Transcription

99% Oxygen Production with Zeolitesand Pressure Swing Adsorption:Designs and Economic AnalysisPresentation by:Blake AshcraftJennifer Swenton

Project Goals Develop a portable and hospital airseparation process/device with silverzeolites to produce a continuous flow of99% oxygenRecommend the application of theprocess/device in different marketsDetermine if process/device will beprofitable in those markets

Overview Market for Purified OxygenAir Separation MethodsAdsorbent MaterialsProposed Use of TechnologyHospital DesignPortable DesignConsumer Utility and PreferenceBusiness PlanRiskRecommendations

Market for 99% Oxygen Oxygen is the third most widely usedchemical in the worldAnnual worldwide market of over 9billion.Main applications: Medical oxygen for hospitals and individualuseIndustrial applications for refineries andprocessing plants

Oxygen in Medicine Inhalation therapy During surgery to maintain tissue oxygenation underanesthesia Resuscitation of patients The treatment of such diseases as chronic obstructivepulmonary disease, pneumonia, and pulmonary embolism For the newborn experiencing respiratory distress syndrome The treatment of respiratory burns or poisoning by carbonmonoxide and other chemical substances

Portable OxygenConcentrators Currently no portable device capable ofproducing 99% oxygen continuously Portable oxygen cylinders with 99% oxygenlasts up to 8 hours Percentage of individuals suffering fromlung diseases such as chronic obstructivepulmonary disease (COPD) is increasing COPD is 4th leading cause of deathworldwide

Hospital Unit Large hospitals spend an estimated 170,000 per a year on oxygenApproximately 350 large hospitals inUnited StatesOn-site unit allows for:– unlimited supply of Oxygen– Annual savings

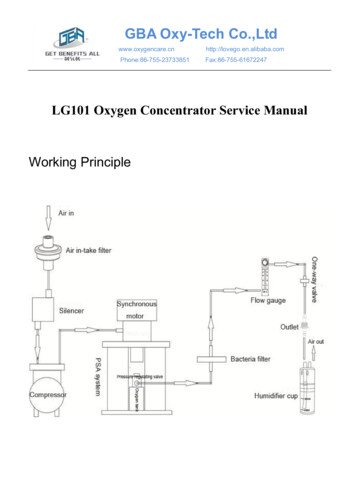

Air Separation Air is used as feedstockOxygen isseparated based onphysicalcharacteristicsMust removeNitrogen and Argonfor 99% Oxygenpurity

Air Separation Methods Cryogenic Distillation Membrane Separation Pressure Swing Adsorption (PSA)

Cryogenic Separation

Cryogenic Separation Leading process for producing99% oxygen in bulk. Involves liquidifying air anddistilling the liquid air toseparate the Oxygen, Nitrogen,and Argon. Can be sold in a liquid form.1 L of liquid Oxygen 860 L ofgaseous Oxygen

Cryogenic Separation Drawbacks– Process uses large bulkyequipment– Energy requirements aresubstantial unless demandis more than 60 tons ofoxygen per a day– Liquid oxygen evaporatesback into the atmosphereover time

Membranes

Membranes Permeable materials used to selectively separateOxygen, Nitrogen, and ArgonLarge and medium scale production.Pressurized air is passed through the membraneand is separated by permeability characteristics ofeach component in relation to the membrane.

MembranesDrawbacks Membranes require a large surface area to achieve highproduct flow rates. Large pressures are typically used– Safety hazard– Large compressors Oxygen and Argon molecules are similar in size and havesimilar permeability properties.– This results in a selectivity of 2.5 O2/Ar and a low oxygenrecovery.

Pressure Swing Adsorption

Pressure Swing Adsorption Uses sorbents (zeolites,nanotubes) in two adsorptioncolumns to separate molecules. Two columns allow for theprocess to operate semicontinuously. 4 Process stages– Adsorption/Production– Blowdown/Purge

Pressure Swing AdsorptionStage 1 Compressed air is fedinto the first bed. Nitrogen and argonmolecules are trapped,while oxygen isallowed to flowthrough.

Pressure Swing AdsorptionStage 2 The adsorbent in thefirst bed becomessaturated with nitrogenand argon moleculesThe airflow feed isdirected into thesecond bed.

Pressure Swing AdsorptionStage 3 The adsorbent adsorbsnitrogen and argon inthe second bed. The first bed isdepressurized allowingargon and nitrogen tobe purged out of thesystem and released tothe atmosphere.

Pressure Swing AdsorptionStage 4 The process startsover. Compressed air is onceagain fed into the firstbed. The second bed isdepressurized releasingargon and nitrogenmolecules to theatmosphere.

Adsorbents for PSA Introduction to Zeolites and CarbonNanotubesStructuresApplications

Silica Gel Pretreatment Pretreatment bed to remove water vapor and impuritiessuch as carbon dioxide– Air at 100% humidity is approximately 3% water vapor Water can impair the performance of adsorbents in thePSA adsorption columns. Silica gel beds are necessary to remove water vaporfrom the air.– A heating coil used to evaporate the water from the silicagel

Kinetic Separation Molecular Sieve Carbon (MSC)adsorbents using PSA technologyIdeal for separation of Argon andOxygen– MSCs in kinetic adsorption can adsorbOxygen 30 times faster than Argon Createsa problem in design, requiring twoPSA systems to collect the adsorbed Oxygen

Carbon Nanotubes Sheets of carbon atoms rolledinto tubes of varying diameters Nanotubes have extraordinarystrength Potential uses in many industrialprocesses, including adsorption.

Carbon NanotubesAdvantages Nanotubes have little interaction with nitrogen athigh temperatures due to oxygen’s higher packingefficiency, smaller diameter, and entropic energies Research has shown that single walled carbonnanotubes (SWCN) of 12.53Å have a selectivity ofO2/N2 of 100:1 at 10 bar. It has been indicated that Argon will have very littleinteraction with nanotubes

Carbon NanotubesDisadvantages Nanotubes are so efficient the volume ofnanotubes required for separation of airis much smaller than the volume of feedair.– Nanotubes’ surface area is not largeenough to react with the volume of airrequired.– No current way to disperse nanotubeseffectively for PSA air separation Price range for nanotubes is 325 to 500 per gram

Zeolites Microporous crystalline structures Lifespan of 10 years The zeolite’s structure governs whichmolecules are adsorbed. Various ways of controllingadsorption– separate molecules based ondifferences of size, shape andpolarity

ZeolitesIon Exchange: Metal cations (calcium,sodium, silver) are boundto the zeolite structure– Silver cation zeolites have beproven to be best for airseparation Creates an electrostaticinteraction between thecation ion and themolecules being adsorbed

LiAgX Zeolite Useful for removing Nitrogen fromOxygen with product throughput .1 kg02/hr/kg adsorbent. Can obtain 96.42% oxygen purity with62.74% Oxygen recovery. Drawback is the selectivity of Argon toOxygen is approximately 1:1.

AgA Zeolite Argon to Oxygenselectivity of 1.63 to 1 7 cm3/g of Argonadsorbed atatmospheric pressure Nitrogen to Oxygenselectivity of 5 to 1

FN0 2 t L1 AN 1N 2 1 AN 1N 2Equilibrium Adsorption Theory Competition between the differentmolecules on the adsorbent sitesexists.– Langmuirian Multi-component Theoryis used to determine the fractionalloading of each component on theadsorbent Selectivity describes how selectiveone component is to bind to theadsorbent over anothercomponent

FN0 2 t L1 AN 1N 2 1 AN 1N 2Equilibrium Adsorption Theory Material Balances–––Nitrogen Oxygen Argon

FN0 2 t L1 AN 1N 2 1 AN 1N 2Equilibrium Adsorption TheoryFor the adsorption bed to remove both Nitrogen and Argon thevelocity ratio of the argon front must be greater than that ofthe nitrogen front

Proposed Use of thePresentedTechnologies

Proposed Use of Technology Pressure Swing Adsorption (PSA) will be used in the design for:– Medium scale capacity– Safety– Cost savings An analysis of 4 designs using zeolites LiAgX and AgA in the PSAadsorption beds was performed. The column diameter and cycletime was held constant.– Design 1 LiAgX zeolite– Design 2: AgA zeolite– Design 3: Mixed ratio of zeolites LiAgX and AgA– Design 4: Both LiAgX and AgA zeolites separating them

Design 1: LiAgX zeolite Nitrogen Removal– LiAgX removes nitrogen with a 96.42% purity Oxygen and 62.74%recovery.– The is the best zeolite for nitrogen removal Argon Removal– Argon to Oxygen selectivity of 1:1.– Requires a large volume of LiAgX zeolite to accomplish required purity Large volume of zeolite is required. Costs and inlet airflow rateincreases.

Design 2: AgA zeolite Nitrogen Removal– Nitrogen to Oxygen selectivity of 5 to 1 in AgA zeolite– Selectivity is lower than if using LiAgX zeolite Argon Removal– Argon to Oxygen selectivity of 1.63 to 1– Best design for Argon removal Large volume of zeolite is required– Costs and inlet airflow rate increases.

Design 3: Mixed zeolites Nitrogen Removal– LiAgX has a higher loading and selectivity of nitrogen thanAgA.– Not beneficial to mix them in order to rid of the nitrogen. Argon Removal– AgA has a higher loading and selectivity toward argon,selectivity being 1.63 than LiAgX which has a 1:1 ratio– Mixing in LiAgX in the argon removal section would onlyhurt performance as well.

Design 4: LiAgX and AgAzeolites separated Nitrogen– LiAgX zeolite with a 96.42% Oxygen purity and 62.74% recovery Argon– AgA zeolite with an Argon to Oxygen selectivity of 1.63 to 1 The volume is dramatically lower– Save money on the zeolite cost and overall unit The inlet air flow rate would be less due to the higher recovery ofoxygenHas been determined most beneficial design

Zeolite Design Analysis

Hospital Air SeparationDesign with PressureSwing Adsorption

Proposed Design HospitalLarge hospital information Approximately 350 largehospitals in the United States(500-1000 beds). At any time have 150 usersusing 5L/min.

Proposed Design - Hospital Goals– Use PSA technology to produce 99%oxygen with all specifications.– Provide for maximum capacity of 300users at 5 L/min of oxygen to adjust forfluctuation in demands.– Determine if product is profitable and aplausible option for large hospitals.

Proposed Design HospitalFirst calculate inlet air flow rate of air:Calculation of Inlet Flow RateRecovery of Oxygen (LiAgX) (%)Recovery of Oxygen (AgA) (%)Total Recovery of Oxygen (%)Assume 30 second Cycle TimeOulet Oxygen needed for 300 users at 5L/minOxygen Adsorbed per 2 columns (L)Inlet Oxygen (L/min)Inlet Air Mixture (L/min)62.755.034.515002850435021750

Proposed Design HospitalAdsorbent ResultsInlet Air Mixture (L)Inlet Air Feed to each column (L)Flow rate air to each column (L/s)LiAgX Section of ColumnProduct Throughput kg O2/h/kg adsorbentTotal 96.42% Pure Oxygen from LiAgXMass of LiAgX Zeolites (kg)AgA Section of ColumnTotal Entering O2/Ar mixture (L)Product Throughput kg O2/h/kg adsorbentMass of AgA Zeolites 9.5

Proposed Design HospitalColumn SpecificationsTotal Mass of Zeolites per Column (kg)Total Volume of Zeolites per Column (L)45324236Column DataVolume of Column (L)Diameter of Column (cm)Height of Column (cm)Total Loading of N2/O2/Ar per Column (kg)42368042122

Proposed Design HospitalFinal Components of DesignCompressor (Palatek)Max Flow of Compressor (CFM)Inlet Flow to be Compressed (CFM)Power Consumption (hP)900776200Silica Gel Drying ColumnVolume (cm 3)Height (cm)Diameter (cm)Mass of Silica Gel (kg)20291652012

Proposed Design HospitalComponents ContinuedHigh Pressure Storage TankVolume to be stored in 60 minutes (L)Volume of stored air at 10 atm921009210Compressor for High Pressure Storage (Palatek)Inlet Flow to be Compressed (CFM)Max Flow of Compressor (CFM)Power Consumption (hP)5510050

Proposed Design HospitalImportant ResultsPurity of Air (LiAgX)Volume of O2/Ar out of LiAgX SectionPurity of Air (AgA)Vol. 99% Oxygen out of 1 Column/30 secVolume 99% O2 out in 1 minUsers Supplied at 5L/minGoals met:Producing 99% OxygenSupply 300 users of oxygen at 5L/min!96.421448 997501501300

PortableOxygenConcentratorDesign

Portable Oxygen ConcentratorsMarket Designs:– Only alternative to carryingbottles of oxygen.– Uses PSA to purify airstream.– Small enough to carry.Less than 30 lbs.– Uses battery power toincrease portability.– 85%-95% oxygen purity.

Portable OxygenConcentratorsNecessary Requirements1. Weighs less than 30 lbs.2. 99% oxygen purity at 5 liters perminute.3. Battery life of at least 8 hours.4. Small enough to take on airplane5. Low noise6. Less than 5,000/unit and covered bymedicare.

Oxygen ConcentratorPartsColumn and TanksAdsorption Columns (Al) 1.5 literDrying Column (Al) 1 literLow Pressure Storage tank (Al) 2 literPackingLiAgX Zeolites (Adsorbent)Silver Zeolite A (Adsorbent)Silica Gel (Drying)Other itemsInlet Feed CompressorNitrogen Exhaust Muffler3 Way Ball Valve2 Way Solenoid ValveBatteryControl ComputerFrame (Aluminum)Casing (Plastic)Final Total Weight (kg)Final Total Weight (lb)Weightkg#21111223111PriceCost1.860.01151.86 100.00 100.00 100.00 200.00 100.00 50.0051.40.08 .4/g .4/g .05/g 2,000.00 560.00 4.002.730.230.090.090.930.090.910.09 100.00 3.00 100.00 100.00 100.00 300.00 100.00 75.00 100.00 3.00 200.00 200.00 300.00 300.00 100.00 75.009.35 Total Cost 4,192.0020.57

Portable OxygenConcentratorsGoals met with portable oxygenconcentrator from initial estimates:Purity: 99% OxygenCost: 4200 under 5000Weight: 20.5 lb under 30lbSmall: Estimated Volume .6ft x 1ft x 1ft

Portable OxygenConcentrators

Portable OxygenConcentratorsConclusions/Recommendations:A competitive/lightweight portableoxygen concentrator with 99% oxygencan be produced.Perform extensive design estimates andeconomic analysis.

ConsumerUtilityandPreference

Consumer Utility and Preference Method used to determine relationshipbetween:– consumer preference– satisfactionin order to predictproduct price andproduct demand.

Consumer Utility and PreferenceTheoryThe solution to consumer utility maximization isgiven by: ( d1 ) p1d1 Y p1d1 p2 p 2 1 d1 0α Inferiority Function (Knowledge of product, function of time)Β Superiority Function (Consumer preference, comparison tocompetition “preference”)Y Consumer budget p1*d1 p2

Project Goals Develop a . – LiAgX zeolite with a 96.42% Oxygen purity and 62.74% recovery Argon – AgA zeolite with an Argon to Oxygen selectivity of 1.63 to 1 The volume is dramatically lower – Save money on the zeolite cost and overall unit The inlet air flow rate would be less due to the higher recovery of oxygen Has been determined most beneficial design. Zeolite Design Analysis .