Transcription

INDUSTRIALIoT PLATFORMSA Manufacturer’s GuideBY GR AHAM IMMERMAN, VP OF MARKE TING, MACHINEME TRICS

The Connected FactoryGartner calls it a game-changer, Forbes named itmanufacturing’s most significant development for thecoming decade, and others believe it will increase thevalue of the global economy by 10%. This is theIndustrial internet of things (IIoT), and everywhere youturn, references to it are being made.These industry watchdogs also put the rise of theIndustrial IoT and its diverse applications at the top oftheir 2020 trends list. Industrial IoT makes this listbecause of the benefits it brings to manufacturing andthe integration of Industry 4.0 concepts in today’sfactories.Interconnectivity, data analytics, and processmonitoring are IoT’s most important benefits. To reapthe benefits of a connected environment, a centralizedplatform is needed to manage the multiple IIoT devicesbeing deployed across manufacturing facilities. This iswhere IIoT platforms come into the picture.If you intend to integrate IIoT in your industrial facilities,then you will likely have heard of different IIoTplatforms and read through hundreds of pamphletsspelling out their benefits.In this comprehensive guide, we will provide a holisticanalysis of the choices available. The guide willdiscuss: The differences between a cloud platform and anedge platform The pros and cons of building versus subscribingto an IIoT platform The key considerations to note when purchasing orsubscribing to an IIoT platformAt the end of this guide, you will be in an excellentposition to decide which IoT platform best meetsyour needs.02

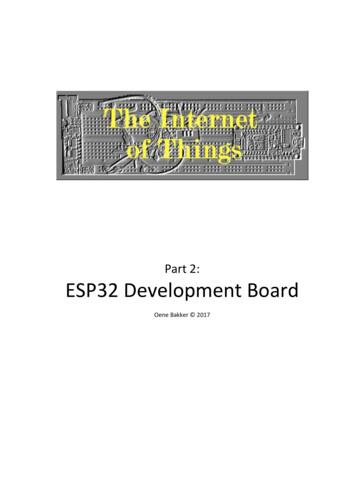

MACHINEMETRICS A M A N U FA C T U R E R ’ S G U I D E T O I N D U S T R I A L I oT P L AT F O R M SWhat is an IoT Platform?It is only natural to start this chapter with adefinition. As with most emerging technologies,many brands and stakeholders define IoT platformsusing terms that favor the features built into theirsolutions. Here is one comprehensive definition thatis making the rounds:‘An IoT platform is a multi-layered technologyconsisting of software and hardware whichincludes an operating environment, storage,computing resources, security, and developmenttools that support the management of smallerapplications and IoT devices’With this definition, it becomes easy to see whythere are more than 500 solutions, both small andlarge, that define themselves as IoT platforms. Inreality, these platforms fall into one of four broadcategories which include:1. Manufacturing Application PlatformsThese platforms connect shop floor operatorsand manufacturing processes through the useof applications. They support the developmentand use of manufacturing applications forscheduling, inventory management, etc.2. Manufacturing Operations and AnalyticsPlatformsThis type of solution provides a platform formanaging manufacturing projects through the useof analytical software applications. They supportboth post-production and pre-production activities.3. Building Information Modeling or ConnectedWorker PlatformsThese platforms are built with the ideaof connecting all parties involved in amanufacturing process to enable effectivecollaboration. This includes the productdesigner, the material supplier, the operator, etc.UNIPL VERUGSA N ALD P PLLAATYFORM01100001 101110 101010100010011RMFOATPLIoTIoT Platforms provide insight at multiple layers of the organization:the machine level, facility level, and organization level.4. IoT PlatformsThese solutions provide computing support forthe sensors, machines, smart devices, and edgedevices within a facility. The aim is to providestakeholders and operators with visibility intomachines and operational performance.With this in mind, a more specific definition of whatexactly is an IoT platform is required. This definitionmust set it apart from other contesting solutionswhile taking into account its uses. Thus, our definitionof an IoT platform is:‘A set of technologies and tools that support thecollection, monitoring, and analysis of machinedata, smart devices, edge devices, and shop floorequipment data in real-time to optimize machineperformance and productivity. ‘This definition highlights the fact that the impactof an IoT platform is felt at diverse levels whichinclude the machine level, facility level, andorganizational level. The ability to monitor andoptimize machine performance also brings thebenefits of an IoT platform to original equipmentmanufacturers (OEM).03

MACHINEMETRICS A M A N U FA C T U R E R ’ S G U I D E T O I N D U S T R I A L I oT P L AT F O R M SG E N E R I C I OT P L AT F O R M SP L AT F O R M Sto the cloud and the receiving of information fromthe cloud by IoT devices. Network connectivityissues will lead to lags that affect the ability ofan IoT device or system to take action in realtime. This limits low latency processing.As you have probably discerned, the answeris in the name. Generic IoT platforms offertechnologies and tools that support themanagement of IoT devices not used in industrialsettings. In this regard, a home automationplatform which manages domestic smartdevices such as refrigerators, smart windows,temperature, etc. can be referred to as a genericIoT platform.On the other hand, edge platforms are built todeliver processing capabilities closer to the IoTor edge device producing the data. This ensuresimportant data analytics are done within theplatform and data transfers occur in real-timewithout time lags. This means that, althoughcloud platforms have the capacity to collect andprocess data, edge platforms are more attuned toproviding real-time feedback to edge devices.VS. INDUSTRIAL IoTOn the other hand, industrial IoT platforms offersupport for the machines and smart devices usedwithin an industrial setting. The IIoT platformprovides custom software built for industrialapplications and analytics.Thus, while a generic IoT solution couldbe tweaked to receive data from industrialequipment, it does not have the tools neededto analyze machine data to provide the insightneeded to optimize industrial operations.C LO U DC LO U D P L AT F O R M S V S .E D G E P L AT F O R M SManufacturing equipment and the IIoT devicesused across a facility have the capacity ofproducing large data sets that require scalablecomputing resources to process. The cloudprovides the centralized platform, but whenapplied to processing machine and IoT data ithas its limitations.These limitations are the latency and bandwidthissues that come with transferring large data setsEDGECONNECTED MACHINES AND EQUIPMENTBy incorporating edge computing with cloud computing capabilities, manufacturers can maximize the potential of both solutions.04

MACHINEMETRICS A M A N U FA C T U R E R ’ S G U I D E T O I N D U S T R I A L I oT P L AT F O R M SEDGE PLATFORMIoT trics Multi-Tenant GE MANAGEMENTUSERSFactory rationalDataWorkflow TriggersTime SeriesDataREST & GraphQL APIsRAW DataStorageDATA &ENGINEERINGTEAMData Lake AnalyticsCustomDashboardsCustom OperatorViewsCustom sIntelligenceERPQualityUSE CASESData ScientistsData AnalystsSoftware EngineersMANUFACTUREREDGE ANALYTICSMachine cturing rer Cloud or on-premise serversRAW Data SyncAnomaly DetectionCustom AlgorithmsLocal StorageCMMST H E M A C H I N E M E T R I C S I I oT P L A T F O R MMachineMetrics Industrial IoT Platform transforms your shop floor data from insights into actions with powerful apps that reducemachine downtime, increase your throughput, and maximize profitability driven by your manufacturing equipment.The use of a real-time scenario explains thesedifferences better. Let’s use the example of afacility with 20 functional edge devices trackingmachine health across the shop floor.In this scenario, the edge devices will send largedata sets to the cloud for in-depth analysis.Once this analysis occurs, the information thatthe edge device needs in order to take specificactions will have to be sent back from the cloudto the edge device. If the machine needs thatinformation to make decisions in real-time, thetime lag and potential connectivity issues duringtransfers will affect real-time implementation.protocols or an IoT gateway back to the edgedevice in real-time. This ensures the edge devicereceives the needed information and acts on itin real-time without the lags associated with acentralized cloud platform.It is also important to note that edge platformsalso leverage the cloud for scalability andextensibility. In situations where more computingresources are needed to process big datafrom multiple devices, the cloud handles theprocessing task and its results are madeavailable through an edge platform.Edge platforms reduce the connectivity issuesby bringing data processing closer to the edgedevice. In the above example, the edge platformwill transfer processed data through MQTT05

MACHINEMETRICS A M A N U FA C T U R E R ’ S G U I D E T O I N D U S T R I A L I oT P L AT F O R M SWhy IIoT PlatformImplementations FailIn 2017, a Cisco study showed that approximately74% of enterprises that attempted an IIoTimplementation failed. A more recent study fromGartner, showed that manufacturing enterprisesstill struggle with IIoT implementations.According to Gartner, although the adoption ratefor IoT is increasing, execution and the returns oninvestments made on IIoT is low. The reasons forthis can be attributed to three major challenges:06

MACHINEMETRICS A M A N U FA C T U R E R ’ S G U I D E T O I N D U S T R I A L I oT P L AT F O R M SApproach to Choosing an IIoT PlatformMany enterprises still struggle withunderstanding the differences in features andservices the different IIoT platforms offer.Thus, they end up choosing solutions that donot fit business needs or choosing to build acustom IIoT platform for themselves and endup being bogged down by technicalities.Integration with Existing SystemsAn IIoT platform functions with the datacollected from shop floor machines. Insituations where the IIoT hardware or legacyequipment cannot be connected to a platform,implementation is affected.The Applications EnvironmentIoT platforms without robust environmentsand tools for developing applications limitwhat you can do with them. This also appliesto IIoT platforms that do not offer coreapplications out of the box. This has led tomany enterprises collectingmachine datawithout knowing what to do with it.B U I L D I N G V S. B U Y I N G/SUBSCRIBING TObecoming uncompleted projects. Time and ResourcesThe core business of IIoT platform end-usersis manufacturing or facility management.Building an IIoT platform from scratch meansdiverting human and capital resources to atime-intensive venture. It takes approximately30 months to build a functional IIoT platform.Dedicating this time to the pursuits ofbuilding one leaves the core business ofmanufacturing neglected. Competitive Pressure75% of industrial enterprises intend tointegrate the use of IIoT in 2020. If firstmover advantage is applied, this means thatcompeting firms will have a 30-month headstart against anyone who intends to build anIoT platform from scratch.The cons attached to building an IIoT platformand the challenges with implementation, makesleaving IIoT platform building and implementationto the experts the more viable option. But beforedoing that, enterprises must first identify whichsolution provides the best fit for their businesscases. The next chapter will outline the processfor picking the right IIoT platform.A N I IoT P L AT F O R MThe first reason for IIoT implementation failurestakes into consideration the challenges of buildingan IIoT platform from scratch. Approximately 50%of DIY IoT platform-building initiatives fail for thefollowing reasons. These include: Technical LimitationsBuilding an IoT platform requires technicalexpertise which most manufacturers do nothave. This is why most DIY initiatives do notscale out of the purgatory stage and end up07

MACHINEMETRICS A M A N U FA C T U R E R ’ S G U I D E T O I N D U S T R I A L I oT P L AT F O R M SHow to Choose the BestIIoT Platform for YouThe diverse IIoT platform options available to youmake choosing the perfect fit a task that must beapproached scientifically. This scientific approachstarts with asking the right questions. Here, the tenmost important questions to ask have been outlinedto help you develop a customized strategy for yourIIoT platform search.enterprise, then compatibility with existingapplications must be considered. How Extensible is the Platform?Industrial processes produce large data setsand an IIoT platform must be able to ingest highvelocity data streams. What is Your IIoT Strategy?The first step to making a choice starts withoutlining the problems you intend to solve withan IIoT platform. With this information, you canquickly draw up a shortlist and move to answerthe next questions. How does the Vendor Handle Data Storage?In many cases machine data should be securelykept and easily accessible. Knowledge about ifa vendor has its own datacenter, uses a cloudservice, and what service it uses is important. Who will Make Use of it?An important aspect of creating an IIoTimplementation strategy is deciding who willbe in charge of the program and the analyticsrequired for process optimization.Does the Vendor offer Edge Computing Support?Support for edge computing is an importantconsideration for choosing an IoT platform.This ensures you're prepared to integrate edgecomputing concepts alongside IIoT within yourfacilities. Does the Platform Support Third-partyApplications?An IIoT platform should provide you withthe option of developing applications thatfit your business needs. Thus, the facility fordeveloping, testing, and deploying apps is a keyconsideration. What in-built Security Measures are in Place?The prevalence of cyber-attacks means specialattention must be placed on the authenticationprocesses and security information and eventmanagement tools protecting the IIoT platformfrom threats. Does it Guarantee Ease of Use?Integrating an IIoT platform with existingsystems should be an intuitive process. A plugand play IIoT platform ensures you receivereturns on the investment made in record time.What is the After-sales Support Like?It is more than likely that additional support willbe needed during system upgrades or throughoutthe continuous use of the IIoT platform. This iswhy knowledge of their response timelines and itseffectiveness is required. Compatibility with Management SoftwareIf you intend to use HR software or enterpriseresource management software within yourThe ten questions outlined here can serve as atemplate for your search for the IIoT platform that fitsyour operational requirements.08

MACHINEMETRICS A M A N U FA C T U R E R ’ S G U I D E T O I N D U S T R I A L I oT P L AT F O R M SConclusionThroughout this guide, we have attempted toanswer all the questions you are more than likely tohave about IIoT platforms and choosing the right fit.The MachineMetrics IoT Platform addressesthe concerns raised with implementationand the questions asked in the third chapter.MachineMetrics provides you with a robustplatform for developing your applications andbringing both legacy and new equipment underone responsive environment.Our IoT platform has been used by manufacturersacross every industrial niche. This includes theaviation industry, medical technology, discretemanufacturing, Oil & Gas, machining shops,among others.One example is a medical device manufacturerwho used the MachineMetrics IoT Platform tooptimize industrial operations by monitoring theperformance of its grinding machines.With the aid of MachineMetrics, the enterprise wasable to cut down on downtime and increase itsmachine performance rate by 50%. The analyticalsupport MachineMetrics provided also led to largescale changes in operational scheduling and stafftraining within the organization.TRANSFORMINSIGHTINTO ACTIONMANUFACTURING’SINDUSTRIAL IOT PLATFORMMachineMetrics Industrial IoT Platform transformsyour shop floor data from insights into actions withpowerful apps that reduce machine downtime,increase your throughput, and maximize profitabilitydriven by your manufacturing equipment.BOOK A DEMO09

A BOUT M ACHINEME TRIC SMachineMetrics is accelerating industrial digital transformation by providingan intuitive and flexible platform to easily collect and transform data from anypiece of manufacturing equipment into powerful, actionable applications thatreduce machine downtime, optimize capacity, and drive increased throughputand profitability for factories. Right now, hundreds of manufacturers haveconnected thousands of machines to MachineMetrics across global factories.CONTAC T s.com

management of IoT devices not used in industrial settings. In this regard, a home automation platform which manages domestic smart devices such as refrigerators, smart windows, temperature, etc. can be referred to as a generic IoT platform. On the other hand, industrial IoT platfo