Transcription

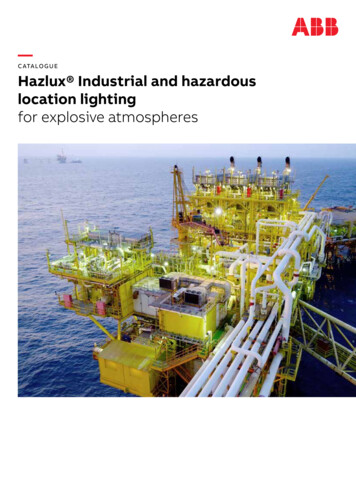

—C ATA LO G U EHazlux Industrial and hazardouslocation lightingfor explosive atmospheres

—Hazlux lighting fixtures areconstructed to meet HazardousLocation and Adverse Environmentapplications. You can rely onHazlux to safely provide lightwhere you need it - even under theharshest indoor and outdoorconditions.

—Table of contents004 – 007 Introduction008 – 011Overview012 – 0? Area lighting0? – 0?Floodlights0? – 0?Strobe lights0? – 0? Technical section0? – 0?Quick pole assembly0? – 0?Index

4IN DUSTR IAL AN D H A Z AR DOUS LOC ATION LIG HTING FOR E XPLOSI V E ATMOSPHERES—IntroductionMade in Canada at the Thomas & Bettsproduction facilityHazlux products are assembled in Canada to meet strict Thomas & Betts qualitystandards and shipped quickly. We produce what you need when you need it no waiting for large production runs or shipments from overseas.All units are inspected on site and thenprofessionally packed so that your order willarrive intact at your installation site. When youneed speed and service without sacrificingquality or reliability. you can count on theThomas & Betts Hazlux production team.SpeedThomas & Betts offers a lead time advantagethanks to the dedicated Hazlux productionoperation in Canada. When you need an orderfulfilled right away, we have everything we needin house to meet your requirements. The flexiblecapacity of our assembly operation can easilyaccommodate both large and small productionruns with a fast turnaround. All units are madeto order and assembled by our efficient,experienced in-house Hazlux team. Yourcomplete order is sent out the door as quicklyas possible.

5ExcellenceOur skilled professionals build quality into everyproduct at every step of the process, from designto final assembly.Each product is inspected and tested to ensurethat it meets strict Thomas & Betts qualitystandards.DependabilityThe reliability and high standards of the Thomas& Betts brand stand behind all Hazlux products.We take extra steps to ensure that each unit isprotected all the way from our production facilityto your installation. Special expandable foampackaging is used on all units to prevent shiftingin transport so that your order arrives safely.To reduce the carbon footprint and minimize theenvironmental impact of operations, aSustainable Development policy is in effect at theThomas & Betts production facility. Through aseries of initiatives, reductions in usage of water,water bottles, electricity and natural gas,packaging, and pallets have already been realized.Forward-looking initiatives include reductions inpaper, further recycling of pallets, andimplementation of an eco-delivery schedule.The Thomas & Betts production facility has beenISO 9001 compliant since 2001.

6IN DUSTR IAL AN D H A Z AR DOUS LOC ATION LIG HTING FOR E XPLOSI V E ATMOSPHERES—IntroductionQuality productsThomas & Betts is committed to delivering high quality industrial lightingfixtures designed, tested and certified for use in hazardous locations and adverseenvironment conditions.—01 ?—02 ?—03 ?You can rely on Hazlux to safely provide lightwhere you need it - even under the harshestindoor and outdoor conditions. If safety, laborreduction, quality and reliability are yourpriorities, consider Hazlux lighting products.—01—03—02Features & benefits Nameplate displays third party certification forall electrical ratings and hazardous locationratings as required by the Canadian ElectricalCode, OSHA regulations and CSA, allows forpeace of mind, confirming the right lightingfixture is installed in a certified condition Cast, copper-free aluminum construction forhigh strength, light weight and corrosionresistance meeting the highest life expectancyyou can expect from a lighting fixture in aparticular application The paint used in our standard finish is baked,electro-deposited, pure epoxy powder formaximum corrosion protection. Additionalpaint finishes are available, offering increasedprotection against harsh environment All exposed hardware is corrosion-resistantstainless steel will limit and ease all maintenancerequired on the lighting fixture Faster and easier installation with simple hingearrangement that permits “hands-free” wiring

INTRODUC TION - QUALIT Y PRODUC TS—04—04 ?—05 ?7—05Design & components Hazlux products are designed with top andbottom fins to provide maximum heatdissipation In order to use the whole luminaire as a heatsink, the ballast/generator is installed so that ittransfers heat to the luminaire body Select induction lamp options feature anadditional inner heat sink to provide the coolestpossible design for maximum luminaireefficiency A metal plate provides two separatecompartments for the ballast/generator andlamp source to maximize life expectancy Hazlux 5 fixtures feature electromechanicalconnect block for quick, safe fixture removal forbench relamping and/or maintenance High strength mechanical mounting, robustdesign and components to withstand ice,strong wind loads or heavy vibrations Heat tempered glass for greater strength andthermal shock resistance to selection ofrefractors to meet your application and lightingrequirementsInstallation & operation Seizure-resistant threads make installation andmaintenance easy over years, and Hazlux 5,Dual pitch acme threads for easier, fasterassembly Heat-sunk internal components results in cooleroperation for extended ballast life, higher lampwattage and a broader range of hazardouslocations

8IN DUSTR IAL AN D H A Z AR DOUS LOC ATION LIG HTING FOR E XPLOSI V E ATMOSPHERES—OverviewHazardous locationsHazardous location – An area where the possibility of explosion and fire iscreated by the presence of flammable gases, vapors, dust, fibers or flyings.Class I - GasClass I locations are those in which flammablegases, flammable liquid-produced vapors orcombustible liquid-produced vapors are or maybe present in the air in quantities sufficient toproduce explosive or ignitable mixtures.Typical Class I Locations: Petroleum refineries and gasoline storage anddispensing areas Industrial firms that use flammable liquids indip tanks for parts cleaning or other operations Petrochemical companies that manufacturechemicals from gas and oil Dry cleaning plants where vapors from cleaningfluids can be present Companies that have spraying areas where theycoat products with paint or plastics Aircraft hangars and fuel serving areas Utility gas plants and operations involvingstorage and handling of liquified petroleum gasor natural gasClass II - DustClass II locations are those that are hazardousbecause of the presence of combustible dust.Typical Class II Locations: Grain elevators, flour and feed mills Plants that manufacture, use or storemagnesium or aluminum powders Plants that have chemical or metallurgicalprocesses: producers of plastics, medicines andfireworks, etc. Producers of starch or candies Spice-grinding plants, sugar plants and cocoaplants Coal preparation plants and other carbonhandling or processing areas—Divisions vs. Zones: Area ClassificationContinuoushazardZone 0Division 1IntermittenthazardZone 1Hazard underabnormal conditionsZone 2Division 2Note: These are simplified definitions - complete data is in theCanadian Electicral Code (C.E.C)Class III - FibersClass III locations are those that are hazardousbecause of the presence of easily ignitable fibersor where materials producing combustible flyingsare handled, manufactured or used, but in whichsuch fibers/flyings are not likely to be insuspension in the air in quantities sufficient toproduce ignitable mixtures.Typical Class III Locations: Textile mills, cotton gins, cotton seed mills andflax processing plants Any plant that shapes, pulverizes or cuts woodand creates sawdust or flyingsNote: Fibers and flyings are not likely to besuspended in the air but can collect aroundmachinery or on lighting fixtures and where heat,a spark or hot metal can ignite them.Division 1 - Normally hazardousHazardous gases or dusts are present undernormal operation conditions or during frequentrepair and maintenance activity.Groups A, B, C, DThe gases and vapors of Class I locations are brokeninto four groups by the code A, B, C and D. Thesematerials are grouped according to the ignitiontemperature of the substance, its explosionpressure and other flammable characteristics.Groups E, F, GClass II dust locations groups E, F and G areclassified according to the ignition temperatureand the conductivity of the hazardous substance.Division 2 - Not normally hazardousHazardous gases or dusts are not present undernormal operating conditions.

O V E R V I E W - H A Z A R D O U S LO C AT I O N S9—Four step method for selecting lighting fixtures forhazardous locations1. Select a fixture that meets your Class,Division and Group requirements.For example: Class I, Division 2, Group D Class II, Division 1, Group G2. Determine the T-Number for your selectedfixture. Be sure it is for the specific wattage,ballast housing, optical assembly and ambienttemperature. Use the published information in this catalogor in Hazlux product brochures3. Determine the Maximum AllowableTemperature for the hazardous materialsinvolved.Class I Gas: Ignition Temperature for the Specific Gas(from NFPA497M)Class II Dust: Group E - 200 C Group F - 200 C Group G - 165 C Or ignition temperature of dust if lower Above from NEC Table 500-3(F)4. Compare T-Number (from Step 2) to MaximumAllowable Temperature (from Step 3). If T-Number is cooler than the MaximumAllowable Temperature, the selected fixture issuitable. If T-Number is hotter than the MaximumAllowable Temperature, the selected fixture isnot suitable.—T-Number TableClass I, II, Div. 1,2 T-NumberMax. Temperature( 165T3C160T4135T4A120T5100T685

10IN DUSTR IAL AN D H A Z AR DOUS LOC ATION LIG HTING FOR E XPLOSI V E ATMOSPHERES—OverviewHazlux applicationsFrom an offshore oil rig in the Atlantic Ocean to the factory floor,there’s a Hazlux lighting fixture to stand up to virtually everyhazardous location.Here are some of the places you’ll find Hazlux fixtures: Chemical manufacturing and processing plants Oil refineries Oil drilling rigs Offshore platforms Pipeline pumping stations Pulp and paper plants Aluminum and copper smelting Steel mills and foundries Mining operations Grain handling facilities Flour, sugar and starch processing—01 Hose down—02 Vibration—03 High ambient—04 Dust Food processing plantsPaint and rubber manufacturing facilitiesMarine and coastal facilitiesShipyards and shipbuilding plantsPower generation plantsWaste treatment facilitiesPaint, chemical and plastic mixing/storage areasBulk truck terminalsSolvent/cleaning areasHazlux lighting fixtures are built to withstandthe harsh environmental conditions that existin real ��05 Corrosion—06 Marine—07 Ice—08 Wind

O V E R V I E W - H A Z LU X A P P L I C AT I O N S—Note: Tuff-Skinis a registeredtrademark of ThomasManufacturing Corp.Hose-Down and Wet Locations Certified for wet locations - NEMA 4X, IP66(indoor and outdoor); UL1598A (marine) andCSA Listed Superior gasketing system - both tank andglobe gasketing systems withstand hose-downpressures Uninterrupted globe thread - assures positiveseal Baked-on, dry epoxy coating - not paint but100% dry solids Globes, refractors and finish designed towithstand thermal shock during hose downHigh-Ambient Temperature Areas All standard fixtures are tested and listed for atleast 40 C ambient - even under heavy dustblanket and no air flow Exclusive heat sink design results in a cooloperating fixture, extended ballast/lamp lifeand lower maintenance costs Unmatched selection of high-ambient,temperature rated fixtures- contact factoryfor fixtures certified for 55 C and 65 Capplications Steam spray and thermal shock resistantCorrosion and Abrasion Baked-on, dry epoxy coating - not paint but100% dry solids Stainless steel external hardware Sand-blast resistant finish Superior silicone gasketing system on bothtank and globe. Other gasketing systemsavailable for special corrosive applications suchas phosphates Aluminum components contain less than 0.4%copper - maximum corrosion resistance Special HazCote corrosion fighter finishavailable for extremely corrosive areas; consultThomas & Betts for detailsIce and Arctic Conditions Gasketing system and finish allow for expansionand contraction through wide temperaturevariations Metal halide ballasts start at -29 C; highpressure sodium ballasts start as low as -51 C(consult Thomas & Betts for details) High-strength mechanical mountings withstandextra ice loading Tempered glassware available for extra thermalshock safety margin11Vibration, Seismic Shock and Vandalism Vibration tested by UL and CSA Vibration-resistant hardware throughout fixture Screw retainers on guard ensure retention evenif screws are not completely tightened Vibration-resistant globe thread and sealingsystem Optional refractors, high-strength temperedglass and Tuff-Skin globes for protection fromvandalismDust Blanket Tested and listed by UL and CSA Thermal performance is at 40 C ambient;optional thermal performance to 55 C and 65 Cambient available (consult factory) Cone pendant mount available (45 slopedsides) for areas where dust or other residuebuildup is a problem Exclusive heat sink design - results in a cooloperating fixture, extended ballast/lamp lifeand lower maintenance costsMarine-Duty Option This feature is supplied as standard on mostHazlux 3 fixtures Designed for abuse - hose down, arctic,hurricane, vibration and shock, hightemperature, corrosion and otherenvironmental conditions typical of adversemarine locations E xclusive combination of marine and hazardouslocation approvals on the same fixture lineWind Wind-tunnel tested at McDonnell DouglasCorporation at air flow speeds in excess of 198mph (320 km/h) Guard specially designed to secure reflectorduring high wind loading All fasteners are stainless steel High-strength mechanical mountings withstandstrong wind loads

12IN DUSTR IAL AN D H A Z AR DOUS LOC ATION LIG HTING FOR E XPLOSI V E ATMOSPHERES

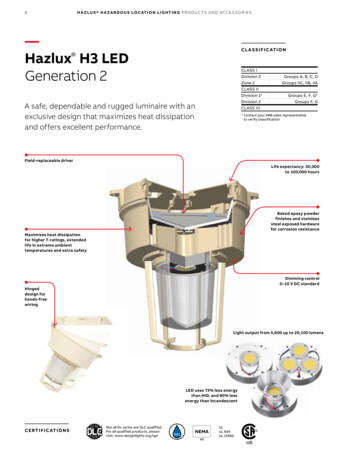

A RE A LIGHTING - H A ZLUX 3 LED DL SERIES13—Area lightingHazlux 3 LED DL SeriesHazlux durability meets LED technology.Superior performance lighting for hazardous locations.Safe, durable and now available with LEDtechnology for superior energy efficiency.Thomas & Betts Hazlux luminaires are known ashigh quality industrial lighting fixtures designed,tested and certified for use in hazardouslocations and adverse environment conditions.Specifiers rely on Hazlux to safely provide lightwhere it’s needed - even under the harshestindoor and outdoor conditions.Safe, dependable, durable Hazlux luminaires arenow available with LED technology to offer longerlife, enhanced energy efficiency, reducedmaintenance, and a smaller footprint.All Hazlux LED products are designed andassembled in Canada for exceptional service andsupport with reduced lead times. Experiencedassembly operation easily accommodates bothlarge and small production runs with a fastturnaround.High-efficacy luminaire offers excellentperformance and energy savingsThomas & Betts has taken the rugged, reliabledesign of Hazlux lighting fixtures andintroduced the capabilities of LED technology tocreate a high-performance luminaire with animpressive lumen output.—High-efficacy luminaireModelAC power 20,400123—T-ratings & thermal management40 CModelClass IDiv 2Class I Div 2& Class II55 CClass IDiv 2Class I Div 2& Class r T-ratings and optimal thermalmanagementWith an exclusive design that maximizes heatdissipation, Hazlux LED fixtures lower internaltemperature allow for higher T-rating andextended LED and driver life in extreme ambienttemperatures. With the entire luminaire acting asa heat sink, Hazlux LED fixtures allow higherwattages for better performance.Versatile optics include reflector options fordiffuse light distributionThe Hazlux LED fixture is available with a thermalresistant globe and a variety of reflectors for theideal beam angle from 35 to 65 .

14IN DUSTR IAL AN D H A Z AR DOUS LOC ATION LIG HTING FOR E XPLOSI V E ATMOSPHERES—Area lightingHazlux 3 LED DL SeriesLabor-saving installation and maintenance-friendly construction.Designed for easy retrofit installationUsing the same mounting style options asexisting Hazlux lighting fixtures, the new LEDluminaires can easily be attached as retrofitfixtures.*The HazVertor adapter ring makes it easy toreplace Crouse-Hinds Champ series lightingfixtures without removing the top hat from theconduit system.Hinged design for hands-free wiringEasy tank access allows Hazlux lighting fixturesto be maintained quickly and safely. The hingedlid is designed to support the weight of the tank,leaving both the installer’s hands free.Field-replaceable LED engine and driverThe LED driver is designed in its owncompartment so it can be easily replaced in thefield using a connector, with no re-wiringrequired. A fiberglass insulator protects thedriver from the heat of the LED engine.Robust construction for long life expectancyCast, copper-free aluminum construction offerscorrosion resistance in a strong, lightweightfixture for maximum life expectancy. Baked epoxypowder finishes and stainless steel exposedhardware provide additional corrosion resistance.Certifications shown on external surfaceAn easily identifiable nameplate displays thirdparty certification for all electrical and hazardouslocation ratings as required by the CanadianElectrical Code, OSHA regulations and CSA toprovide peace of mind, confirming that thecorrect lighting fixture with the requiredcertifications is in place.

H A ZLUX 3 LED DL SERIES - A SSEMBLY GUIDE15—Hazlux 3 LED DL SeriesAssembly guideComplete luminaire consists of: A mounting style Driver tank Globe or refractor Optional guard and/or reflectorMounting styleCone-toppendantCeiling andpendant mountHazVertor adapter ringWall mount25 anglestanchionBallast tankStandard housingGlobe or refractorRefractor globeHeat-resistant prismatic glass globePolymeric guardCast guardGuardReflector*—*Reflectors aresold separately30 angle reflectorStandard domeStraightstanchion

IN DUSTR IAL AN D H A Z AR DOUS LOC ATION LIG HTING FOR E XPLOSI V E ATMOSPHERES16—Hazlux 3 LED DL SeriesCatalog numbering systemLED driver tankDL10210E34UN50T667C8C2Fixture series2Fixture3Lumen output4FIxture5Voltage/frequency6E9—LED driver tank1OptionsOptics & mounting10T11UNIPAK LED Driver Tank Optics & Mountings Options (if necessary)1612—Optics & mountingOrdercodeDescriptionDLHazlux 3 fixtureCStandard fixture055,800 lumens, 45W077,100 lumens, 58W1010,100 lumens, 88W1515,600 lumens, 122W1717,800 lumens, 131W2020,400 lumens, GThermal shock-resistant globeR1Type I glass refractor globeR3Type III glass refractor globeR5Type V glass refractor globeCCast aluminium guardGuardoptionMountingstyleLPolymeric guardA2¾” Cone-top pendantA31” Cone-top pendant¾” wall mountEElectronic LED DriverB2UN120 to 277VAC 50/60Hz(voltage range includes 208V,220V, 240V etc.)B31” wall mountC2¾” Ceiling / pendant mountUN2Universal 347/480VAC 50/60Hz(Not available for DL017and DL020)0Standard housingSStandard housing with stainlesssteel insertsLED driverhousing styleC31” Ceiling mountHV1HazVertor ring - Class I, Div. 2, Zone 2HV2HazVertor ring - Class I Div. 2 Zone 2,Class IIL41¼” Straight stanchionL51½” Straight stanchionS41¼” 25 Angle stanchionS51½” 25 Angle stanchionBlankNo mounting (to replace exisiting fixture)EUNIPAK with LED light source10 UNIPAK options—Certifications, standards & teristicsCertifications & standardsClass I—OptionsDivision 2, Groups A, B, C and D11 Special optionsTZone 2, Groups IIC, IIB, IIAClass IIClass IIIDivision 1 and 2,Groups E, F and GUL Listed (UL1598A) forMarine LocationsUL844NEMA 4XCSA C22.22 No. 13712 Light distributionoptionsDescriptionHazcote custom anti-corrosion coating(consult factory)GGrey colour option13Internal reflector 35 beam angle*14Internal reflector 45 beam angle*15Internal reflector 65 beam angle**DL005, DL007 and DL010 only

H A Z LU X 3 L E D D L S E R I E S - I N D I V I D U A L C O M P O N E N T S ( TO B E U S E D W I T H L E D D R I V E R H O U S I N G )17—Hazlux 3 LED DL SeriesIndividual components (to be used with LED driver housing)—Mounting optionsDescriptionConduit hub size(in)VA2Cone-top pendant¾VA3Cone-top pendant1VC2Ceiling mount¾VC3Ceiling mount1Wall mount¾Part no.Ceiling andpendant mountCone-toppendant25 AnglestanchionWall mountHazVertor adapter ringStraightstanchionVB2-VIBVB3-VIBWall mount1VS4-VIB25 angle stanchion1¼1½VS5-VIB25 angle stanchionVL4-VIBStraight stanchion1¼VL5-VIBStraight stanchion1½HV1HazVertor adapter ringN/AHV2HazVertor adapter ringN/A—Globes or refractorsPart no.VGT15Refractor globeDescriptionHeat-resistant prismatic glass globeVGL15R1IES Type I refractor globeVGL15R3IES Type III refractor globeVGL15R5IES Type V refractor globeHeat-resistant prismaticglass globe—Globes or refractorsPart no.DescriptionVGU22PPolymeric guardVGU22Polymeric guardCast guardCast guard—Optional components—Reflectors or exit signPart no.VR15PVRA15P30 Angle reflectorDescriptionStandard dome, fiberglass-reinforced polyesterAngular dome, fiberglass-reinforced polyesterStandard DomeNote: Reflectors are shipped bulk unless specified

IN DUSTR IAL AN D H A Z AR DOUS LOC ATION LIG HTING FOR E XPLOSI V E ATMOSPHERES18—Hazlux 3 LED DL SeriesDimensions & photometry – Standard housing with globe and guard—Standard housing with globe and guardPhotometry – Ceiling mountDimensionsReference dataCatalogue No.16-3/4 in. (425mm)18-11/32 in. (466mm)Luminaire Lumens131Input Watt260Spacing CriterionSpacing Criterion (90-2701.31.44Ceiling MountCatalogue No.Luminaire Lumens15-3/16 in. (386mm)16-3/4 in. (425mm)1.313-3/8 in. (340mm)13-3/8 in. (340mm)Luminaire Efficacy Rating (LER)Input WattDL010EUN0TGC2E10,12311588.19Spacing Criterion1.24Spacing Criterion (90-2701.24Spacing Criterion (diagonal)1.416-1/8 in. (410mm)14-7/8 in. (378mm)Wall Mount5,895Luminaire Efficacy Rating (LER)Spacing Criterion (diagonal)Cone-Top PendantCandlepower curveDL005EUN0TGC2E25 Angle Stanchion MountLuminaire Lumens14-3/4 in. (375mm)15-3/16 in. (386mm)Catalogue No.15-3/4 in. (400mm)Straight StanchionLuminaire Efficacy Rating (LER)Input WattSpacing Criterion13-3/8 in. (340mm)DL010EUN0TGC2E15,605128121.81.08Spacing Criterion (90-2701.08Spacing Criterion (diagonal)1.42HazVertor RingCatalogue No.Luminaire LumensLuminaire Efficacy Rating (LER)Input WattSpacing CriterionDL020EUN0TGC2E20,476123166.11.46Spacing Criterion (90-2701.46Spacing Criterion (diagonal)1.58

H A Z LU X 3 L E D D L S E R I E S - S TA N D A R D H O U S I N G W I T H G L A S S R E F R A C TO R – C E I L I N G M O U N T—Hazlux 3 LED DL SeriesPhotometry – Standard housing with glass refractor – Ceiling mount—Standard housing with globe and guardPhotometry – Ceiling mountReference dataCatalogue No.Luminaire LumensCandlepower curveDL010EUN0R1C2E8,047Luminaire Efficacy Rating (LER)92Total luminaire watts87Maximum CandelaMaximum Candela ( 90 Vertical)Maximum Candelaat 90 VerticalMaximum Candelafrom 80 to 90 VerticalCatalogue No.Luminaire LumensLuminaire Efficacy Rating (LER)2,8902,890887 (11.0%)luminaire lumens)1,463 (18.2%)luminaire lumens)DL010EUNOR3C2E8,64999Total luminaire watts87.27Maximum Candela3,731Maximum Candela ( 90 Vertical)3,731Maximum Candelaat 90 VerticalMaximum Candelafrom 80 to 90 VerticalCatalogue No.Luminaire LumensLuminaire Efficacy Rating (LER)883 (10.2%)luminaire lumens)1,308 (15.1%)luminaire lumens)DL020EUN0R5C2E17,004102Total luminaire watts166.3Maximum Candela3,413Maximum Candela ( 90 Vertical)Maximum Candelaat 90 VerticalMaximum Candelafrom 80 to 90 Vertical3,4131,171.3 (6.9%)luminaire lumens)1,662.7 (9.8%)luminaire lumens)19

20IN DUSTR IAL AN D H A Z AR DOUS LOC ATION LIG HTING FOR E XPLOSI V E ATMOSPHERES

A RE A LIGHTING - H A ZLUX 321—Area lightingHazlux 3Designed, tested and certified for use in hazardous locations andadverse environments. New labor-saving features for Hazlux 3 fixturesInduction LightingLong life for reduced maintenanceHazlux 3 induction lighting provides a 60,000 hour lamp life, drastically reducing expensivemaintenance costs of industrial lighting inhazardous locations.HazVertor Adapter RingReplace other brand fixtures without removingthe top hatThe HazVertor adapter ring gives you thefreedom to replace Crouse-Hinds Champ serieslighting fixtures (VMV, DMV or LMV types) withHazlux 3 lighting fixtures without removing theCrouse-Hinds top hat from the conduit system,eliminating the need to replace conduit and wiring.Save time and increase efficiency. TheHazVertor can be ordered as a separate item oras part of a Hazlux 3 fixture assembly. Look forthe HV1 or HV2 mounting style options andswitch to increased efficiency, wider suitabilityfor hazardous locations, improved lightdistribution and improved T-numbers.Hazlux UNIPAK Packaging UNIPAK is the Hazlux customized packagingsystem that is designed to save money for allconcerned UNIPAK fixtures are normally assembled andcan include globes, guards, reflectors, lamps,fuses and other options Outlet boxes are normally shipped separately;consult factory regarding outlet boxes to beassembled to UNIPAK fixtures Assembled UNIPAK fixtures are shipped inone carton with the fixture foam packed inplace Refer to the “Catalog Numbering System” foreach individual Hazlux fixture series forordering informationUNIPAK saves seven ways: Fewer cartons to receive, count, move, open anddisposeFewer storage problems Reduces inventory expense Eliminates lost or back-ordered parts Eliminates mismatched fixtures or lamps Significantly reduces labor costs Reduces total installed cost per fixture

22IN DUSTR IAL AN D H A Z AR DOUS LOC ATION LIG HTING FOR E XPLOSI V E ATMOSPHERES—Area lightingHazlux 3Fixtures for Class I, Division 2; Class II; wet and marine locations.—01 ?—02 ?—03 ?—04 ?—05 ?—06 ?—07 ?—08 ?—09 ?—10 ?—11 ?—12 0—11—12Applications Chemical Plants Oil Refineries Paint, Rubber Manufacturing Offshore Platforms Oil Drilling Rigs Oil, Gas Transmission Waste Treatment Facilities Airplane, Aerospace Facilities Electronics Manufacturing Pharmaceutical Plants Aircraft Manufacturing Vehicle Maintenance Facilities Grain Handling, Food Processing Coal Handling and Processing Flour, Sugar, Starch Processing Ammunition Manufacturing Coal, Gold and Copper Mining Pulp and Paper ManufacturingCopper, Aluminum SmeltingBreweries, Malt PlantsShipyards, Shipbuilding FacilitiesAutomobile ManufacturingMarine and Coastal FacilitiesUtility Power PlantsSteel Mills, FoundriesGeneral Manufacturing Plants

A R E A L I G H T I N G - H A Z LU X 323—Fixtures for Class I, Division 2; Class II; wet and marine locations.—Note: Tuff-Skinis a registeredtrademark of ThomasManufacturing Corp.Features Modular fixture components enable hundredsof easy-to-assemble combinations Cast copper-free aluminum housings andmounting covers are lightweight and resistcorrosion Electrostatically applied powder-coat finish foradded corrosion resistance Thermal shock-resistant glass globes andrefractors protect lamps in wet, marine andoutdoor applications All glass globes and refractors are fullythreaded and provide a dust-tight, watertight seal with siliconerubber gaskets Standard globe guards are made from ruggedpolycarbonate plastic or cast aluminum withkeyhole slots for ease of installation and do notinterfere with globe threads All exposed hardware is stainless steel forcorrosion resistance and screws are slotted,hex-head style to further ease installation Comprehensive UL Listings for Class I, Division2; Class I, Zone 2; and Class II Available for use with high-pressure sodium andmetal halide lamps up to 400 watts Eight different mounting styles - rigid pendant,flexible pendant, cone pendant, ceiling, wall,25 angle stanchion, straight stanchion andHazVertor Adapter Ring Three ballast housing choices - standardhousing, R-housing and large housing Heat sinks in ballast housings enable ballasts tooperate cooler, provide longer life and improvetemperature performance Bright white FRP (fiberglass-reinforcedpolyester) angle or dome reflectors resistcorrosion while maximizing lightingeffectiveness Many optical choices - standard globes, threadedrefractor globes, 73 4“ globes, 12“ refractors,enclosed high-bay reflectors and more All mounting covers provided with dual-leadground wire for connection to field and fixturegrounds Optional HazCote coating for extremelycorrosive applications Optional stainless steel inserts for guard screwsand ballast tank closure screw for enhancedcorrosion resistance Optional Tuff-Skin silicone coating on glassoptics contains fragments if glass is broken (forfood processing) Optional instant restrike starter for HPS lampsup to 150 watts restarts hot HPS lamp aftermomentary power failureCertifications / CompliancesUL Listed (UL844) and CSA certified (csa C22.2no. 137) for: Class I, Division 2, Groups A, B, C, D Class I, Zone 2, Groups IIA, IIB, IIC Class II, Divisions 1 & 2, Groups E, F, G Class III Wet locationsUL Listed (UL1598A) for: Marine Locations NEMA 4X, IP66Materials and Finishes Ballast Housings - Copper-free aluminum,powder finish Mounting Covers - Copper-free aluminum,powder finish Guards - Pol

Hazlux applications From an offshore oil rig in the Atlantic Ocean to the factory floor, there’s a Hazlux lighting fixture to stand up to virtually every hazardous location. Here are some of the places you’ll find Hazlux fixtures: Chemical manufacturing a