Transcription

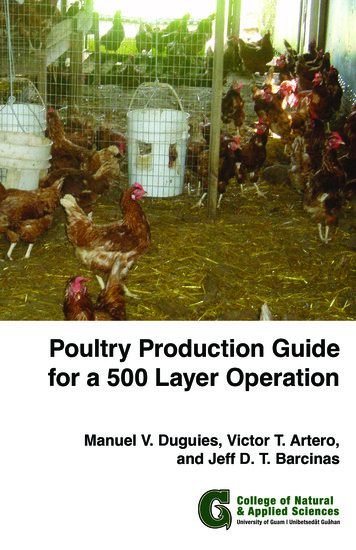

Poultry Production Guidefor a 500 Layer OperationManuel V. Duguies, Victor T. Artero,and Jeff D. T. Barcinas

ContentsForeword. iIntroduction. 1Stages of Poultry Production. 3Related Poultry Production Information. 12Activity Report Charts. 24Expense and Sales Report Chart. 26management of poultry as well as record-keeping and marketingtips. As mentioned, the guide should be viewed as a source of basicinformation. Efforts should be made by poultry producers to obtainmore information regarding recommended production practices,environmental concerns and issues, and the marketing of poultryproducts. For information and assistance on poultry, contact theCollege of Natural & Applied Sciences' Extension and Outreach(CNAS E&O).Many thanks to Dr. Hauhouot Diambra-Odi and Dr. ThomasPoole for lending their expertise for the 2016 revised version ofthis publication.The following lists some government agencies and their servicesthat may be of benefit/concern to poultry producers:Revised Forward - February 2016This revised guide is for individuals interested in raising poultryfor egg production, whether on a commercial scale (full or parttime basis) or as a hobby, with some financial benefits. The guideprovides basic information to raise a poultry flock of 500 birds.The information could be adapted for any number of layers onewants to raise.Department of AgricultureGovernment of GuamImport requirements,financial (loan) andmarketing assistanceGuam EnvironmentalProtection Agency (GEPA)Waste/manure handlingrequirementsGuam Economic DevelopmentAuthority (GEDA)Financial (loan) assistanceFarmers Home Administration (FmHA)U.S. Department of AgricultureFinancial (loan) assistanceNatural ResourcesConservation Center (NCRS)U.S. Department of AgricultureWaste managementand windbreak assistanceU.S. Small Business Administration (SEA)Financial (loan) assistanceThe content of the guide includes a brief description of the differentstages of poultry production and suggested cultural practices in theForeword i

IntroductionIn food production, the poultry industry is generallydistinguished by two major enterprises; egg production and meatproduction. In egg production, the most common shell eggs arefrom chickens and ducks. In meat production, the most commonbirds are frying and stewing chickens, turkeys, ducks and geese.The terms “broiler” and “fryer” in poultry meat productionrefer to young and tender meat-type birds. This publication,however, is for layer or chicken for egg production. Except whenotherwise noted, the use of the term “poultry farming” in thispublication refers to egg production.Poultry farming on Guam can be an exciting and profitableenterprise. As a business venture, the success and profitabilityof poultry farming depends on several major factors includingproper cultural practices, dependable source of healthy stocks,a balanced nutrition program, dependable infrastructure, soundfinancial management practice, and a good marketing strategy.In the early 1970s, Guam reached a 95 percent self-sufficiencylevel and even exported fresh eggs to islands within Micronesia.Since the mid-1980s, the island's poultry industry has declined inproduction levels due to the closure of some fairly large poultryoperations. In the 1990s, the situation changed significantly withproduction trends shifting from large commercial operations tosmall backyard-type poultry production units. The average smallproduction unit ranged from 100-500 birds. At present, UOG’sCollege of Natural & Applied Sciences Triton Farm is the onlyexisting poultry operation on Guam. There have been lots ofinquiries on egg production over the years but none of these havematerialized. High cost of commercial feeds and environmentalpolicies on waste management could be some of the reasons whythe egg industry has not developed at this time.fresh eggs. In addition, many consumers are willing to pay ahigher price for local fresh eggs.Because of the demand for local fresh eggs, one can often makea profitable operation even on a 500 layer farm. Poultry farmingcould be treated either as a hobby after a workday or a part-timeactivity after retirement. For the hobbyist and backyard farmer,it is a source of fun and fulfillment as well as a source of extraincome. For the full-time poultry producer, it is an agri-businessactivity that provides farm and family income. Overall, poultryfarming provides opportunities for everyone from a hobbyistto a commercial poultry farmer. Opportunities include the saleof eggs, manure for fertilizer, and hens for stewing after theirproductive egg cycle.The sale of eggs could generate significant farm income. Afterthe chickens' laying capacity decreases, usually after two yearsof egg production, the chickens could be sold as fresh meat forstewing or for “kadon pika” (a Chamorro delicacy). Chickenmanure contains essential plant nutrients and can be used orsold to crop farmers and plant nurseries as fertilizer or soilconditioner.Poultry farming is not highly labor intensive. The time neededto brood, grow and feed 500 birds or to collect an average of280 eggs a day at production can be managed easily. It normallytakes one to two hours to feed, clean, and collect eggs daily.Depending on the objectives of the producer, the pleasures ofworking with poultry, seeing the chicks grow to produce eggsoften cannot only be measured in dollars and cents.Fresh eggs are in heavy demand on Guam. Consumers on Guamhave a preference for locally-produced fresh eggs over imported1 IntroductionIntroduction 2

Stages of Poultry ProductionPoultry operators generally categorize their operation into fivemajor stages (Table 1). These stages signify the age of the birdsin relation to their 1) growth, 2) space requirement, and 3)recommended type of feed. Table 1 lists the five stages of poultryproduction with corresponding bird ages, while the discussionthat follows provides information on essential managementpractices. Additional information on types of feed for eachcorresponding growth stage can be found on the “Feeds andFeeding” section of this publication.Table 1. Five Stages of Layer Operation.StageAgeBrooding1 to 6 weeksGrowing6 to 12 weeksPullet12 to 20 weeksLaying20 to 120 weeksReplacement Process80th weekshredded cardboard boxes. Wet and caked litter must be replacedwith fresh litter periodically.It is recommended that the chicks be brooded in groups of 100.The grouping makes observation easier as well as prevents“piling-up” (chicks stepping on each other) which can lead todeaths.Another option for the poultry producer is the use of a batterybrooder. The battery brooder could either be constructed orpurchased from commercial livestock outlets or catalogs. Abattery brooder is made up of wire cages, supported by eitherwooden or steel legs. The battery brooders could be stacked upto three to four compartments (see Fig. 1). However, a plyboardor similar material must be placed underneath each compartmentto catch the manure. The recommended compartment size is 3'wide, 4' long and 14" high. The distance between compartmentsshould approximately be 14". You can request a special order forcommercial brooders through your local feed stores.The Brooding StageBrooding refers to the early growing period of chicks. Thebrooding period extends from day-old to six weeks of age.The recommended feed for brooding layer chicks is “layerstarter.” Brooding facilities range from litter brooding to batterybrooding.In litter brooding, chicks are placed on the floor that is coveredwith litter materials such as sawdust, rice hulls, shreddednewspaper, or any absorbent material. The chicks are maintainedwith very few problems. At least 550 square feet would beneeded to brood and grow 500 chicks.Dry litter needs to be maintained throughout the brooding period.Litter should be at least 4-6" thick. Litter materials recommendedfor Guam's conditions include sawdust, shredded newspaper, and3 Poultry Production Guide for a 500 Layer OperationFig. 1. Battery Brooder.It is recommended that newspapers be placed on the wire floorduring the first week of brooding so the toes of the chicks won'tgo through the holes and to prevent draft from below the brooder.The newspaper bedding should be replaced each time it gets toowet. Cardboard materials may used in place of newspaper.Poultry Production Guide for a 500 Layer Operation 4

Recommended Brooding PracticesThe following recommended management practices are providedto ensure a good head start.1. Two weeks prior to chick arrival, the brooder, waterer,feeder, litter, and other materials for brooding should becleaned and sanitized. Use a one-gallon capacity watererfor every 50 chicks. The use of a narrow lid base watererwill help prevent chicks for getting into the water. Chicksare very thirsty upon arrival and tend to dive into the water.Once they get too wet, they chill and die. Wet chicks mustbe put under heat until they are dried. Start feeding 1-2 hoursafter arrival. Use the chick carton as feeders for the first threedays. Provide a small amount of feed each time to avoidwastage. Use galvanized feeders when chicks are consuminga greater volume of feed.2. Effort needs to be made to protect chicks from predatorssuch as the brown tree snake, rats, cats, and dogs. Chicksare especially susceptible to the attack of the brown treesnake. Brown tree snakes are the predator credited with thereduction and/or extinction of Guam's native bird population.To ensure greater protection from snakes as well as ratsit is recommended to use 1/4" x 1/4" wire mesh enclosedbrooders/coops. Also, seal off any openings in the brooder.3. Two days before chicks arrive, the brooder must be set upproperly. Preparation of the brooder for chick arrival is mostimportant. It becomes the key to the success of a poultryoperation. The chicks' health and environmental conditionsbecomes a major concern during the preparation of thebrooding facility. If utilizing a used brooder, clean withammonia and water solution. Also, ensure that the water infeed troughs (containers) is from potable sources.4. Starter feeds and water soluble antibiotics should beavailable and stored (per label instructions) for use duringthe growing period. Use layer starter feed. Starter feedsare normally medicated to prevent common baby chick5 Poultry Production Guide for a 500 Layer Operationdiseases like coccidiosis and bacteria that can cause wetdroppings. Treat water with soluble antibiotic for at leastfive days. Antibiotics can be purchased at local feed stores.It is also advisable to make advance orders for starter feedsand antibiotics from these suppliers when anticipating tobrood chicks. Note: If an automatic watering system is used,be sure that a backflow (anti-siphon) device is installed toprevent antibiotics from entering the main water line.5. Heating elements, whether light bulbs or gas heaters, mustbe tested. Three hours before chicks arrive, turn on heatingelements to get the brooder to the recommended temperatureof 95 F. Keeping this temperature could be accomplished byhanging a 50-watt light bulb approximately 4" from the floorfor every 50 chicks. As the birds grow older, the light bulbsshould be elevated. When litter brooding, galvanized sheetscan be used as guards/partitions to confine chicks within theheated area. When using a light bulb, the temperature may beregulated by raising or lowering the bulb. Heating elementscan be removed when birds are fully feathered.6. Trim chicks' beaks after the third or fourth day of arrival.Beak trimming involves the clipping of the upper beak.The use of a debeaker machine will facilitate the debeakingof chicks. Debeaking the birds will minimize incidence offeather picking and cannibalism. This also prevents feedwastage as the birds cannot select the ingredients in the feed.7. While maintaining adequate ventilation, eliminate or reducewind drafts for consistent brooder temperature and comfortof chicks. A cold brooder predisposes the chicks to “ventpasting.” Vent pasting is the situation when chicks may havewatery discharges from their anuses which dries up andeventually plugs up the opening. Feeders and waterers mustbe close to the source of heat so the chicks are continuallywarmed. The chicks should be evenly distributed in thebrooder. Non-stop chirping or piling-up of chicks in onecorner is generally a sign of a drafty or cold brooder. Onthe other hand, panting chicks generally indicate that thePoultry Production Guide for a 500 Layer Operation 6

temperature in the brooder is too high, and needs to beturned down immediately.8. Monitor, on a regular basis, the conditions in the broodingfacility. By the second day, look for for vent pasting.Manually remove dried discharge to lessen chick mortality.Increase the source of heat to help prevent vent pastingincidence by adding 50-watt light bulbs for additionalheat (one 50-watt bulb per 100 chicks). Lower the broodertemperature at least 5 F every week until birds are fullyfeathered. Observe the chicks regularly during feeding.Dead birds should be removed right away and disposed ofproperly.Growing StageThe growing stage, age 6-12 weeks, is primarily an importantstage for producers utilizing battery brooders or similar smallcage-type enclosures. After six weeks of age, birds must beremoved from the battery brooders and transferred into slightlylarger confinements. While feed, water and certain vaccines/medications are essential during the growing stage, the need forample space to accommodate the body expansion of birds is veryessential. Litter type houses or large coops are su

income. For the full-time poultry producer, it is an agri-business activity that provides farm and family income. Overall, poultry farming provides opportunities for File Size: 1MBPage Count: 17