Transcription

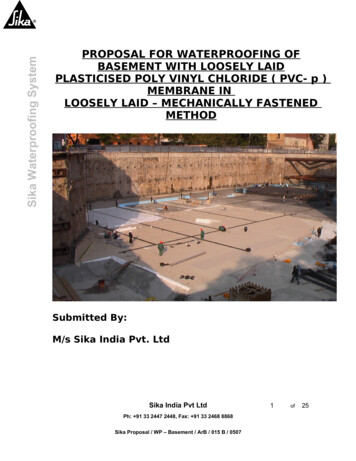

Sika Waterproofing SystemPROPOSAL FOR WATERPROOFING OFBASEMENT WITH LOOSELY LAIDPLASTICISED POLY VINYL CHLORIDE ( PVC- p )MEMBRANE INLOOSELY LAID – MECHANICALLY FASTENEDMETHODSubmitted By:M/s Sika India Pvt. LtdSika India Pvt LtdPh: 91 33 2447 2448, Fax: 91 33 2468 8868Sika Proposal / WP – Basement / ArB / 015 B / 05071of25

Sika Waterproofing SystemSika Company ProfileSika is a global company with a world-wide network of subsidiaries active in the fieldsofSpeciailty chemicals for CONSTRUCTION and INDUSTRY. Sika is committed to quality,service, safety and environmental care. Our world-leading branded products are allprovensolutions and are based on our core capability in the following areas: Sealing Bonding Damping - Reinforcing – Protecting.Presently Sika is the world s largest manufacturer of speciality chemicals forconstructionindustry. Subsidiaries in 70 countries worldwide and 11,000 employees linkcustomersdirectly to Sika and guarantee the success of all of its business relationships. Withthisstructure, Sika generates sales of approximately USD 2.9 billion annually. Sika India isawholly owned subsidiary of Sika AG and is a leading player in the Indian ConstructionChemicals Industry.Sika is active in the field of speciality chemicals dividing its activities into twobusinessareas; the Construction Division and the Industry Division. While on the technical sidethese two business areas are closely linked, on the commercial side they reduce thevulnerability to economic cycles because they depend on different markets. Thetechnological affinities permit economies of scale in the areas of R&D, purchasing andproduction. Sika is a company with a strong innovative tradition, constantly strivingfor newlevels of excellence. This means developing innovative technologies that will open upnewopportunities for the company, its employees, and its partners in trade and industry.Our valuesEach product and service reflects our commitment to the three core values thatdefine ourcompany: Innovation - Consistency – PartnershipSika India Pvt LtdPh: 91 33 2447 2448, Fax: 91 33 2468 8868Sika Proposal / WP – Basement / ArB / 015 B / 05072of25

Sika Waterproofing SystemOur voiceWe speak from experience and with a global understanding. We talk knowledgeablyaboutthe local and geographical issues faced by our customers. We respond to ourcustomersquickly, wherever they are, in an approachable and friendly way.Sika India has four manufacturing facilities located at Goa, Kalyani (West Bengal),Jaipur (Rajasthan), Chennai ( Tamil Nadu ) respectively. We have a nation widenetwork ofover 200 dealers andapplicators. Sika products have been used in many prestigiousprojectsacross the country.INTRODUCTION TO PVC WATERPROOFING MEMBRANESPVC (polyvinyl chloride) roof membranes have the longest track record of anythermoplastic membrane, with the first PVC-based systems installed in Europe in the early1960s. The use of PVC waterproofs membranes for under ground structures ( even challengingstructures like canals, Tunnels, etc. ) continues to grow in the recent years all across the globe.Besides the important feature of heat-welded seam technology, PVC waterproof membranes offermany other inherent features.These additional features include :a comprehensive history of product testing,root resistance.a high resistance to puncture and impact.resistant against permanent compressive strength.an excellent resistance to flame exposure and subsequent fire propagation,proven durability against aggressive ground water, chemicals etc.good low-temperature flexibility and high-temperature tolerance.long Life expectancy.resistance to high water pressureease of application and faster installation time.Sika India Pvt LtdPh: 91 33 2447 2448, Fax: 91 33 2468 8868Sika Proposal / WP – Basement / ArB / 015 B / 05073of25

Sika Waterproofing SystemPVC: A history of performanceSpecifically, vinyl is “polyvinyl chloride.” PVC is a molecule comprised of carbon, hydrogenand chlorine (taken from salt). As mentioned above, today’s reinforced and non reinforcedplasticized poly vinyl membranes have a long history of installations worldwide; many that wereinstalled over 30 years ago , are still performing today. Vinyl membranes for roof and underground structure applications were first developed in Germany and Switzerland in the 1960s andarrived in North America in the 1970s. The use of vinyl membranes has grown significantly andrapidly in North America ever since then. In Asian market too, the technology has got itssuccessful footings quite a long time back in countries like China, Japan etc. However, as far asIndian market is concerned, the technology is still in its initial days and Sika is proud to pioneerthat effort with a vast experience in the field with already few major projects undertaken on Indiansoil.The Thermoplastic Advantage:Vinyl is the best known thermoplastic roof membrane. “Thermoplastic” means that whenheated sufficiently, the material temporarily changes from a solid to a semisolid stateenabling the sheets or panels that are overlapped to be fused together and return to asolid upon cooling, yielding one continuous membrane. It is this feature that enables theseam overlaps of vinyl roof membranes to be fused or heat welded together.To accomplish the welding, specialized, electrically-powered welding equipment that is either selfpropelled or handheld is used. These units operate on electricity and inject heated air into theseam area, softening the membrane surfaces. A roller that is either hand-held or part of the selfpropelled unit, presses the seam overlap together. As the welder moves away from a given seamlocation, the membrane quickly cools down to ambient temperature and the heat weld is made,providing a watertight bond.Vinyl roof membranes are manufactured by various methods, including extrusion,calendering, laminating, extrusion coating, spread coating or a combination of the above.In all cases, however, the finished vinyl roof membrane contains polyester or fiber glassreinforcement, vinyl resins, ultra-violet light inhibitors, heat-stabilizers, biocides, pigmentsand plasticizers. Polyester reinforcement imparts high tearing and breaking strengthsneeded for mechanically- fastened roofing systems.The versatility of vinyl affords the membrane manufacturer many options when formulatingfor enhanced chemical resistance, flexibility and/or tensile strength. Vinyl membraneshave great versatility of application. Vinyl membranes are usually mechanically attached, adheredto the substrate . In addition, vinyl membrane can be readily produced with “fleece cushion”Sika India Pvt LtdPh: 91 33 2447 2448, Fax: 91 33 2468 8868Sika Proposal / WP – Basement / ArB / 015 B / 05074of25

Sika Waterproofing Systembacking (typically polyester) that enables it to be installed over slightly rough surfaces and/or to beadhered with a variety of adhesives.In order to complement this versatility of application, vinyl roof membranes can bemanufactured in a variety of colors. This feature allows for the application of rooftop logosor multiple-color roofs. The look of steep slope metal can also be simulated with a coloredvinyl membrane.Another significant benefit of Poly vinyl waterproof membranes is their fire resistance. Vinylmembranes are inherently self-extinguishing which enables them to perform exceptionally well infire tests undertaken at organizations such as Underwriters Laboratories and Factory Mutual, etc.and to perform reliably in real-world flame exposure. In addition to fire resistance, vinylmembranes also meet or exceed other industry performance standards that involve waterleakage, puncture resistance, root resistance and so on.Over a long period of time, vinyl roof membranes have earned the recognition of being aproven and versatile thermoplastic for under ground waterproofing applications.Specification for waterproofing of basement structure( For Higher water pressure situation with PVC membrane system )ScopeThis specification covers waterproofing of basement structure by open cut excavation method withplasticized PVC membrane Sikaplan WP 1100-15HL formerly known as Sikaplan 9.6 by installationmethod of loosely laid and mechanically fastened.General The surface where waterproofing system needs to be installed shall be made free from all otheractivities that could disrupt the installation of the waterproofing system.The specified waterproofing system shall be applied by a specialist applicator certified by themanufacturer of the system strictly se per the written method statement submitted by the manufacturer.All products in the system shall preferably be manufactured by Sika India Pvt Ltd, an ISO 9001 certifiedcompany, meeting the minimum key performance properties listed below against each; Should theapplicator choose to use alternative equivalent products he shall provide proof of compliance withspecified key performance properties.The applicator shall ensure that the products in the system are received in good condition withoutdamage, stored as per manufacturer’s instructions.Sika India Pvt LtdPh: 91 33 2447 2448, Fax: 91 33 2468 8868Sika Proposal / WP – Basement / ArB / 015 B / 05075of25

All products in the specified system shall be produced by a single manufacturer or if the contractor orthe applicator chooses to use some products from different sources they shall submit proof ofcompatibility.Sikaplan WP 1100-15HL and geo textile rolls etc. should be stored in horizontal positions in dry areasand protected against weathering on site as shown below.Waterproofing applicators’ staff should only wear suitable shoes with rubber soles ( e.g. sports shoesand jogging shoes ) when walking over Sikaplan WP 1100-15HL during and after installationSmoking and open fires must not be permitted at the site.Sika Waterproofing System Waterproofing system :Highly flexible Sikaplan WP 1100-15HL membrane can protect an underground / basement structureagainst moisture , penetrating water and ground water under hydrostatic pressure.Application : Horizontal Slab Over the base P.C.C, provide a 20 mm smooth plaster screed with cement – sand mortar reinforcedwith poly propylene fibres to control shrinkage cracking. However, if the P.C.C layer is finishedsmooth without any sharp projections of aggregate, the covering plaster layer may be omitted.Over the smooth screed, apply geo textile Sika – Sarnafelt 300 with weight / unit area as 300 gm /sq. m with a minimum of 100 mm overlap by loosely lay out method.Loosely lay out Sikaplan WP 1100-15HL with a minimum of 50 mm overlap which should be weldedby hot air welding gun of approved make ( Leister guns ).loosely lay out the geo textile ( 500 gm / sq. m ) with a minimum of 100 mm overlapping. Water barsfor compartments should be kept unprotected. Use provisional ballast for geo textile with sand bags.Loosely lay out the polyethylene ( HDPE ) sheet ( 0.300 mm ) as separation / gliding layer on geotextile . Over lap the HDPE sheet for 100 mm with adhesive tape for fixing at overlaps.Provide a protection screed plaster layer with minimum 300 kg / cu. m cement content and minimumof 25 mm thickness with poly propylene fibre as reinforcement.At the junction of the base slab and vertical wall ( kicker joint ), water bar ( Type AR ) to be used asper the guidelines from manufacturer. Application : Vertical Walls Recommendation would be to cast the vertical wall fully and apply the membrane with bottom downapproach with strategic fastening with metal strip and fasteners.In case, the wall is cast in stages and the membrane is applied simultaneously, the membraneshould be provisionally tucked with the exposed reinforcement or the form work depending on thesite conditions and should be heat welded with the surface water bar ( Type AR ) at the joints ofpours.PVC discs of 100 mm diameter of approved round shape such as Sika - Sarnafil PVC DISC D 100should be fixed mechanically onto the vertical wall and Sikaplan WP 1100-15HL should be weldedonto the discs to hold the membrane in vertical position against sagging due to self weight.Provide protection with Sika - Sarnafelt 300, a geo textile membrane with weight / unit area as 300gm / sq. mt ). Refer to Annexure 1 for technical specification. To secure geo textile with themembrane, use stitching method with PVC small strips of the same membrane which shall bewelded with the main membrane.Sika India Pvt LtdPh: 91 33 2447 2448, Fax: 91 33 2468 8868Sika Proposal / WP – Basement / ArB / 015 B / 05076of25

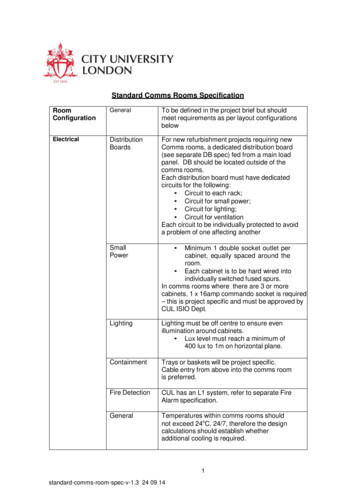

Sika Waterproofing System Erect brick work firmly on the waterproofing.Please refer to the method statement for details on installation guidelines. Accessories :1.2.3.4.Sikaflex 11FC – Fast curing single component polyurethane sealant cum adhesiveSika Thinner DSStainless Steel plates and anchors. ( refer annexure 2 for specification of anchors and fasteners )PVC disc ( Sika – Sarnafil PVC DISC D 100 ) Equipment for hot air welding :1.2.3.3.Leister Triac S ( manual for detailing )Leister Electron ( manual for seam welding )Leister Varimat ( Semi automatic for long seam welding )Tool Box with roller, nozzles etc.Key performance properties of the specified product SIKAPLAN 9.6 :Performance propertyStandard / test methodValueSikaplan WP 1100-15HL ( conforms to DIN 16730 and DIN 16938 )Sika India Pvt LtdPh: 91 33 2447 2448, Fax: 91 33 2468 8868Sika Proposal / WP – Basement / ArB / 015 B / 05077of25

Sika Waterproofing Systema. Thickness1.5 mm as per DIN 533353 1.5mmb. Chemical baseSoft Polyvinyl chloride ( PVC )Plasticized PVC nonbleed type and unreinforcedc. Water vapour DiffusionresistanceDIN 53122 24000 µd. Tensile StrengthDIN EN !SO 527 – 3Longitudinal andTransversal :16 N / sq. mme. Elongation 300 % as per DIN EN !SO 527 – 3Longitudinal andTransversal :313%f. Seam StrengthDIN 16726Cracks occur nexttothe seamg. Behaviour under hydrostaticpressure.DIN 16726f. Puncture resistanceDIN

e m PROPOSAL FOR WATERPROOFING OF BASEMENT WITH LOOSELY LAID PLASTICISED POLY VINYL CHLORIDE ( PVC- p ) MEMBRANE IN LOOSELY LAID

![[MS-ADTS-Diff]: Active Directory Technical Specification](/img/1/ms-adts-170316-diff.jpg)