Transcription

Ready Mixed Concrete IndustryLEED Reference GuideUpdated Third Edition with LEED 2009 Information

This page intentionally left blank.

The Ready Mixed Concrete IndustryLEED Reference GuideThird EditionCopyright 2005-2010 by the RMC Research & Education Foundationwww.rmc-foundation.org

This page intentionally left blank.

This document was underwritten by theexpress their thanks to the following peopleReady Mixed Concrete (RMC) Research &for their assistance in the preparation andEducation Foundation and the Portlandreview of this document: Erin Mack Ashley,Cement Association (PCA). The originalDavid Goss, Edward R. Herbert III, Beatrixversion was researched and written byKerkoff, Jennifer LeFevre, Lionel Lemay,Steven Winter Associates, Inc. (SWA),Jan Prusinski, David Shepherd, and Martha(www.swinter.com). The Third Edition wasVan Geem.edited and revised by Lionel Lemay, PE, SE,Abstract: Ready mixed concrete offersLEED AP, CAE and Erin Mack Ashley, PhD,opportunitiesLEED AP of the National Ready Mixedengineers, contractors, concrete producersConcrete Association (NRMCA). The projectand others in the building industry towas managed by NRMCA.maximize credits offered by the U.S. GreenTheRMCarchitects,Building Council’s (USGBC) Leadership inFoundation is a non-profit organizationEnergy and Environmental Design (LEED )dedicated to improving the concrete industry2009 for New Construction and Majorthrough achieving its mission of promotingRenovationseducation and research projects that willdocumentstrengthen and improve an already superiorunderstanding the LEED system and areasproducttowhere ready mixed concrete can be appliedPCA is an organization ofin a project to earn LEED points, inResearchforcommittedcement companies to improve and extendthe uses of portland cement and concrete(LEEDwill2009guidetheNC).Thisreaderinits sustainability.Keywords:Energyconservation,through market development, engineering,environmental factors, innovative design,research, and public affairs work. NRMCA isLEED, ready mixed concrete, recycling,a leading industry advocate working tosustainability.expand and improve the ready mixedReference: Steven Winter Associates,leadership,Inc., Ready Mixed Concrete Industry LEEDpartnering,ReferenceGuide,ensuring that ready mixed concrete is theEducationFoundation,building material of ducationandSWA, RMC Research & EducationFoundation, PCA, and NRMCA would like toUSA,RMCResearch&SilverSpring,October,2009.

INDIT IS AGREED THAT SELLER’S LIABILITYANDPURCHASER’SSOLEREMEDY,RESPECTING THIS PUBLICATION ORWHETHER IN CONTRACT, UNDER ANYANYCONTAINEDWARRANTY,WARRANTY,NEGLIGENCE), IN STRICT LIABILITY OREXPRESS OR IMPLIED, IS EXCLUDEDOTHERWISE, SHALL NOT EXCEED THEANDRETURN OF THE AMOUNT OF R,PARTICULAR PURPOSE; NOR IS THERECIRCUMSTANCES SHALL SELLER BEANYLIABLE FOR ANY SPECIAL, INCIDENTAL,THATTHISPUBLICATION OR ANY INFORMATIONCONTAINED HEREIN WILL MEET ORCOMPLY WITH THE REQUIREMENTS OFANYSAFETYORENVIRONMENTALCODE OF ANY STATE, MUNICIPALITY OROTHER JURISDICTION.ORCONSEQUENTIALUNDERBYMERCHANTABILITY AND FITNESS FOR AWARRANTYAND(INCLUDINGNODAMAGES.

TABLE OF CONTENTSExecutive Summary . 1Table 1 - Potential Leed Credits For Ready Mixed Concrete . 2Introduction . 4The LEED Certification Process . 5The Ready Mixed Concrete Industry LEED Reference Guide . 6Using Ready Mixed Concrete To Achieve LEED 2009 NC Credits . 8Sustainable Sites . 8SS Credit 6.1: Stormwater Design - Quantity Control . 8SS Credit 6.2: Stormwater Management - Quality Control . 8SS Credit 7.1: Heat Island Effect - Nonroof . 17Energy And Atmosphere . 21EA Prerequisite 2: Minimum Energy Performance . 21EA Credit 1: Optimize Energy Performance. 21Materials And Resources Credits . 29MR Credit 2: Construction Waste Management . 29MR Credit 4: Recycled Content . 35MR Credit 5: Regional Materials . 48MR Credit 7: Certified Wood . 50Innovation In Design Credits . 55ID Credit 1: Exemplary Performance . 57ID Credit 1: Innovation In Design . 60RP Credit 1: Regional Priority . 63Incidental Ready Mixed Concrete Use In Other Credits. 64SS Credit 3: Brownfield Redevelopment [1] . 64SS Credit 5.1: Site Development - Protect Or Restore Habitat. 64SS Credit 7.2: Heat Island Effect - Roof. 65WE Credit 1: Water Efficient Landscaping . 65WE Credit 2: Innovative Waste Water Technologies . 65MR Credit 1.1: Building Reuse - Maintain Existing Walls, Floors And Roof . 65MR Credit 6: Rapidly Renewable Materials . 66IEQ Credit 4.2: Select Low-Emitting Materials – Paints And Coatings . 66

IEQ Credit 4.3: Low-Emitting Materials – Floor Systems . 66IEQ Credit 5: Indoor Chemical And Pollutant Source Control. 67IEQ Credit 7.1: Thermal Comfort - Design . 67Other Environmental Issues . 68Plant Waste Water Disposal . 68On-Site Wash Water Disposal . 68Solid Waste . 69Site Protection . 69Appendix A – Sample Letter From Ready Mixed Concrete Producer . 71

EXECUTIVE SUMMARYTheresultingdocumentpresentsaOf all the green building design anddetailed discussion of the LEED program,construction evaluation programs in thehow LEED points are assigned, how materialUnites States, the U.S. Green Buildinguses and construction methods must beCouncil’s (USGBC) LEED Rating System isdocumented, and what issues must bethe most widely adopted standard. Publiccarefully considered in using ready s, trade groups, and other ghout the United States constructionindustry have adopted LEED as the standardPotential LEED points gained throughthe use of ready mixed concrete arediscussed in the following areas: stormwatermanagement; landscape paving; minimizingenergy use; optimizing energy ent; use of regional materials; use ofcertified wood; innovation in design; andreduction in the use of portland cement. Thedocument also covers plant waste waterConcrete offers several opportunities for buildingdisposal; on-site wash water disposal; solidprojects to gain LEED points.waste; and site protection. In each of theseareas,fordeterminingpresentssustainability. Recognizing the importance ofcontractor, and the ready mixed concreteLEED,RMCsupplier in achieving LEED points. ThisFoundationinformation is supplemented by extensivecommissioned the development of a LEEDlists of citations, references, and otherReference Guide that could be used byresource documents, trade groups, andarchitects,builders,websites. A summary of how concretemanufacturers, suppliers, and others in thecontributes to LEED 2009 NC is provided inconstruction industry to determine how theTable on useful to the designer, ents,use of ready mixed concrete can contributeto green building.1

TABLE 1 - Potential LEED Credits for Ready Mixed ConcreteConcrete contributes to this LEED CreditIncidental concrete use in this LEED CreditSustainable SitesPrerequisite 1Construction Activity Pollution PreventionCredit 1Site SelectionCredit 2Development Density and Community ConnectivityCredit 3Brownfield RedevelopmentCredit 4.1Alternative Transportation―Public Transportation AccessCredit 4.2Alternative Transportation―Bicycle Storage and Changing RoomsCredit 4.3Alternative Transportation―Low-Emitting and Fuel-Efficient VehiclesCredit 4.4Alternative Transportation―Parking CapacityCredit 5.1Site Development―Protect or Restore HabitatCredit 5.2Site Development―Maximize Open SpaceCredit 6.1Stormwater Design―Quantity ControlCredit 6.2Stormwater Design―Quality ControlCredit 7.1Heat Island Effect―NonroofCredit 7.2Heat Island Effect―RoofCredit 8Light Pollution ReductionWater EfficiencyPrerequisite 1Water Use ReductionCredit 1Water Efficient LandscapingCredit 2Innovative Wastewater TechnologiesCredit 3Water Use ReductionEnergy and AtmospherePrerequisite 1Fundamental Commissioning of Building Energy SystemsPrerequisite 2Minimum Energy PerformancePrerequisite 3Fundamental Refrigerant ManagementCredit 1Optimize Energy PerformanceCredit 2Onsite Renewable EnergyCredit 3Enhanced CommissioningCredit 4Enhanced Refrigerant ManagementCredit 5Measurement and VerificationCredit 6Green PowerMaterials and ResourcesPrerequisite 1Storage and Collection of RecyclablesCredit 1.1Building Reuse―Maintain Existing Walls, Floors and RoofCredit 1.2Building Reuse―Maintain Existing Interior Nonstructural ElementsCredit 2Construction Waste ManagementCredit 3Materials ReuseCredit 4Recycled ContentCredit 5Regional MaterialsCredit 6Rapidly Renewable MaterialsCredit 7Certified WoodIndoor Environmental QualityPrerequisite 1Minimum Indoor Air Quality PerformancePrerequisite 2Environmental Tobacco Smoke (ETS) ControlCredit 1Outdoor Air Delivery MonitoringCredit 2Increase VentilationCredit 3.1Construction Indoor Air Quality Management Plan―During ConstructionCredit 3.2Construction Indoor Quality Management Plan―Before Occupancy226 Possible PointsRequired1516132111111110 Possible PointsRequired2-422-435 Possible PointsRequiredRequiredRequired1-191-7223214 Possible PointsRequired1-311-21-21-21-21115 Possible PointsRequiredRequired1111

Credit 4.1Low-Emitting Materials―Adhesives and SealantsCredit 4.2Low-Emitting Materials―Paints and CoatingsCredit 4.3Low-Emitting Materials―Flooring SystemsCredit 4.4Low-Emitting Materials―Composite Wood and Agrifiber ProductsCredit 5Indoor Chemical & Pollutant Source ControlCredit 6.1Controllability of Systems―LightingCredit 6.2Controllability of Systems―Thermal ComfortCredit 7.1Thermal Comfort―DesignCredit 7.2Thermal Comfort―VerificationCredit 8.1Daylight and Views―DaylightCredit 8.2Daylight and Views―ViewsInnovation and Design ProcessCredit 1Innovation in DesignCredit 2LEED Accredited ProfessionalRegional PriorityCredit1Regional PriorityTotal PointsCertified 40-49 points Silver 50-59 points Gold 60-79 points Platinum 80 points and above3111111111116 Possible Points1-514 Possible Points1-4110 Possible Points

INTRODUCTIONLEED certification can be achieved at aCertified, Silver, Gold, or Platinum levelEstablished in 1998, the LEED Greenbased on how many of the 110 LEED 2009Building Rating System for New ConstructionNC Credits are awarded after a project meets(LEED NC) is a voluntary, consensus-basedeight LEED Prerequisites. The LEED 2009national standard for designing and buildingNC Rating System divides these credits andhigh-performance,buildings.prerequisites into seven credit categories:Several versions of the LEED rating systemSustainable Sites, Water Efficiency, Energyhaveinceptionand Atmosphere, Materials and Resources,including LEED 2.0, 2.1, 2.2, and mostIndoor Environmental Quality, Innovation inrecently, LEED 2009. LEED 2009 for NewDesign, and Regional Priority. PrerequisitesConstruction and Major Renovations (LEEDand Credits are based mostly on established2009governmental, trade group, or vedbyUSGBCmembers in November 2008 and officiallystandards,issued for public use in April 2009. June 27,“Stormwater Management for Construction2009, was the last date projects couldActivities,” or the standards for energyregister under the old LEED NC version 2.2efficiency and ventilation effectiveness of thesystem. All new projects registering afterAmerican Society of Heating, Refrigerating,June 27, 2009 must use LEED 2009 NC.and Air Conditioning Engineers (ASHRAE).criteriabuilding industry and environmental science.ofthevariousLEEDcreditsbe certified.qualifies as a "green building" by establishingofUSEPA’sdetermines the level at which a project canLEED’s mission is to: define that whichstandardthesatisfying the environmental performanceUSGBC representing many segments of thecommonasThe number of points a project earns byLEED was developed by members of theasuchmeasurement;While the LEED NC Rating System waspromote integrated, whole-building designinitially designed for commercial high-risepractices;environmentaloffice buildings, the system can be used for aleadership in the building industry; stimulatewide variety of projects. LEED 2009 NCgreenincludes requirements suitable for multi-recognizecompetition;raiseconsumerawareness of green building benefits; andfamilytransform the building market. While theinstitutional buildings, and hotels. Existingnumber of registered LEED projects startedprojects undergoing significant renovationslowly, this number has grown dramaticallysuchfrom 12 registered LEED projects in 1999 toenvelope modifications, and major interior24,789 by June 2009. The number of LEEDrehabilitation can also use LEED 2009 NC.certified projects reached 3,111 in June 2009USGBC created several additional ratingequating to 385 million square feet of LEEDsystems for other project types; LEED forcertified commercial space.Commercial Interiors, LEED for ects,significant

Buildings, LEED for Core and Shell, LEEDcertification programs. Project registration isfor Schools, and LEED for Homes. Severalinitiated by one of the project team members.new rating systems are under developmentThis process requires completing an onlineincludingNeighborhoodform that asks for information on the projectDevelopment, LEED for Healthcare, LEEDand the design team. The registration fee isfor Retail, LEED for Retail Interiors, and 450 for USGBC members and 600 for non-LEED for Existing Schools. This documentmembers. The registration process entitlesaddresses only LEED 2009 NC for Newthe project team access to LEED Online, aConstruction and Major Renovations.special website designed to help projectLEEDforteam members navigate through the projectThe LEED Certification Processcertification process and Credit InterpretationRequests (CIR). CIRs are made throughLEED is a voluntary rating system. AnLEED Online when the team members deemenvironmentally conscious building owner at compliance with a credit’s intent can beandmet without meeting the letter of a givenminimizeCredit Requirement. Informally, most projectenvironmental impact using the LEED ratingsystem asquantifiesa guide. LEEDthelevelofrepresentatives begin the LEED process bycertificationevaluating criteria of the various LEEDenvironmentalcredits and targeting those most compatibleperformance for a building. Typically thewithowner’s representative, who is usually antheprojectscope,budget,andenvironmental goals. Representatives whoarchitect, is directed to design the building tostart this process in the early stages of themeet a certain level of LEED certification.design process are usually more successfulSome building owners have committed tobecausehaving all of their projects LEED certified andtheysynergiesothers have committed to certifying onlycanbetweentakeadvantageLEEDcreditsofandbecause they do not need to make designselected buildings. For example, severalchanges to meet LEED criteria.public agencies such as city governments orfederal agencies have declared that all ofThe process of documenting compliancetheir new buildings shall be LEED certified.with LEED criteria can begin early in theSome private companies have built newdesign, but many of the credits related toheadquarters using LEED certification.construction activities and building materialsrequire documentation that is not availableA project formally begins the LEEDuntilcertification process by having it pletion.websitecreatedfinalAdministration,as a LEED project on the Green nevenSubstantialthebuildingcommissioning (the process of making finalbychecks and adjustments to construction andUSGBC to manage project and personnelbuilding operations) may need to continue5

beyond substantial completion for seasonalIf upon final review the project meetsor deferred testing, projects are usually ablerequirements for certification, a set of LEEDto assemble all the documentation needed toCertified,submit an application for LEED certificationCertificates are issued to the design team into the GBCI at about the same time asrecognition of the LEED Rating earned. ASubstantial Completion.LEED plaque is then ordered for display onSilver,Gold,orPlatinumthe project.The application for LEED certificationincludessupportingLEEDcompliance for all LEED Prerequisites andintegratedtargeted LEED credits. The application isconstruction that involves all team membersaccompanied by a certification fee that canin the project, including the design andrange from 2,250 to 22,500 for USGBCconstruction team, owners, product suppliersmembersand manufacturers, construction managers,members)documentation( 2,750 to 27,500 rewardsdesignanandcost estimators, specification writers, andcertification and size of the building in squareothers.feet. The application, submitted throughresponsibility of several team members,LEED Online, includes detailed informationalthough it is typically coordinated by aon the required ofessional,iswhothealsoapplication. Once the project representativeprepares CIRs, the final submittal, and thehas submitted the application to GBCI, aresponses to GBCI during the review period.review process begins. The GBCI will issue apreliminary review of the LEED applicationThe Ready Mixed Concrete Industry LEEDwithin 25 business days. This first formalReference Guidepreliminary review will detail which creditsThisare accepted, which credits need opportunities for achieving LEED creditsreviewthrough the use of ready mixed oncrete”project team then has 25 business days ythroughout this publication and meant toprovide the requested materials to the GBCI.describe concrete that is delivered to theThe final review then occurs within 15project site in the plastic state in concretebusiness days from the date in which thetrucks. The document is organized under fourGBCI receives the additional requestedcategories: “Sustainable Sites,” “Energy andmaterials. There is also an appeals process ifAtmosphere,” “Materials and Resources,”the project team disagrees with GBCI reviewand “Innovation in Design.” These fourrulings.categories are taken directly from the LEED2009 NC standard. A fifth section, “Incidental6

Ready Mixed Concrete Use in Other Credits,”responsible for completing documentationoffers guidance in how the material canrequirements. In general, “Design Issues”enhance opportunities for gaining LEEDdeals with issues that must be decidedcredits in other areas.before the project begins construction, while“Trade Contractor and Manufacturer Issues”In each section, the discussion of theis concerned with actual construction andLEED 2009 NC Credits relevant to readyclose-out.mixed concrete is separated into onofthedocumentdesigners (in the section “Design Issues”)addresses environmental considerations inand those primarily affecting the concreteusing ready mixed concrete with reference totrade professionals (in the section “Tradeplant waste water disposal, on-site ction.However, each group needs to read ste,andsite

USING READY MIXED CONCRETE TOSS Credit 6.2: Stormwater Management -ACHIEVE LEED 2009 NC CREDITSQuality ControlIntent: To limit disruption of natural waterSustainable Sitesflows by managing stormwater runoffRequirementsSS Credit 6.1: Stormwater Design - QuantityImplement a stormwater managementControlplanIntent: To limit disruption of natural waterimperviouscover,the stormwater runoff from 90% of theeliminatingrunoffreducespromotes infiltration and captures and treatsby reducing impervious cover, increasing onsitethataverage annual rainfall using acceptable bestandmanagement practices (BMPs).eliminating contaminants.BMPs used to treat runoff must beRequirementscapable of removing 80% of the averageannual post-development total suspendedCASE 1. Sites with Existing Imperviousnesssolids50% or Less(TSS)loadbasedonexistingmonitoring reports. BMPs are considered toOPTION 1meet these criteria if:Implement a stormwater management planThey are designed in accordance withthat prevents the post-development peakstandards and specifications from a state ordischarge rate and quantity from exceedinglocalthe pre-development peak discharge rateperformance standards,and quantity for the 1- and 2-year 24-hourOR,programTheredesign monitoring data demonstrating complianceOR,with the criteria Data must conform toOPTION 2acceptedprotocol(e.g.,TechnologyImplement a stormwater management planAcceptance Reciprocity Partnership [TARP]that protects receiving stream channels fromWashington State Department of Ecology) forexcessiveBMP mmary of Concrete Applications andMaterials Relevant to the Creditsstrategies.LEED includes Stormwater ManagementCASE 2. Sites with Existing Imperviousnesscredits to reduce the negative effects ofGreater Than 50%runoffImplement a stormwater management plancreatedbydevelopment.Roofs,sidewalks, parking lots, driveways, streetsthat results in a 25% decrease in the volumeand other impervious surfaces prevent waterof stormwater runoff from the 2-year 24-hourfromdesign storm.8naturallyinfiltratingsoil,filtering

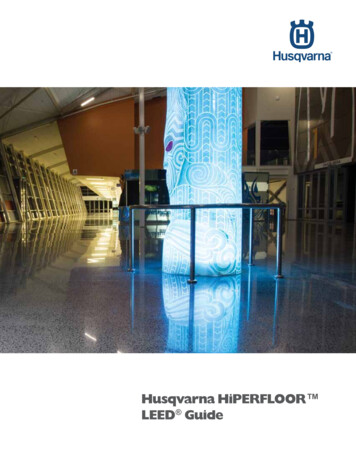

pollutants and recharging aquifers. As aDESIGN ISSUESresult, large volumes of sheet runoff must bePervious Concrete Pavingcollected, concentrated, and directed intoPerviouswaterways. These volumes of stormwaterwaterquality.allowswatertopercolate to the ground, filter contaminantscarry sediment and other contaminants thatcompromisepavingand recharge groundwater and aquifers.ExpensivePerviousinfrastructure works are necessary to controlconcreteconsistsofspeciallyformulated mixtures of portland cement,the erosion and flooding that occur whenstormwater is concentrated and released intowaterways.Stormwater runoff picks up pollutantssuch as spilled oil, tire particles, detergents,pesticides, fertilizer, de-icing salt, llutantsareotherthendeposited into waterways with palitiessewageroutetreatmentfacilities, and when heavy storms cause flowrates to exceed treatment plant capacity,untreatedsewageisdischargedPervious concrete paving example –intoplacing pervious screed.waterways.uniform, open-graded coarse aggregate, andConcrete can be an important part ofwater. It usually contains little or no sand. Itstrategies to achieve these two credits: first,has enough void space to allow rapidby controlling the rate and quantity ofpercolation of liquids through the pavement.stormwater runoff; and second by removingThesome of the most important pollutants fromperviouspavementsurfaceistypically placed over a highly permeablethe runoff.layer of open-graded gravel and crushedCommon and well documented uses ofstone. Voids in the aggregate layers act as aconcrete for stormwater management includestorage reservoir for stormwater. A filterpiping, collection systems and wastewaterfabric may be placed beneath the gravel andtreatment. This report will concentrate onstone layers to screen out fine soil particles.pervious pavement made from concrete, aThe amount of storage in the stone reservoirvery promising technology that is rapidlybeneath the pavement can be varied. If thegaining popularity throughout the Unitedsoil has low permeability, or is highlyStates.vulnerable to freeze-thaw cycles, perforatedpipes can be added near the top of the9

reservoir to discharge excess stormwaterFilteringafter the reservoir has been filled. PerviousPervious Concrete Pavingpaving has many advantages in addition tomeeting LEED credit erwithPervious pavement pollutant removalIt is atechnologyandmechanisms include absorption, straining,withand microbiological decomposition in the soil.benefits that are still being discovered by theAn estimate of pervious pavement pollutantindustry.removal efficiency is provided by two long-MaintenancetermVA.can only be realized if it is designed andindicateremovalremoval rates for zinc, lead, and chemicaldebris into pervious paving (alternatively,oxygen demand. There is some question ofrainhow closely these results reflect othergardens and bio-retention swales, can besituations, but the treatment effectiveness ofadded to filter out particles before they flowproperly designed and maintained perviousonto the pavement).includestudiesRockville, MD, site also indicated highfrom paving to prevent the flow of dirt andcouldThesebetween 80% and 85% of total nitrogen. Theprevent clogging. Grade site areas awayMaintenanceinsediment, 65% for total phosphorus, andsuccess, employ design strategies to helpincludingconductedefficiencies of between 82% and 95% formaintained to prevent clogging. To ensureborders,studiesRockville, MD, and Prince William County,The advantages of pervious pavement“pretreatment”monitoringpavement is not in doubt.vacuumsweeping or pressure washing on a periodicbasis commensurate with the level and typePollutant Removal (%)of debris that might come onto the pavementsurface. The pavement should be inspectedStudyTSS TPTN COD Metalseveral times during the first few monthsfollowing installation and annually thereafter.Prince WilliamAnnual inspections should take place afterCounty, VAs826580--Rockville, MD 9565858298–99large storms, when puddles will make anyclogging obvious. The condition of able 2. Effectiveness of porous pavementProvide maintenance guidelines for thepollutant removal (Schueler, 1987)building owner. Consider posted signage on-Somesite to identify pervious pavement areas.keyfactors(otherthanmaintenance) that increase pollutant removalThese can also serve an educational andinclude a drainage time of at least 24 hoursenvironmental promotion function.and the use of clean-washed aggregate.10

“Stormwater hot

maximize credits offered by the U.S. Green Building Council’s (USGBC) Leadership in Energy and Environmental Design (LEED ) 2009 for New Construction and Major Renovations (LEED 2009 NC). This document will guide the reader in understanding the LEED s