Transcription

Software ApplicationsFLOCALC TM Calculation DetailsAbstractThis document contains the calculation details for working with the KELTON StandardCalculation Package (FLOCALC)Document Number/Rev: DS/SA/57/Rev: 1.6Document Title: FLOCALC Calculation Details

Contents1.0Revision Control . 32.0Calculations by Associated Standards . 33.0Calculation by FLOCALC Reference Number . 6Document Number/Rev: DS/SA/57/Rev: 1.6Document Title: FLOCALC Calculation DetailsPage 2 of 22

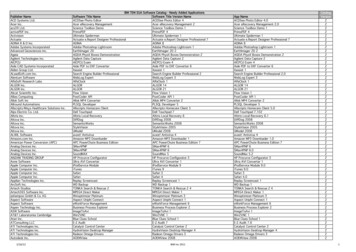

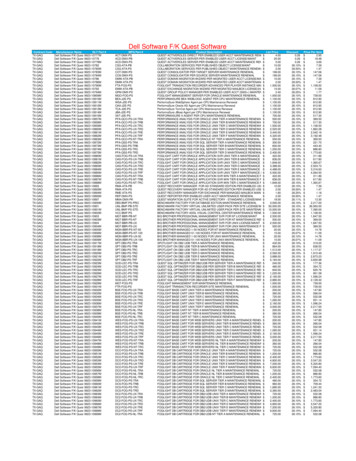

1.0 Revision ControlRevIssue edReformattedUpdatedUpdated in accordance with Brand GuidelinesUpdated to include new ModulesUpdated to include new ModuleUpdated to include new calculation2.0 Calculations by Associated ishedAGA Report No. Orifice Metering of Natural Gas and Other Related F034, F074,3Hydrocarbon FluidsF0981992, 2012AGA Report No. Natural Gas Energy Measurement5F0872009AGA Report No. Measurement of Natural Gas by Turbine Meters7F0882006AGA Report No. Compressibility Factors of Natural Gas and Other8Related Hydrocarbon GasesF013, F014,F063, F3181985, 1994,2017AGA Report No. Measurement of Gas by Multipath Ultrasonic9MetersF0892007AGA Report No. Speed of Sound in Natural Gas and Other Related10Hydrocarbon GasesF0932003API MPMS Chapter11.1Temperature and Pressure Volume CorrectionFactors for Generalized Crude Oils, RefinedProducts, and Lubricating OilsF060, F0922004API MPMS Chapter11.1Volume correction factors - Volume X Background, Development and ProgramDocumentationF0231980API MPMS Chapter11.2.1Compressibility Factors for Hydrocarbons: 6381074 Kilograms per Cubic Meter RangeF023, F028,F0911984API MPMS Chapter11.2.2Compressibility Factors for Hydrocarbons: 350-637 F023, F028,Kilograms per Cubic Meter Density (15 C) and F091, F09246 C to 60 C Metering Temperature1986API MPMS Chapter11.2.4Temperature Correction for the Volume of LightHydrocarbons/LPG and NGL1998, 2007Document Number/Rev: DS/SA/57/Rev: 1.6Document Title: FLOCALC Calculation DetailsF090, F091,F092Page 3 of 22

StandardNameCalculationNumbers(s)YearPublishedAPI MPMS Chapter11.2.5A Simplified Vapor Pressure Correlation forCommercial NGLsF0582007API MPMS –Chapter 14.3Concentric, Square-Edged Orifice MetersF034, F0741992ASTM D1250Petroleum Measurement TablesF023, F028,F029, F060,F062, F073,F083, F084,F085, F0861952, 1980,2004ASTM D1555Standard Test Method for Calculation of Volumeand Weight of Industrial Aromatic Hydrocarbonsand CyclohexaneF1012009ASTM D3588Standard Practice for Calculating Heat Value,Compressibility Factor, and Relative Density ofGaseous FuelsF0671998BS 1904Specification for industrial platinum resistancethermometer sensorsF0421984BS EN ISO 3171 Petroleum liquids - Automatic pipeline samplingF0951999BS 7577Calculation procedures for static measurement ofrefrigerated light hydrocarbon fluidsF0541992BS EN 60751Industrial platinum resistance thermometersensorsF0421996GPA 2145Table of Physical Constants for Hydrocarbons andOther Compounds of Interest to the Natural GasIndustryF036, F049,F0672000, 2003,2009GPA 2172Calculation of Gross Heating Value, RelativeDensity, Compressibility and TheoreticalHydrocarbon Liquid Content for Natural GasMixtures for Custody TransferF0382009GPA TP-15A Simplified Vapor Pressure Correlation forCommercial NGLsF0582007GPA TP-25Temperature Correction for the Volume of LightHydrocarbons - Tables 24E and 23EF0911998GPA TP-27Temperature Correction for the Volume of NGLand LPG - Tables 23E, 24E, 53E, 54E, 59E, and 60EF090, F0922007IP 200Petroleum Measurement TablesF023, F028,F029, F060,F062, F073,1952, 1980,2004Document Number/Rev: DS/SA/57/Rev: 1.6Document Title: FLOCALC Calculation DetailsPage 4 of 22

, F084,F085, F086IP Paper No.2Guidelines for Users of the PetroleumMeasurement TablesF022, F0291984IP PetroleumMeasurementManual- Part XMeter ProvingF0661989IP PetroleumMeasurementManual- Part XIIStatic and Dynamic Measurement of LightHydrocarbon LiquidsF059, F105,F1061998ISO 3171Petroleum liquids - Automatic pipeline samplingF0951988ISO 5167Measurement of fluid flow by means of pressuredifferential devices inserted in circular crosssection closed conduits running fullF026, F032,F033, F037,F068, F069,F070, F075,F076, F079,F080, F0991991, 1998,2003, 2016ISO 6578Calculation procedures for static measurement ofrefrigerated light hydrocarbon fluidsF0541991ISO 6976Natural Gas - Calculation of calorific value, density F001, F002,and relative density and Wobbe indexF003, F036,F049, F1101983, 1995,2016ISO 8222Petroleum measurement systems - Calibration Temperature corrections for use when calibratingvolumetric proving tanksF0972002BS EN 60751Industrial platinum resistance thermometersensorsF0421996GPA 2145Table of Physical Constants for Hydrocarbons andOther Compounds of Interest to the Natural GasIndustryF036, F049,F0672000, 2003,2009ISO 12213Natural gas – Calculation of compressor factorF0142006ISO TR 9464Guidelines for use of the ISO 5167F037, F068,F069, F070,F075, F076,F0801998, 2008ISO TR 12748Natural gas – Wet gas flow measurement innatural gasF0722015Document Number/Rev: DS/SA/57/Rev: 1.6Document Title: FLOCALC Calculation DetailsPage 5 of 22

3.0 Calculation by FLOCALC Reference NumberCalc.No.StandardTitleCalculation DescriptionF001ISO6976:1983Calorific Value andRelative DensityVolumetric calorific values, standard density,relative density and Wobbe index from a gascomposition. Results are calculated for thecomposition treated as both a real and an idealgas, inferior (net) and superior (gross) calorificvalue and Wobbe index are displayed in eachcase.ISO 6976:1983 - Natural Gas - Calculation of calorific value, density and relative densityF002ISO6976:1989Calorific Value andRelative DensityCalorific values, standard density, relativedensity and Wobbe index from a gascomposition. Results are calculated for thecomposition treated as both a real and an idealgas, inferior (net) and superior (gross) calorificvalue and Wobbe index are displayed in eachcase.ISO 6976:1989 draft - Natural Gas - Calculation of calorific value, density and relative densityF003ISO6976:1995Calorific Value andRelative DensityCalorific values, standard density, relativedensity and Wobbe index from a gascomposition. Results are calculated for thecomposition treated as both a real and an idealgas, inferior (net) and superior (gross) calorificvalue and Wobbe index are displayed in eachcase.ISO 6976:1995 - Natural Gas - Calculation of calorific value, density and relative density and Wobbe indexF013AGA 8:1985Gas Density andCompressibilityThe compressibility and density of a gas arecalculated from its composition, temperatureand pressure in accordance with the ‘DetailCharacterisation’ method outlined in thisstandard. Results are displayed for bothstandard (user configurable) temperature andpressure and operating temperature andpressure.AGA Report No.8 - Compressibility and Supercompressibility for Natural and Gas and Other Hydrocarbon Gases (1985)F014AGA 8:1994Gas Density andCompressibilityThe compressibility and density of a gas arecalculated from its composition, temperatureand pressure in accordance with the ‘DetailCharacterisation’ method outlined in thisstandard. Results are displayed for bothstandard (user configurable) temperature andpressure and operating temperature andpressure. This 1994 printing of the SecondEdition 1992 achieves computationalconsistency with GPA 2172-94 and AGA 3 1992.AGA Report No.8 - Compressibility Factors of Natural and Gas and Other Related Hydrocarbon Gases (1994), ISO 12213-2:2006 - Naturalgas - Calculation of compression factor - Part 2: Calculation using molar composition analysisDocument Number/Rev: DS/SA/57/Rev: 1.6Document Title: FLOCALC Calculation DetailsPage 6 of 22

Calc.No.StandardF015TitleCalculation DescriptionOrifice Plate BucklingCalculationsAn orifice plate, when exposed to differentialpressure, will always experience a degree ofelastic deformation, in certain cases the elasticdeformation can be augmented by plastic(permanent) deformation. The calculationcalculates the differential pressure that wouldcause the plastic distortion of a simplysupported orifice plate. In addition to this, flowmeasurement errors caused by the deformationof the orifice plate are estimated.Effect of Plate Buckling on Orifice Meter Accuracy - P Jepson and R Chipchase, Journal Mechanical Engineering Science Vol. 17 No. 6 (1975)Buckling and Eccentricity Effects on Orifice Metering Accuracy - R Norman, M S Rawat and P Jepson (1983)F017Solartron Appendix ACalculationThe ‘Solartron Appendix A calibrationconsiderations’ calculated using this formreduce the effect of systematic errors associatedwith the density sensor, and also the non-idealbehaviour of gasses.Solartron 3098 Specific Gravity Transducer Technical ManualF018F022IP Paper 2Pressure Calculation - Determine the pressure generated byAbsolute and Gaugedeadweight testers, pressure indicators andgauges. Pressure can either be calculated fromfirst principals using mass and piston area orsimply applying corrections to the nominalapplied pressure. The calculation can also bereversed to calculate the mass required togenerate a required pressure. Absolutepressure can be calculated for either using adeadweight tester in absolute mode orcombining gauge pressure with barometricpressure.Density ReferralTo ‘convert’ density values between standardconditions and operating conditions by applyinga correction for the change in temperature (Ctl)and pressure (Cpl). Cpl is calculated using themethods outlined in IP Paper 2 and Ctl using theAPI equations from which the appropriateproduct group can be selected. The option isgiven to either perform the calculation followingthe rounding/truncation algorithms outlined inthe standard or to use full precision.IP Petroleum Measurement Paper No.2/ IP 200/ ASTM D1250 - Guidelines for Users of the Petroleum Measurement TablesF023API Density Referral1980-86Document Number/Rev: DS/SA/57/Rev: 1.6Document Title: FLOCALC Calculation DetailsTo ‘convert’ density values between standardconditions and operating conditions by applyinga correction for the change in temperature (Ctl)and pressure (Cpl). Cpl is calculated using themethods outlined in the petroleummeasurement standards and Ctl using the APIequations from which the appropriate productPage 7 of 22

Calc.No.StandardTitleCalculation Descriptiongroup can be selected. The option is given toeither perform the calculation following therounding/truncation algorithms outlined in thestandard or to use full precision.ASTM D1250-80 / IP 200/80 / API Manual of Petroleum Measurement Standards Chapter 11.1 - Volume correction factors - Volume X Background, Development and Program Documentation (1980), API Manual of Petroleum Measurement Standards - Chapter 11.2.1 Compressibility Factors for Hydrocarbons: 638-1074 Kilograms per Cubic Meter Range (1984), API Manual of Petroleum MeasurementStandards - Chapter 11.2.2 - Compressibility Factors for Hydrocarbons: 350-637 Kilograms per Cubic Meter Density (15 ) and -46 C to 60 CMetering Temperature (1986)F025Local GravityCalculationThe local value of gravitation acceleration for ageographical location can be estimated from thelatitude and height above sea level. Thecalculation provides a choice of three acceptedformulae for determining this value. In additionto this the option is given to calculate for anoffshore or an onshore location which takesapplies an additional correction for the densityof the rock base.References: The Geodetic Reference System 1967, The new gravity system - changes in international gravity base values and anomalyvalues - Woollard G.P. (1979), WGS84 - IAG Developed Geodetic Reference System 1980, leading to World Geodetic Reference System(1984)F028API/Table 54Density ReferralThe calculation ‘converts’ density valuesbetween standard conditions and operatingconditions by applying a correction for thechange in temperature (Ctl) and pressure (Cpl).Cpl is calculated using the methods outlined inthe petroleum measurement standards and Ctlusing the petroleum measurement tabled forlight hydrocarbons (Table 53/54). The option isgiven to either perform the calculation followingthe rounding/truncation algorithms outlined inthe standard or to use full precision.References: ASTM D1250, IP 200 - Report on the Development, Construction, Calculation, and Preparation of the ASTM-IP PetroleumMeasurement Tables (1960), API Manual of Petroleum Measurement Standards - Chapter 11.2.1 - Compressibility Factors forHydrocarbons: 638-1074 Kilograms per Cubic Meter Range (1984), API Manual of Petroleum Measurement Standards - Chapter 11.2.2 Compressibility Factors for Hydrocarbons: 350-637 Kilograms per Cubic Meter Density (15 ) and -46 C to 60 C Metering Temperature(1986)F029IP Paper2/Table 54Density ReferralThe calculation ‘converts’ density valuesbetween standard conditions and operatingconditions by applying a correction for thechange in temperature (Ctl) and pressure (Cpl).Cpl is calculated using the methods outlined in IPPaper 2 and Ctl using the petroleummeasurement tabled for light hydrocarbons(Table 53/54). The option is given to eitherperform the calculation following therounding/truncation algorithms outlined in thestandard or to use full precision.References: IP Petroleum Measurement Paper No.2/ IP 200/ ASTM D1250 - Guidelines for Users of the Petroleum Measurement Tables,ASTM D1250, IP 200 - ASTM-IP Petroleum Measurements Tables - Metric Edition (1952), ASTM D12

AGA Report No. 8 Compressibility Factors of Natural Gas and Other Related Hydrocarbon Gases F013, F014, F063, F318 1985, 1994, 2017 AGA Report No. 9 Measurement of Gas by Multipath Ultrasonic Meters F089 2007 AGA Report No. 10 Speed of Sound in Natural Gas and Other Related Hydrocarbon Gases F093 2003 API MPMS - Chapter 11.1 Temperature and Pressure Volume