Transcription

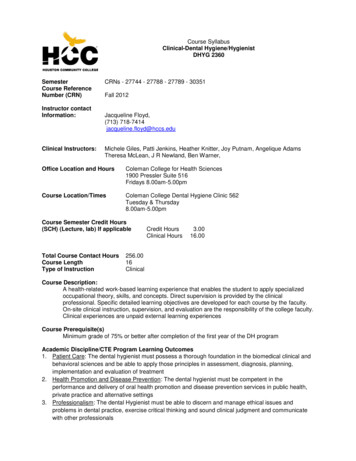

Introduction to IndustrialHygiene for the SafetyProfessionalJeffery K. Dennis, MS, CSP, CHMM, CET,CSSM, WSO-CSEWelcome Today we will introduce and discuss theelements of effective Industrial HygieneMonitoring Programs for the SafetyProfessional Jeffery K. Dennis, MS, CSP, CHMM, CET,CSSM, WSO-CSE – President – IndustrialSafety Solutions, Inc.1

Learning Objective #1At the conclusion of this presentation, attendees will beable to:State the importance and use of an effective industrialhygiene monitoring programLearning Objective #2At the conclusion of this presentation, attendeeswill be able to:List the steps involved in the industrial hygienemonitoring process42

Learning Objective #3At the conclusion of this presentation, attendeeswill be able to:List the different roles of different individualsand organizations involved in the industrialhygiene monitoring process5Industrial Hygiene?Many people think “Industrial Hygiene” is beingsure to brush your teeth prior to coming to workeach day As important as Personal Hygiene is in theworkplace, Industrial Hygiene is somethingcompletely different 3

Definition - Industrial HygieneThe American Industrial Hygiene Association(AIHA) defines Industrial Hygiene as:The science and art devoted to the anticipation,recognition, evaluation, and control ofenvironmental factors or stresses arising in orfrom the workplace which may cause sickness,impaired health and well-being, or significantdiscomfort and inefficiency among workers oramong citizens in the communityDefinition - Industrial HygienistThe AIHA defines an Industrial Hygienist asoccupational safety and health professionalsconcerned with the control of environmentalstresses or occupational health hazards that ariseas a result of or during the course of work4

Importance of an Effective IndustrialHygiene Monitoring ProgramAn Industrial Hygiene Monitoring Programallows safety professionals to scientificallyquantify worker exposures at the job site,and then base each hazard control upon thisactual exposure data.Importance of an Effective IndustrialHygiene Monitoring ProgramCompanies involved in construction, generalindustry, maritime industry, and the serviceindustry all expose employees to hazards.An effective Industrial Hygiene MonitoringProgram will serve to identify, quantify, andprioritize workplace hazards5

Importance of an Effective IndustrialHygiene Monitoring ProgramIndustrial Hygiene includes the development ofcorrective measures to control health hazards byeither reducing or eliminating the exposureImportance of an Effective Industrial HygieneMonitoring ProgramOnce we can quantify the exposures, we canbase all of our engineering controls,administrative controls, and Personal ProtectiveEquipment (PPE) on the actual exposure levels,in order to control and eliminate the hazards andprevent injuries and illnesses126

Importance of an Effective IndustrialHygiene Monitoring ProgramThe four (4) elementsof Industrial ng, and;4.Controlling Occupational HazardsImportance of an Effective IndustrialHygiene Monitoring ProgramThe main goal of an organization’s OccupationalSafety and Health Program is to preventoccupational injury and illness by:1.Anticipating;2.Recognizing;3.Evaluating, and;4.Controlling Occupational Hazards . Look Familiar?7

Anticipating HazardsAnticipatinghealthhazards before they occurallows a more efficient useofresourcesbyminimizing costly retrofitsand renovations needed toprotect the health ofworkersHazard Recognition and EvaluationAn unrecognized hazard can not be controlled,evaluated, or eliminatedUpon recognition of a hazard, the IndustrialHygienist identifies a set of measures necessaryfor proper evaluation of the hazard8

Controlling HazardsThe Industrial Hygienist, working with othermembers of the work team, can implement andmonitor controls that will reduce exposure toacceptable limitsThe Industrial Hygiene Monitoring Program isan integral part of this processAn Effective Industrial HygieneMonitoring Program Will serve to identify, evaluate, and quantifyhazard exposuresAllows the organization to prioritize theworkplace hazards in order to assignresources towards the control or eliminationof the hazardsThus, preventing injuries and illnesses fromrecurring9

Sources of Hazard InformationHazard Information is available in manydifferent forms: General KnowledgeProcessesofChemicals General Knowledge of the Materials UsedandSources of Hazard Information Observations of Work Practices Safety Data Sheets (SDS) Review of Plans for New Facilities and Renovations Conversations with Workers Objective Data10

Sources of Hazard Information Types of Processes Number of Employees Types of Exposures HistoricalInjury/Incident DataSources of Hazard Information Review of Historical Data/Information Test Reports/Chemical AnalysesEarlier Monitoring DataInformation from Professional cumenting Previous Studies, Results, andFindingsResearch Data11

Sources of Hazard Information DiscussionsPersonnelwithMedical Production / Process Review Environmental Analysis Data Process Flow Diagrams Job Safety Analyses (JSA)Sources of Hazard Information Review of Literature Inventory of Chemicals Equipment Field Survey12

Preliminary Survey We can take all ofthis preliminaryinformation andcreate an initialPreliminaryIndustrial HygieneSurvey ReportIndustrial Hygiene Monitoring Plan Using information discovered during thepreliminary survey, the Industrial HygieneMonitoring Plan can be formulated The Industrial Hygiene Monitoring isperformed to evaluate the degree of employeeexposure to hazards in the workplace13

Industrial Hygiene Monitoring Plan Industrial Hygiene Monitoring is a continuousprogram of observation, measurement, andjudgment. Industrial Hygiene Monitoring is a combination ofobservation, interview, and measurement thatpermits a judgment to be made regarding thepotential hazards present in the workplace and theeffectiveness of each hazard controlIndustrial Hygiene Monitoring Plan The Industrial Hygiene Monitoring Planestablishes what we will measure, how wewill measure it, how we will analyze the data,and how we will report the findings of ouranalyses Our Industrial Hygiene Monitoring Plan ismade up of the objectives that will allow us tosystematically reach our monitoring goal14

What Should We Measure?Common WorkplaceHazards include: Industrial NoiseExposureExposure to HeatExposures to ColdBiological ExposuresWhat Should We Measure?Common Workplace Hazards include: Exposure to Chemicals in the Air that are Inhaled Exposure to Chemicals that Contact the Skin Exposure to Chemicals that are Ingested Potential “Injection” Exposures15

What Should We Measure?Common Workplace Hazards include: Exposure to Vibration Exposure to Low or High Illumination Levels Exposure to Radiation (Ionizing and NonIonizing)Chemical HazardsChemicals pose a widerange of potentialhealth hazards: IrritationDiseaseSensitizationCarcinogenicity16

Chemical HazardsChemicals pose a widevariety of PhysicalHazards: FlammabilityCorrosivityReactivityToxicityChemical HazardsChemical Hazards can befound in many forms: DustsLiquidsFumesMistsGasesVaporsSmoke17

Physical Hazards Ionizing Radiation Non-Ionizing Radiation Noise Vibration Heat ColdRadiationIonizing and Non-Ionizing Radiation should bemonitored by an Industrial Hygienist .18

NoiseNoise SurveysDetermine: Sources of NoiseAmount of NoiseExposurePopulationDuration ofExposureProper PPEAttenuationTemperature Very Hot Temperatures are very dangerous tohuman beings and are also very common inthe workplace Very Cold Temperatures are very dangerousto human beings and are also very common inthe workplace19

TemperatureGuidelines for Evaluation: Occupational Exposure Limits are designed toprotect industrial workers from temperaturerelated illnesses Thermal Comfort Limits are used to ensureproductivity and quality of workBiological HazardsSources of BiologicalHazards (biohazards)include: BacteriaVirusesInsectsPlantsBirdsAnimalsHumans20

Ergonomic HazardsErgonomics is thescience of fitting thejob to the worker.Ergonomichazardsinclude: xicity Versus Hazardous Toxicity is the ability of a substance toproduce an unwanted effect when thatmaterialhasreachedasufficientconcentration at a certain site in the body. A Hazard is the practical likelihood thatexposure to the toxic material will causeharm.21

Routes of EntryRoutes of Entryinclude: InhalationAbsorptionIngestionInjectionPersonnel Monitoring Personnel Monitoring is the measurement of aparticular employee ’ s exposure to aworkplace hazard, and in theory, reflectsactual exposure to the employee Personnel Monitoring is usually performedusing personnel monitoring devices, portable,and battery powered air sampling pumps, thatallow the employee to work as usual22

Area Monitoring Area Monitoring measures theambient concentration of ahazard or contaminant in agiven area during a given periodof time AreaSamplingisoftenperformed utilizing portablesampling devices that may ormay not be battery-powered.Personnel and Area Monitoring Personnel and Area Monitoring are oftencombined to determine employee ’ s TimeWeighted Average (TWA) Exposure A Time Weighted Average (TWA) isrequired to determine if the exposure exceedsthe Permissible Exposure Limit (PEL)23

Personnel and Area Monitoring Many times Personnel and AreaMonitoring Samples are collectedand then subsequently submittedto a laboratory for analysis The laboratory analyses eachsample by accepted analyticalmethods and then reports theresults of the analysisDirect Reading Instruments Certain types of analyses areperformed using a Direct ReadingInstrument that performs the analysisonsite and provides the data directly Examples include Noise Dosimeters,which are capable of performing allanalyses onsite and provide resultsimmediately24

Biological Monitoring and MedicalScreening Biological Monitoringis a tool that can beused to assess worker’stotalexposuretochemicals. Exhaled air, blood, andurine can be analyzedin order to determinethe worker’s exposureBiological Monitoring and MedicalScreeningThree main types of Biological Monitoringinclude: Measurement of the contaminant itself (directly) Measurement of a metabolite of the chemical Measurement of enzymes or functions that reflectharm caused by a hazardous exposure25

Medical Surveillance MedicalSurveillanceisperformed in order todetermineemployee ’ sexposure to chemicals inorder to track exposure and toprovide for early detection ofdisease. Over 20 OSHA Standardsnow have requirements forMedical SurveillanceSampling Strategy The preliminary research and initial fieldsurvey help you to identify potential hazardsto which workers may be exposed The Industrial Hygiene Sampling Plandevises the strategy that will be utilized inorder to determine the intensity of thehazards, the source of the contaminants, andthe adequacy of current hazard controls26

How to Sample The Industrial Hygiene Samples shouldrepresent each worker’s exposure The National Institute for OccupationalSafety and Health (NIOSH) has developedthe NIOSH Analytical Methods that willprovide you with the correct method to collectand analyze each sampleMethods of Air Sampling Charcoal TubesCassettesSorbent TubesPassive SamplingDirect Reading InstrumentsPersonnel SamplingArea SamplingGrab SamplesTime Weighted Average(TWA) Samples27

Where to Sample Personnel Sampling – The collection media isattached to the employee Area Sampling – The Work Area is Sampled Determine which method of sampling andwhat sampling technology will work best ineach situationWhom to Sample Use the results of thepreliminary investigation andobservations to determine whichpersonnel are the most likely tobe exposed to each hazard Regulatory issues Studyprocessesmovement patterns Study differences inpatterns, habits, tasksandairwork28

When to Sample Sampling can be performed at different timeswith varying results Study temperature patternsStudy ventilation patternsStudy Work FlowStudy Work LoadTo determine the most opportune times toperform Industrial Hygiene MonitoringHow Long Do We Sample?Each NIOSH Analytical Methodprescribes the type of samplingmedia to utilize and therecommended duration of thesampling event Flow RatesSampling TimesExpected Concentration RangesDuration of the Sampling Event29

Time Weighted Average TWA Measuring the exposure over an eight (8) hour period,typically the entire work shift The TWA is the average concentration for a conventional 8Hour 40 Hour a week work week, to which it is believed thatnearly all workers may be repeatedly exposed, day after day,without adverse effect. TWA data is compared to the Permissible Exposure Limit(PEL)Short Term Exposure Limit (STEL)STEL is the concentration to which it is believedthat workers can be exposed continuously for ashort period of time without suffering from: IrritationChromic or irreversible tissue damageNarcosis of sufficient degree to increase thelikelihood of accidental injury or impair selfrescue30

Short Term Exposure Limit (STEL) An STEL is a 15-Minute TWA exposure thatshould not be exceeded at any time during theworkday Exposures above the TLV-TWA up to theSTEL should be no longer than 15 minutesand should not occur more than 4 times perdayCeiling (TLV-C) The Ceiling Concentrationis the concentration thatshould not be exceededduring any part of theworking exposure. An airborne concentrationof a toxic chemical in theworkplace that shouldnever be exceeded31

Documenting Sampling ActivitiesAccurate Records are a NecessitywhenperformingIndustrialHygiene Monitoring Time SampledFlow RatesSample LocationsSample IdentificationsParametersEngineering Controls PresentSketches of the Sampling AreasChain of Custody FormsHow Many Samples Should We Collect? Each situation will requirea different number ofsamples to be collected Base your judgment uponthe factors unique to eachsituation Try to represent each JobDescription32

How Many Times Should We Sample? OSHA or MSHA Regulated Chemicals willrequire that monitoring is performed on aroutine basis After all Changes Monitoring should be repeated if the results,the analyses, or the sampling media arecompromised or questionableHow Many Times Should We Sample? Monitoring should be repeated if previousresults indicate that corrective actions arerequired – to evaluate if the corrective actionswere effective Monitoring should be performed whenevermaterials, processes, or equipment arechanged33

Who Should Sample? An Occupational Health and Safety Teammay consist of many members dependingupon the organization: Industrial HygienistSafety ProfessionalOccupational Health NurseOccupational PhysicianEmployeesManagers and SupervisorsWho Should Sample? In some organizations allof these functions may beperformed by the sameperson! Although the concept ofperformingIndustrialHygiene Sampling mayseem very simple, it can beverychallengingandtechnical in reality34

Sampling Considerations Sampling EquipmentSampling MethodsSampling PlanSampling MediaChemistryLaboratoryData AnalysisReportingSuggested CorrectiveActionsIndustrial Hygienist Some organizations haveIndustrial Hygienist on staffafull-time Industrial Hygienist can also be Consultants,working for organizations on a contract basis Certain Industrial Hygiene Laboratories willrent monitoring equipment and also provideconsulting services35

Locating Industrial HygieneConsultants American Industrial Hygiene Association(AIHA)Certified Industrial Hygienist (CIH) by theAmerican Board of Industrial Hygiene(ABIH)Insurance Company Industrial onsWorking with Industrial Hygienists Request a Proposal Project InformationScope of ServicesAgree to Fees/ExpensesAgree to SchedulingCheck ReferencesWritten Authorization Manage your Consultants36

Analytical Chemists Industrial Hygiene Analytical Laboratoriesgenerally seek accreditation through a thirdparty such as AIHA, ISO, and many otherthird party registrars Analytical Chemists analyze the IndustrialHygiene Samples submitted to the laboratoryby the Industrial HygienistEngineers/Scientists Engineering and Science is the basis for allSamplingMedia,SampleCollectionEquipment, Direct Reading Instruments, etc. Many companies design, fabricate, and sellthis equipment to Industrial Hygienists,Laboratories, and Organizations37

ReviewLearning Objective #1 – Can We:Recognize the importance and use of aneffective industrial hygiene monitoring program?ReviewLearning Objective #2 – Can We:List the steps involved in the industrial hygienemonitoring process ?7638

ReviewLearning Objective #3 – Can We:List the different roles of different individualsand organizations involved in the industrialhygiene monitoring process?77Review Industrial HygieneMonitoring allows safetyprofessionals to quantitate thelevel of exposures in theworkplace which allows us tobase each EngineeringControl, AdministrativeControl, and PersonalProtective Equipment (PPE)on the actual hazard exposure39

Review We may then utilizeIndustrial HygieneMonitoring to gagethe effectiveness ofeach hazard controlemployed in theworkplaceReviewSteps Involved in the Industrial Hygiene Process Preliminary InvestigationInitial SurveySampling PlanIndustrial Hygiene MonitoringData AnalysisCorrective ActionEvaluation of Corrective Actions40

ReviewDifferent Roles in the Industrial HygieneProcess: Safety ProfessionalIndustrial HygienistConsultantOccupational NurseOccupational PhysicianAnalytical LaboratoryEmployeeManagement / SupervisorEquipment Designers / Manufacturers / SalesmenConclusion Industrial Hygiene Monitoring is a powerfultool that can be used to great effectiveness Utilize Industrial Hygiene Monitoring toAnticipate, Recognize, Evaluate, and Controlworkplace hazards Identify, control, and eliminate hazards toprevent injuries and illnesses41

Questions and Discussion Questions? Discussion? Thank YouSourcesSources: Hagan, et al, National Safety Council, AccidentPrevention Manual for Business & Industry –Administration & Programs, 12th Edition, 2001 Plog, et al, National Safety Council,Fundamentals of Industrial Hygiene, 5th Edition,200242

Industrial Hygiene Monitoring is a combination of observation, interview, and measurement that permits a judgment to be made regarding the potential hazards present in the workplace and the effectiveness of each hazard control Industrial Hygiene Monitoring Plan The Industrial Hygiene