Transcription

4/9/2015WHAT TO EXPECT DURING AN OSHAPROCESS SAFETY MANAGEMENT (PSM)INSPECTIONWCS 2015 ConferenceApril 21, 2014Allen GrisarOccupational Safety and Health AdministrationMilwaukee Area Office1Process Safety Managementof Highly Hazardous Chemicals (HHCs)29CFR1910.119Objectives OSHA PSM Inspection processDefine what is PSM and who is covered by thestandardDefine the elements of the PSM standardRecognized and generally accepted good engineeringpractices (RAGAGEP)What Is Process Safety Management(PSM)? PSM: Addresses the management of HighlyHazardous Chemicals (HHCs) through amanagement system, intended to preventcatastrophic events .Which . Integrates Technology of the process Operating Procedures Standard management protocols31

4/9/2015Why Did OSHA Develop PSM? PastDisastersDisasters CurrentIn 1991, OSHA Released the Standard4The Standard Was Promulgatedin 1991 - Is it Working? BP Products Texas City- March 2005 15 Workers Killed170 InjuredMajor PropertyDamage 50.6 Million in Fines5Why Did OSHA Develop PSM? Formosa Plastics Corp - Vinyl Chloride Monomer Explosion -Illiopolis IL - 2004. (5 Dead, 3 Injured)62

4/9/2015OSHA National EmphasisProgram (NEP)Process Safety ManagementPurpose of NEPProgram (NEP) for inspecting:Facilities covered by PSMPrimary Purpose: Tool for OSHA CSHOs to determine compliancewith PSM Contains policies and procedures to verifyemployers’ coverage Compliance with OSHA’s PSM standard8OSHA National EmphasisProgram (NEP) for Refineries &Chemical Facilities Petroleum RefineriesNEP Issued August 2009 Chemical FacilitiesNEP Issued July 201093

4/9/2015ScopeApplies OSHA wide.10What Facilities are CoveredApplication - 1910.119(a) Those Who Use Chemicals in Appendix A: A List ofhighly hazardous chemicals, toxics and reactive(Mandatory). Contains a listing of toxic and reactivehighly hazardous chemicals which present apotential for a catastrophic event at or above thethreshold quantity ExamplesChemical Anhydrous Ammonia ChlorineThreshold Quantity (TQ)10,000 lbs1,500 lbs11What Facilities are Covered A process whichinvolves a flammableliquid or gas (asdefined in1910.1200(c) of thispart) on-site in onelocation, in a quantityof 10,000 pounds(4535.9 kg) or more124

4/9/2015A covered process includes theprocessing of HHCs within Any group of vessels whichare interconnected, andSeparate vessels which arelocated such that a highlyhazardous chemical couldbe involved in a potentialreleaseWhat Facilities are Covered Important Interpretation: 2007 - 06/11/2007 OSHA defines "on-site in one location" forProcess Safety Management of HighlyHazardous Chemicals standardOSHA interprets "on-site in one location" to mean thatthe standard applies when a threshold quantity of ahighly hazardous chemical (HHC) exists within anarea under the control of an employer or group ofaffiliated employers. It also applies to any group ofvessels that are interconnected, or in separatevessels that are close enough in proximity that theHHC could be involved in a potential catastrophicrelease.14What Facilities are CoveredAffect of the “Meer” Decision:MEER ruling and the MEER Memorandum addressed in theSecretary's letter, OSHA's enforcement policy that the Agencywould not cite employers for violations of 1910.119 where storedflammable liquids in atmospheric tanks were connected to aprocess, unless the process outside of the amount in storagecontained more than 10,000 pounds of the substance.155

4/9/2015What Types of Industries? Industries that Process Chemicals Such As: Industrial Organics & Inorganics Paints Pharmaceuticals Adhesives Sealants and Fibers Petrochemical facilities Paper Mills Food Processing with Anhydrous Ammoniaover the TQ16There are Exclusions1910.119(a)(1)(ii)(A)An employer is exempt from the requirements ofPSM when: A threshold quantity of flammable liquids is storedin atmospheric tanks or transferred without thebenefit of chilling or refrigeration Hydrocarbon fuels used solely for workplaceconsumption as a fuel (e.g., propane used forcomfort heating, gasoline for vehicle refueling), If such fuels are not a part of a processcontaining another highly hazardous chemicalcovered by this standard 17Exclusions Retail facilities; Oil or gas well drilling orservicing operations; or, Normally unoccupiedremote facilities186

4/9/2015PSM Inspection Coverage ProcessDetermination:Let’s Start the PSMInspection Process;19PSM Inspection Coverage ProcessDetermination: Referral - Result of anIncident? Complaint Programed PSM “NEP” Inspection Follow-Up of previous PSMinspection20PSM Inspection Coverage ProcessDetermination: Determine type of process(s) and chemical(s) used – Can bemore than one covered process/chemical What are the quantities – Do they meet Appendix AThreshold Quantities (TQ) – Maximum Intended QuantityOnsite at one time **Requesting of chemical listing and inventory levels ofchemicals on site to determine the TQ levels.217

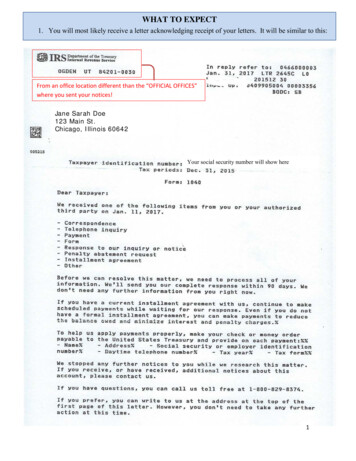

4/9/2015PSM Inspection Coverage ProcessDetermination:Coverage has been determined .Initial documentation request provided 22PSM Inspection Process: Document RequestRe: OSHA Document Request for Process Safety Management (PSM) InspectionPlease supply the following information. Any items that are not applicable please identify.1.2.All contract employee injury and illness logs as required by 1910.119(h)(2)(vi).A list of all Ammonia Anhydrous refrigeration units in the complex and the maximum intendedinventories of all.3.A summary description of the facility’s PSM program.4.Unit process flow diagram(s).5.Piping and instrumentation diagrams (P&IDs) including legends.6.Unit Plot plans.7.Unit Electrical classification diagrams.8.Process narrative descriptions.9.Descriptions of safety systems (e.g. interlocks, detection or Suppression systems).10. A listof workers presently involved in operating equipment covered under the PSM program.23PSM Inspection Process: Document Request11. The initial Process Hazard Analysis (PHA) and the most recent update or revalidation for the coveredsystem. Include PHA reports, PHA Worksheets, actions to address findings and recommendations, writtenschedules for actions to be completed, and documentation of findings and recommendations.12. Provide operating procedures that have been developed for the operation of the ammoniarefrigeration systems and equipment.13. Provide the emergency action plan / procedure that have been developed to cover the release ofammonia at the facility.14. Provide procedure for accomplishment of Management of Change (MOC).15. Provide Procedure for Incident Investigation and documentation of incident investigations conducted.16. Provide Mechanical Integrity (MI) Procedure.17. Compliance Audits of the PSM program to include the two most recent audit reports.18. Training plan and documentation of employee understanding and knowledge of the PSM Program.19. Employee Participation plan.If any of these items are not available/applicable please note accordingly. Please provide these itemsby .248

4/9/2015PSM Inspection Process: Initial Walk Around Initial evaluation of the covered process and equipment If more than one process – use this initial walk around tohelp determine the process to be selected for inspection –may select more than one process. Will take pictures, video and conduct brief employeeinterview(s)(Review of initial documentation request will also be used toselect process for inspection)25PSM Inspection Process: Main Body ofInspection Evaluation of each PSM Element Review written program documentation for each elementimplementation Interview Employees – Management, Process Operators,Maintenance Employees, and Contractors Take samples of compounds if required Identify hazards / deficiencies identified as the inspectionprogresses.26The Elements of the PSMStandard ApplicationExclusionsDefinitionsEmployee ParticipationHazards of the ProcessToxicityTechnology of the ProcessEquipment in the ProcessMechanical IntegrityInspection & TestingQuality Assurance Process Hazard AnalysisManagement of ChangeOperating ProceduresSafe Work PracticesTrainingContractor ManagementEmergency Planning &ResponseIncident InvestigationCompliance AuditsTrade Secrets279

4/9/2015The Elements of the PSMStandard ApplicationExclusionsDefinitionsEmployee ParticipationHazards of the ProcessToxicityTechnology of the ProcessEquipment in the Process Mechanical Integrity Inspection & Testing Process Hazard AnalysisManagement of ChangeOperating ProceduresSafe Work PracticesTrainingContractor ManagementEmergency Planning &ResponseIncident InvestigationCompliance AuditsTrade Secrets28The Elements of the PSMStandard ApplicationExclusionsDefinitionsEmployee ParticipationHazards of the ProcessToxicityTechnology of the ProcessEquipment in the ProcessMechanical IntegrityInspection & TestingQuality Assurance Process Hazard Analysis Management ofChange Operating ProceduresSafe Work PracticesTrainingContractor ManagementEmergency Planning &ResponseIncident InvestigationCompliance AuditsTrade Secrets 29The Elements of the PSMStandard Process Hazard Analysis ApplicationExclusionsDefinitionsEmployee ParticipationHazards of the ProcessToxicityTechnology of the ProcessEquipment in the ProcessMechanical IntegrityInspection & TestingQuality Assurance Management of Change Operating Procedures Safe Work PracticesTrainingContractor ManagementEmergency Planning &ResponseIncident InvestigationCompliance AuditsTrade Secrets 3010

4/9/2015The Elements of the PSMStandard ApplicationExclusionsDefinitionsEmployee ParticipationHazards of the ProcessToxicityTechnology of the ProcessEquipment in the ProcessMechanical IntegrityInspection & TestingQuality Assurance Process Hazard AnalysisManagement of ChangeOperating ProceduresSafe Work Practices Training Contractor ManagementEmergency Planning &ResponseIncident InvestigationCompliance AuditsTrade Secrets 31The Elements of the PSMStandard Process Hazard Analysis ApplicationExclusionsDefinitions Employee Participation Hazards of the ProcessToxicityTechnology of the ProcessEquipment in the ProcessMechanical IntegrityInspection & TestingQuality Assurance Management of ChangeOperating ProceduresSafe Work PracticesTrainingContractor ManagementEmergency Planning &ResponseIncident InvestigationCompliance AuditsTrade Secrets32The Elements of the PSMStandard Process Hazard Analysis ApplicationExclusionsDefinitionsEmployee ParticipationHazards of the ProcessToxicityTechnology of the ProcessEquipment in the ProcessMechanical IntegrityInspection & TestingQuality Assurance Management of ChangeOperating ProceduresSafe Work PracticesTraining ContractorManagement Emergency Planning &ResponseIncident InvestigationCompliance AuditsTrade Secrets 3311

4/9/2015The Elements of the PSMStandard Process Hazard Analysis ApplicationExclusionsDefinitionsEmployee ParticipationHazards of the ProcessToxicityTechnology of the ProcessEquipment in the ProcessMechanical IntegrityInspection & TestingQuality Assurance Management of ChangeOperating Procedures Pre-Start up SafetyReview Hot Work PermitSafe Work PracticesTrainingContractor ManagementEmergency Planning &Response 34The Elements of the PSMStandard Process Hazard Analysis ApplicationExclusionsDefinitionsEmployee ParticipationHazards of the ProcessToxicityTechnology of the ProcessEquipment in the ProcessMechanical IntegrityInspection & TestingQuality Assurance Management of ChangeOperating ProceduresPre-Start up SafetyReview Hot Work Permit Safe Work PracticesTrainingContractor ManagementEmergency Planning &Response 35The Elements of the PSMStandard Process Hazard Analysis ApplicationExclusionsDefinitionsEmployee ParticipationHazards of the ProcessToxicityTechnology of the ProcessEquipment in the ProcessMechanical IntegrityInspection & TestingQuality Assurance Management of ChangeOperating ProceduresPre-Start up SafetyReviewHot Work PermitSafe Work PracticesTrainingContractor ManagementEmergency Planning& Response3612

4/9/2015The Elements of the PSMStandard Process Hazard AnalysisApplicationExclusionsDefinitionsEmployee ParticipationHazards of the ProcessToxicityTechnology of the Process Equipment in theProcess Mechanical IntegrityInspection & TestingQuality Assurance Management of ChangeOperating ProceduresPre-Start up SafetyReviewHot Work PermitSafe Work PracticesTrainingContractor ManagementEmergency Planning &Response37The Elements of the PSMStandard Process Hazard Analysis ApplicationExclusionsDefinitionsEmployee ParticipationHazards of the ProcessToxicityTechnology of the ProcessEquipment in the ProcessMechanical Integrity Inspection & Testing Quality Assurance Management of ChangeOperating ProceduresPre-Start up SafetyReviewHot Work PermitSafe Work PracticesTrainingContractor ManagementEmergency Planning &Response38The Elements of the PSMStandard Process Hazard Analysis ApplicationExclusionsDefinitionsEmployee ParticipationHazards of the ProcessToxicityTechnology of the ProcessEquipment in the ProcessMechanical IntegrityInspection & TestingQuality Assurance Management of ChangeOperating ProceduresPre-Start up SafetyReviewHot Work PermitSafe Work PracticesTrainingContractor ManagementEmergency Planning &Response3913

4/9/2015The Elements of the PSMStandardWe determined coverage Document Request Provided Let’s Explore Some of the Elements tobe evaluated for implementation andperformance Employee Participation(Cross Function of Personnel)(Need a written Plan of Action regardinghow employee participation implementationis to function across all employee groups)1910.119(c)How is Employee ParticipationImplemented? Team members directly involvedin the program and those onperiphery of the program, i.e. Process Engineers Operators Saf

Process Safety Management of Highly Hazardous Chemicals standard OSHA interprets "on-site in one location" to mean that the standard applies when a threshold quantity of a highly hazardous chemical (HHC) exists within an area under the control of an employer or group of affiliated employers. It also applies to any group of