Transcription

eBookRheology for quality control –Better rheological resultsReliable measurements from sample preparation todata interpretation

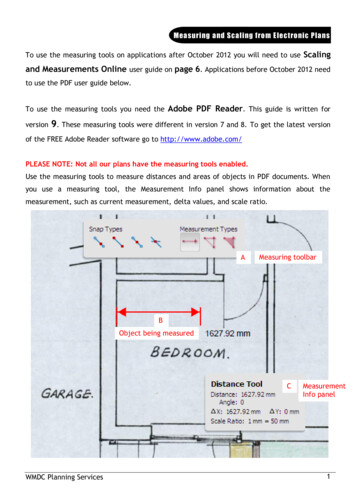

Can you rely on your rheological measuring results? This e-bookprovides insight into the importance of standardized measuringprocedures (SOPs) and what you should consider when it comes torheological measurements.Standard operating procedures (SOP) for routine rheology offer an opportunity to improve efficiency, safety, qualityand uniformity through written, step-by-step instructions. An SOP ensures continuous quality in the results, even whenuntrained operators conduct tests. The application notes describe the development of an effective, complete SOP forrheological measurements in QC. The rheometer, accessory and software are taken into consideration. Plates, cones, coaxial cylinder. Which one is most suitable? Sample consideration. What do I need to think about for sample history, evaporation, slippage, etc? Sample loading, trimming, and gap closing. How can you ensure optimal sample filling? User management, measurement and data evaluation. Which capabilities does the software offer to support routinemeasurements for QC?This guide provides answers to these and many other questions.Table of contentsQC rheology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3Measurements overview by instrument type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4Better rheological results (on-demand webinar) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Well prepared – good results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6HAAKE RheoWin Software – features for quality control and routine measurements . . . . . . . . . . . . . . . . . . . . . . . 11

QC rheologyFrom production to consumption, rheological properties play an important role during the entire life cycle of liquid orsemi-solid samples. Rheological measurements with different types of instruments are performed on a daily base.These include: Simple single point viscosity measurements for a fast batch release in production Flow curve or yield point measurements in the Quality Control laboratory Comprehensive rheological investigations for the development of new formulations in the research and developmentdepartmentProcessability, stability and consistency are the attributes determining consumer perception and thus the overallacceptance of the final product. They can be investigated with various rheological test protocols. In productionevery stage requires different instrument capabilities. Below the different types of instruments are presented withsuggestions on how to select the most suitable one according to the particular formulation or production stage.Handheld spindleviscometers for on-siteviscosity measurements at asingle rotational speed:This type of instrument is easyto operate and provides relativeviscosity values within secondswith the push of a single button.By using different types ofspindles these viscometerscan measure a wide range ofviscosities.QC rheometers withautomatic lift and integratednormal force capabilities forcomprehensive rheologicalinvestigations:Our QC rheometers provideextensive flexibility, ensure fastand consistent characterization ofa wide range of samples by usingStandard Operating Procedures(SOPs) that are easy to create withthe rheometer control software.With automatic lift control and theability to measure and apply axialforces it can perform squeeze,break and tack tests or eventribological measurements. Forsimulating pressure dependentproper- ties, different pressurecells are available.Benchtop spindle viscometersfor measurements accordingto the ISO 2555 standard:Rotational viscometers withmultiple rotational speeds foreach spindle can identify morecomplex flow behavior. Theobtained viscosity values are stillrelative for all non-Newtonianmaterials but allow for comparingdifferent samples.Research grade rheometersfor extended materialcharacterization over thewidest measuring range:The advanced rheometer canbe equipped with dedicatedmeasuring cells for specificapplications. With automatic liftcontrol and the ability to measureaxial forces it can performsqueeze, break and tack tests. Itcan also be coupled with otheranalytical techniques such asmicroscopy or spectroscopy forsimultaneous data acquisition.Entry level rheometers forabsolute viscositymeasurements with integratedtemperature control:Rheometers enable thedeter- mination of yield stress,thixotropy and viscoelasticproperties. These instruments areavailable with a broad portfolio ofdif- ferent measuring geometriessuch as parallel plates, cone &plate, coaxial cylinders and vanerotors in various dimensions.

The following table provides an overview of the measurements that can be performed and of the properties that can beinvestigated by the different instruments:The following table provides an overview of the measurements that can be performed and of the properties that can be investigated bythe different instruments:Thermo ScientificTMThermo ScientificTM Thermo ScientificTM Thermo ScientificTMThermo MTMTMTMThermoTMThermoScientificThermo ScientificTMThermo ARSTM iQ/iQ AiriQ/iQ AirViscotesterC, D & E AKEHAAKETMTMTMMARSTM rheometer40/60MARSTM rheometeriQ/iQ Air RotationaliQ/iQ Air RotationalViscotesterC, D & E ViscotesterViscotester3viscometerBenchtop viscometerRotational rheometerType of rheometer HandheldPortableinstrument Handheld YesYesviscometer BenchtopviscometerType of rheometerTemperaturePortable instrumentYesYescontrol optionsTemperatureAutomatic liftcontrol optionsfunctionalityAutomatic liftStandalone operationYesYesfunctionalitySoftware controlledLimitedStandalone ests in stressoperationcontrolled (CS) modeTests in stressTests in oscillationcontrolled (CS) modemode (CD & CS)Tests in oscillationTests in controlledYesYesmode (CD & CS)rate mode (CR)Tests in controlledNormal forceYesYesrate mode (CR)capabilitiesNormal od specific accessoriesNoYes*RotationalYesrheometer Rotational rheometer Rotational sYesYesYesYesYesYesiQ Air onlyYesiQ Air onlyYesYesiQ Air sure cellsApplicationspecific measuring accessoriesTribologyPressure ationTribologycapabilitiesUV curingApplications and sample typesInterfacial rheologyYesQuality controlHyphenationResearch &capabilitiesDevelopmentPolymer rheologyYesSingle-point viscositytoolsAbsolute viscosityApplicationsand sample typesdataYesQuality controlFlow/viscosity curveResearch &Viscoelastic YesYesYesYesYesYesYesYesYesiQ LimitedAir onlyLimitediQ AironlyYesLow viscous viscositysamplesYesYesYesonlyYesSingle-pointiQ AiriQ AironlyYesYes(juices, inks etc.)Absolute viscosityLimitedonly for model D, HAAKEYes*Thermo ScientificTM HAAKETM RheoWinTM data evaluation softwareRheoWin softwareYesfor model Edata**Rheo-DEA (dielectrical analysis, Rheo-Microscope, Rheo-FTIR, Rheo-RamanFlow/viscosity curveLimitedYesYesYesYesYesYesFora more detailedlocalThermo ScientificYesMaterialiQ Airpleaseonly contact youriQ AironlyViscoelasticbehaviordiscussion and custom tailored instrument industrial/food-rheology-extrustionLow viscous samplesiQ Air onlyiQ Air onlyYesYesYescontact-request.html.(juices, inks etc.)CompositesFind more information how rheological measurement can support your QC and*Thermo ScientificTM HAAKETM RheoWinTM data evaluation software only for model D,food formulation development in this food compendium and visit our food rheologyHAAKE RheoWin software available for model Ehomepage at e, Rheo-FTIR, Rheo-Raman***Solid sample fixuture for DMTA and Sentmanat Extensional Rheometer AccessoryFor a more detailed discussion and custom tailored instrument configurations,please contact your local Thermo Scientific Material Characterization representativeor www.thermofisher.com/ContactUsRheometer. Yes22

On-demand webinarBetter rheological results – it all starts up front On-demand training 1What to do before pressing the start button?Good quality control requires reliable and reproduceabletesting the structure of samples throughout the processfor critical characteristics. Yet rheological testing canbe impacted by some simple mistakes in both samplehandling and the selection of the test method itself. Makesure your lab is getting it right.On-demand training 2Select the correct measuring geometryChoosing the right measuring systems is critical forreliable and reproducible rheological data. Learn howto select the optimal geometry according to type ofrheometer, test conditions and sample properties.Duration: 50 minSpeaker: Nate Crawford, Ph.D., Rheology ApplicationsSpecialist, Thermo Fisher ScientificDuration: 25 minSpeaker: Fabian Meyer, Ph.D. Team Leader RheologyApplications, Thermo Fisher Scientific

APPLICATION NOTEAuthorsCornelia Küchenmeister-Lehrheuer and Klaus OlddörpThermo Fisher Scientific, Karlsruhe, GermanyIntroductionIn recent years the demands regarding the reliability ofrheological test results have grown significantly, likefor most analytical methods. Only if correct test resultscan be produced and easily be reproduced they canbe used for the reliable characterization or comparisonof substances.Based on correct test results it is e.g. possible for theQC department to compare different incoming materialsor different batches from production no matter whetherthese results have been produced on different instruments or even on different sites. It is nevertheless essential to use a viscometer or rheometer with a measuringgeometry, which gives absolute results, like e.g. coaxialcylinders or cone and plate geometries. Depending onthe sample’s nature in can also be necessary to agreeupon the test routine and data evaluation method.Figure 1: Connect Assist measuring geometry with a mark on itsFigureceramic shaft for defined mounting.data quality in the low-torque-range (nNm), its resultscan also be used for later tests since the whole setupmotor plus measuring geometry is always assembledexactly the same way.Every test result contains a certain error, which is thesum of many effects mainly related to the sample, theinstrument and the handling. Using the example ofplate-plate (PP) and cone-plate (CP) measuring geometries, this report will describe the pre-paration of arheological test aiming to show the possible errors andhow to minimize them. It is assumed that the rheometerhas been installed correctly and is properly levelled.Measuring plates, used as the lower part of PP- or CPgeometries are also designed to be mounted only inone position (Figure 2) [1].Cone or plate? How to choose the rightmeasuring geometryMeasuring geometries with “Connect Assist“ for ThermoScientificTM HAAKETM rheometers feature a marking,which, is aligned with a corresponding marking on theaxis of the rheometer when inserted into the coupling.Thus the rotor can be inserted in a defined positionrelative to the motor shaft. When a calibration like theMicroStressControl (MSC) is performed to improve the1 No. V-248V-248Well prepared - good results

In a CP-geometry, the shear rate is constant over thewhole radius in the measuring gap, whereas in a PPgeometry the shear rate decreases from its maximumvalue at the edge to zero at the centre of the geometry.When non-Newtonian samples are tested with a PP-geometry, viscosity values always contain an intrinsic errorbecause different parts of the sample are exposed todifferent shear rates. Therefore if possible, a CP-geometryshould be used for viscosity tests. Still, due to the biggerflexibility regarding the measuring gap, PP-geometriesare the better and sometimes the only choice for manyapplications.The diameter of the geometry has to be chosen in relationto the sample’s viscosity. For water-like samples it isrecommended to use cones or plates with the biggestdiameter (60 mm). With increasing viscosity smallerdiameters have to be used. For e.g. bitumen or hardrubber an 8 mm plate is often the best choice.zero gap determination into the HAAKE RheoWin Job(Figure 4). This prevents forgetting this important stepand leads to a user-independent precisely determinedzero gap.A correct and reproducible amount of sample is especially important in case of small sample volumes andlarge edge effects, which can occur for PP- and CP-geometries. Therefore to load the correct amount of samplebecomes more important for smaller diameters, smallergaps and higher sample viscosities.Figure 3: Automatic determination of the zero gap using the monitormode.Figure 2: For our PP- and CP-geometries, measuring plates TMP withthe corresponding diameters are available. The notch under the markon the TMP slides over the pin in the temperature control unit for easyand precise positioning.Determination of the zero gap - reference for themeasuring gapWhenever a cone, a plate o

plate-plate (PP) and cone-plate (CP) measuring geo-metries, this report will describe the pre-paration of a rheological test aiming to show the possible errors and how to minimize them. It is assumed that the rheometer has been installed correctly and is properly levelled. Cone or plate? How to choose the right measuring geometry