Transcription

AircraftSHEET METAL WORK- Prem Mahendranathan-

STRUCTURAL REPAIRStructural repair can be classified asn Corrosion Repairn Modificationsn Interior Cabinetn Stainless Steel Container Repair/Fabricationn Part FabricationPrem Mahendranathan

STRUCTURAL REPAIRStructural repair involvesn Modificationn Weldingn Compositesn Structures D.E.R.n Aircraft Fuel Tank Bladder Repairn Airport Ground Equipment RepairPrem Mahendranathan

AIRCRAFT STRUCTURE: MATERIALSq AluminumAlloysq Titaniumq CompositePrem Mahendranathan

AIRCRAFT STURCURAL REPAIRSn While making a structural repair, followingparameters should be maintained as originalstructural strengthq designq safety standardsq cosmetic appearanceq A perfect repair may reduce further cracksPrem Mahendranathan

WORK STANDSPrem Mahendranathan

THIS COULD BE REPAIRED TOOPrem Mahendranathan

BASIC PRINCIPLES OF SHEET METAL REPAIRn Examineq Evaluaten Planq Estimate§ Execute“Sizing Up”Prem Mahendranathan

EXAMINE THE DAMAGEn Examineq the damage visuallyq the load damageq the supporting structural membersq closely for partially failed rivetsq for elongated holesq for corrosion damageq the white crystalline deposits around theloose rivetsPrem Mahendranathan

EVALUATE THE DAMAGEn Location?q Primaryq Secondaryn Extent of the damagen “Cleanout” areaPrem Mahendranathan

SHEET METAL WORKPrem Mahendranathan

PLANNINGn Repair schemen Type of materialn Rivet type and quantityn Rivet patternn Durationn Skilled personalPrem Mahendranathan

ESTIMATEn Material costq Rivets costn Required man-hourq Profit loss due to grounded aircraft§ Material and components arrival time§ Time required to complete the workPrem Mahendranathan

EXECUTEn Clean the damage arean Cutout the corners into oval or circular shapen Make a template using papern Select the appropriate materialn Identify the rivet patternn Rivet the material to the structure.Prem Mahendranathan

FIRST THING FIRST: SAFETYWearn Safety Glassn Ear plugsn Glovesn Cloths

CLASS ROOM TOOLS REQUIREDn n n n n CalculatorMachinist's Ruler (1/32, 1/64,1/100)CompassRight angle or triangleMarking tool (No lead pencil)

WORKSHOP TOOLSn n n n n n n n n Drill bits:Center punchSharpie - Ultra Fine – (no pencil for marking)Files (round, half round, flat)Scrape of woodDeburring toolRivet GunClampsTape

AIRCRAFT RIVETS

RIVET GUN, SNAPS ANDBUCKING BARSImage source: overthehills.com

HOLDING RIVET GUN ANDBUCKING BARImage source: hotrod.com

STEP 1: STOP DRILLCrackStop drillPrem Mahendranathan

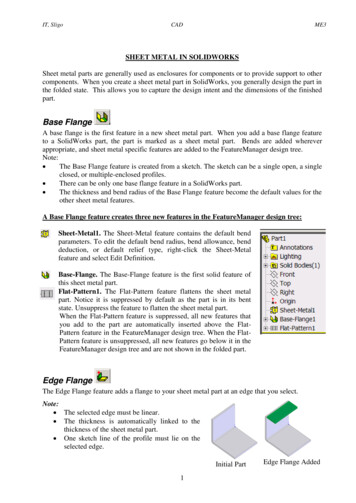

STEP 2: PATCHING PROCEDUREPrem Mahendranathan

DAMAGED AREA

CUT OUT THE DAMAGED AREA

MAKE A PATCH PLATE

MAKE A DOUBLER TO COVERTHE PATCH

RIVETS LAYOUT PATTERN

RIVET THE FOUR CORNERS

EDGE DISTANCE

RIVET

RIVETS LAYOUT

COMPLETE JOB

BASIC PRINCIPLES OF SHEETMETAL REPAIRn Maintain the original strengthn Maintain the original contourn Keep the weight to a minimumPrem Mahendranathan

MAINTAIN THE ORIGINAL STRENGTHn The patch plate should have across-sectional areaq equal to or greater than that of the originaldamagen Place a splice, where the member is subjected tocompression or bending loadsn Cutout radius; not no smaller than 1/2inchn Material used; same as the originalCont .Prem Mahendranathan

n If it is necessary to use an alloy weaker than theoriginal, useq a material of heavier gauge to equivalentstrengthn If 2024-T were substituted with 2024-T80q 2024-T shall be higher gauge (thicker).n Normally go for 1 gauge higherq Ex. 0.32; use 0.40; use 0.50Prem Mahendranathan

n Heat treated or cold worked alloys are hard tobend; they will crack – Ex, T2,T3 typematerial .n Soft alloys are easily formed but not strongenough to use in the primary structure. – “O”type materialn Strong alloys are formed in annealedcondition and heat treaded to develop theirstrength before assemblingPrem MahendranathanCont.2

RIVET sizen Multiply the thickness of the skin by threeand next larger size rivet corresponding tothat figureq Ex. Skin thickness - 0.040-inn 0.040 * 3 0.120n use the next larger size rivet;1/8 (0.125)Prem Mahendranathan

RIVETSn QUANTITYFormula to calculate rivets quantityq Number of rivets required on each side of the break n L * T * 75000 / S or Bn L- Length of the breakn T- Thickness of the materialn S- Shear Strengthn B- Bearing Strengthn Thickness is measured in thousands of inchPrem Mahendranathan

Example - 1Rivet Quantityn Using the formula, determine the numberof 2117- T rivets needed to repair abreak 2-1/4 in. long in material 0.040-in.thick:Prem Mahendranathan

Answer 1n L * T * 75,000 / S or Bq Given:n L 2-1/4 (2.25) inn T 0.040 inn S 331 or B 410n (2.25 * 0.040 * 75000) / 331n 6750 / 331n 20.39 ( or 21)n Total number of rivets required 21 21 42n Rivet size 0.040 * 3 0.120, so rivet size is 1/8Prem Mahendranathan

BASIC PRINCPLES OF SHEETMETAL REPAIRn Maintain original strengthn Maintaining Original Contourn Keeping Weight to a MinimumPrem Mahendranathan

MAINTAINING ORIGINAL STRENGTHn Make a repair in such a way that it shouldbring back the original structural strength asclose as possiblePrem Mahendranathan

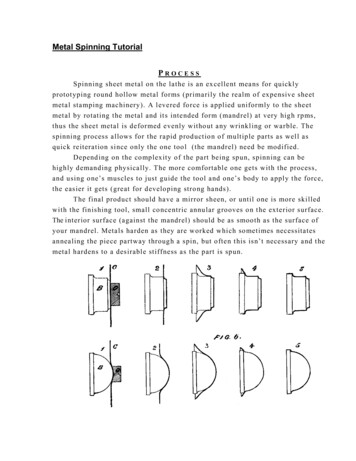

MAINTAING ORIGINAL CONTOURn Form all repairs in such a manner thatthey will fit the original contourperfectly.n A smooth contour is desirable whenmaking patches on the smooth externalsurface on high speed aircraftPrem Mahendranathan

KEEPING WEIGHT TO A MINIMUMn Keep the weight of all repairs to a minimumn Make the size of the patches as small as practicablen Don’t use more rivets than necessaryn Repairs disturb the original balance ; may requireadditional weight or adjustment on trim- and –balance tabsn Repairs on prop spinner, require application ofbalancing patches; for perfect balancePrem Mahendranathan

Fabrication ! Part Fabrication Prem Mahendranathan . STRUCTURAL REPAIR Structural repair involves ! Modification ! Welding ! Composites ! Structures D.E.R. ! Aircraft Fuel Tank Bladder Repair . BASIC PRINCIPLES OF SHEET METAL RE