Transcription

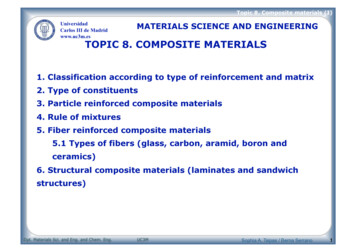

Topic 8. Composite materials (I)UniversidadCarlos III de Madridwww.uc3m.esMATERIALS SCIENCE AND ENGINEERINGTOPIC 8. COMPOSITE MATERIALS1. Classification according to type of reinforcement and matrix2. Type of constituents3. Particle reinforced composite materials4. Rule of mixtures5. Fiber reinforced composite materials5.1 Types of fibers (glass, carbon, aramid, boron andceramics)6. Structural composite materials (laminates and sandwichstructures)Dpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano1

Topic 8. Composite materials (I)DEFINITION AND TYPES“Mix of two or more constituent materials with significantly different physical orchemical properties which remain separate and distinct on a macroscopic levelwithin the finished structure”1. CLASSIFICATIONReinforcement: Particles (dispersion strengthenedor large particles) Fibers (discontinuous - short orcontinuous - aligned ) Structural (laminates and sandwichstructures)Matrix: Metal matrix composites (MMC) Ceramic matrix composites (CMC) Polymer matrix composites (PMC)When is a material considered to be a composite?Microstructural level ( 0,01 cm) to macrostructural ( 0,01 cm)WoodHypoeutectoid steelAustenitic stainless steelCellophane?ConcreteReinforce concreteCementReinforced plasticPaperDpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano2

Topic 8. Composite materials (I)DEFINITION AND TYPESWood (lignin celullose)Concrete (gravel cement)Hypoeutectoid steel (ferrite pearlite)Reinforced concrete (gravel cement steel)Austenitic stainless steel (grains )CementCellophane (Multiple polymeric layers)Reinforced plastic (it doesn’t improve its properties)Paper (only cellulose fibers)- Composite material- Limit of composite material- Not a composite materialDpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano3

Topic 8. Composite materials (I)COMPOSITES IN NATURESea shellsAbalone shell:CaCO3 3% organic material 3000* stronger than calciteWoodcellulose-filaments in a matrix of lignin and hemicellulosegrowth rings form a layered compositeOak woodperpendicular to the growth rings are radially orientedribbon-like structures : rays which provide a redial stiffeningand e:Wood structure Hard Soft Wood.jpgDpt. Materials Sci. and Eng. and Chem. Eng.UC3Mpine woodSophia A. Tsipas / Berna Serrano

Topic 8. Composite materials (I)CLASSES ACCORDING TO REINFORCEMENT AND MATRIXDifferent matrix, reinforcement and properties of CMMatrixMetalCeramicGlassOrganicReinforcement materialPropertiesElectric resistance to temp. Metal fibers, ceramic, carbon, glassthermal stabilityParticles and metallic fibers andChemical and thermalceramicsresistance to temp. Mechanical strength andchemical resistance to temp. Glass and ceramic particlesthermal stabilityMechanical strength to hightemp. chemical and electrical,Carbon, glass and organic fibersand erosion resistance,flexibility and thermal stabilityProperties to take into account for material design For ceramic and metallic component: Physical (thermal, electrical,optical ) and mechanical (stiffness, toughness, stress-strainbehaviour ) For plastic components: Physical and mechanical. Also the waterabsorption and transmissionDpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano

Topic 8. Composite materials (I)TYPE OF CONSTITUENTSStructures, reinforcements, types and properties of compositematerialsCOMPOSITE panelsRandomly orientedStructureDpt. Materials Sci. and Eng. and Chem. Eng.ReinforcementComposite ropicShort fibresRandomIsotripicAlignedAnisotropicContinious fibersAligned continous fibresAnisotropicLaminates orlayerslaminatesAnistotropicUC3MSophia A. Tsipas / Berna Serrano6

Topic 8. Composite materials (I)TYPE OF CONSTITUENTSThe composite material properties depend upon the properties of each ofits phases, their relative proportions and their geometrySchematic representation of several geometric and spatial characteristics ofparticles of the dispersed phaseDpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano7

Topic 8. Composite materials (I)3. PARTICLE-REINFORCED COMPOSITE MATERIALSParticles: geometrical varietyFactors that have an influence in physical an mechanical properties:size, distribution and particle contentGeneral aspects of particle reinforce composites: Advantages of particle reinforced composite materials Low cost High stiffness and strength (inorganic particles) Wear resistance Simpler manufacturing process Mechanical properties depend on the reinforcement, manufacturingand subsequent treatments Most used metallic matrixes are Al, Mg, Ti y Ni Polymeric matrixes are reinforced to improve their mechanicalstrength and abrasion resistanceDpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano8

Topic 8. Composite materials (I)3. PARTICLE-REINFORCED COMPOSITE MATERIALSTYPES OF PARTICLESGreat variety of ceramic particlesTo select the appropriate reinforcement it should be taken into account: Structural High modulus Low density Particle shape (avoid corners) Thermal: Expansion coefficient and conductivityProperties of SiC and Al2O3 particles:ParticleDpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano9

Topic 8. Composite materials (I)3. PARTICLE-REINFORCED COMPOSITE MATERIALS Dispersed phase: Particles with d 10-250 nm Dislocation movement isblocked causing hardening ( hardness, E, σ). Continuous phase: Matrix is bearing the loadExamples and applications of dispersion strengthened 20% Cr-ThO2Pb-PbOPt-ThO2Dpt. Materials Sci. and Eng. and Chem. Eng.ApplicationElectrical connectorsNuclear reactorsNuclear reactor and aerospaceMagnetic materials resistant to yieldTurbojet componentsBattery gridWires, electrical componentsUC3MSophia A. Tsipas / Berna Serrano10

Topic 8. Composite materials (I)3. PARTICLE-REINFORCED COMPOSITE MATERIALS3.2 Composite materials reinforced with large particlesDpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano11

Topic 8. Composite materials (I)3. PARTICLE-REINFORCED COMPOSITE MATERIALSCERMETS (cemented carbides) Hard ceramic particles scattered in a metallicmatrixTungsten carbide particles, WC (hard, stiff, and Tm) scattered in metallicmatrixes are used as cutting toolsThese composites are brittle toughness improvement: it is combined with Copowder that when sintered acts as an adhesive for WC particles.ABRASIVE cutting and forming discs from alumina Al2O3, silicon carbide, SiC cubic boronnitride, BN. This particles are cemented in vitreous or polymeric matrixesCAST PARTICLE REINFORCED COMPOSITES Al casting with SiC particles forapplications in the car industry (pistons and connecting rods)Dpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano12

Topic 8. Composite materials (I)3. PARTICLE-REINFORCED COMPOSITE MATERIALSCONCRETEIt is a matrix of cement together with gravel or sand particles“It is a composite of particles held together by cement”There are two kinds of cement: Asphalt cement (for paving) and Portland cement (forbuilding construction)PORTLAND CEMENT CONCRETEIngredients: Fine aggregate Portland cement (sand), coarse aggregate (gravel) and water fine sand particles occupy the empty spaces between gravel particles. Theseaggregates are 60-80% of the total volume. The cement-water mixture must cover the sand and gravel particles. The finalbonding cement-particles depends upon the quantity of water (insufficient water:incomplete bonding; excess water: porosity)PROBLEMS: low strength and extremely brittle; it dilates and contractswith temperature; cracks appear when it undergoes freezing-defreezingcycles.SOLUTION: Reinforcements REINFORCED CONCRETE (STEEL tubes,bars, wires or meshes in cement before curing)Dpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano13

Topic 8. Composite materials (I)3. RULE OF MIXTURESRule of mixtures: The properties of a composite material depend upon the relative quantitiesand properties of its constituentsPCM Properties of the composite material;f volumetric fraction of each i ( fi 1)i i-th componentParticle-reinforced composite Isotropic propertiesRelationship between volume fraction and E ”Value of E constrained”Minimum:Maximum:E: elastic modulusV: fraction of volumem: matrixp: reinforcementc: composite materialWilliam D. Callister, Jr. ,Materials Science andEngineering: An Introduction, John Wiley & Sons, Inc.Dpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano14

Topic 8. Composite materials (I)Examples: Particle Reinforced composite1 µmCarbon Black particle reinforcement inStyrene-Butadiene synthetic rubber forcar tire application.WC–Co cemented carbide. Lightareas are the cobalt matrix; darkregions, the particlesof tungsten carbide x100.William D. Callister, Jr. ,Materials Science and Engineering: An Introduction, John Wiley & Sons, Inc.Dpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano

Topic 8. Composite materials (I)5. FIBER-REINFORCED COMPOSITE MATERIALSDpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano16

Topic 8. Composite materials (I)5. FIBER-REINFORCED COMPOSITE MATERIALSClassification according to shapeContinuous fibers(aligned)Short or discontinuous fibers (alignedor randomly scattered)Longitudinal directiona)Continuous and aligned fibersb)Discontinuous and alignedfibersc)Discontinuous and randomlyplaces fibersTransversedirectionDpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano17

Topic 8. Composite materials (I)5. FIBER-REINFORCED COMPOSITE MATERIALSGlass FibersComposite material fiberglassreinforced polymeric matrix(stereoscopic SEM image of thefracture ss reinforced plastic SEM Stereo 200x.JPGDpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano18

Topic 8. Composite materials (I)5.1 TYPES OF FIBERS: Glass FibersUsed to reinforce plastic matrixesComposition: Base of SiO2 (50-70%) Oxides Ca, Al, B, Na, Mg and KProperties: non combustible, good chemical, biological and thermalresistance (Tm ,α ), thermal insulator (K ), electric insulator (σ ),low expansion coefficient and low costTypes and composition of different fiberglass:Material, % in weightType ofglassSilicaE (1)541420,50,58111A (2)72184-14-1ECR6111223-0,6-2,4S (3)6425-10-0,3-0,7Alumina Ca OxideMagnesiumB OxideNa2CO3 Ca FluorideSecondaryOxides(1) Ca Aluminoborosilicate(2) Rich in alkali(3) Mg Aluminosilicate without BDpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano19

Topic 8. Composite materials (I)5.1 TYPES OF FIBERS: Glass FibersFiberglass propertiesTypeρrelativeofglassσtensile(MPa)-6E (GPa) α 10ε(K)(a 20 ºC y 1MHz)Tm (ºC)For applications that requireGood electrical properties and dimensionalstability (circuit 96 Chemical resistanceECR2,62362572,55,06,51204Good electrical properties and chemicalresistanceS2,48459086,05,65,11454Tensile strength and thermal stability(aerospace and aeronautic industries) The strength of these fibers is high but not extreme: there are limits in their application E glass is the cheapest and has the highest moisture resistance (polymeric matrixes) All the fibers are good insulatorsCommon polymeric matrixes:Thermoplastics: Nylon 66, Polycarbonate y PolystyreneThermoplastics: Epoxy, polyesters, phenolic, siliconDpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano20

Topic 8. Composite materials (I)5.1 TYPES OF FIBERS: Glass FibersThere are three possible configurations for fiberglass reinforcedcomposite materials:a.b.c.a) Continuous fibersb) Discontinuousc) Woven fiber (for laminated structures)Dpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano21

Topic 8. Composite materials (I)5.1 TYPES OF FIBERS: Carbon fiberAdvanced composites for aerospace and aeronautic fibers Very good thermal and physical properties (High electrical conductivity and highthermal conductivity). Carbon fibers in composites with plastic resins (i.e.: epoxy) good combination ofhigh mechanical strength, stiffness and low weight aerospace applications-Low cost: sport equipment manufacturing, industrial and commercial products(70’s 220 /kg and 80’s 9 /kg) Manufactured from organic precursors: Rayon and isotropic tars (fibers E , 50 GPa) Polyacrylonitrile (PAN) and liquid crystal tar (E ) (easier to orientate)PAN fiberStabilizationat 200-220oCCarbonization at1000-1500oCGrafitization at1800oCHigh-strengthcarbon fiberHigh-moduluscarbon fiber1. STABILIZATION Stretching (200-300ºC): fibrillar network2. CARBONIZATION 1000-1500ºC inert atmosphere Removal O,H,N HT-CF3. GRAPHITIZATION T 1800ºC. Degree of orientation increased: E and strength: HM-CFDpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano22

Topic 8. Composite materials (I)5.1 TYPES OF FIBERS: Aramid fiber Kevlar polyamide (poly(paraphenylene terephthalamide )) The aromatic ring provides thermal vlar chemical structure H-bonds.png E due to its configuration: rigid molecules are arrayed in ordered domains (liquidcrystal polymer) during extrusion they are oriented in the direction of the flow Thermal and electrical insulator, α, high impact strength and E (compared tocarbon)Properties of the three types of KevlarMaterialρ (g/cm3)Dwire (µm)σtensile(GPa) E (GPa)Kevlar 291,44123,683Kevlar 491,44123,6-4,1131Kevlar 1491,47123,4186Dpt. Materials Sci. and Eng. and Chem. Eng.UC3Mε (%)4,02,82,0Sophia A. Tsipas / Berna Serrano23

Topic 8. Composite materials (I)5.1 TYPES OF FIBERS: Boron and ceramicsBoron fibersManufactured through a vapor deposition of B over a core of WCeramic fibers: Mainly quartz (Al2O3, Si3N4, )Dpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano24

Topic 8. Composite materials (I)5.1 TYPES OF FIBERSMechanical properties of the different fibersWilliam F. Smith, Foundations of Materials Science and Engineering, 3/e, McGraw-Hill 2004Dpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano25

Topic 8. Composite materials (I)6. STRUCTURAL COMPOSITE MATERIALSFormed by composite materials and homogeneous materialsProperties depend on the geometry of the structural elementsTypes laminated composites sandwich structuresPiling of layers or lamina of unidirectional composite materialLaminar composite example: continuous and aligned fiber reinforced plasticswith matrixes such as epoxy, polyester, PE, PA, PET In order to get different mechanical properties layers of materials withdifferent properties are piled, or a different way of piling layers on top of eachother.Dpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano26

Topic 8. Composite materials (I) Orientation of fibers with respect to the lamina: Usual fiber orientations: 0, 90, /-45. By combining these orientations, the desired strengthand stiffness is achieved. Plane isotropy can be achieved. Fiber layers arranged in a way so that strength is maximized and weight is minimized.UnidirectionalCrosspliedQuasi-isotropic Laminated composites must alwaysbe symmetric with respect to theirmiddle plane, and the must also bebalanced to avoid anomalousdistortions in the structure The strength and stiffness variesgreatly with the orientation. A piling of woven materials withoutany bonding does not have anystructural use. Therefore a matrix isneeded.Piled lamina. The orientation of the direction with R changes in each of the layersDpt. Materials Sci. and Eng. and Chem. Eng.UC3M Exclusively unidirectional compositesare never used.Sophia A. Tsipas / Berna Serrano27

Topic 8. Composite materials (I)2 external strong layers (face sheets) attached to a layer of less dense material(core) with low stiffness and low strength Role of the face sheets they withstand most of the plane loads and transversal bendingstresses Face sheet material Al alloys, fiber-reinforced plastics, Ti, steel and plywood. Core material separates both face sheets and resists deformations perpendicular to theface plane. Provide resistance to shear stress along the planes perpendicular to the facesheets Core materials may have differentand have different structures: polymerfoams, synthetic rubber, inorganiccement and balsa wood Typical core with honeycombstructure thin layers arranged inhexagonal cells.honeycomb panel used in positeSandwich.pngDpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano28

Topic 8. Composite materials (I)Applications of compositeshoneycomb panelused in aircraftGLARE"GLAss-REinforced" Fibre Metal Laminate (FML),http://commons.wikimedia.org/wiki/File:LCA Composites.jpgDpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano

Topic 8. Composite materials (I)Applications of compositesDpt. Materials Sci. and Eng. and Chem. Eng.UC3MSophia A. Tsipas / Berna Serrano30

Dpt. Materials Sci. and Eng. and Chem. Eng. UC3M Topic 8. Composite materials (I) 2 “Mix of two or more const