Transcription

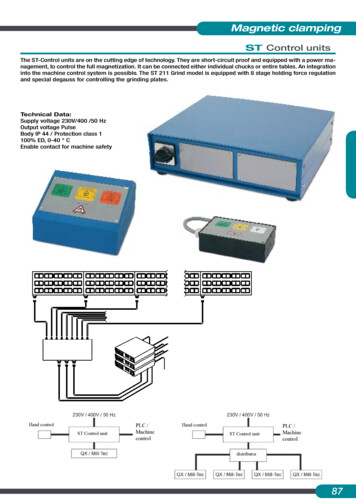

Magnetic clampingST Control unitsThe ST-Control units are on the cutting edge of technology. They are short-circuit proof and equipped with a power management, to control the full magnetization. It can be connected either individual chucks or entire tables. An integrationinto the machine control system is possible. The ST 211 Grind model is equipped with 8 stage holding force regulationand special degauss for controlling the grinding plates.Technical Data:Supply voltage 230V/400 /50 HzOutput voltage PulseBody IP 44 / Protection class 1100% ED, 0-40 CEnable contact for machine safetyHand controlST Control unitPLC /MachinecontrolHand controlST Control unitPLC /Machinecontroldistributor87

MagneticMagnetischesclampingHebenST Control unitsModelItem-Nr.Weight(kg)Size(mm)Supply voltageInputOutputCablelengthPlugST 120 ER9050 11202,2 kg140x150x80230V/ 50HZ 16A2m SchukoLine3mErgonMagnetic ChuckQX from 2012ST 120 SK2439 1202,2 kg140x150x80230V/ 50HZ 16A2m SchukoLine3mErgonMilltecST 211 ER9050 121111kg331x275x85400V/50HZ 25A3m 32 A CEELine5mErgonQX from 2012ST 211 SK2439 21111kg331x275x85400V/50HZ 25A3m 32 A CEELine5mErgonMilltecST 211 Feme9050 120111kg331x275x85400V/50HZ 25A3m 32 A CEELine6mFEME 4polQX 68mm/SQ/QX-Lock/QC Block/UST 212 SK2439 21211kg331x275x85400V 50HZ/25A3m 32 A CEELine6mFEME 4polMilltec on distributorST 212 Feme9050 120211kg331x275x85400V/50HZ/25A3m 32 A CEELine6mFEME 4polQX on distributorST 214 SK2439 21411kg331x275x85400V 50HZ/25A3m 32 A CEELine6mFEME 7polMilltec on distributorST 214 Feme9050 120411kg331x275x85400V/50HZ/25A3m 32 A CEELine6mFEME 7polQX on distributorST 211 GR9050 122111kg331x275x85400V/50HZ 25A3m 32 A CEELine5mfixed connectionEFP, TFP, UGP, TFP/CPFR, RPJunction boxes made of sheet steel housings, Protection IP putpluggableOutputCableCablelengthPlugVB1-2 K/ Feme1 in 29050 1502-13,576x80x58feme2x Lineyes6mFemeVB1-2 K/ Ergon1 in 29050 1502-23,576x80x58feme2x Lineyes5mErgonVB1-2 B/ Feme1 in 29050 1502-3376x80x58feme2x BushnononeFemeVB1-3 K/ Feme1 in 39050 1503-18160x160x90feme3x Lineyes6mFemeVB1-3 K/ Ergon1 in 39050 1503-27160x160x90feme3x Lineyes5mErgonVB1-3 B/ Feme1 in 39050 1503-33160x160x90feme3x BushnononeFemeVB1-4 K/ Feme1 in 49050 1504-112160x160x90feme4x Lineyes6mFemeVB1-4 K/Ergon1 in 49050 1504-210160x160x90feme4x Lineyes5mErgonVB1-4 B/ Feme1 in 49050 1504-33160x160x90feme4x BushnononeFemeMCU-FS Safety Foot-SwitchSafety foot-switch with mechanical double press. It allows you to hang up workpieces with both hands and to turn themagnetic clamping system on or off on foot. In particular in the production of serial parts and vertical spread out thusboost effectiveness and safety.88ModelItem-Nr.MCU-FS2411 010Dimensions (mm)LxWxH150 x 150 x 200Weight(kg)6

Magnetic clampingZero-point-clamping-systemsThe automation has become indispensable in the mechanical processing. In order to keep machine downtime to aminimum, in EDM, milling and grinding machines, palletizing and zero-point clamping systems are used. This allowsthe user to span the workpiece already outside the machine, so that a supply of strained workpieces for the machinecan be prepared.This allows zero-point clamping systems, to change workpieces between 2 machines without re- calibration of theposition, or even to interrupt a machining operation, to take the workpiece from the machine and to continue to runthe program at a known position.The external clamping is carried on pallets which can be accommodated in the machine repeatability. The pallets arethen passed manually or automatically in the machine.The magnetic clamping plates described on the following pages are suitable for use with palletizing systems from allmanufacturers.To produce self-sustaining magnetic palettes reference elements can also be incorporated directly into the magneticchuck. We also supply ready-made with original clamping and positioning equipped magnetic pallets for all Systems.For heavy cutting and large workpieces we recommend Electro-Permanent square pole, in combination with UniLock-Rquick-change pallet systems.UniLock-R Zero-point-clamping-systemPMNM Magnet plate with Reference-elementsSystem Erowa UPCRS Magnet round fodder with System ErowaITSStandard Palette System 3R89

ng-systemsAssembly operation in an EDM machine with palletizing magnetic chucks system ErowaPMNM-AL permanentMagnetic range with reference elementsSystem Erowa UPCHSC milling on PMNEOMagazine for palletising magnetic chucks and tools90

Magnetic clampingPMNM Permanent Magnetic ChuckPermanent magnetic chucks type PMNM are high precision plates for clamping small and thin parts for precisiongrinding and eroding. The low magnetic field height prevents magnetization of processing tools. The chipboard isactivated via a removable hex shifter.PMNM palletising clamping plates are available in 3 versions:Type 1:Height 54mm, with steel body to reference elements to integratedirectly into the magnetic disk, so that no additional spectrum isrequired under the magnetic chuck.ModelItem-Nr.PMNM 1515-48PMNM 2828-54PMNM 3232-482004 15152004 28282004 3233OtherDimensions (mm)LWH150150482802805432032048dimensions on requestcorner chamfer (mm)Weight(kg)10 x 45 10 x 45 40 x 45 103335Recommendation:High-precision plate for grinding and erodingType 2:Height 40 mm with steel body, flat and easy to build on standardpallets.ModelItem-Nr.PMNM 2424-40PMNM 2828-40PMNM 3232-402019 24242019 28282019 3233OtherDimensions (mm)LWH240240402802804032032040dimensions on requestStructure:Neodymium Magnet system, Seel body,Transverse pole pitch 1.4 0.5 mmHolding power ca. 100 N/cm²Magnetic field height ca. 5 mmPole plate wearing limit 6 mmcorner chamfer (mm)Weight(kg)10 x 45 10 x 45 40 x 45 18252991

MagneticMagnetischesclampingHebenPMNM-AL Permanent Magnetic ChuckType 3:Super lightweight aluminum body for direct installation of clamping elements.ModelPMNM-AL 2424-48PMNM-AL 2828-48PMNM-AL 3232-48Item-Nr.Dimensions (mm)LWH2008 2424240240482008 2828280280482008 323332032048Other dimensions on requestcorner chamfer (mm)Weight(kg)10 x 45 10 x 45 40 x 45 182426The PMNM UPC pallet is delivered completely ready fitted to fit the ErowaUPC clamping system with original Erowa elements. Optional with handlesand/or link Gripper.ModelPMNM-AL 3232-48 UPCGripper LinkHandles92Item-Nr.Dimensions (mm)LWH82008 3233320320488000 80118000 8010Other dimensions on requestcorner chamfer (mm)Weight(kg)40-27-

Magnetic clampingPMNEO Permanent Magnetic ChuckPermanent magnetic chucks type PMNEO are super strong, compact plates for heavy cutting. Parts from about30x15x6mm can be stretched with max. achievable holding forces. Good holding forces can be achieved even on roughsurfaces. Optional pole blocks can be built on the PMNEO. This allows turning up the workpiece so that all sides arefreely accessible, can be drilled on the magnetic clamping plate and leaves more space for accumulating chips aroundthe component. This allows long-running HSC milling-pieces never sink into the resulting chips.The chipboard is activated via a removable hex shifter. The PMNEO magnetic clamping plate, in 48mm height, isprepared to integrate reference elements directly into the magnetic chuck, so that no additional spectrum is requiredunderneath the 3240402007200720072007Dimensions 0040048Other dimensions on requestcorner chamfer (mm)10104040xxxx45 45 45 45 Weight(kg)19283550Structure:Double Neodymium, Magnet system,Steel body,Transverse pole pitch 11 4 mmHolding power ca. 150 N/cm²Magnetic field height ca. 10 mmPole plate wearing limit 6 mmRecommendation:Super Strong plate for millingThe PMNEO UPC pallet is delivered completely ready fitted to fit theErowa UPC clamping system with original Erowa elements. Optionalwith handles and/or link Gripper.ModelItem-Nr.PMNEO 3232-48 UPCGripper LinkHandles102 threaded bushings M510 Pole-bars82007 32348000 80118000 80108000 80168000 801410010Other dimensions on requestDimensions (mm)LWH3203204814corner chamfer (mm)Weight(kg)40-36---93

MagneticMagnetischesclampingHebenPMNEO Permanent Magnetic ChuckSpecial versions are also available with threaded inserts and additional strips. Optimal for highlighting the workpiecefor machining the outer contour or to work through.PMNM / RS / RNF Clamping-system with Erowa ITSFor use with the EROWA ITS palletizing system we recommend our PMNM Magnetic Chucks and our RNF and RSmagnetic chuck. Suitable for light milling, EDM and grinding.94

Magnetic clampingQX-LOCK HD50 Electro-Permanent Magnetic ChucksQX Lock magnetic chucks are equipped with extra strong frame construction. The overall height is 68 mm and the rearpanels can be 22 mm deep drilled or milled 12 mm. Optimal for introducing reference elements for zero-point clampingsystems. Transport thread around allows an easy horizontal or vertical crane transport.For more information on the magnetic technology the QX Lock and interesting accessories like pole extensions andpole plates look at Page 69.QX-Lock Magnetic sions 49968NumberPoles NWeight(kg)1024405060363978118156195122Matching Control eFemeFemeMatching pole-reversal devices ST 211 FEMEon Pages 87 and 88.95

MagneticMagnetischesclampingHebenUNILOCK -R Zero-point-clamping-systemsWith the universal UNILOCK R zero-point clamping system, you change your workpieces and jigs made within secondsZero oriented. The repeatability lies under 0,005mm. Reduce your machine downtime by up to 90 %!Magnetic clamping pallets, fixtures, vises, grid plates or workpieces are provided with the UNILOCK bolt and positivelyto the UNILOCK zero-point clamping system, highly accurate excited and locked.Simple and reliable:Unilock R spanned always and only needs to loosen a compressed air pulse. As an option the turbo input can beconnected to a compressed air pulse with particularly strong chipping. This increases the pull-in force to threetimes.release 6 barTurbo 6 bar PulseSolid and StableThe super strong universal clamping pin can be mounted in various ways to the part to clamp. The intelligent combination of bolt types A, B and C, the repeatability is achieved by 0.005 mm.mounting options UNILOCK-clamping boltType 1: with threaded bolt DIN 913 M12x35Type 2: below with cylindric screw DIN 912 M10x45 (Q 12.9)Type 3: above with cylindric screw DIN 912 M12 (Q12.9) strongest ltspacial-clamping-bolt

Magnetic clampingUNILOCK -R Zero-point-clamping-systemsThe standard pallets R2 to R10 are prepared ready for use on the machine. It can, for example, built on a R10 Unilockpalette 5 small magnetic plates, each with 2 clamp bolt as well as 2 pieces R4 UNILOCK pallets a magnetic chuck with8 bolts are tightened.All pneumatic connections are in the massive, polished base plate, the holes drilled in many places can be carried out.Simply screw and edit the first part after a few simple steps.Technical features that convince: Repeatability 0.005 mm Positive locking; Holding force 75kN Pneumatic system, the compressed air is used simultaneously for cleaning Free media , self-locking clamping system with very high Surface pressure by power transmission and locking the clamping wedges Compressed air supply of 6 bar to release sufficient (no hydraulics necessary) Massive construction of clamping modules, strongly dimensioned clamping bolt Large room during retraction of the clamp bolt by conical Collection of short taper High-precision centering in the module and at the clamping bolt Diverse Options to fix the clamping bolt Direct installation into the machine table possible97

MagneticMagnetischesclampingHebenTogehter we are strong!Magnetic chucks clamp the workpiece quickly,Change zero point clamping systems the clamping device quickly and accurately,both together are the solution when it comes to productivity!During the day, Pre-milling during the day, interrupting simple during the night, half-finished programs and take theworkpiece on the machine later, accurately position move from one machine to another, tighten the set-up stationand minimize machine downtime - no problem with Unilock R QX Lock.98

Magnetic clampingModels and DimensionsBack:- drilling depth max. 22mm- millable 12mmQX-Lock Magnetic 924192419402404406408410UNILOCK -R Zero-point-clamping-SystemsDimension berPoles NWeight(kg)10244050603978118156195ModelItem-Nr.LR2 ESMR4 ESMR6 ESMR8 ESMR10 96796996Dimension (mm)WH 0,02/-0,03196613966139661396613966199

MagneticMagnetischesclampingHebenRM Permanent Magnetic circular ChuckPermanent Magnetic Circular Chuck Type RM, with reinforced ceramic magnet system can be used for clamping bulkyand heavy workpieces. The magnetic force is infinitely variable, in the surface incorporated centering grooves facilitatealignment of the workpiece. In the rake face, a center hole can be introduced.Structure:Ceramic Magnet system, Aluminum body,Max-Pole pitch 5 8 mmHolding power ca. 140 N/cm²Magnetic field height ca. 8mmPole plate wearing limit 8 mmSwitch travel MAG - ENT-MAG 500 Recommendation:Super Strong round fodder for turning, alsofor rough partsModelRM 20RM 25RM 30RM 35RM 40RM 45RM 50100Item-Nr.2101 202101 252101 302101 352101 402101 452101 50A200250300350400450500Dimension (mm)BCD801504.5802004.5852504.5853004.4100 3005100 3505100 4005E182232285334350400450HolesPole pitchWeight(kg)V-Max.(U/min.)4 x M84 x M84 x M84 x M86 x M106 x M106 x M108 58 58 58 58 58 58 513202737567090800700700600500450400

Magnetic clampingRF Permanent Magnetic circular ChuckUse permanent magnet type rotary feed RF, with ceramic magnet system and fine pole for clamping of thin and smallworkpieces, in particular for grinding and turning of thin slices and rings. The magnetic force is infinitely variable, inthe surface incorporated centering grooves facilitate alignment of the workpiece. In the rake face, a center hole canbe introduced.Structure:Ceramic Magnet system, Aluminum body,Fine-pole pitch 4/6 2 mmHolding power ca. 80 N/cm²Magnetic field height ca. 4 mmPole plate wearing limit 8 mmSwitch travel MAG - ENT-MAG 500 Recommendation:Precise Fine-pole-plate for thin mension le pitchWeight(kg)V-Max.(U/min.)4 1.5 2 1.54 1.5 2 1.56 1.5 2 1.56 1.5 2 1.56 1.5 2 1.56 1.5 2 1.5358132027150012001000800700700101

MagneticMagnetischesclampingHebenRN Permanent Magnetic circular ChuckPermanent Magnetic Circular Chuck Type RN, with neodymium magnet system and low height are used for clampingof small workpieces with sufficient material thickness, especially for grinding and for assembly work. In all steel polescan be drilled 15mm deep. There may be a centering hole max. 22x5mm, or a threaded M8x12mm are introduced.Structure:Neodymium Magnet system, Steel body,Pole pitch 11 3 mmHolding power ca. 80 N/cm²Magnetic field height ca. 6 mmPole plate wearing limit 8 mmSwitch travel MAG - ENT-MAG 180 Recommendation:Strong round fodder in flat 104210410131520A100130150200Dimension olesPole pitchWeight(kg)V-Max.(U/min.)3xM64xM64xM84xM811 311 311 311 335812150012001000800RNF Permanent Magnetic circular ChuckPermanent Magnetic Circular Chuck Type RNF with neodymium magnet system and low height are used for clampingof small and thin workpieces.Structure:Neodymium Magnet system, Steel body,Pole pitch 1,5 0,5mmHolding power ca. 80 N/cm²Magnetic field height ca. 4mmPole plate wearing limit 4 mmSwitch travel MAG - ENT-MAG 180 Empfehlung:Feinpoliges Rundfutter für kleine TeileModelRNF 6RNF 8RNF 10RNF 13RNF 15RNF 16RNF 20RNF 25102Item-Nr.2106 062106 082106 102106 132106 152106 162106 202106 25A6080100130150160200250Dimension 4E417085115132140180230HolesPole xM84xM104xM101,5 0,51,5 0,51,5 0,51,5 0,51,5 0,51,5 0,51,5 0,51,5 0,511,835791219150015001500120010001000800700

Magnetic clampingRS Permanent Magnetic circular ChuckPermanent magnet rotary chuck type RS, with neodymium magnet system and radial pole pitch, used for clampinghard to holding rings and washers. Especially with large diameter, the radial or Star-pole-pitch characterized by greaterrigidity and stability. RS round fodder are specially designed for hard turning and can be operated at high speeds. Themagnetic force is infinitely variable. Centering grooves facilitate alignment of the workpiece. In the center, a throughhole can be introduced with the diameter C. The diameter B is magnetically inactive.Structure:Neodymium Magnet system, Steel body,Radial-pole pitchHolding power ca. 140 N/cm²Magnetic field height ca. 10 mmPole plate wearing limitRS 13, 3 mm, RS 15 - 80, 7 mmSwitch travel MAG - ENT-MAG 180 Recommendation:Super Strong Round food for rings and forhard turningModelRS 13RS 15RS 20RS 25RS 30RS 35RS 40RS 50RS 60RS 70RS 80Item-Nr.2103 132103 152103 202103 252103 302103 352103 402103 502103 602103 702103 5777777110B16202830404040609090110Dimension 50114 12001100900700600500500103

MagneticMagnetischesclampingHebenRS Permanent Magnetic circular ChuckSpecial versions of the magnetic circular chuck RS is available with center hole, central through-hole and lockinggroove or T-slots for sliding pole pieces, which are available for various applications. It can also be built pole plates orpole-blocks.RS magnetic round chuck with integrated148 EROWA ITS reference elements104

Magnetic clampingShort taper flangesChucks – short taper flanges mounting of circular magnets on your spindle head. The flanges on the machine sidefinished and chuck-side plain shot. They are made of soft steel. Upon request we provide our round fodder readyflanged-on.For spindle heads with bayonet-plate mounting in accordance with DIN 55027 (formerly DIN 55022).Item-Nr.9001 031609001 042009001 042509001 053159001 064009001 085009001 115009001 2110221112211122613531170412204129041400Other sizes andDimension 56363 104,8M10106,375 63 133,4M12139,719 80 171,4M16196,869 80235M20285,775 80 330,2M24flanges of cast upon 68For spindle heads with Camlock DIN 55029 (formerly ASA B 5.9.D1).Item-Nr.9002 31609002 42009002 42509002 53159002 64009002 85009002 115009002 her sizesDimension (mm)BCDEFGH2192,153,97540 70,66 7/16-201321117,563,51350 82,55 7/16-201321117,565,51361 82,55 7/16-20132614682,56363 104,8½-201631181106,375 63 133,4 5/8-181741225,4 139,719 80 171,4 3/4-161941298,4 196,869 802357/8-142141403285,775 80 330,21-1423of cast flanges, special flange and taper on request105

MagneticMagnetischesclampingHebenTFP/C Electro-Permanent Magnetic circular ChuckTFP/C electric permanent magnet round chuck with a fine pole pitch combine the advantages of permanent andelectromagnetic chucks. The particle board does not heat up during long chip times, has a very controlled magneticfield and offers the possibility of holding force control and demagnetization.TFP / C magnetic chucks designed for grinding operations with the highest precision - even on small workpieces from2 mm material thickness. They impress with uniform holding force over the entire gripping range. TFP / C magneticchucks have a pole-plate-less construction. Thus, they are particularly flat, very easily and in many places machinable.The cable connection to the pole-reversal device may be laterally plugged or rear connected via a slip ring contact.Structure:Electro-Permanent Magnet system,Steel body Mono-blockTransversal Pole pitch 4 2 6mm with Steps.Holding power ca. 80 N/cm²Magnetic field height ca. 4 mmPole plate wearing limit 5 mmPerformance 210 V PulseProtection IP 2Recommendation:High-precision, slimline electro-permanent magnetic chuckfor grinding thin slices and rings.Matching pole-reversal devices Type ST211 GR on Pages 87 - 88.1063004005006000300040005000600Dimension (mm)LW30054400545005460054Weight(kg)285280120

Magnetic clampingPFR Electro-Permanent Magnetic circular ChuckPFR magnetic chuck suitable for final processing of rings and for hard turning or grinding. The reinforced ceramicmagnet system also allows to fully demagnetize high-alloy and hardened materials after processing. The monoblockbase body and the brass isolated magnetic poles ensure maximum rigidity and best heat dissipation.Optional deployable mobile and flexible pole extensions allow to span the workpiece indemnify and non-warping.Diameter up to 2000mm are manufactured massively from a base body. Larger diameters can be composed of individualsegments. The cable connection to the pole-reversal device may be laterally plugged or rear connected via a slip ringcontact.Structure:Electro-Permanent Magnet system,Steel body Pole-plateRadial Pole pitchHolding power ca. 100 N/cm²Pole plate wearing limit 6 mmPerformance 400 V PulseProtection: IP 67ModelPFR 060030PFR 080030PFR 100030PFR 125030PFR 125050PFR 150050PFR 200100Item-Nr.2503 06032503 08032503 10032503 12032503 12052503 15052503 2010ØD160080010001250125015002000Dimension 10NumberPolesWeight(kg)121220 1020 1020203218033050080080011001700Matching pole-reversal devices Type ST211 GR onPages 87 - 88.107

MagneticMagnetischesclampingHebenRP Electro-Permanent Radial Magnetic-round-chuckRP electro-permanent magnetic round chuck with radial poles are designed for the machining of bearing rings. AboutT-slots in the magnetic poles and pole extensions mechanical clamping aids can be constructed. The cable connectionto the pole-reversal device may be laterally plugged or rear connected via a slip ring contact.Structure:Electro-Permanent Magnet system,Steel body Mono-blockRadial Pole pitchHolding power ca. 100N/cm² RP/SHolding power ca. 140N/cm² RP/HPole plate wearing limit 4 mmPerformance 400 V PulseProtection: IP 67Recommendation:Uncompromising magnetic chuck forMachining of bearing rings.ModelItem-Nr.RP/S 6025RP/S 8025RP/S 10050RP/S 12550RP/S 15085RP/S 17085RP/H 6025RP/H 8025RP/H 10050RP/H 12550RP/H 15085RP/H 17085The inner2501 060252501 080252501 100502501 125502501 150852501 170852502 060252502 080252502 100502502 125502502 150852502 17085diameter B isMatching pole-reversal devices Type ST211 GR on Pages 87 - 88.108Dimension 850125361490magnetically inactive Other sizes on request

Magnetic clampingLAMELLA-LAY MY-SHEETSLamella-lay my-sheets and beams are used in conjunction with magnetic clamping plates. If parts can be clamped ona magnetic chuck very difficult or impossible because of very low material thickness, three-dimensional structure orpoor magnetic properties, Lamella-lay my-sheets offer several additional opportunities. In lamella plates pins can beused and contours are incorporated, or to use them, for example, T-shaped parts as bearing surfaces. Lamella-lay mysheets be hung up or screwed onto the magnetic chuck. Our sheets are, unless stated otherwise, silver-hard-solderedand can be machined to any type.Lamella-Lay my-sheets in longitudinal pole pitch,silver-hardened soldered, pole pitch 2 4 or 1 3.Item-Nr.Dimension (mm)LW2301 101320752301 1023201002301 103320752301 1043201002301 105650752301 1066501002301 107650752301 108650100Other dimensions on requestLamella-Lay my-sheets in transversal pole pitch,silver-hardened soldered, pole pitch 2 4 or 1 3.Item-Nr.H2525404025254040Dimension (mm)LW2302 101250752302 1022501002302 1032501502302 104250752302 1052501002302 1063001502302 1073002002302 108400752302 1094001002302 1104001502302 1114002002302 1124002502302 113400752302 1144001002302 115500752302 1165001002302 117500752302 118500100Other dimensions on A-BLOCK with StepsThe stepped LBS magnetic bars can be used in the heights 30, 40, 50mm. Pole pitch 2 4 or 1 3.Item-Nr.2303 101L100Dimension (mm)W50H40109

MagneticMagnetischesclampingHebenLAMELLA-BLOCKSLay my-blocks in pole pitch 1,5 3 , screwed, can not be shortened.Item-Nr.L60801002304 1012304 1022304 103Dimension (mm)W80100140H304050LAMELLA-PLATES roundRound Lamella-lay my-sheets, silver-hardened soldered.Item-Nr.230523052305230523052305Dimension 0025Other dimensions on requestLAMELLA-PLATES round radialRounde Lay my-sheets for Radial 62306Dimension 6002030Andere Abmessungen auf AnfrageAngle-blocks and Prisms on request110

Magnetic clampingLAMELLA-PLATE carrying caseUniversal 8-part Liges range, carrying case, belongs to every grinder. The lamella plates and prisms are g case ILamella-platescarrying case IIItem-Nr.LDimension (mm)WHWeight(kg)2302 098340270125122302 09934027012512Carrying case I contentDesignationLamella-plates transversalpoleLamella-plates transversalpolePrism 90 , Wide 47mmPiecesPole pitch31 331 321 3PiecesPole pitchL100Dimension (mm)W80H40755025675747L57Dimension (mm)W32H15975726975322675747Carrying case II contentDesignationLamella-plates transversalpoleLamella-plates transversalpoleLamella-plates horizontalpolePrism 90 , Wide 47mm21 321 321 321 3111

MagneticMagnetischesclampingHebenSPML Permanent Magnetic clamping BlocksSPML permanent magnetic clamping blocks are equipped with two opposed, independently switchable clampingsurfaces. The neodymium magnet system with fine pole 1.5 0.5 affects about 5 mm deep and is ideal for clampingsmall and medium sized workpieces. The switching shaft can be actuated from two sides, so that the magneticclamping block may also be used standing. Two M5 threads are located on the sides of the head on which stops orpositioning can be attached. SPML clamping blocks are watertight and especially suitable for grinding, wire and sinkerEDM. For use in aggressive media we recommend 302230223022302230212182512 INOX18 INOX25 INOX010203060708Dimension (mm)LWH125 5250180 5250250 5250125 5250180 5250250 5250Pole pitch Holding power(mm)(N/cm²)1,51,51,51,51,51,5 3,65

Magnetic clampingSPM Permanent Magnetic clamping BlocksSPM magnetic clamping blocks have 4 clamping sides and can be switched via the front panel rotary knob. They canbe used for surface grinding, angle-grinding, coordinate grinding, eroding, measuring, etc. Because of the fine 2 2mm pole pitch (0.5 mm) thinnest parts can securely be clamped. On the back there are four M5 threaded for mountingstops. The low magnetic field height of only 2mm and the complete hermetic seal to recommend SPM clamping blocksespecially for use in wire and die-sinking EDM. SPM clamping blocks are also available in stainless chrome steeldesign.ModelItem-Nr.SPM2301 01SPM-L2301 02SPM-X2301 03SPML-X2301 04-X Stainless versionDimension (mm) clamping areas Pole pitch Holding powerWeight4 St., (mm)(mm)(N/cm²)(kg)LBH175 6464115 x 642 2803,2195 6464135 x 642 2803,8175 6464115 x 642 2503,2195 6464135 x 642 2503,8made of chrome steel Be careful when sanding, less holding forceSPMQ Permanent Magnetic clamping BlocksSPMQ permanent magnetic clamping blocks have 3 clamping sides (top, left and right side surface) and can beswitched via the front panel. On the top there is a cross prism. Main areas of application can be found in the grindingand measuring. Angularity 0.025mm, 0.015mm parallelism.ModelSPMQ 1SPMQ 2SPMQ 3Item-Nr.2303 012303 022303 03Dimension (mm) Holding power(N/cm²)LWH100 100 10080150 150 15080180 180 18080Weight(kg)62441113

MagneticMagnetischesclampingHebenMH Permanent Magnetic clamping BlocksMH permanent magnetic clamping blocks have 2 or 3 magnetic clamping surfaces that are not switchable. They areused for clamp the finest parts or poorly magnetizable materials such as high-alloy chromium steels or carbide. Afterediting, the block and the clamped workpiece can be taken completely for inspection of the machine. MH clampingblocks are available in a standard or reinforced (with SE - magnet). Main areas of application can be found at thegrinding, measuring, wire cutting.Standard version ca. 100 020304*Dimension (mm)Pole pitch(mm)LWH100 100 504100 50504100 25254100 25251,3especially suitable for t

Magnetic clamping pallets, fixtures, vises, grid plates or workpieces are provided with the UNILOCK bolt and positively to the UNILOCK zero-point clamping system, highly accurate excited and locked. UNILOCK -R Zero-point-clamping-systems Solid and Stable The super strong universal clamping