Transcription

9. Sequence ,Quantification-.06/2002PRA Basics for Regulatory Applications (P-105)f127

Sequence QuantificationPurpose: This topic will provide students with anunderstanding of the quantitative basis of PRA.Elements of accident sequence quantification andimportance analysis will be presented."* Objectives:At the conclusion, students will be able to: Describe the major processes for accident sequencequantification Explain the concepts of importance analysis" References: NUREG/CR-2300, NUREG-1489 (App. C)"*06/2002PRA Basics for Regulatory Applications (P-105)128

Quantification Inputs* Initiating events and frequencies Event trees to define accident sequences Fault trees and Boolean expressions for allsystems (front line and support)Data (component failures and human errors)06/2002PRA Basics for Regulatory Applications (P-1 05)129

Parameter Inputs for SequenceQuantification"*Initiating event frequencies"X IE"*Demand failures Qd P"*Mission time failures (failure to run) " ",X htmStandby failuresQS x st/2Test and maintenance unavailability""*Qr Qm XmdmCommon-cause parameters06/2002PRA Basics for Regulatory Applications (P-105)130

Fault-Tree Linking Approach to AccidentSequence QuantificationS-"*Link fault tree models on sequence level using event trees" Evaluate each sequence for minimal cut sets (Boolean reduction)"*Quantify sequence minimal cut sets with data"*Add operator recovery actions and common cause failures" Determine dominant accident sequences" Place in plant damage state bins"*Perform sensitivity, importance, and uncertainty analysis06/2002PRA Basics for Regulatory Applications (P-105)131

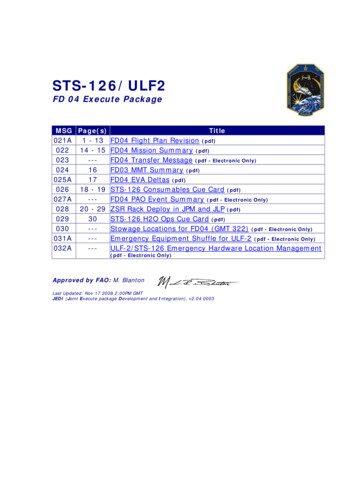

Example of Quantification Process. Let's look at Sequence TBC06/2002PRA Basics for Regulatory Applications (P-105)132

Example of Quantification Process (cont.)T 10 transients (demands) / RA Basics for Regulatory Applications (P-105)1.OE-3PUMP-2133

Example of Quantification Process (cont.)Systems B AND C Fail System B Fails * System C Fails (Pump 1 Valve X) * (Pump 1 * Pump 2) (Pump 1 * Pump 1 * Pump 2) (Valve X * Pump 1 * Pump 2) (Pump 1 * Pump 2) (Valve X * Pump 1 * Pump 2) Pump 1 * Pump 2 (1E-3) (1E-3) 1E-6 (Probability)Sequence TBC T * System B Fails * System C Fails 1O/Year * 1E-6 1 E-5/Year (Frequency)06/2002PRA Basics for Regulatory Applications (P-105)134

1,Recovery Analysis Analysis on accident,sequence level-Examination of -contributors to failureIdentification of potential for recovery.',. yRecovery,Ifactors i-;,Critical, time for, recovery Action required* Time for"action Time versus probability of recovery,,o Final accident sequence frequency includesrecovery06/2002PRA Basics for Regulatory Applications (P-1 05)135

Summary of Sequence T2 L1 P"*This sequence is initiated by a loss of main feedwater (T2), followed by failure of theauxiliary feedwater (AFW) system, and failure of feed and bleed cooling due to theinability to open both power operated relief valves (PORVs)." The loss of main feedwater initiator places a demand on auxiliary feedwater to removecore decay heat. Failure of the AFW system causes a demand for feed and bleedcooling. Failure to initiate feed and bleed and various failures which prevent one of thetwo PORVs from opening contribute to this sequence. Success criteria require that twoPORVs open for successful feed and bleed."*The dominant contributors to AFW failure are common cause failure of the air-operatedsteam generator level control valves and the common cause failure of all three AFWpumps due to steam binding. The dominant contributor to failure of feed and bleed isoperator failure to open PORVs, followed by mechanical failures of the PORV blockvalves and PORVs.06/2002PRA Basics for Regulatory Applications (P-105)136

Event Tree for T 2 - Loss of Main T 2 D3 WSeal LOCA vulnerable - Go to Seal LOCA Tree[OKCDT 2 L1 H2CDT 2 L1 H3CDT2L1 P1CDT2L1D1Stuck-Open PORV - Go to S 2T 2QATWS - Go to ATWS TreeT2K-PRA Basics for Regulatory Applications (P-105)137

Identifiers for T2 Event ierHPID1Failure of charging pump system with 1 of 4 success requirementsD3Failure of charging pump system in seal injection flow modeSIFH2Failure of charging pump system in the high pressure recirculation modeHPRH3Failure of low pressure injection/recirculationKFailure of reactor protection systemRPSL1Failure of auxiliary feedwater required for transients with reactor tripAFWP1Failure of both pressurizer PORVs to open for feed & bleedPRVQ1Failure of any relief valve to recloseRVCWFailure of component cooling water to the thermal barrier of all reactorcoolant pumpsCCWPRA Basics for Regulatory Applications (P-105)LPI/LPR138

Dominant Contributors to Sequence T2 L1 P,Minimal Cut SetAFW-AO V-CC * BETA-8AOV * HPI-XHE-FO-FDBLD,T2 * STEAM-BINDING '* HPI-XHE-FO-FDBLDT2 "*AFW-'AOV-CC * BETA-8AOV * PPS-SOV-FT-334AFW -AOV-CC * BETA-8AOV * PPS-SOV-FT-340AT2:' AFW-TDP-FS-1AS * AFW-MDP-FS * BETA-AFW * HPI-XHE-FO-FDBLDT2*T2, .AFW-TDP-FR-1AS6H * AFW-MDP-FS*BETA-AFW*HPI-XHE-FO-FDBLD,T2* STEAM-BINDING *,PPS-SOV-FT-334,T2* STEAM-BINDING * PPS-SOV-FT-340AT2*AFW-ACT-FA-TRNA * AFW-ACT-FA-TRNB * HPI-XHE-FO-FDBLDT2' AFW-TDP-TM-1AS"*AFW-MDP-ES,* BETA-AFW * HPI-XHE-FO-FDBLDTotal T2 L1 P106/2002PRA Basics for Regulatory Applications (P-105)MinimalCut 6E-84.6E-84.1E-82.7E-81.3E-6139

Term DescriptionsT2Loss of main feedwater7.2E-1/reactor TDP-FS-1 AFW-ACT-FA-TRNBSteam-binding of all AFWS pumpsPORV 334 fails to openPORV 340A fails to openAFWS turbine pump fails to startAFWS turbine pump fails to run 6 hoursAFWS turbine pump unavailable test and maintenanceAFWS AOV fails to openCommon cause failure factor of 2 motor pumpsCommon cause failure factor of 8 AOVsAFWS motor pump fails to startOperator fails to initiate feed and bleedAFWS Train A actuation failsAFWS Train B actuation E-23.4E-23.OE-32.2E-21.6E-31.6E-306/2002PRA Basics for Regulatory Applications (P-105)140

Importance Measures Provide quantitative perspective on dominantcontributors to risk and sensitivity of risk tochanges in input values* Usually calculated at-core damage frequencylevel, ,. Three are, encountered most commonly: Fussell-Vesely Risk Reduction Risk Increase or Risk Achievement06/2002PRA Basics for Regulatory Applications (P-105)141

Fussell-Vesely ImportanceMeasures overall contribution of an event to risk (CDF)" Calculated by adding up frequencies of cutsetscontaining event of interest and dividing by total CDF" FVx ZCutsets with event x / F(x)orFVx [F(x) - F(O)] / F(x)where,F(x) is risk with event x at nominal failure probability, andF(O) is risk when event x is never failed (failure probability 0)"*Range is from 0 to 106/2002PRA Basics for Regulatory Applications (P-1 05)142

Fussell-Vesely Importance (cont.)Consider these minimal cut sets: 6 x 10-4A 6 x 10- 4B I x 10-2 * 3 x10-3 3 x3C * D 3 x 10-3 * 1 x' 10- 3 xF(X)10-!10-6 6.33x10-4where,A 6 xý 10-74,B 1 x 10-2,3C 3; x, 10D 1 X 10-3 Fussell-Vesely ImportanceF/A 6.0 x 10-4/6.33 x 10-4 0.948FVB 3.0 x 10-/6.33 x 10-4 0.04706/2002FVc 3.3 x10-/6.33 x 10-4 0.052FVD 3.0 x10-6/6.33 x 10-4 0-005PRA Basics for Regulatory Applications (P-105)143

Risk Reduction Importance" " Measures amount by which CDF would decrease if event'sfailure probability were set to 0 (never fails)Calculated as either ratio or difference between baseline CDFand CDF with event failure probability at 0Ratio: RRR(x) F(x)/F(0)Difference (or Interval): RRI(x) F(x) - F(0)where,F(x) is risk with event x at nominal failure probability, andF(0) is risk when event x is never failed (failure probability 0)" " " Ratio - Range is from 1 to ooGives same ranking as Fussell-VeselyFor Maintenance Rule (10 CFR 50.65), NUMARC Guide 93-01(endorsed by NRC) uses a RRR significance criterion of 1.005 - Equivalent to Fussell-Vesely importance of 0.00506/2002PRA Basics for Regulatory Applications (P-1 05)144

Risk Reduction Importance (cont.)Consider these minimal cut sets:A 6-x 10- 4B *C 1 x 10-2 *3C *,D 3 x10- 6 x 10-4*10-3 3 x 10-51 x 10-3 3 x 10-6xF (x) 6.33x10-4where,A 6 x 10 4"', B1 x--10-2x 10D, lx1o-3C 33SRis-k Reduction Ratio ImportanceRRRA 6.33 x 10-4/3.3 x10-S 19.18RRRB 6.33 x 10-4/6.03 x 10-4 1.05RRRC 6.33 x 10-4/6.00 x 10-iRRRD 6.33 x06/2002 ý 1.0610-4/6.30 x I0-4 1.00PRA Basics for Regulatory Applications (P-105)145

Risk Increase Importance,Measures amount by which CDF would increase if event's failureprobability were set to 1 (e.g., component taken out of service)* Calculated as either ratio or difference between CDF with eventfailure probability at 1 and baseline CDFRatio: RAW(x) or RIR(x) F(1)/F(x)Difference (or Interval): RII(x) F(1) - F(x)where,F(x) is risk with event x at nominal failure probability, andF(1) is risk when event x is 4always failed (failure probability 1)* Ratio measure referred to as risk achievement worth (RAW), RAW- Range is 1* For Maintenance Rule (10 CFR 50.65), NUMARC Guide 93-01(endorsed by NRC) uses a RAW significance criterion of 206/2002PRA Basics for Regulatory Applications (P-105)146

Risk Increase Importance (cont.) Consider these minimal cut sets: 6 x 10-4 6 x 10-4A I x 10-2B *CC * D 316-3* 3 x 10-3 3 x 10-93 3 x10-6* 1 x106.33 x10F (X)where,A 6 x- 10-4B'I1 X 10-2, C 3 x 10-3D 1 x 10-3Risk' Achievement Worth ImportanceRAWA 1.0 /4 5.69RAWC 1.16 X 10o2/633 x 10-4 18.33RAWB 3.603 x 10-3/6.33 x 10RAWD 3.63 x 10-3/6.33 x 10- 406/20021579.786.33 x 10-4 5.73PRA Basics for Regulatory Applications (P-105)147

Limitations of Risk Importance Measures Numerical values can be affected by: 06/2002Exclusion of equipment from PRA modelModel truncation during quantificationParameter values used for other events in modelPresent configuration of plant (equipment that isalready out for test/maintenance)PRA Basics for Regulatory Applications (P-105)148

Core Damage Frequency and Number of Cutsets Sensitive toTruncation Limits1 -071E-081E-091E-101E-111E-121E-13Truncation levelD .06/2002Number of cut sets (Y1)-Core damage frquency (Y2)PRA Basics for Regulatory Applications (P-105)149

Truncation Limits Affect 7III1 E-081E-09Truncation LevelRRW 1.00506/20021 E-10F-DRAW 2PRA Basics for Regulatory Applications (P-105)150

Limitations of Risk Importance Measures(cont.). Risk rankings are not always well-understoodin terms of their issues and engineeringinterpretations* RAW provides indication of risk impact of-taking equipment out of service but full impactmay not be-capturedis, taking component out of service for, test andTThatmaintenance may increase likelihood of initiatingevent due to human error06/2002PRA Basics for Regulatory Applications (P-105)151

Other Considerations When UsingImportance Measures F-V and RAW rankings can differ significantly whenusing different risk metrics Such as, core damage frequency due to internal events versusexternal events, shutdown risk, etc. Individual F-V or RAW measures cannot be combined toobtain risk importance for combinations of events Critical combinations can be extremely important due to failureof redundant components whereas individual components inone train may have low rankings06/2002PRA Basics for Regulatory Applications (P-105)152

10. Accident Progression &Consequence Analysis06/2002PRA Basics for Regulatory Applications (P-105)153

Accident Progression Analysis, ContainmentResponse, Fission Product Transport, andConsequence Analysis" Purpose: Students receive a brief introduction to accident progression(Level 2 PRA) and consequence analysis (Level 3 PRA)." Objectives: At the conclusion of this topic, students will be able to: List primary elements which comprise accident phenomenology Explain how accident progression analysis is related to full PRA Explain general factors involved in containment response Explain general factors involved in fission product transport &consequences Name the major computer codes used in accident process andconsequence analysis" Reference: NUREG/CR-2300, NUREG-1489 (App. C)06/2002PRA Basics for Regulatory Applications (P-105)154

Principal Steps in PRA ProcessLevel 1Accident FrequenciesPlant Damage StatesAccident Progression, ContainmentLevel 2Loading, and Structure Response1Accident Progression BinsTransport ofRadioactive MaterialUILevel"3Source Te rm GroupsOffsIte ConsequencesConsequence MeasuresRisk Integration06/2002PRA Basics for Regulatory Applications (P-1 05)155

Accident Progression Analysis There are 4 major steps in Accident ProgressionAnalysis1. Develop the Accident Progression Event Trees(APETs) 2. Perform structural analysis of containment 3. Quantify APET issues 4. Group APET sequences into accident progressionbins06/2002PRA Basics for Regulatory Applications (P-105)156

Schematic of Accident Progression EventTreeBoundaryConditions:Plant Damage StatesRecovery of CorePrior to VesselBreachPressurein vesselSystemIn-vessel Processes& essel Processes& coolabilityYesNoZRecovery ofinjectiont"Pressureincrease due toH2 burn duringCCI gas generationSource: NUREG-1 15006/2002PRA Basics for Regulatory Applications (P-105)157

Containment Response* How does the containment system deal withphysical conditions resulting from the accident? Pressure Heat sources Fission products Steam and water Hydrogen Other noncondensables06/2002PRA Basics for Regulatory Applications (P-1 05)158

Elements in the Analysis of Radionuclide Behaviorin the ReactorEvent, times ThermalHydraulic conditions1Radi6nuclide and structuralmaterial source term from thecoreRadionutide &istructuml materialinventoriesI,i4Primary system transport,deposition, and releaseIdcContainment transport,Sdeposition, anid releaseOutputRadionuclide releases tothe environment06/2002PRA Basics for Regulatory Applications (P-105)159

Computer codes used to model AccidentProgression & Fission Product Behavior"*RELAP5/SCDAP - in-vessel behavior" CONTAIN - containment behavior" VICTORIA - fission product behavior* Integrated, comprehensive codes MAAP-industry code MELCOR - NRC code06/2002PRA Basics for Regulatory Applications (P-1 05)160

Fission Product Source Term Outcomesof Interest* Fractions ReleasedOutside Containment Noble Gases Iodine "Cesium - Rubidium Tellurium - Antimonry Barium - StrontiumkRuthenium- MolybdenumRhenium - TechnetiumCobalt Lanthanum and other rareearth metals-06/2002 Parameters forConsequence Model Time of releaseDuration of releaseWarning time for evacuationElevation of releaseEnergy of releasePRA Basics for Regulatory Applications (P-105)161

Source Term Calculation ModelsIntegrated Deterministic Code (MELCOR)" Point estimate radionuclide release calculations for scenarios importantto risk" Selected sensitivity calculations to explore uncertainties that can bemodeled by the codeParametric Source Term Code" Point estimate radionuclide release calculations for scenarios lessimportant to risk (simulation of source code package)" Extensive sensitivity calculations to explore uncertainties that cannot bemodeled by code package06/2002PRA Basics for Regulatory Applications (P-105)162

Schematic of Parametric Source Term AlgorithmContainmentrelease: laterevolatilizationContainment releaseof in-vessel speciesIEarly containmentdecontamination:deposition, etc.Containmentrelese ofCCI speciesHigti-pressureLate containmentdecontaminationprocessesejec tion releaseDecontamination:suppression pool,sprays &other featuresLate releaseof iodinefrom water poolsOther decon:pools, sprays, etc.06/2002Release during coreconcrete interactionPRA Basics for Regulatory Applications (P-105)163

Components of a Consequence ModelAtmospheric transport and diffusion model" Pathways models"*Dosimetry models" Health effects model"*Other models:"*Evacuation" Interdiction" Decontamination" Economic effects" 06/2002PRA Basics for Regulatory Applications (P-105)164

Pathways to People""-Radiation fromRadionuclides in air-/jI/InhalatioiI of"radionuclides/Radionuclides in food and waterradionuclides on ground06/2002PRA Basics for Regulatory Applications (P-105)165

ConsequencesPopulation dose"*Acute effects"* Number of fatalities, injuries, and illnesses occurringwithin one year due to initial exposure to radioactivity;nonlinear with dose equivalentLatent effects"* Number of delayed effects and time of appearance asfunctions of dose for various organs; linear, nothreshold model typically used06/2002PRA Basics for Regulatory Applications (P-105)166

Consequence Evaluation ModelsMACCS (MELCOR Accident Consequence Code System)" Improved environmental transport, dosimetry, healtheffects, and economic cost models" Improved wet deposition model for rainout"* Dependence of dry deposition velocity on particle size" Multi-plume-dispersion model, including multi-stepcrosswind concentration profile" Improved code architecture" 06/2002PRA Basics for Regulatory Applications (P-105)167

Block Diagram of MACCS Models06/2002PRA Basics for Regulatory Applications (P-105)168

Dominant Risk Contributors SometimesNot Dominant With Respect to CDF For PWRs, SGTR and bypass sequences (e.g.,ISLOCA) dominate LERF and therefore earlyfatalities SGTR and bypass not dominant contributors tocore damage frequency If SGTR or bypass occur, consequences are large Remember: risk frequency x consequence06/2002PRA Basics for Regulatory Applications (P-105)169

Page Intentionally Left Blank06/2002PRA Basics for Regulatory Applications (P-105)170

S1 .External Events06/2002PRA Basics for Regulatory Applications (P-1 05)171

External Events"*" Purpose: This topic will acquaint students with thedefinition of external events and the IPEEEs.Objectives:Define external events and understand how they differ frominternal events" List several of the more significant external events, including thoseanalyzed in the IPEEEs" Know the objectives of the IPEEE and the acceptable approachesfor seismic events and fires" Explain the ways in which external events may be evaluated andhow this evaluation is related to the overall PRA task flow." " Reference: NUREG/CR-2300, PRA procedures Guide;Generic Letter 88-20 Supplements 4 and 5, NUREG-140706/2002PRA Basics for Regulatory Applications (P-105)172

Overview of External Events AnalysisExterna ! Events (EE) refers to those events thatare external to system being analyzed e.g., fires, floods, earthquakesSIncludes on-site events such as flooding of various rooms withinplant,,* Concern is with dependent nature of EESi.e., EE both initiates potential core damage accidentAND results in failure of safety systems* General approachIdentify hazard and its intensityprobability of plant SSCs failureSConditional Assess overall plant response to event-.06/2002PRA Basics for Regulatory Applications (P-105)173

NPP External Events Risk First Analyzed 1979*****1979 - Oyster Creek (first seismic PRA)1979 - HTGR (first fire PRA)1981 - Big Rock Point1982 - Zion/Indian Point1983 - NUREG/CR-2300 (PRA Procedures Guideincludes external events)* 1988 - GL 88-20 (IPEs to include internal floods)* 1989 - NUREG-1150 (fire and seismic)* 1991 - GL-88-20, Supplement 4 (IPEEE, revisedin 1995 with supplement 5, which revised seismicrequirements)06/2002PRA Basics for Regulatory Applications (P-105)174

Initial List of Potential External EventHazards Very Extensive (1 of 2)Aircraft" Avalanche" *Earthquake *Fire in plant Flooding, internal *High winds (includingtornadoes)' Hurricane* Fire outside plant but on. site* Fire off site . Flammable fluid release" Fog.Fog Ice,Industrial or military accident" * *FIooding, external (includingseiche', storm surge, damfailure, and tsunami)06/2002offsite* Landslide Lightning Meteorite impact,PRA Basics for Regulatory Applications (P-105)175

Initial List of Potent External EventHazards Very ED nsive (2 of 2) Pipeline accident. Sabotage, Ship impact"* Toxic gas release", Transportation accident"- Turbine missile", Volcanic activityo War06/2002Blizzard/Snow"* Drought"* Erosion. Hail, Heavy rain"* High temperature" Low Temperature" River diversion or changein lake level".PRA Basics for Regulatory Applications (P-105)176

Most Hazards Excluded for VariousReasons* IPEEE required-analysis of hazards believed todominate external event risk Seismic Internal fires High winds and tornadoes External-floods (internal flood analysis required in,IPE) Transportation and nearby' facility accidents Any, known plant-unique hazards06/2002PRA Basics for Regulatory Applications (P-1 05)177

External Events Analyses Performed atVarious Levels of DetailSeismic"* Seismic PRA or Seismic Margins Assessment (includesHCLPF - high confidence of low probability of failureassessment)Fire"* Fire PRA or Fire Vulnerability Evaluation (FIVE)Other"* EE PRA or screening analysis06/2002PRA Basics for Regulatory Applications (P-105)178

Seismic Hazard PRA - 3 Basic Steps* Hazards analysis (frequency-magnituderelationship for earthquakes)ý Location-specific hazard cUrves produced by NRC(LLNL) and EPRI"*Fragility analysis, ("strength" of component). Conditional probability of failure given a specificearthquake severity* Accident sequence analysisAnalysis process briefly looked at in following slides06/2002PRA Basics for Regulatory Applications (P-105)179

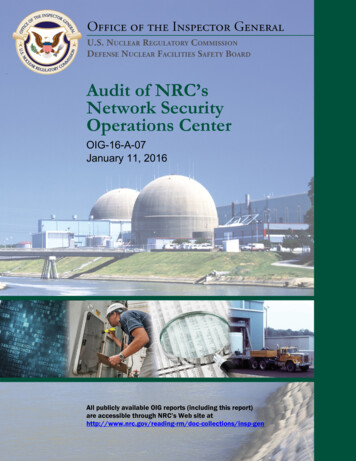

Four Steps inSeismic HazardCurve Development1. Identify seismicsourcesFI "E HOuEISOURCE2. Develop frequency "SOURCESmagnitude model foreach sourceSTEP ISRLINCE11TAIN'TYN ATI"ElDAT 1ON3. Develop groundmotion model for eachsource4. Integrate over06/20021.0 :.ONDISTANCEsourcesSTEP 2RECURRENCER0ACCELERATIONSTEP 4STEP 3ATTENUATIONPRA Basics for Regulatory Applications (P-105)PROBABILITY OFNON- EXCEEDENCEWITHIN A TIME PERIOD t180

Frequencies Estimated for VariousGround Acceleration LevelsFrequency of O lg, 0.2g, 0.3g, etc. earthquakeestimated"* Each g-level earthquake analyzed separately (i.e.,as a separateand unique, event),Failure probabilities of plant SSCs calculated" based on g-level and fragility of SSC* Internal everits PRA re-evaluated using "new"seismic failu re probabilities" 06/2002PRA Basics for Regulatory Applications (P-105)181

Seismic Fragility Expressed in Terms ofPeak a round Acceleration* Fragility (A) Am 13R Pu (lognormal modelassumed) Ammedian ground acceleration capacity of SSC OR PU Measure of the uncertainty in median fragilitydue to randomness and confidence, respectively (canalso be labeled aleatory and epistemic, respectively).SAm derived from various safety and response factors(FCFREFRsAsSE), in turn are products of other factors-' Fc - Capacity FactorResponse factor for equipment*FRs - Response factor for structure"-AssE -Safe Shutdown Earthquake accelerationSFRE06/2002PRA Basics for Regulatory Applications (P-105)182

Range of Seismic Fragilities for SelectedComponents*DominantFailureModeConcrete containmentbuildinq Shear failureComponenent/StructureMedian FragilityRange (g)2.50-9.20Reactor Pressure VesselAnchor bolt1.04-5.70Flat-bottom tank0.20-1.00Motor control centersShell wallbucklingCases andplatesChatteringDiesel generatorAnchor bolt0.70-3.89Offsite powerCeramicinsulators0.20-0.62Batteries and racks0.90-5.950.06-4.20* Y.,J. Park, etaI, Survey of Seismic FragilitiesUsing in PRA Studies of Nuclear Power Plants,.Reliabilitig Engineeringand System Safety, Vol. 62, pages 185-195, 1998.06/2002PRA Basics for Regulatory Applications (P-105)183

Probability of "Initiating Events" Estimated Given Occurrence of EE(Provides Link to Sequence geLOCAMediumLOCASmallLOCALoss ofOff-SitePowerRx-Tnpwith IC - Seismic IE06/200206/2002PRA Basics for Regulatory Applications (P.105)PRA Basics for Regulatory Applications (13-105)2002/05/29Pace 5184184

Fire Analysis Follows Phased Approach* Qualitative Screening ,Fire in area does not cause' a demand for reactor trip Fire area does not contain safety-related equipment Fire area does not have credible fire source orcomhbus'tible's Quantitative Screening Utilized .existing internal events PRA. ,Estimate ,fire frequency for area:and assume allequipment in fire area failed by fire, calculate CDF Detailed Analysis06/2002PRA Basics for Regulatory Applications (P-105)185

Detailed Fire Analysis Includes* Fire occurrence frequency assessment Either location based or component based Generic data updated with plant-specific experience Fire growth and propagation analysis Considers: Combustible loading, fire barriers, and fire suppression Modeled with specialized computer codes (COMPBRN Ille)* Component fragilities and failure mode evaluation Fire detection and suppression modeling* Detailed fire scenarios analyzed using transient ET06/2002PRA Basics for Regulatory Applications (P-105)186

Fire-Induced Vulnerability Evaluation(FIVE)Developedby"EPRI as an alternative to a firePRA fobrsatisfying IPEEE requirements"* Equivalent to a fire-area screening analysis," worksheet-based systematic evaluation usinginformation from Appendix R implementation does, not produce. detailed. quantification of fire CDFMoSt FIVE users. (IPEEE) also quantified fire CDFof unscreened areas',"*06/2002PRA Basics for Regulatory Applications (P-105)187

Other External Events Analyzed UsingStructured Screening Process IPEEE Guidance - Progressive Screeningapproach (see Figure 5.1 of NUREG-1407) Review Plant Specific Hazard Data and Licensing Basis(FSAR) Identify Significant Changes, if any, since OP Issuance Does Plant/Facility Design Meet 1975 SRP Criteria (viaquick screening & confirmatory walkdown)- Ifyes, no further analysis is needed- If no, continue analysis (next slide)06/2002PRA Basics for Regulatory Applications (P-105)188

Examples of SRP Non-Conformance Flood Probable Maximum Precipitation (PMP) at site basedon old National Weather Service data*High-Wind/To rnadobDesign basis tornado missile spectrum different from'that specified'in SRP06/2002PRA Basics for Regulatory Applications (P-105)189

If 1975 SRP Criteria Not Met9 Is Hazard Frequency Acceptably Low ( 1 E-5/yr)?If Not:* Does bounding analysis estimate CDF 1 E-6/yr?If Not:* Perform detailed PRA Details of analysis are tailored to particular hazard06/2002PRA Basics for Regulatory Applications (P-105)190

Jd12. SHUTDOWNRISKA,06/2002PRA Basics for Regulatory Applications (P-105)191

Low-Power and Shutdown Risk Purpose: Discusses why low-power and shutdown modesof operation are thought to be of concern from a riskperspective, and introduces approaches to analyzingshutdown risk. References: NUREG-1449 - Review of shutdown events NUREG/CR-6143 and -6144 - Analysis of low-power shutdownrisks at Grand Gulf and Surry NUREG/CR-6616 - Risk comparison of scheduling preventivemaintenance at shutdown vs at power operation for PWRs06/2002PRA Basics for Regulatory Applications (P-1 05)192

Risk From LP/SD -Operations Was NotConsidered in Early. PRAs Low-power and shutdown (LP/SD) encompassesoperation when the reactor is subcritical or in transitionbetween' subcriticality and power operations up to -15% ofrated power In early: risk, studies, risk from full power operation wasassumed to be dominant because during shutdown:SReactor is subcritical-Decay heat is decreasing with time-,06/2002Longer time is available to respond to accidentsPRA Basics for Regulatory Applications (P-105)193

LP/SD Operational Events Established theCredibility of LP/SD Risk* Precursor events implied that potential genericvulnerabilities existed: April 87 Diablo Canyon event resulting in loss of RHRwhile in mid-loop operation (and numerous similarevents at other plants) March 90 Vogtle plant loss of all AC power whileshutdown Two generic letters were subsequently issued relatingto low-power and shutdown operations: -GL 87-12-'GL88-1706/2002---Loss of RHR while the RCS is partially filledLoss of Decay Heat RemovalPRA Basics for Regulatory Applications (P-105)194

Operating Experience Insights Reinforcedby Early LP/SD Risk StudiesLimited risk,.studies of low-power and shutdown operationshave suggested that shutdown risk may be significantbecause Systems may not be available as Tech. Specs. allow moreequipment to be inoperable than at power Initiating events can impact operable trains of systems providingcritical plant safety functions Human errors are more prevalent because operators may findthemselves in unfamiliar Conditions not covered by training'andprocedures , Plant instruments and indications may not be available or accurate06/2002PRA Basics for Regulatory Applications (P-105)195

Subsequent LP/SD Risk StudiesExamined a Range of Issues Studies included: Further review of operating experience for domesticand foreign reactors (discussed on next slide)Analysis of selected significant events to estimateconditional probability of core damage using ASPmodels Review of PRAs that included LP/SD operationsNRC sponsored Level 1 PRAs for LP/SD operations forSurry and Grand Gulf06/2002PRA Basics for Regulatory Applications (P-105)196

Operating Experience Analysis*AEOD* investigation of approximately 90 significant

Systems B AND C Fail System B Fails * System C Fails (Pump 1 Valve X) * (Pump 1 * Pump 2) . Failure of charging pump system with 1 of 4 success requirements . (never fails) " Calc