Transcription

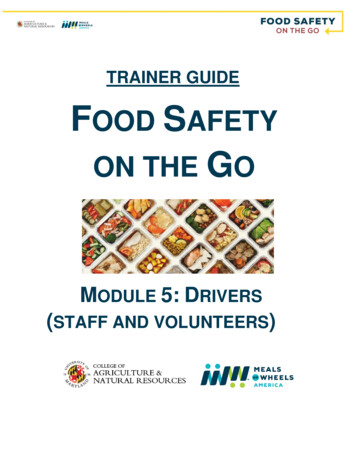

Archival copy: for current recommendations see http://edis.ifas.ufl.edu or your local extension office.FCS8769Good Worker Health and Hygiene Practices: TrainingManual for Produce Handlers1Amy Simonne, Jeffrey Brecht, Steve Sargent, Mark Ritenour, and Keith R. Schneider2ContentsPreface1. IntroductionReferencesPreface8. What can you provide for workersThe goal of this first Edition of Good WorkerHealth and Hygiene Practices: Training Manual forProduce Handlers is to provide owners, managers,and/or supervisors in Florida's produce industry atraining tool for their workers. Drawn from manysources in the subject area including the FDA-GAPs,FDA-GMPs, FDA Model Food Code,recommendations from the American College ofOccupational and Environmental Medicine, and otherpublications from federal government agencies, thismanual is designed to be a reference to accompanythe other educational materials included in theUF/IFAS Worker Health and Hygiene TrainingProgram:9. Stressing personal hygiene for workers1) Handwashing posters:2. Choosing the appropriate FDA Guidelines3. Understanding foodborne illness4. How biological contaminants spread at the farmand in packing facilities5. Importance of personnel health and hygiene6. Preventing produce contamination by workers7. Safe from the start10. Proper hand washing for employees Printed (11” x 18”) full color handwashingposter in EnglishAppendices1. This document is FCS8769, one of a series of the Family Youth and Community Sciences Department, Florida Cooperative Extension Service, Institute ofFood and Agricultural Sciences, University of Florida. Original publication date May 2005. Reviewed August 2008. Visit the EDIS Web Site athttp://edis.ifas.ufl.edu.2. Amy Simonne, PhD, assistant professor, Food Safety and Quality, Department of Family, Youth and Community Sciences, University of Florida,Gainesville, FL 32611-0310; Jeffrey Brecht, PhD, professor, Postharvest Physiology; and Steve Sargent, PhD, professor, Postharvest Physiology andTechnology, Horticultural Sciences Department; Mark Ritenour, PhD, associate professor, Postharvest, Indian River REC- Ft. Pierce; and Keith R.Schneider, PhD, assistant professor, Food Safety, Food Science and Human Nutrition Department, University of Florida.The Institute of Food and Agricultural Sciences (IFAS) is an Equal Opportunity Institution authorized to provide research, educational information andother services only to individuals and institutions that function with non-discrimination with respect to race, creed, color, religion, age, disability, sex,sexual orientation, marital status, national origin, political opinions or affiliations. U.S. Department of Agriculture, Cooperative Extension Service,University of Florida, IFAS, Florida A. & M. University Cooperative Extension Program, and Boards of County Commissioners Cooperating. LarryArrington, Dean

Archival copy: for current recommendations see http://edis.ifas.ufl.edu or your local extension office.Good Worker Health and Hygiene Practices: Training Manual for Produce Handlers Printed (11” x 18”) full color handwashingposter in Spanish2) Three videos Manager Guide to Worker Health and Hygiene(18:02 Minutes, English) Proper Handwashing for Workers (9:42minutes, English) Proper Handwashing for Workers (10:52minutes, Spanish)3) DVDs containing the digitized version of all videomaterials4) Check list for managers, and fact sheetsIt is our intention to update and revise thismanual on a regular basis to reflect changes in thefield. We welcome any feedback or suggestions forimprovement from the people using this trainingmanual and training program. We thank the FloridaFruit and Vegetable Association (FFVA) for partialfunding of this project. Our gratitude is extended toDr. Douglas L. Archer who reviewed this manual.1. Introduction, The Importance ofFood SafetyIt is estimated that 76 million cases of foodborneillness occur in the United States each year leading toapproximately 325,000 hospitalizations and 5,000deaths (Mead et al. 1999). While some of thesefoodborne illnesses can be attributed to one of morethan 200 known diseases, the majority of foodborneillnesses have yet to be identified with their causativeagent. Causative agents for foodborne illness includeviruses, bacteria, parasites, toxins, metals, chemicals,and prions. Wide ranges of foods from both animaland plant origins (including produce) have beenimplicated in foodborne illness outbreaks.Fresh produce is a crucial part of a healthy diet,but in the last three decades the number of foodborneillness outbreaks caused by foodborne pathogensassociated with fresh produce consumption hasincreased (Sivapalasinagam, et al., 2004). Accordingto the Centers for Disease Control and Prevention(CDC), at least 12% of foodborne outbreaks in the2US in the 1990s were linked to produce. The problemwas prevalent enough that the FDA developed andreleased the FDA Good Agricultural Practices(GAPs) document, and the FDA's Guide toMinimized Microbial Food Safety Hazards for FreshFruits and Vegetables. In June 2004, the FDA furthercommitted to addressing the problem by releasing anaction plan to reduce produce related illness, ProduceSafety From Production to Consumption: A ProposedAction Plan to Minimize Foodborne IllnessAssociated with Fresh Produce Consumption. Themajor goals of this action plan are to (a) preventcontamination of fresh produce; (b) improvecommunication with producers, preparers, andconsumers about fresh produce; and (c) to facilitateand support research relevant to fresh produce.Foodborne illness can result in litigation andregulatory actions that can bring major financialhardship to any food related business. Many produceoperations and farms have gone out of business afterfoodborne illness outbreaks were traced back to them.The United States Department of AgricultureEconomic Research Service (USDA ERS) estimatedthat for the six major bacterial pathogens, the costsassociated with human illness were 9.3 to 12.9billion annually (Busby et al. 1996). Estimatedeconomic loss is highly variable depending on thefactors used in the equation. Therefore, to protectyour business and interests, one of your mostimportant goals is to be proactive and followworkplace guidelines or rules established byregulatory agencies. These guidelines will help youprovide your customers with the safest and highestquality fresh produce. Food safety must become animportant part of your daily activities. This proactiveapproach will help your company acquire the trust ofboth consumers and suppliers.Points to remember: Foodborne illness may cause mild to seriousdisease in consumers, depending on theindividual. Common symptoms of foodborneillness include upset stomach, vomiting, cramps,diarrhea, or more serious symptoms that canresult in death.

Archival copy: for current recommendations see http://edis.ifas.ufl.edu or your local extension office.Good Worker Health and Hygiene Practices: Training Manual for Produce Handlers Babies, children under five, the elderly,pregnant women, and people who have medicalproblems are more likely to contract foodborneillness, and to have more serious symptoms and ahigher death rate. Foodborne illness results in monetary penaltiesand lost revenue. Foodborne illness could bring about negativepublicity, which could ultimately result in theclosing of your operation.2. Choosing the Appropriate FDAGuidelinesGuidelines for worker health and hygiene areprovided in many documents from the United StatesFood and Drug Administration (FDA). For farmsettings or packinghouse operations, guidelines thatapply can be found in both the FDA GoodAgricultural Practices (GAPs), and GoodManufacturing Practices (GMPs) documents. Whilethe FDA GAPs extensively covers farm operation, theGMPs document is more suitable for packing houseoperations. The GMPs (21 CFR Part 110.10 a, b)target those people in contact with food or foodcontact surfaces. Workers are taught to adhere togood hygienic practices to prevent foodcontamination.The FDA Model Food Code provides regulatoryauthority governing foodservice operations. Althoughwritten for the food service industry, the FDA FoodCode can provide a good guideline for preventingfoodborne illness from spreading throughout yourproduce farm or packaging facilities. For otherprocessing facilities (seafood, meat and poultry, andjuice) the specific Hazard Analysis and CriticalControl Point (HACCP) outlining mandatory rulesand guidelines is available.Please note that currently, no MANDATORYrules are ENFORCED on the produce industry;the current RULES (GAPs) are VOLUNTARYonly. This document will serve as GUIDELINESnot RULES for the produce industry.Following these guidelines will help reduce therisk of being implicated in a “reckless spread” of3foodborne illness through poor personnel hygiene.The scope of this document will be relevant topersonnel health and hygiene.3. Understanding Foodborne IllnessTypes of contaminationFoodborne illness is a direct result of thecontamination of food such as produce, by harmfulsubstances or disease-producing microorganisms.Contaminants are classified into three categories:biological, chemical, or physical agents. Ninetypercent of foodborne illnesses come from biologicalcontamination!Biological ContaminantsBiological contamination, the most common ofthe three types of contamination, can include viruses,bacteria, parasites, and other living agents: agents thatcan multiply or grow in or on the human body. Someof these biological contaminants are located on theskin or in the nose, mouth, urine, or stool of peoplewho handle food or produce.Bacteria. Bacteria are ubiquitous in nature.Some are beneficial (e.g., those used in makingfermented foods) and some can cause foodborneillnesses. Some bacteria, especially those thatcan make spores, can survive on produce or foodcontact surfaces for a long period of time. If andwhen the conditions are right, some of thebacteria that survive on food and produce cangrow and make toxins on the food or produce.Viruses. Viruses multiply in the living cell only.The most common foodborne viral illness isassociated with Noroviruses, formerly calledNorwalk and Norwalk-like virus. The moreserious foodborne viral infection is caused byHepatitis A, which is transmitted by an infectedperson who frequently handles food or producethat requires no further heating, such as salads orherbs (e.g., green onions), and has not washedhis or her hands after using the toilet. Hepatitis Ahas been implicated in outbreaks related toproduce.

Archival copy: for current recommendations see http://edis.ifas.ufl.edu or your local extension office.Good Worker Health and Hygiene Practices: Training Manual for Produce HandlersParasites. Harmful microscopic parasites foundin many produce-related outbreaks areCryptosporidium and Cyclospora. Theseparasites can also be transmitted viaperson-to-person contact if good personalhygiene practices are not followed. Thesemicroscopic parasites are also associated withpoor water quality.Fungi, molds, and yeast. In a practical sense,this group of biological contaminants on freshproduce causes little concern to human health,because consumers discard fresh produceshowing signs of mold, fungi, or yeast.However, if fresh produce is infested orcontaminated by fungi, or molds, it could lead tofinancial losses for the farmers and packers.Once contaminated, it is very difficult todecontaminate. Therefore, applying food safetyrules will also increase the profit margin byreducing produce lost from spoilage caused byfungi, mold, or yeast.Chemical ContaminantsAny chemicals used in your operation canpotentially become chemical contaminants if they areimproperly used. Keep all chemicals in a lockedstorage area in their original containers. If chemicalsmust be transferred to smaller containers or spraybottles, label each container appropriately. If used,pesticides should only be applied by a licensedpesticide applicator. Strictly following directionssupplied by the manufacturers can help preventcontamination of fresh produce in your operation.Chemical contaminants include pesticides, cleaningsolutions, dangerous metal products (e.g., lead,copper, paint), and any foreign chemical that comesin contact with food or produce.Physical ContaminantsAny foreign objects that are accidentally mixedin with foods or produce become physicalcontaminants. Physical contaminants include glass,metal fragments (e.g., nails, screws, staples),packaging materials, fingernails, nail polish chips,hair, jewelry pieces, and any foreign objects that aremixed in with produce.4Food Infection, Food Intoxication, and ToxinMediated InfectionFood InfectionFood infection occurs whenever a person eatsproduce or foods that contain enough live germs(bacteria, viruses, or parasites) that can grow insidethe human body. The way to reduce infection is toreduce the possibility of produce contaminationduring growing, harvesting, packaging, and handling.Consumers can also cook or heat produce to a propertemperature, which can kill some of these germsmaking the food safe to eat. However, cooking orheating many types of fresh produce is not an option.Therefore, emphasis on prevention or minimizingcontamination is very important in the fresh produceindustry. The following are some infections that aretraced back to biological contamination of produce.Salmonella. Traditionally, Salmonella isassociated with poultry, red meat, shellfish, eggs,and other high protein foods, but in recent yearsoutbreaks caused by Salmonella have been linkedto produce such as tomatoes, cantaloupes, andother crops. The symptoms usually appear within12 to 36 hours after consumption and includefever, vomiting, diarrhea, and cramps. As few as15-20 Salmonella cells are needed to causeillness. This number can vary depending on theage, health status of host, and strain differencesamong the members of the genus.E. coli. E.coli is sometimes found inunpasteurized milk and raw or rare ground beef(e.g., E. coli O157:H7). In recent years thisbacterium has also been linked to outbreaks inproduce. The E. coli bacteria can lead tofoodborne infections or toxicoinfections withvarious levels of severities, depending on thestrain ingested and the health status of the host.Symptoms appear within 12 to 25 hours andinclude severe diarrhea, cramps, and dehydration.Shigella. A multi-state outbreak ofshigellosis in 1999 was traced back to theconsumption of fresh parsley contaminatedwith Shigella sonnei. This species ofbacterium has been implicated in manymore foodborne outbreaks in recent years.

Archival copy: for current recommendations see http://edis.ifas.ufl.edu or your local extension office.Good Worker Health and Hygiene Practices: Training Manual for Produce HandlersOnset symptoms can appear within 12 to 50hours of exposure and include fever,vomiting, abdominal pain, cramps, diarrhea(with blood, pus, or mucus in stools), andtenesmus (desire to empty bowel).Depending on a persons health status, asfew as 10 cells of the organism can causeillness.Hepatitis A. The hepatitis A virus has beenimplicated in several outbreaks related toproduce (i.e. green onions and strawberries).Hepatitis A is usually a mild illness withsymptoms including fever, malaise, nausea,anorexia, and abdominal discomfort, followed inseveral days by jaundice (yellow skin). Aninfectious dose of this virus ranges from 10-100virus particles.Points to remember:Once infected with any enteric pathogen, aperson can continue to carry the bacteria/virus inthe intestinal tracks and stool for a long period oftime without showing symptoms. Therefore,fecal-oral transmissions can become a majorroute of infection if good personal hygiene is notpracticed.Staphylococcus aureus toxin. One of the mosthigh profile multiple outbreaks related to S.aureus toxin associated with produce was foodpoisoning caused by canned mushrooms from thePeoples Republic of China in 1989 (CDC, 1989).Staphylococal toxin is produced byStaphylococcus aureus, a bacterium that is oftenfound on the human body, mainly on wounds,cuts, burns, infections, and pimples located onthe hands, in the nose, and in the throat. Thistoxin is heat stable (cannot be destroyed byheat). The microorganism can grow best onfoods such as custards, dressings, meats, andtofu; thus it has been implicated in the outbreaksrelated to these foods. Symptoms appear within 2to 4 hours after eating and include severevomiting, diarrhea, cramps and prostration.Symptoms may last 1 to 2 days.Toxin Mediated Infection or ToxicoinfectionToxicoinfection occurs when a food that containspathogens is eaten. The pathogens grow and producetoxin(s) in the intestine of the victim.Microorganisms that are capable of causing thetoxin-mediated infection include all Shigella species,Clostridium perfringens, and E. coli O157:H7. BothShigella and E.coli O157:H7 have been implicated inthe outbreaks with fresh produce.Food IntoxicationFood intoxication occurs when a person eats foodcontaining toxins or chemicals that cause illness. Thetoxins may have been produced by pathogens foundon the food, or may be the result of a chemicalcontamination. The toxin might also be a natural partof the plant or animal consumed. Although theheating process destroys bacteria and some heat-labiletoxins, it does not destroy those toxins that are heatstable. Eating food contaminated by these remainingtoxins leads to foodborne illness. Onset symptoms forfoodborne intoxication appear quickly, within a fewhours. The following are some food intoxications thatwere traced back to biological contamination ofproduce.54. How Biological ContaminantsSpread at the Farm or PackingFacilitiesBacteria, viruses, and parasites (microscopicparasites) are spread by the following means. sick employees unwashed hands or contaminated gloves employees with open cuts and scrapes employees who touch their faces and mouthswith their hands improperly disposed hygienic items (i.e., toiletpaper, paper towels)

Archival copy: for current recommendations see http://edis.ifas.ufl.edu or your local extension office.Good Worker Health and Hygiene Practices: Training Manual for Produce Handlers employees who do not wash their hands afterusing the restroom unwashed and poorly sanitized preparationsurfaces, utensils, and preparation areas rotten produce that drips onto other produce unwashed surfaces or packing equipment soiled wiping cloths, brooms, or other cleaningitemsOnce items are contaminated, bacteria, viruses,and parasites can survive on the following surfacesfor long periods of time: cooling coils and cooling ducts, produce, produce contact surfaces, and floors, floor drains, and equipment.The situations provided here are only partialexamples; there are many more instances where thespreading of biological agents can occur.5. The Importance of PersonnelHealth and Hygiene6Resident microorganisms are the ones that residepermanently on the different body parts of bothhumans and animals (i.e., skin, hair, and nasalcavities). One pathogenic resident microorganisms ofhigh concern is Staphylococcus aureus. S. aureuslevels are highest in pimples and boils. 15% to 50%of healthy individuals may be carriers of S. aureus,but never show symptoms. Under certain conditions,S. aureus can multiply at low water activity (dryconditions) and produce toxins which are heat stable.The other group is the transient (temporary)microorganisms from sources such as feces, soil/dust,raw materials, dirty surface, etc. Pathogens fromfeces include, but are not limited to, Salmonella spp,E. coli O157:H7, Cryptosporidium, and Hepatitis A.Below is a partial list of infectious and communicablediseases that are transmitted through food.Pathogens Often Transmitted by FoodContaminated by Infected Employees*1. Hepatitis A virusFever, jaundice2. Salmonella typhiFever3. Shigella speciesDiarrhea, fever, vomiting4. Noroviruses5. Staphylococcus aureusDiarrhea, vomiting6. StreptococcuspyogenesFever, sore throat withfever*This table is an excerpt from the FDA Food CodeThere is a direct correlation between poorpersonal hygiene and foodborne illness. For thisreason, it is critical that produce handlers and otherfarm or packinghouse personnel understand andpractice good basic hygiene habits, including properhandwashing, on a regular basis. The FDA whitepaper (FDA 1999) cited poor personal hygiene andimproper handwashing as the third most importantcause of foodborne illness. This report also cited that93% of outbreaks related to food handlers involvedsick workers. Problems associated with theseoutbreaks included poor personal hygiene, poorhandwashing, open sores, improper glove use, andeating while on the job.Human bodies carry a variety of microorganismssome of which are non-pathogenic (not diseasecausing), while others are pathogenic (diseasecausing). These microorganisms can be furtherdivided into two categories: resident and transient.Diarrhea, fever, and vomiting are also symptomsof several other pathogens occasionally transmittedby food contaminated by infected employees.Practicing good personal hygiene helps to ensuregood health and to prevent the spread of illness.Management should explain to employees the manyways of keeping themselves clean. Almost any freshproduce item can become contaminated if nothandled properly. By ensuring that produce handlersand other farm or packinghouse employees practicegood personal hygiene, you can reduce the chance ofselling contaminated produce to consumers, therebyreducing the risk of losing your business. Remember,we are all responsible for food safety!

Archival copy: for current recommendations see http://edis.ifas.ufl.edu or your local extension office.Good Worker Health and Hygiene Practices: Training Manual for Produce Handlers6. Preventing Produce Contaminationby WorkersGood worker health and hygiene is critical forpreventing foodborne illness. The first step towardsgood worker health and hygiene practices is first handknowledge of how foodborne illnesses and otherinfectious diseases spread. The second step is toknow how to contain or limit the spread of foodbornediseases by practicing scientifically knownintervention techniques such as handwashing. Lastly,one should have a healthy life style. After all, ahealthy body can fight germs better than an unhealthybody, and a healthy worker is a productive worker.Although written for health professionals andphysicians, the guidelines from the American Collegeof Occupational and Environmental Medicine(ACOE) are highly applicable for controllinginfectious diseases in many settings. Maintaininggood worker health and hygiene requires a sanitaryfacility, and workers who are healthy, practicepersonal cleanliness, and who refrain from personalbehaviors known to spread sickness. Here are someof the simple steps that the operators or managers cantake to help prevent the spread of foodborne illnesses.How Infectious Diseases SpreadAs stated above, the first step towards goodworker health and hygiene practice is the first handknowledge of how foodborne illnesses and otherinfectious diseases spread. It is important formanagers, operators, and/or owners to convey thatfoodborne illness can spread through contaminatedfoods, oral-fecal contact, or person-to-person contact.And that good worker health and hygiene is one ofthe major ways to control infectious diseases.Infection Control TechniquesHandwashing. Handwashing is one of the mosteffective ways to stop the cycle of infectiousdisease, especially those diseases spread throughoral-fecal or person-to-person contact. Properhandwashing can remove dirt, soil, and someother contaminants including chemical (e.g.,pesticides, cleaning solutions) and biologicalagents (e.g., bacteria, viruses, parasites).7Cleaning and disinfecting or sanitizing.Cleaning is the action of removing visible soil ordirt from food or produce contact surfaces.Cleaning reduces the amount of availablenutrients that can support the growth ofmicroorganisms. Disinfecting or sanitizingactions can reduce the level of harmful microbesso that the natural immunities in the body canhandle their presence.Safe food handling and preparation. Becausemany foodborne illnesses are transmitted byfoods, making sure that food is handled andprepared in a safe and sanitary manner canreduce the chance of people contractingfoodborne illnesses. Thus reducing the chance oftheir spreading them to others. The mosteffective food safety behaviors include keepingfoods at safe temperatures, using a thermometerto determine the adequate cooking of foods,avoiding cross-contamination, washing hands,and avoiding high-risk foods. These principlesare referred to as the four steps: clean, separate,cook, and chill (Partnership for Food SafetyEducation, revised 2004).Healthy lifestyle. Healthy lifestyles include, butare not limit to, adopting healthy behaviors suchas eating nutritious foods, being physicallyactive, and avoiding tobacco use. A healthylifestyle can prevent or control the devastatingeffects of some chronic and infectious diseases.Vaccination. Various kinds of vaccinations arealso listed as tools for a healthy lifestyle forcertain population groups. Hepatitis Avaccination is relevant to food handlers.Vaccination for hepatitis A is recommended forpeople in higher risk groups for this diseaseincluding men who have sex with men, and illicitdrug users. Food handlers are not at higher riskof contracting hepatitis A (HAV) because oftheir occupation. However, food or producehandlers may belong to demographic groups thathave a higher incidence of Hepatitis A than therest of the population (such as young personsand persons with lower socioeconomic status).

Archival copy: for current recommendations see http://edis.ifas.ufl.edu or your local extension office.Good Worker Health and Hygiene Practices: Training Manual for Produce HandlersExperts conclude that food handlers acquireHAV infection from others within theircommunities, and that reducing foodbornetransmission of Hepatitis A will ultimately beachieved through routine vaccination ofthose populations at risk (Fiore, 2004).Some county Health Departments in the USalready impose mandatory hepatitis Avaccination for food handlers, but there isno mandatory Hepatitis A vaccination forproduce handlers or for people working inthe produce industry.8contact with foods, or with food contactsurfaces and packing materials [FDA FoodCode].Encourage a healthy life style. In general,healthy employees are more productive thanunhealthy employees, and can help in preventingcontamination during handling of produce. It isimportant to note that sick employees do notalways show symptoms. People who have justrecovered from a foodborne illness can continueto excrete microbes. These people cancontaminate produce during handling or caninfect other workers and surfaces they touch.7. Safe from the StartManagement should communicate to staff andnew applicants their commitment to food safety, andthat employee health is a priority in preventing afoodborne illness outbreak. Without commitmentfrom management, the program will not besuccessful.Identify Employees. Identify employees whorisk infecting others and contaminating food.Employees experiencing the followingsymptoms should be instructed to report them toa supervisor and should be restricted fromworking or coming into contact with food(21CFR Part 110.10a,b): vomiting diarrhea fever sore throatEstablish a health and hygiene policy in youroperation. Establish protocols for sickemployees to report their illness. Train youremployees and leaders to report illness as well aseducating them on the consequences of notreporting. Encourage sick employees to seektreatment, give them alternative work, or askthem to take leave.Temporary help. Set up a hiring plan thatincludes replacing permanent staff with qualifiedtemporary staff whenever permanent staff areunable to get the job done.8. What You Can Provide forWorkersTraining. Training and orientation on the basicprinciples of health and hygiene, handwashingtechniques, and recognizing foodborne illnesssymptoms can help workers understand their role indisease prevention. jaundice (seen by yellow eyes or skin) common cold symptomsThese symptoms could pose an increased risk ofcontaminating produce and a health risk forothers.Medical clearance. Set up a plan that requiresemployees who risk spreading infection receivemedical clearance before they return to work.Employees diagnosed with Salmonella typhi,Shigella spp., E.coli O157:H7 or Hepatitis A arerestricted from performing jobs that requireAdequate handwashing stations. An adequatenumber of handwashing units should be available.They should be fully stocked and easily accessible,and no more than a five-minute walk (in the field)from where any employee is working. Instructions forproper use of the handwashing unit should beprominently posted. As a general rule, one facility isrequired for every 20 employees (FDA GAPs).Toilet facilities in the field. An adequate numberof toilet facilities with handwashing units should beavailable. One facility is required for every 20

Archival copy: for current recommendations see http://edis.ifas.ufl.edu or your local extension office.Good Worker Health and Hygiene Practices: Training Manual for Produce Handlersemployees (FDA GAPs). Facilities should be fullystocked, easily accessible, and no more than afive-minute walk from where any employee isworking. Instructions for proper use should beprominently posted.Employee accommodations. Provide a cleanarea designated for employees to eat, drink, and usetobacco. Lockers or other suitable facilities toaccommodate employees personal belongings shouldalso be provided.Other alternative hygiene products. Whendisposable gloves are provided for employees, theemployees must be trained to use gloves properly.Even though hand sanitizers can be used, they are byno means a

9. Stressing personal hygiene for workers 10. Proper hand washing for employees Appendices References Preface The goal of this first Edition of Good Worker Health and Hygiene Practices: Training Manual for Produce Handlers is to provide owners, managers, and/or supervisors in Florida's produce industry a