leakage field. Magnetic particle testing is a process used to detect thepresence of leakage fields and thereby the presence of discontinuities, either voids orinclusions.202MAGNETIC MATERIALSSome materials are attracted by a magnet, while others are repelled. From thedefinition of magnetism it follows that magnetic materials are those which are attractedby magnetism. These materials are known as paramagnetic materials, whereas materials which repel are known as diamagnetic materials. In the realm of magneticparticle testing, the subdivision of, paramagnetic, also called ferromagnetic, is a mainconcern, as only ferromagnetic materials can be strongly magnetized. In Table 2-1,the characteristics of diamagnetic and paramagnetic materials are shown.Table 2-1. Magnetic Characteristics of Materials.DIAMAGNETIC MATERIALSPARAMAGNETIC MATERIALSCANNOT BE MAGNETIZEDCAN BE MAGNETIZEDARE REPELLED BY MAG.NETISMARE AFFECTED BY MAGNETICFIELDSSUB-CLASS OF PARAMAGNETIC(FERROMAGNETIC) MATERIALSCAN BE STRONGLY MAGNETIZEDARE STRONGLY ATTRACTED TOMAGNETIC FIELDSCAN BE MAGNETIC PARTICLETLSTED2031.ELECTRICALLY INDUCED MAGNETIC FIELDSGENERALWhen an electric current passes through a conductor, a magnetic field is formedaround the conductor. If the conductor has a uniform shape (a copper rod), the densityof the field, i. e. , number of lines of force per unit area, is uniform at any pointalong the conductor, and it uniformly decreases as the distance from the electricalconductor increases. Direction of the magnetic field (lines of force), is at a 90 degree2-10

5330. 1.6angle to that of the current in the condubtor.NOTE:2.For the purpose of simplicity throughout this handbook, magnetizing forceis considered to be the total electrical force required to set up a flux in amagnetic circuit. It is usually designated by the letter (H).RIGHT HAND RULEAn easy method for finding the direction of an electrically induced magnetic field is toimagine grasping the conductor in the right hand with the thumb pointing in the direction of current flow. The fingers will then point in the direction of the lines of force.This is the right-hand rule and is shown in Figure 2-9. From this figure it can beseen that the current flow in the conductor creates circular lines of force; (circularmagnetic field).DIRECTION OFCURRENT (1)DIRECTION OF THEMAGNETIC FIELD(LINES OF FORCE)Figure 2-9. Right-Hand Rule3.COILWhen a current-carrying conductor is formed into a loop, the lines of force circlingthe conductor form a magnetic field inside and outside the loop, as illustrated inFigure 2-10. Inside the loop the field is similar to that of a bar magnet and is said tobe a longitudinal magnetic field. When a coil consists of several loops the magneticfield within the coil is strengthened in proportion to the number of loops.4.MAGNETIC FLUXThe lines of force in a magnetic circuit always form closed loops or paths; hence, amagnetic circuit is always closed. The total number of magnetic lines existing in amagnetic circuit is called magnetic flux. Its unit is a single line force called theMaxwell, usually designated by the Greek letter Phi.2-11

5330.16MAGNETICFIELDCURRENTFigure 2-10. Longitudinal Field Around Coil5.FLUX DENSITYThis is the flux-per-unit area through an element which cuts the unit area at rightangles to the direction of the flux. Flux density, or induction, is usually designatedby the letter B, and its unit is the gauss.6.PERMEABILITYThe ease with which a magnetic -flux is established in a given material is referred to aspermeability. Permeability is numerically equal to B/H, or the ratio of flux density toto magnetizing force. Thus, a material which has high permeability has low reluctance,and vice versa.7.RELUCTANCEReluctance is the opposition of a magnetic material to the establishment of magneticflux. The reluctance of the material determines the magnitude of the flux produced bya given magnetic force. Reluctance is analogous to the resistance in an electriccircuit.8.RESIDUAL MAGNETISMResidual magnetism is the amount of magnetism which a magnetic material retainsafter the magnetizing force is removed.9.RETENTIVITY1The retentivity of a particular magnetic material is its property to retain to a greateror lesser degree a certain amount of residual magnetism.2-12

5330.1610.COERCIVE FORCECoercive force is defined as the reverse magnetizing force necessary to remove theresidual magnetism so as to demagnetize a specimen.2041.HYSTERESIS LOOPGENERALThe hysteresis loop (curve) is illustrated in Figure 2-11. This curve is a plot of fluxdensity (B) vs. magnetizing force (H). The test specimen used to plot this curve is apiece of unmagnetized steel.B ( FLUX DENSITY)H ( MAGNETIZINGFORCE)H(- MAGNETIZINGFORCE)B- (FLUX DENSITY OF OPPOSITEPOLARITY TO B )Figure 2-11. The Hysteresis Curve2.VIRGIN CURVEStarting from zero (0) with the specimen in the unmagnetized condition and increasingthe magnetic force in small increments, the flux in the material increases quiterapidly at first, then more slowly until it reaches a point beyond which any increasein the magnetizing force does not increase the flux density. This is shown by thedotted line o-a, and referred to as the virgin curve of the steel. The specimen ismagnetically saturated when it reaches the point where an increase in magnetizingforce does not increase the flux density.3.RESIDUAL MAGNETISMWhen the magnetizing force is gradually reduced to zero, the curve a-b results. Theamount of magnetism which the steel retains at point b, is called residual magnetism.

5330.16COERCIVE FORCE4.When the magneti7,ing current is reversed and gradually increased in value, the fluxwill continue to diminish. The flux does not become zero until point c is reached, atwhich time the magnetizing force is represented by c-o. The line c-o graphicallydesignates the coercive force in the material.REVERSED POLARITY5.As the reversed field is increased beyond c, point d is reached. At this point thespecimen is again saturated. The magnetizing force is now decreased to zero andthe portion of the d-e line is formed, and retains reverse polarity residual magnetism (Br) in the specimen. Again increasing the magnetizing force in the originaldirection completes the curve e-f-a. Now the cycle is complete, and the area withinloop (abcdefa) is called the hysteresis curve.CURVE CHARACTERISTICS6.The definite lag between the magnetization force and the flux throughout the cycle, iscalled hysteresis. A wide hysteresis loop, for example, indicates that the materialhaving high reluctance is difficult to magnetize. On the other hand, such materialcontains a considerable residual field, high retentivity, and probably makes a goodmagnet If the loop is slender, the indication means the material has low retentivity(low residual field) and is easy to magnetize (low reluctance). The theory of thehysteresis loop is illustrated in Figure 2-12.205CIRCULAR AND LONGITUDINAL MAGNETIZATIONGENERAL1.As determined by the specimen under test and available equipment either circular orWIDE LOOPSLENDER LOOPLOOP SHOWS;LOOP SHOWS;LOW PERMEABILITYHIGH RETENTIVITYHIGH COERCIVE FORCE- CCHIGH RELUCTANCEHIGH RESIDUAL MAGNETISM-HIGH PERMEABILITYLOW RETENTIVITYLOW COERCIVE FORCELOW RELUCTANCELOW RESIDUAL MAGNETISMFigure 2-12. Hysteresis Loop Characteristics2-14

5330.16longitudinal magnetization is used with magnetic particle testing. Methods of inducingthese types of magnetization in a specimen are discussed in the following paragraphs,2.CIRCULAR MAGNETIZATIONA circular magnetic field is Induced into a specimen by either direct magnetization,i.e., passing the current directly through the article, or indirectly, i.e., througha conductor surrounded by a hollow article.a.Direct Induction: Direct induction of a circular field into an article isaccomplished by passing a current through the article as shown in Figure2-13a. This method illustrated is called a head shot.b.Direct Induction Using Prods. Another direct method of inducing and establishing a circular field into a specimen, is by the use of prods. Prod magnetization is used where the size or location of an article does not permitthe use of a head shot or central conductor. Current flow and field distribution are shown in Figure 2-13b.c.Indirect Induction. In the indirect method of inducing a circular field, thespecimen to be magnetized is placed so that a current-carrying conductorinduces a magnetic field into the specimen. This method is 'mown as thecentral conductor technique and is illustrated in Figure 2-13c.CURRENTCIRCULARFIELDCURRENT(A) HEAD SHOTFIELD(B) PRODSMU*,MCURRENT(C) CENTRAL CONDUCTORFigure 2-13. Circular Magnetization by Direct and Indirect Current Induction2 -15

5330.163.LONGITUDINAL MAGNETIZATIONLongitudinal magnetization of a specimen is accomplished by' the use of longitudinalfields set up in a coil or solenoid.a.Coil (Solenoid). When the length of a specimen is several times its diameteror cross section, the specimen may be successfully magnetized by placing itlengthwise in the field of the coil or solenoid. This is referred to as a "coilshot, " and is shown in Figure 2-14a.NOTE:b.In a coil whose diameter exceeds its length, the field strength at itscenter line is approximately proportional to the current (in amperes) times the number of turns of the coil. Thus field strengthis usually indicated in units of ampere-turns.Yoke. A yoke may be used to magnetize a specimen longitudinally. Essentially, it is a temporary horseshoe magnet made of soft, low retentivityiron, which is magnetized by a small coil wound around its horizontal bar.When the energized yoke is placedon a specimen (see Figure 2-14b), theflux flow from the yoke's south pole through the specimen to the north poleindu

Testing, Magnetic Particle Test Equipment, Mediums and Their Preparation, Magnetic Particle Applications, Classification of Discontinuities, and Comparison and Selection of Nondestructive Testing Processes. High product reliability and quality in metal . tive test methods and a proven t