Transcription

SCHUNK Clamping TechnologyProduct Overview

Superior Clamping and GrippingJens Lehmann stands for safe, precise gripping and holding.As a brand ambassador of the SCHUNK team,the No. 1 goalkeeper represents our global competenceleadership for gripping systems and clamping technology.The top performance of SCHUNK and Jens Lehmann arecharacterized by dynamics, precision, and reliability.For more information visit our website:schunk.com/lehmannJens Lehmann

Familienseite Broschuere 2016-11 EN.pdfHenrik A. Schunk, Kristina I. Schunk, brand ambassador Jens Lehmann, and Heinz-Dieter SchunkTop Performance in the TeamSCHUNK is the world’s No. 1 for gripping systems andclamping technology – from the smallest parallel gripperto the largest chuck jaw program.As a competence leader, we recognize and developstandards with a large potential for the future, whichwill drive the rapid progress in many industries.In order to boost efficiency, SCHUNK customers havebought more than 2,000,000 precision toolholders,1,000,000 SCHUNK grippers, and 100,000 lathe chucksand stationary workholding systems so far.Our customers profit from the expert knowledge, theexperience, and the team spirit of about 3,000employees in our innovative family-owned company.This makes us proud and motivates us to attain new topperformances.Heinz-Dieter SchunkThe Schunk family wishes you improved end results withour quality products.Henrik A. SchunkKristina I. Schunk

SCHUNK Clamping TechnologyProduct OverviewFrom Standard toHigh-tech SolutionsAt SCHUNK, you will benefit from over 50 years of experienceand expertise in tool and workpiece clamping. Whether it‘slathe chucks, chuck jaws, toolholders, stationary clampingtechnology or magnetic and vacuum clamping technology –our components and solutions offer the ideal basis for safe,efficient and highly precise processes. Due to their outstanding quality, they satisfy the highest requirements of modernprocessing and demanding machining.We develop, manufacture and optimize powerful, economicalproducts and solutions for the machine table and machineroom that are tailored to the individual needs of each customerand application. Moreover, we are setting standards in theongoing development of clamping technology and customizedsolutions. in your Lathe for your APage 6Page 10Page 14Chuck JawsLathe ChucksToolholdersThe SCHUNK range of standard chuckjaws for any conceivable applicationon lathe chucks delivers maximumsafety, functionality and precision.SCHUNK offers manual and powerchucks with or without throughholes for precise and safe clampingof workpieces on your lathe. More than 1,200 different types Jaw change 60 secondsSCHUNK toolholding systems coverthe entire range of machining taskslike volume machining, drilling,thread milling, reaming, right up tomicromachining. Over 16 million standard chuckjaws in use worldwide Up to 410 kN clamping force More than 2,000,000 soldprecision toolholdersSCHUNK Standard Chuck JawsROTA-S plus 2.0TENDO SDF INDIVIDUAL4

SCHUNK Clamping TechnologyProduct OverviewIt’s time to useyour machine’s full potential!Our superior components, find potentials in your machine, where youwould least expect to find them. SCHUNK Synergy – the perfectly harmonizedinterplay of gripping systems and clamping technology turns our customersinto productivity champions . in your AutomatedHandling SystemAutomated Machine Loading in your Machining Center in your Automated AssemblyPage 18Page 22Stationary WorkholdingMagnetic and Vacuum Clamping TechnologyStationary workholding from SCHUNK ensures themicron-precise link between the machine table andthe workpiece with complete solutions from themodular system for individualists.SCHUNK magnetic and vacuum clamping technologiesfor 5-sided machining in one set-up are impressivedue to short retrofitting times, high holding forces,maximum precision and deformation-free clamping. More than 1,000 possibilities for workpiececlamping Up to 90% set-up time reductionVERO-S NSE plusMAGNOS5

Chuck JawsSCHUNK Clamping TechnologyChuck JawsSoft Top JawsJaw BlanksFull Grip JawsMonoblock JawsAreas of applicationClamping of raw partsClamping of finished parts I.D. clamping O.D. clamping Compensation of formtolerancesAdjustable clampingdiameter via turningLow-deformation clampingJaw quick change CharacteristicsJaw interface/type(standard design)90 fine serration60 fine serrationTongue and groove90 fine serration60 fine serration90 fine serration60 fine serrationTongue and grooveStraight and angledwedge-bar serrationAvailable for lathe chuck sizes 80 – 1200 mm(standard design)160 – 800 mm80 – 630 mm140 – 800 mmMaterialSteel 16MnCr5case-hardenableSteel 16MnCr5case-hardenable orhigh-tensile aluminumC 45, tempered, inductive hardenableSteel 16MnCr5case-hardenable orhigh-tensile aluminumHighlights Available with or with- The large locating surface evenly distributesout bore holesthe gripping forces Ground groove andaround the workpiece.fine serrationThereby the work Can be turned to thepiece deformation is Can be turned to therequired size of clampdecreasingrequired size of clamping diametering diameter Depending on theversion: ground grooveand fine serration orfinemilled tongue andgroove6 Inductive hardenedserration and guidances permit a longer toolservice life of the lathechuck Available in variousversions

Claw JawsStepped Top Jaws Stepped Block Jaws Jaw Quick-changeSystem PRONTO QUENTESFiberglass Jaws Pendulum Jaws 90 fine serration60 fine serrationTongue and groove90 fine serration60 fine serrationTongue and grooveStraight and angledwedge-bar serration90 fine serration60 fine serration90 fine serration60 fine serrationStraight and angledwedge-bar serration90 fine serration60 fine serrationTongue and groove140 – 1000 mm110 – 1200 mm160 – 630 mm200 - 315 mm200 – 500 mm160 – 315 mmSteel 16MnCr5case-hardenedSteel 16MnCr5case-hardenedSteel 16MnCr5case-hardenable orsteel 16MnCrS5KSteel, hardened andtempered or casehardenedCase-hardened steelGlass fiberreinforced plastic The diamond serration May be used forO.D., I.D., and barenables first set-up,clampingwhere the clamping teeth penetrate Used for coveringthe workpiece onlylarge clampingslightlyranges Available for O.D., I.D., May be used for O.D.,I.D., and bar clampingand bar clamping The claw serrationallows form-fitclamping, which alsoenables transmissionof very high machining forces Used for covering largeclamping ranges Various quick-change For clampingthin-walled andinserts for raw anddeformation-sensitivefinished parts clampingworkpiecesavailable Clamping rangeexpansion of 700%without supportingjaw adaptation in5 seconds per jaw Compensation of deviations in shape viapendulum motion Clamping inserts areavailable in hardenedand unhardenedversions With soft and hardclamping inserts withdiamond serration The light and stabledesign enables minimal loss of clampingforce No clamping marks,making it ideal forclamping surfaces thatare especially sensitive, already ground oreven surface-treated Cost-efficient systemdue to quicklychangeable clampinginserts

Chuck JawsSCHUNK Clamping TechnologyCustomized solutionsSerrated BarsBase JawsMore than 30 years of experience in the developmentand manufacturing of chuck jaws in special designmake us a partner in high demand for specializedapplications. Whether it is modified standard chuckjaws or sophisticated customized designs, our teamof experts will develop the right solution for anyapplication.Challenge us, and we’ll convince you!Examples of customized solutions 1 2 4 90 fine serration60 fine serrationStraight and angledwedge-bar serration125 - 800 mm125 - 1000 mmSteel or aluminumHardened and precisionground steel For universal use Hardened and precisionground base jaws for topjaws35 Standard length 420 mmundrilled for custom cutting With mount for top jaws For producing long chuckwith tongue and groove orjaws; this allows any customfine serrationlength to be implementedquickly and economically1 Clamping a lifting hook using a rigid jaw with workpiece stopsand a jaw with axially and radially oscillating clamping inserts2 Square clamping on a 2-jaw chuck with two customized prismjaws3 4-point clamping solution for a conrod eye in a 2-jaw chuck witha rigid jaw and a pendulum jaw4 6-point pendulum jaw for conrods in a 3-jaw chuck5 I.D. clamping of a thin-walled ring by a 12-point pendulum jawwith changeable clamping inserts8

Chuck JawsChuck JawsSCHUNK Clamping TechnologySCHUNK Chuck Jaw Quickfinderon the Internet Faster through guided product searchesPrescribed selection menus facilitate the search. Find the right jaw fasterIn a few seconds the suitable chuck jaws with theassociated accessory products are presented. A faster qualified enquiryAn online form enables a clear enquiry. A faster standard chuck jaw quotationQuotations for standard chuck jaws are guaranteed within 55 minutes after receipt of theenquiry on every working day between 7 a.m.and 5 p.m.Lathe ChucksAt schunk.com/chuck-jaw-quickfinder, youwill receive an overview on possible chuck jawsolutions, including accessory products such asT-nuts and screws. Faster – around the clockInformation retrieval and requests are possibleonline 24 hours a day.ToolholdersJa wic k f i nStationary WorkholdingckQuC hu Faster, individual product configuration andmodificationJust enter your desired changes and send them.You will then receive an individual quotationwithin 24 hours.de rTake Advantage of the mobile andflexible SCHUNK Chuck Jaw AppMagnetic and Vacuum Clamping TechnologyEverything at a glance – the chuck jaw appThe SCHUNK chuck jaw range is always at hand:You can quickly order with our app directlyfrom your smart phone.App download is available under iTunes or Android9

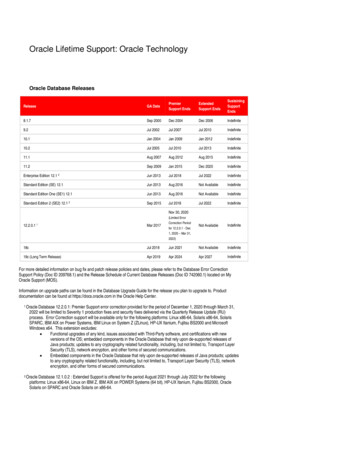

Lathe ChucksSCHUNK Clamping TechnologyManual Lathe ChucksROTA-S plus 2.0ROTA-S plusPower Lathe Chucks withJaw Quick-change SystemROTA-S flexROTA SPKROTA THW plusROTA THWROTA THW varioFields of applicationLight and versatile Large through-hole Max. speed Modular center sleeve system Large jaw stroke Jaw quick-change system High jaw change repeataccuracy High clamping repeat accuracy Centrifugal force compensation Media feed-throughClamping of small workpieces Bar machining Overlap clampingWedge bar chuck 180 – 260165 – 315400 – 630Wedge hook chuckFine serration in inches1/16“ x 90 /3/32“ x 90 Serration, metric1.5 mm x 60 /3.0 mm x 60 Tongue and groove Tube ends machiningLever chuckActive jaw pull-down functionHermetically sealedCharacteristicsSizes160 – 315400 – 1000550 – 1400215HighlightsAll lathe chucks can also be used instationary applications! Jaw quick-change Jaw quick-change Steel bodychuckchuck Sealed against Large through High accuracydirthole Exchangeable Variable gauge Jaw quick-change Jaw quick-changechuckchuck Large throughhole Large throughhole High accuracy High jaw changerepeat accuracy High jaw changerepeat accuracy Modular centersleeve system Modular centersleeve system Modular centersleeve system (upto size 315) Can be combinedwith arbor (size200 and 250)10guideway extension Clamping range8 – 1422 mmclearance High clampingforces Collet chuck orarbormountable

Power Lathe Chucks with Through-holeROTA NCXROTA NCEROTA NC plus 2ROTA NCPower Lathe Chuckswithout Through-holeROTA NCF plus 2ROTA NCFROTA NCDROTA NCK plus ROTA NCO 165 – 315165 – 260185 – 315400 – 1000 Jaw quick-changechuck Extremely weightreduced powerchuck Very large through- Integratedholecentrifugal forcecompensation Modular center High jaw changerepeat accuracy Interface compatible with KitagawaBB200 series Easy replacementof existing chuckswith fine serration Minimumacceleration andbraking times Modular centersleeve system Simplest handlingsleeve system185 – 315400 – 630 Modular centersleeve system Special optimizedpump lubricationsystem132 – 630165 – 315165 – 1000 Very large through- Jaw connectionholemetric or inches Very small chucksize Patented collet jaw Interface 100%system availablecompatible withupon requestKitagawa B200series High accuracy High clampingforce and large jawstroke Integrated blankdraw nut Additional dirtsealing

Lathe ChucksSCHUNK Clamping TechnologyPneumatic Power ChucksROTA 2BROTA NCRROTA NCS 3ROTA NCS 6ROTA TPROTA TBROTA TB-LH ROTA TB2ROTA TB2-LH 125 – 400165 – 1600175 – 500 Very large jaw stroke Also availablewith centrifugal forcecompensation Active jaw pull-down With integratedpneumatic cylinder Integrated pendulum Weight-optimizeddesign Mounting thread forworkpiece stopscompensation Deformation sensitive Hermetically sealedclamping of thin Low maintenancewalled workpieces Compensating orcentral clamping125 – 350400 – 1000470 – 1000 With integratedpneumatic cylinder With integratedpneumatic cylinder Very large throughhole Very large throughhole Very large throughhole Also for stationaryapplications With dual strokesystem (LH version) With dual strokesystem (LH version) Seal of the base jawguide Chemical coating forcorrosion protection Wireless clampingpressure control12

Lathe ChucksChuck JawsSCHUNK Clamping TechnologyZENTRICO THL plus Steady RestsDue to optimized lever kinematics, central lubrication,integrated roller rinsing, and dirt guard, the newSCHUNK ZENTRICO THL plus steady rest achieves maximum clamping forces per roller and excellent centering and repeat accuracies. High centering and repeatoptimized lever kinematics Much lower contamination, less chip nestingSimple attachment, fits on almost every machineExisting steady rests can be replaced easily, no Lathe ChucksYour benefits:accuracy due tospecial parts required Slim cylindrical design, no interfering contouron the steady restToolholders Easy supply and long lifetim

thread milling, reaming, right up to micromachining. More than 2,000,000 sold precision toolholders SCHUNK Standard Chuck Jaws At SCHUNK, you will benefit from over 50 years of experience and expertise in tool and workpiece clamping. Whether it‘s lathe chucks, chuck jaws, toolholders, stationary clamping technology or magnetic and vacuum clamping technology – our components and .