Transcription

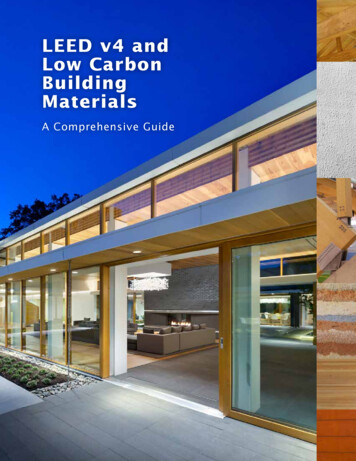

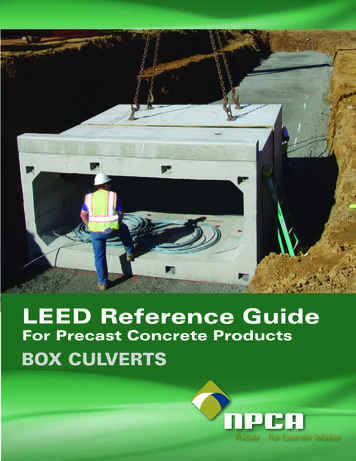

LEED Reference GuideFor Precast Concrete ProductsBOX CULVERTS

BOX CULVERTSBox Culverts in the EnvironmentPrecast concrete box culverts are used for conveyance of fluids such as stormwater and sewage as well asfor short span-bridges and access ways. Precast concrete three-sided culverts allow for natural streambeds toremain intact while providing for short-span bridge applications. Because precast box culverts are produced ina controlled environment, they will exhibit high degrees of quality and uniformity. They also offer a multitudeof advantages such as superior strength and durability, reduced weather dependency for installation, designflexibility and reduced impact to the job site. Precast concrete is also an environmentally friendly materialthat will always be readily available. Box culverts are common products and many manufacturers maintain aninventory of several sizes of box culverts ready to be delivered in short notice.General Benefits of Precast Concrete Box Culverts . 3LEED 2009 – New ConstructionSS 5.1 – Site Development: Protect or Restore Habitat. 4SS 5.2 – Site Development: Maximize Open Space. 5SS 6.1 – Sustainable Sites: Stormwater Design Quantity Control. 6SS 6.2 – Sustainable Sites: Stormwater Design Quality Control. 7MR 4 – Recycled Content. 8MR 5 – Regional Materials . 9LEED 2009 – Neighborhood DevelopmentGIB 7 – Minimize Site Disturbance In Design & Construction .10GIB 8 – Stormwater Management.11GIB 15 – Recycled Content in Infrastructure.12National Precast Concrete Association1320 City Center Dr. Suite 200, Carmel, IN 46032(800) 366-7731 www.precast.orgThis publication is designed to provide accurate and authoritative information in regard to the subject matter covered; however, National PrecastConcrete Association acts as a mediator without approving, disapproving or guaranteeing the validity or accuracy of any data, claim or opinion appearingherein. Information is provided and disseminated with the understanding that the National Precast Concrete Association is not engaged in renderingengineering, legal or any other professional services. If engineering, legal or other professional assistance is required, the services of a competentprofessional should be obtained. The National Precast Concrete Association does not assume and hereby disclaims liability to any person for any loss ordamage caused by errors or omissions in the material contained herein, regardless of whether such errors result from negligence, accident or any othercause whatsoever. The Credit Requirements listed in this document are contained within the Leadership in Energy and Environmental Design GreenBuilding Rating System developed by the United States Green Building Council. For more information on the LEED Green Building Rating System,please visit www.usgbc.org.For additional information about using precast concrete within the LEED system, please visit www.precast.orgLEED 2009 Reference Guide for Precast Concrete Products www.precast.org2

BOX CULVERTSINSIDE THE BOXPrecast Concrete Box Culverts HaveMany Advantages Over Competing MaterialsBuilt toughThe strength of precast concrete gradually increasesover time. Other materials can deteriorate, experiencegreater creep and stress relaxation, lose strengthand/or deflect over time. The load-carrying capacityof precast concrete is derived from its own structuralqualities and does not rely on the strength or qualityof the surrounding backfill materials. Properlydesigned precast concrete box culverts can easilysupport vehicular, aircraft and railway loads meetingAASHTO, FAA and AREMA specifications.We’re talking quality hereBecause precast concrete products are manufacturedin a controlled environment, they exhibit highquality and uniformity. Factors affecting qualitytypically found on a job site – temperature, impropercuring, poor craftsmanship and material quality– are nearly eliminated in a plant environment.Precast concrete box culverts produced in a qualitycontrolled environment and installed with high-qualitysealants offer a superior solution to watertightnessrequirements.Ready when you areBecause precast concrete box culverts aremanufactured well in advance of installation, they areready for transportation to the job site at a moment’snotice. They are quickly installed in a matter of hoursusing a crane and a small crew. Backfilling can beginimmediately rather than waiting several days or morefor cast-in-place concrete to gain proper strength.Once backfilled, road construction can begin, greatlyreducing the deviation of any associated lanes andcongestion in the surrounding communities.Nasty weather? No problemPrecast concrete increases efficiency becauseweather will not delay the manufacturing process inthe precast plant. In addition, weather conditions atthe job site do not significantly affect the schedule.Lookin‘ goodPrecast concrete box culverts can also includespandrel and wingwall panels with a multitude ofarchitectural finishes. Finishes commonly availableare: colored, smooth-as-cast, textured form liner,exposed aggregate, acid etched, brick and sandblast.Each is distinctly different, providing specifiers andowners a broad choice in appearance. Architecturalfinishes complement the surrounding environmentand comply with local aesthetic requirements.Good for the planetPrecast concrete is nontoxic, environmentally safeand made from allnatural materials, making it an idealmaterial for use below grade or for the conveyanceof water. Concrete has no proven ill effects ongroundwater and surface water quality, which helpspreserve our natural water resources.A better bottom lineIncorporating precast concrete box culverts into yournext project can save you time and money. Fewerskilled laborers and fewer man-hours will be requiredfor the project, making precast concrete box culvertsideal for meeting the needs of today’s fast-pacedconstruction projects. Whether you are spanning asmall creek, designing a combined sewer overflowsystem or housing telecommunications equipmentbelow grade, precast concrete box culverts are theclear choice.LEED 2009 Reference Guide for Precast Concrete Products www.precast.org3

BOX CULVERTSBOX CULVERTSLEED New ConstructionSS 5.1Sustainable SitesSite DevelopmentProtect or Restore HabitatCredit RequirementMax. Points: 1Site Development – Protect or RestoreHabitatCase 1 – Greenfield SitesLimit all site disturbances to the following parameters: 40 feet beyond the building perimeter 10 feet beyond surface walkways, patios, surface parkingand utilities less than 12 inches in diameter 15 feet beyond primary roadway curbs and main utility branchtrenches 25 feet beyond constructed areas with permeable surfaces(such as pervious paving areas, stormwater detentionfacilities and playing fields) that require additional stagingareas to limit compaction in the constructed area.Case 2 – Previously Developed AreasRestore or protect a minimum or 50% of the site (excluding thebuilding footprint) or 20% of the total site area (including buildingfootprint area), whichever is greater, with native or adaptedvegetation.Precast ContributionPrecast concrete products are cast andcured in the plant and delivered to thesite ready to set so they reduce thestaging area required, which can reducethe overall site disturbance.The impact on the construction siteis also reduced because there isno additional formwork, which oftenrequires more construction area forabove-ground products and largerexcavation areas for undergroundproducts.Less impact on sites can reduceconstruction waste, shorten theconstruction schedule and require fewerlaborers on-site.LEED 2009 Reference Guide for Precast Concrete Products www.precast.org4

BOX CULVERTSBOX CULVERTSLEED New ConstructionSS 5.2Sustainable SitesSite DevelopmentMaximize Open SpaceCredit RequirementMax. Points: 1Site Development – Maximize Open SpaceRequirementsCase 1: Sites with Local Zoning Open SpaceRequirementsReduce the development footprint and/or provide vegetated openspace within the project boundary such that the amount of openspace exceeds local zoning requirements by 25%.Case 2: Sites with No Local Zoning Requirements(example – some university campuses and military bases)Provide a vegetated open space area adjacent to the building thatis equal in area to the building footprint.Case 3: Sites with Zoning Ordinances but No OpenSpace RequirementsProvide vegetated open space equal to 20% of the project sitearea.Precast ContributionPrecast concrete box culverts can helpmaximize open space when utilized asunderground detention/retention. Thesecomponents can easily be locatedbeneath paved parking, which reducesthe need for an on-site water retentionpond and reduces the site disturbancewhile maximizing vegetated openspaces.Note: The precast products must belocated within the site boundaries ofa LEED rating system project type.Currently, infrastructure projects that arenot part of a rating system would notcontribute toward any LEED credits.ALL CASESFor projects in urban areas that earn SS Credit 2: DevelopmentDensity and Community Connectivity, pedestrian-orientedhardscape areas can contribute to credit compliance. For suchprojects, a minimum of 25% of the open space counted must bevegetated.Wetlands or naturally designated ponds may count as open spaceand the side slope gradients average 1:4 (vertical:horizontal) orless and are vegetated.LEED 2009 Reference Guide for Precast Concrete Products www.precast.org5

BOX CULVERTSBOX CULVERTSLEED New ConstructionSS 6.1Sustainable SitesStormwater DesignQuantity ControlCredit RequirementMax. Points: 1Stormwater Design – Quality ControlCase 1 – Sites with existing imperviousness50% or lessOption 1Implement a stormwater management plan that preventsthe postdevelopment peak discharge rate and quantity fromexceeding the predevelopment peak discharge rate and quantityfor the 1 and 2-year 24-hour design storms, orOption 2Implement a stormwater management plan that protectsreceiving stream channels from excessive erosion. Thestormwater management plan must include a stream channelprotection and quantity control strategies.Case 2 – Sites with existing imperviousness greaterthan 50%Implement a stormwater management plan that results in a 25%decrease in the volume of stormwater runoff from the 2-year 24hour design storm.Precast ContributionPrecast concrete is an excellentchoice to help control the quantity ofstormwater runoff with a wide variety ofproducts that can contribute to a properstormwater management plan.Precast box culverts with headwalls andwingwalls help protect stream channelsfrom excessive erosion by controllingthe flow of water in and out of the boxculverts to the open channel or ditch.Precast concrete underground stormsystems are sized to channel largedischarges to nearby bodies of waterduring heavy rains. Precast concretenot only withstands the forces fromfluids inside the pipe, but also handlesextreme loading conditions outside thepipe.LEED 2009 Reference Guide for Precast Concrete Products www.precast.org6

BOX CULVERTSBOX CULVERTSLEED New ConstructionSS 6.2Sustainable SitesStormwater DesignQuality ControlCredit RequirementMax. Points: 1Stormwater Design – Quality ControlImplement a stormwater management plan that reducesimpervious cover, promotes infiltration and captures and treats thestormwater runoff from 90% of the average annual rainfall usingacceptable best management practices (BMPs).BMPs used to treat runoff must be capable of removing 80% ofthe average annual postdevelopment total suspended solids (TSS)load based on existing monitoring reports.BMPs are considered to meet these criteria if: They are designed in accordance with standards andspecifications from state or local program that has adoptedthese performance standards, or There exists infield performance monitoring datademonstrating compliance with the criteria. Data mustconform to accepted protocol for BMP monitoring.Precast ContributionPrecast concrete box culverts capturestormwater runoff in retention/detentionsystems. The outlets in these structuresare sized to release the stored runoffat flow rates that serve to reduce theeffects of pollutants leaving a siteduring peak flows.Flow-through stormwater treatmentstructures can be utilized to separatesediments and other pollutants througha swirl flow pattern.Precast concrete structures are oftendesigned to fit stormwater treatmentsystems within them.LEED 2009 Reference Guide for Precast Concrete Products www.precast.org7

BOX CULVERTSBOX CULVERTSLEED New ConstructionMR 4Materials and ResourcesRecycled ContentCredit RequirementMax. Points: 2Recycled ContentRequirementsUse materials with recycled content such that the sum ofpostconsumer recycled content plus 1/2 the preconsumer contentconstitutes at least 10% or 20% (based on cost) of the total valueof the materials in the project. The minimum percentage materialsrecycled for each point threshold is:Recycled Content Points10%120%2The recycled content value of a material assembly is determinedby weight. The recycled fraction of the assembly is then multipliedby the cost of the assembly to determine the recycled contentvalue.Mechanical, electrical and plumbing components and specialtyitems such as elevators cannot be included in this calculation.Include only materials permanently installed in the project.Furniture may be included if it is included consistently in MRCredit 3: Materials Reuse through MR Credit 7: Certified Wood.Precast ContributionPrecast concrete products may containsupplementary cementitious materialssuch as fly ash and blast furnace slagwhich will add to the project’s recycledcontent goals.Precast products may also contain rebarand welded wire mesh which is oftenmade from recycled steel.Other less frequently used recycledcontent components include variousfiber reinforcements, glass aggregates,silica fume, and recycled crushedconcrete.The NPCA LEED calculator helpsmembers respond with the properdocumentation required for this credit.Simply input the Zip Code/Postal Codeand weight for each component togenerate a pdf file that can be e-maileddirectly to the LEED AP, contractor orarchitect.LEED 2009 Reference Guide for Precast Concrete Products www.precast.org8

BOX CULVERTSBOX CULVERTSLEED New ConstructionMR 5Materials and ResourcesRegional MaterialsCredit RequirementMax. Points: 2Regional MaterialsUse materials or products that have been extracted, harvested,and manufactured within 500 miles of the project site.The calculation is based on the overall materials cost. Materialscosts include all expenses to deliver the material to theproject site. Materials costs should account for all taxes andtransportation costs incurred by the contractor but exclude anycost for labor and equipment once the material has been deliveredto the site.Regional Materials of 10% 1 pointRegional Materials of 20% 2 pointsSee the NPCA LEED Calculator at www.precast.org/leed for helpwith this credit.See the LEED Canada guide for information on Canada’s creditrequirements.Precast ContributionBecause concrete uses plentifuland natural raw materials, concretecomponents can be extracted,harvested and manufactured within 500miles of the project site. Using locallyobtained raw materials helps reducetransportation distances which reducesthe environmental impact of carbonemissions.If shipping is done by rail or water, LEEDCanada allows up to 2,400 km (1,500miles) from both the manufacturingsite to the project site and the locationwhere building materials are extracted,harvested, recovered and processed tothe manufacturing site.The NPCA LEED Calculator helpsprovide the proper documentationrequired for this credit. Simply inputthe Zip code or postal code where eachraw material originates and the weightof each material to generate a printablefile that can be e-mailed to the LEED AP,contractor or architect.LEED 2009 Reference Guide for Precast Concrete Products www.precast.org9

BOX CULVERTSBOX CULVERTSLEED NeighborhoodDevelopmentGIB 7Green Infrastructureand BuildingsMinimized SiteDisturbance in Designand ConstructionCredit RequirementMax Points: 1Minimized Site Disturbance in Design andConstructionOption 1 – Development Footprint on PreviouslyDeveloped Land:Locate 100% of the development footprint on areas previouslydeveloped, orOption 2 – Undeveloped Portion of Project LeftUndisturbed:Limit disturbance to: 40 feet beyond the building perimeter 10 feet beyond surface walkways, patios, surface parking andutilities less than 12 inches in diameter 15 feet beyond street curbs and main utility branch trenches 25 feet beyond constructed areas with permeable surfacesthat require additional staging areas to limit compaction inthe constructed zone.Precast ContributionPrecast concrete products are plantcast and delivered to the site ready toset so they reduce the staging arearequired which can reduce the overallsite disturbance.The impact on the construction siteis also reduced because there isno additional formwork, which oftenrequires more construction area forabove-ground products and largerexcavation areas for undergroundproducts.Less impact on sites can reduceconstruction waste, shorten theconstruction schedule and require fewerlaborers on-site.Note: This is a condensed version of the credit. The full creditmay be downloaded from USGBG’s Neighborhood DevelopmentGuide.LEED 2009 Reference Guide for Precast Concrete Products www.precast.org10

BOX CULVERTSBOX CULVERTSLEED NeighborhoodDevelopmentGIB 8Green Infrastructureand BuildingsStormwater ManagementPrecast ContributionCredit RequirementMax. Points 4Stormwater ManagementImplement a comprehensive stormwater managementplan for the project that retains on-site, through infiltration,evapotranspiration, and/or reuse, the rainfall volumes listed below.Rainfall volume is based on the project’s development footprint,any other areas that have been graded so as to be effectivelyimpervious, and any pollution-generating pervious surfaces,such as landscaping, that will receive treatments of fertilizers orpesticides.Precast concrete stormwatermanagement products can helpmaximize open space when utilized asunderground stormwater detention/retention. These components can easilybe located beneath paved parking,which reduces the need for an on-sitewater retention pond, reduces the sitedisturbance and maximizes vegetatedopen spaces.Your product must be located within thesite boundaries of a LEED rating systemproject type. Currently, infrastructureprojects are not part of a rating systemand would not contribute toward anyLEED credits.Percentile rainfall eventTotal volume to be retained80%85%90%95%Points1234Note: This is a condensed version of the credit. The full creditmay be downloaded from USGBG’s Neighborhood DevelopmentGuide.LEED 2009 Reference Guide for Precast Concrete Products www.precast.org11

BOX CULVERTSBOX CULVERTSLEED NeighborhoodDevelopmentGIB 15Green Infrastructureand BuildingsRecycled Content inInfrastructureCredit RequirementMax. Points: 1Recycled Content in InfrastructureUse materials for new infrastructure such that the sum ofpostconsumer recycled content, in-place reclaimed materials andone-half of the preconsumer recycled content constitutes at least50% of the total mass of infrastructure materials.Count materials in all of the following infrastructure items asapplicable to the project: Roadways, parking lots, sidewalks, unit paving, and curbs Water retention tanks and vaults Base and subbase materials for the above Stormwater, sanitary sewer, energy distribution, and waterpipingSee the NPCA LEED Calculator at www.precast.org/leed for helpwith this credit.See the LEED Canada guide for information on Canada’s creditrequirements.Precast ContributionPrecast concrete products may containsupplementary cementitious materialssuch as fly ash and blast furnace slagwhich will add to the project’s recycledcontent goals.Precast products may also contain rebarand welded wire mesh which containsrecycled steel.Other less frequently used recycledcontent components include variousfiber reinforcements, glass aggregates,silica fume, and recycled crushedconcrete.Beyond precast products themselves,recycled crushed concrete can alsocontribute to this credit when utilized asroad fill base.LEED 2009 Reference Guide for Precast Concrete Products www.precast.org12

LEED 2009 Reference Guide for Precast Concrete Products www.precast.org . The Credit Requirements listed in this document are contained within the Leadership in Energy and Environmental Design Green Building Rating System developed by the United States Green Building Council. . LEED New