Transcription

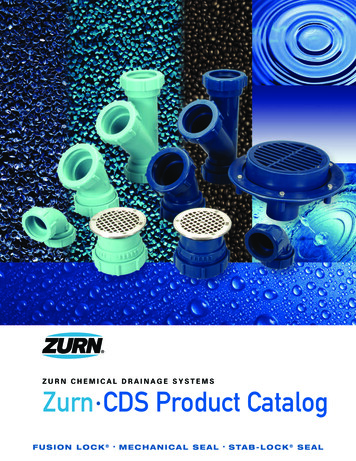

ZURN CHEMICAL DRAINAGE SYSTEMSZurn·CDS Product CatalogF U S I O N L O C K · M E C H A N I C A L S E A L · S TA B - L O C K S E A L

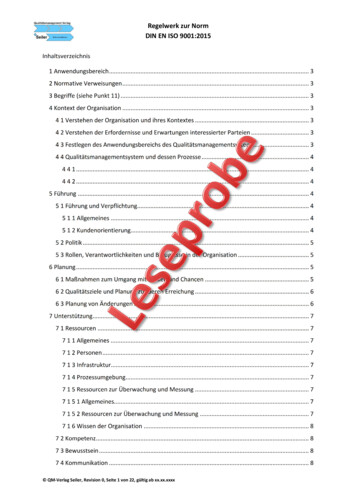

TABLE OF CONTENTSAn OverviewIntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1System Benefits and Features . . . . . . . . . . . . . . . . . 2Fusion Lock Joining System . . . . . . . . . . . . . . . . 3-4Stab-Lock Joining System . . . . . . . . . . . . . . . . . . . 5Mechanical Joining System . . . . . . . . . . . . . . . . . . . 6Polypropylene ProductsIntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21Floor Drains . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-23Cleanouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24Sinks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25Traps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-26Physical Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . 27Chemical Resistance Guides . . . . . . . . . . . . . . 28-33Neutralization TanksIntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36PVDF ProductsIntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38-45Traps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46Floor Drains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47-48Cleanouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48Physical Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49Chemical Resistance GuidesInorganic Media . . . . . . . . . . . . . . . . . . . . . . 50-52Organic Media . . . . . . . . . . . . . . . . . . . . . . . 53-58Miscellaneous Media . . . . . . . . . . . . . . . . . . . . . 59ToolsProducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60-62Electro Fusion Welder . . . . . . . . . . . . . . . . . . . . . . . 63TechnicalGeneral Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 64Adapting To Other Systems – Polypropylene . . . . . . . . 65Terms and Conditions . . . . . . . . . . . . . . . . . . . . . . . . 66INTRODUCTIONThe Zurn Plumbing Products Group offers a century-oldtradition of high-quality products and customer service.Zurn Industries was founded in 1900 in Erie, Pennsylvania.Created initially to manufacture a patented backwater valve,Zurn has worked faithfully throughout the past century toexpand its product offering. Today, Zurn now manufacturesthe largest breadth of plumbing products in the industry.This commitment to the plumbing industry has made Zurnthe leader in its field. To spur this growth, Zurn Industrieshas consistently followed a mandate of making strategicacquisitions and, more importantly, of internally developingsynergistic products that serve the plumbing industry. WithChemical Drainage Systems, Zurn continues to expand tomeet the needs of the twenty-first century!The Zurn Specification Drainage Operation, previously knownas the Hydromechanics Division, manufactures a variety ofdrainage and water control products that conform to A.N.S.I.standards. Zurn products are frequently specified byarchitects, mechanical engineers and plumbing contractors,and are sold into the non-residential commercial, industrial,and institutional construction markets. Consistent with itscommitment to the plumbing industry, it was a naturalprogression for Zurn to enter the chemical drainage market.Zurn Chemical Drainage Systems were developed withcontributions from all segments of the plumbing andplastic industries. Zurn drew upon the vast expertiseof professional industry consultants, Zurn engineers,contractors, distributors, and sales personnel. In addition,Zurn partnered with a leading academic and researchinstitution in the field of plastic technology. This facilityhas been operating in the plastics industry for threedecades and is Standard-61 compliant.1

SYSTEM BENEFITS and FEATURES“Zurn Chemical Drainage Systems offer reliabilityand quality for the design engineer; simplicity forthe distributor; low cost, easy installation for thecontractor; and peace of mind for the buildingowner/operator.” Simplifies material handling – lowers shipping andreceiving costs.Who it benefits and how: Can combine with other Zurn family products for freight andpromotional advantages.Design Engineer – Reliability and Quality Superior joining methods: Fusion Lock , nut with sealmechanical joint, and Stab Lock . Ease of installation reduces chance for faulty installations –industry’s best fusion machine, grooving tool, and the industry’sonly push-together joining method with Stab Lock .Distributor – Simplicity One fitting for Fusion, Mechanical systems, andStab Lock – no multiple inventory of fittings necessary.Saves inventory dollars. Supported by Zurn sales personnel in every major marketarea in North America.Building Owner – Peace of Mind Reliability and performance – unequalled quality. Approvals: ASTM, IAPMO/UPC, CSA B181.3. Meets applicable ASTM, NSF, IAPMO/UPC, and CSA standards. Modular mechanical joint system: easy to work with duringremodeling – keeps remodeling costs in check. Unequaled manufacturing Quality Control Procedures –manufacturing facility is NSF-61 compliant. Backed by strong, long-term company, Zurn Industries –in business since 1900. Uniformity of material specifications. Manufactured at an NSF-61 compliant facility. Zurn technical support staff. See our installation training video online.Contractor – Low Cost and Easy Easy installation for mechanical joint. Grooving tool is easy touse and carries replacement cutting blade at no extra chargefor easy instant blade replacement. Fast installation using new Stab Lock fittings. Eliminates theneed to groove the pipe before assembly. No ratchet needed to join mechanical joint coupling. Patented single fitting for both fusion and mechanical joint –reduces number of different parts to deal with and offers jobsite flexibility – reduces installation time and costly delays. Easy installation for Fusion Lock – no time-wasting clampsare necessary. Don’t have to go back and tighten joints after fusing –reduces operator error. Ability to fuse multiple joints of different sizes at same timeand to dry fit system before fusing. Very simple and reliable fusion machine: reduces installationtime, can fuse multiple joints of multiple sizes at the sametime, reduces installation costs. Built-in features reduceoperator error and saves installation time (see machinefeatures, page 4). Fusion Lock coil can be adjusted and moved into optimumposition for fusing.2

PATENTED FUSION LOCK JOINING SYSTEM Chemical and acid-resistant (FRPP-210) polypropylene meetsASTM F1412, UPC, and CSA standards – peace-of-mind. Single fittings for Stab Lock , mechanical and fusion joints –The Zurn system, utilizing a combination fitting for bothFusion Lock and mechanical joining methods, is a patentedsystem – reduces handling costs, avoids job site delays,simplifies inventory. The unique Zurn Fusion Lock system eliminates the need foradditional clamping during installation – no clamps arenecessary so you don’t have to go back and tighten clampsafter fusing – simplifies installation, decreases errors,saves money! Machine semi-automatically senses the connection size(s)and delivers the corresponding power to fuse a quality joint –installer selects 1-1/2"-4" or 6" size groups. Multiple joints may be connected in a series, up to the specifiedmaximum – shortens installation time and saves money. Multiple joints, of different sizes within the same size group,can be fused simultaneously without resetting the fusionmachine – reduces installation time and saves money! The Zurn fusion unit will automatically compensate,incrementally, for job site temperature conditions (hot or cold)to reach ideal fusing temperature – ensures joint integrity!(See page 4 for additional Fusion Lock Machine features.) The Zurn manufacturing facility is NSF Standard-61 compliant.An OverviewFeaturesZurn Fusion Lock Installation andOperating InstructionsPower input requirements: 115 Volts AC, 12 amps, 60 Hz.The unit will be ready to operate after turning on and short‘self-test’ is completed.Making the Zurn Fusion Lock Joint ConnectionA Fusion Lock joint connection is simply and quicklyaccomplished by doing the following:1. Cut pipe square and de-burrends. Clean pipe, fitting,and seal.2. Insert Fusion Lock seal intofitting and rotate leads todesired easy access position.Push leads inward and handtighten locking nut onto fitting.Then push leads outward tomake sufficient room for pipe.Remember: There is no needfor an additional band clamp.3. Using Zurn Joint Depth Gauge,mark pipe accordingly to ensurepipe is inserted completely.4. Insert pipe into joint assembly completely and finishtightening the nut an additional 1/4 to 1/2 turn usingspanner wrench.5. Turn on the welder box and follow instructions on the screen.Fusion Lock Joint6. Connect the fusion unit clips to the seal leads, select size group,and press start. Note: After starting, the unit will perform a briefsystem check to ensure that the leads are connected properly,that sufficient power is present, and that the maximum numberof simultaneous joints has not been exceeded. Be certain thatthere is no undue stress on joint lead wires.7. Wait while joint is fusing – the unit display will count downremaining weld time. The Zurn fusion unit will automaticallycompensate, incrementally, for job site temperature conditions(hot or cold) to reach ideal fusing temperature.8. Upon completion, an alarm will sound. Remove the leads andmove on to the next joint. Remember: There is no need to goback and further tighten the nuts.3

An OverviewPATENTED FUSION LOCK JOINING SYSTEMFeatures of the Fusion Lock MachineCaution Simple operation – semi-automatic control and timing. Multiple joints may be connected in-series up to the specifiedmaximum. Joints of different sizes may also be fusedsimultaneously. Any combination of pipe sizes within thesame size group can be welded in series. Versatile and fast!Saves time and money. All joints use the same current. Even heat is applied to all sizes of joints, and any number ofjoints up to stipulated maximum ensures joint integrity andreduces errors. Automatic compensation for ambient temperature. SAFETY! Lighter weight, longer cord for user. Transformer and solid state relay run cool – no “resting” isnecessary – saves installation time and money. Unit is protected by circuit breaker – equipment protection! Unit contains 16 amp fuse to protect unit if wired to 230 VACinstead of 115 VAC. Backlit LCD display. Semi-automatic joint integrity detection before starting –saves time and money. Operator can stop welding if desired. 16-foot long lead cord makes installation easy. Electronics are shock mounted and fully contained – protection! Reinforced power cords and link cables (jumper wires) – durable! Data logging ability to track fusion information.Although we have added shock mounts to the electronics andenclosed the components in a durable box, the fusion control unitis a sophisticated electronic device that should be handled withcare. Do not open device! The unit contains no field serviceableparts. If damaged, please return to Zurn Industries factoryfor repair.Fusion Lock Machine4Do not disturb the joint for 5 minutes after the fusing cycle.Joint should cool for 1/2 hour prior to testing.Do not test with air. Test only with water.After testing, if a leak is detected completely drain the systemand re-fuse the joint per the above instructions.WarningBecause of Zurn’s unique patent pending system, only Zurnsealing components (nuts and seals) are compatible with ourfittings. Only the Zurn fusion unit will provide proper welding ofFusion Lock joints, i.e. do not use other manufacturer’smachines – you must use the Zurn Fusion Lock machineduring installation.Zurn fittings and pipe conform to the highest industry qualitystandards and meet all applicable specifications and tolerances.Zurn Industries can only guarantee that Zurn parts are manufactured to the above standards and recommend that you donot mix parts with other manufacturer’s products.The Zurn combination fitting for both mechanical and fusionjoining methods is a patented system that offers superiorperformance.

STAB LOCK JOINING SYSTEMAn OverviewFeatures Single fitting(s) for Stab Lock , grooved mechanical, andfusion – the Zurn system, utilizing a combination fitting forStab Lock , grooved mechanical and/or Fusion Lock joiningmethods, is a patented system – eases handling costs. Stab Lock features a polyethylene seal and stainless steelgrab ring for rotation strength. May be used with polypropylene and PVDF pipe and fittings. Eliminates the need to groove pipe and/or fittings. Flame retardant pipe provided in standard 10-foot lengths.Can order non-flame retardant pipe in 10-foot or 20-footlengths. Results in faster installation and maximum labor savings. Easy to clean and maintain.Making the Zurn Stab Lock Joint Connection1. Cut pipe square to desiredlength and de-burr ends.2. Remove nuts from fittings.3. Lubricate inside and outsideof seal and threads of fittingwith petroleum jelly.4. Insert seal and rings into thefitting and reapply the nutsuntil they touch the rings.5. Insert pipe into the assembly completely.6. Tighten nuts with Zurn spanner wrench.WarningsZurn fittings and pipe conform to the highest industry qualitystandards and meet all applicable specifications and tolerances.Zurn can only guarantee that Zurn parts are manufactured to theabove standards and recommend that you do not mix parts withother manufacturer’s products.Because of Zurn’s unique patented system, only Zurn components(our nuts and seals) are compatible with our fittings. Only theZurn grooving tool will provide the proper pipe groove depth forthe Zurn system, i.e. you must use Zurn installation tools(groovers and fusion machines) with Zurn products.5

An OverviewMECHANICAL JOINING SYSTEMFeaturesFeatures of the Zurn Grooving Tool Single fitting(s) for Stab Lock , grooved mechanical, andfusion – the Zurn system, utilizing a combination fitting forboth mechanical and/or Fusion Lock joining methods,is a patented system – eases handling costs. No metal bands! Nut and seal system is proven superior tometal band-coupling systems. No ratchet is needed. Fittings are pre-grooved – don’t have to groove the fittingsin the field. No soaking the Olive! No heat or hot water seal treatmentnecessary. Heat treatment may facilitate the installation of3" and 4" seals. Flame retardant pipe provided in standard 10-foot lengths.Can order non-flame retardant pipe in 10-foot or 20-foot lengths. Pipe grooving tool is the best in the industry(see features to right). Modular system makes it easy to remodel. Easy to clean and maintain. Lock-in-place, hardened-steel double-ended blade –ensures high quality cuts with sharp cutting edges that saveinstallation time. Blades are less costly to replace than singleedged blades. Marked cutting edge(s) indicates if cutting blade has beenused – reduces installation errors. Spare blades are contained in storage compartments on alltools – reduces job site hassles and eliminates costly delays. Blade housings are molded in clear polymer to help installervisually align the blades when changing. All metal tool housing provides for durability. Tool also doubles as a seal installation aide (3" and 4" only).Z9-GRVRMaking the Zurn Mechanical Joint ConnectionA mechanical joint connectionMechanical Jointis simply and quickly accomplished by doing the following:1. Cut pipe square andde-burr ends.2. Secure pipe and positiongrooving tool onto the endof the pipe.3. Groove the pipe according toinstructions provided.4. Insert locking nut onto pipe or fitting before putting theseal on.5. Place seal on pipe and/or fitting per instructions –no pre-heating is required. Heat treatment may facilitatethe installation of 3" and 4" seals.6. Insert pipe assembly into the fitting, lubricate nut withpetroleum jelly, and hand tighten.7. Use the spanner wrench to further tighten the nut tocomplete the joint.Mechanical Joint Components6WarningsZurn fittings and pipe conform to the highest industry qualitystandards and meet all applicable specifications and tolerances.Zurn can only guarantee that Zurn parts are manufactured to theabove standards and recommend that you do not mix parts withother manufacturer’s products.Because of Zurn’s unique patented system, only Zurn components(our nuts and seals) are compatible with our fittings. Only theZurn grooving tool will provide the proper pipe groove depthfor the Zurn system, i.e. you must use Zurn installation tools(groovers and fusion machines) with Zurn products.

POLYPROPYLENE PIPE and FITTINGSGeneral Product InformationPolypropylenePolypropylene (PP) has becomethe material of choice of specifyingengineers when designing chemicaldrainage systems. Polypropylene hasthe widest range and highest usetemperature (up to 212 F) of anypolyolefin commercially available.Its excellent physical and chemicalproperties make polypropylenethe ideal thermoplastic for handlingchemical waste solutions foundin laboratory and industrial DWVapplications.As a result of its heterophasicmolecular distribution, polypropyleneoffers excellent resistance to mostcommon organic and mineral acids,alkalis, alcohols and salt solutions.In short, polypropylene is the mostcost-efficient way to handle themixtures of acids, bases and solventsthat are being discarded in laboratoryand industrial piping systems.Applications School laboratoriesUniversity laboratoriesHospitalsResearch facilitiesWineriesFood process facilitiesDairy facilitiesIndustrial facilitiesPharmaceuticalPhoto labs 7

Z9-PP40-FR PIPE SCHEDULE 40Engineering Specification:ASTM-F1412, F.R.P.P. - 210ZURN Z9-PP40-FR – Schedule 40 flame-retardantpolypropylene pipe.DPolypropyleneDimensions in Inches [mm]Model No.Nom. Pipe -FR-4Z9-PP40-FR-61-1/2 [38]2 [51]3 [76]4 [102]6 [152]1-29/32 [48]2-3/8 [60]3-1/2 [89]4-1/2 [114]6-5/8 [168]Z9-PP80-FR PIPE SCHEDULE 80Engineering Specification:ASTM-F1412, F.R.P.P. - 210ZURN Z9-PP80-FR – Schedule 80 flame-retardantpolypropylene pipe.DDimensions in Inches [mm]Model No.Nom. Pipe -FR-4Z9-PP80-FR-61-1/2 [38]2 [51]3 [76]4 [102]6 [152]1-29/32 [48]2-3/8 [60]3-1/2 [89]4-1/2 [114]6-5/8 [168]Z9-PP40-NFR PIPE SCHEDULE 40Engineering Specification: ASTM-F1412ZURN Z9-PP40-NFR – Schedule 40 non-flameretardant polypropylene pipe.DNote: Specify 10' or 20' lengths.Dimensions in Inches [mm]8Model No.Nom. Pipe P40-NFR-4Z9-PP40-NFR-61-1/2 [38]2 [51]3 [76]4 [102]6 [152]1-29/32 [48]2-3/8 [60]3-1/2 [89]4-1/2 [114]6-5/8 [168]

Z9-PP80-NFR PIPE SCHEDULE 80Engineering Specification:ASTM-F1412ZURN Z9-PP80-NFR – Schedule 80 non-flameretardant polypropylene pipe.DNote: Specify 10' or 20' lengths.Dimensions in Inches [mm]Nom. Pipe SizeD1-1/2 [38]2 [51]3 [76]4 [102]6 [152]1-29/32 [48]2-3/8 [60]3-1/2 [89]4-1/2 [114]6-5/8 [168]Z9A-C COUPLINGPolypropyleneModel 0-NFR-4Z9-PP80-NFR-6DEngineering Specification:ASTM-F1412, F.R.P.P. - 210ZURN Z9A-C COUPLING – Flame-retardantpolypropylene coupling assembly.BLAOptions:-F Fusion Lock; -M Mechanical Seal; -S Stab Lock SealDimensions in Inches [mm]Model No.Nom. Pipe SizeABDLZ9A-C-112Z9A-C-2Z9A-C-3Z9A-C-4Z9A-C-61-1/2 [38]2 [51]3 [76]4 [102]6 [152]5/32 [4]1/8 [3]3/16 [5]1/4 [6]9/32 [7]1-1/16 [27]1-9/32 [33]2-3/32 [53]2-1/8 [54]2-5/32 [55]3-1/32 [77]3-17/32 [90]5-21/64 [135]6-3/8 [162]8-19/32 [218]2-1/4 [57]2-5/8 [67]4-3/8 [111]4-1/2 [114]4-19/32 [117]Z9A-SC SLIP COUPLINGEngineering Specification:ASTM-F1412, F.R.P.P. - 210ZURN Z9A-SC SLIP COUPLING –Flame-retardant polypropylene fitting.For use with existing polypropylene stack.Options:-F Fusion LockDimensions in Inches [mm]Model No.Nom. Pipe 1/2 [38]2 [51]3 [76]4 [102]6 [152]3-1/32 [77]3-17/32 [90]5-21/64 [135]6-3/8 [162]8-19/32 [218]2-1/4 [57]2-5/8 [67]4-3/8 [111]4-1/2 [114]4-19/32 [117]9

Z9A-E90 90 ELBOW – 1/4 BendEngineering Specification:ASTM-F1412, F.R.P.P. - 210ZURN Z9A-E90 90 ELBOW – Threaded x threadedflame-retardant polypropylene 90 elbow fitting.LCOptions:-F Fusion Lock; -M Mechanical Seal; -S Stab Lock SealPolypropyleneDimensions in Inches [mm]Model No.Nom. Pipe 0-61-1/2 [38]2 [51]3 [76]4 [102]6 [152]1-3/4 [44]2-5/16 [59]3 [76]3-7/8 [98]5 [127]3-9/32 [83]4-3/32 [104]5-21/32 [144]7-1/16 [179]9-9/32 [236]Z9A-E90S 90 ELBOW – StreetEngineering Specification:ASTM-F1412, F.R.P.P. - 210ZURN Z9A-E90S 90 ELBOW – Threaded spigotflame-retardant polypropylene 90 elbow fitting.CLOptions:-F Fusion Lock; -M Mechanical Seal; -S Stab Lock SealEDimensions in Inches [mm]Model No.Nom. Pipe 9A-E90S-61-1/2 [38]2 [51]3 [76]4 [102]6 [152]1-3/4 [44]2-5/16 [59]3 [76]3-7/8 [98]5 [127]2-27/32 [72]3-19/32 [91]5-1/16 [129]5-15/16 [151]5 [127]2-13/16 [71]3-19/32 [91]5-15/16 [151]5-31/32 [152]7-5/32 [182]Z9A-LS90 90 ELBOW – Long SweepEngineering Specification:ASTM-F1412, F.R.P.P. - 210ZURN Z9A-LS90 LONG SWEEP ELBOW –Threaded x threaded flame-retardant polypropylene90 elbow fitting.LCOptions:-F Fusion Lock; -M Mechanical Seal; -S Stab Lock SealDimensions in Inches [mm]Model No.Nom. Pipe 9A-LS90-61-1/2 [38]2 [51]3 [76]4 [102]6 [152]3-3/16 [81]3-27/32 [98]5-3/4 [146]6-13/16 [173]6-11/32 [161]*One-piece molded.10L4-23/32 [120]5-5/8 [143]8-13/32 [214]10 [254]10-5/8 [270]

Z9A-E45 45 ELBOW – 1/8 BendEngineering Specification:ASTM-F1412, F.R.P.P. - 210ZURN Z9A-E45 45 ELBOW – Threaded x threadedflame-retardant polypropylene 45 elbow fittingassembly.CLOptions:-F Fusion Lock; -M Mechanical Seal; -S Stab Lock SealDimensions in Inches [mm]Nom. Pipe 5-61-1/2 [38]2 [51]3 [76]4 [102]6 [152]11/16 [17]25/32 [20]1-3/4 [44]2-13/16 [56]2 [51]1-3/4 [44]1-27/32 [47]2-1/32 [52]4-5/16 [110]4-5/32 [106]PolypropyleneModel No.Z9A-E45S 45 ELBOW – StreetEEngineering Specification:ASTM-F1412, F.R.P.P. - 210ZURN Z9A-E45S 45 ELBOW – Threaded x spigotflame-retardant polypropylene 45 elbow fittingassembly.CLOptions:-F Fusion Lock; -M Mechanical Seal; -S Stab Lock SealDimensions in Inches [mm]Model No.Nom. Pipe 9A-E45S-61-1/2 [38]2 [51]3 [76]4 [102]6 [152]11/16 [17]25/32 [20]1-3/4 [44]2-3/16 [56]2 [51]1-15/16 [49]2-1/4 [57]4-5/32 [106]4-13/32 [112]4-5/32 [106]1-3/4 [44]2-1/32 [52]1-27/32 [47]4-5/16 [110]4-5/32 [106]Z9A-T SANITARY TEEEngineering Specification:ASTM-F1412, F.R.P.P. - 210ZURN Z9A-T SANITARY TEE – Flame-retardantpolypropylene sanitary tee fitting assembly.BLCOptions:-F Fusion Lock; -M Mechanical Seal; -S Stab Lock SealZ9A-TTAEDimensions in Inches [mm]Model No.Nom. Pipe 9A-T-61-1/2 [38]1-1/2 [38]2 [51]3 [76]4 [102]6 [152]1-3/4 [44]2-3/16 [56]1-5/16 [33]3-1/16 [78]3-7/8 [98]5 [127]1-3/8 [35]2-3/4 [70]1-3/8 [35]2-3/16 [56]2-5/8 [67]5-3/8 [137]1-3/4 [44]3-1/2 [89]2-5/16 [59]3-1/16 [78]3-5/8 [92]5 [127]4-1/16 [103]4-15/16 [125]5-3/32 [129]7-13/32 [188]8-3/4 [222]11-1/2 [292]5-1/4 [133]8-11/32 [212]6-1/4 [159]9-7/16 [240]10-3/4 [273]14-11/16 [373]11

Z9A-TR REDUCING SANITARY TEEFEngineering Specification:ASTM-F1412, F.R.P.P. - 210ZURN Z9A-TR REDUCING SANITARY TEE –Flame-retardant polypropylene reducing sanitary teefitting assembly.Z9A-TTR-2 x 112 DOUBLE REDUCING SANITARY TEEBLCZ9A-TTRZ9A-TROptions:-F Fusion Lock; -M Mechanical Seal; -S Stab Lock SealPolypropyleneDimensions in Inches [mm]Model No.Nom. Pipe SizeReducer SizeBCFLZ9A-TR-2 x 112*Z9A-TTR-2 x 112*Z9A-TR-3 x 112Z9A-TR-3 x 2Z9A-TR-4 x 112Z9A-TR-4 x 2Z9A-TR-4 x 3Z9A-TR-6 x 2Z9A-TR-6 x 3Z9A-TR-6 x 42 [51]2 [51]3 [76]3 [76]4 [102]4 [102]4 [102]6 [152]6 [152]6 [152]2 x 1-1/2 [51 x 38]2 x 1-1/2 [51 x 38]3 x 1-1/2 [76 x 38]3 x 2 [76 x 51]4 x 1-1/2 [102 x 38]4 x 2 [102 x 51]4 x 3 [102 x 76]6 x 2 [152 x 51]6 x 3 [152 x 76]6 x 4 [152 x 102]1-3/16 [30]1-3/16 [30]2-3/16 [56]2-3/16 [56]2-5/8 [67]2-5/8 [67]2-5/8 [67]5 [127]5 [127]5 [127]1-15/16 [49]1-15/16 [49]3-1/16 [78]3-1/16 [78]3-5/8 [92]3-5/8 [92]3-5/8 [92]5 [127]5 [127]5 [127]4-15/16 [125]4-15/16 [125]5-7/32 [133]5-11/32 [136]6-31/32 [177]6-31/32 [177]6 [152]10-9/16 [268]9-19/32 [244]7-1/2 [191]6-1/4 [159]6-1/4 [159]9-7/16 [240]9-7/16 [240]10-1/4 [260]10-3/4 [273]10-3/4 [273]14-11/16 [373]14-11/16 [373]14-11/16 [373]*One-piece molded.Z9A-TC CLEANOUT TEECEngineering Specification:ASTM-F1412, F.R.P.P. - 210ZURN Z9A-TC CLEANOUT TEE – Flame-retardantpolypropylene cleanout tee fitting assembly.BAOptions:-F Fusion Lock; -M Mechanical Seal; -S Stab Lock SealLDimensions in Inches [mm]12Model No.Nom. Pipe 1-1/2 [38]2 [51]3 [76]4 [102]6 [152]1-3/4 [44]1-5/16 [33]3-1/16 [78]3-7/8 [98]5 [127]1-3/8 [35]1-3/8 [35]2-3/16 [56]2-5/8 [67]5-3/8 [137]1-3/4 [44]2-5/16 [59]3-1/16 [78]3-5/8 [92]5 [127]5-1/4 [133]6-1/4 [159]9-7/16 [240]10-3/4 [273]14-11/16 [373]

Z9A-Y 45 WYEEngineering Specification:ASTM-F1412, F.R.P.P. - 210ZURN Z9A-Y 45 WYE – Flame-retardantpolypropylene 45 wye fitting assembly.Options:-F Fusion Lock; -M Mechanical Seal; -S Stab Lock SealBLEACDimensions in Inches [mm]Nom. Pipe 2 [38]2 [51]3 [76]4 [102]6 [152]3-1/8 [79]4-1/16 [103]6 [152]7 [178]11-1/8 [283]3-13/16 [97]4-1/2 [114]7-1/4 [184]9-1/16 [230]11-1/8 [283]21/32 [17]13/16 [21]1-5/8 [41]1-5/8 [41]1-3/4 [44]4-3/16 [106]5-11/32 [136]7-3/4 [197]8-3/4 [222]13-1/4 [337]6-9/16 [167]7-7/8 [200]12-9/16 [319]14-11/16 [373]17-3/16 [437]PolypropyleneModel No.Z9A-YR REDUCING WYEEngineering Specification:ASTM-F1412, F.R.P.P. - 210ZURN Z9A-YR REDUCING WYE – Flame-retardantpolypropylene reducing 45 wye fitting assembly.Options:-F Fusion Lock; -M Mechanical Seal; -S Stab Lock SealBFLCDimensions in Inches [mm]Model No.Nom. Pipe SizeReducer SizeBCFLZ9A-YR-2 x 112Z9A-YR-3 x 112*Z9A-YR-3 x 2*Z9A-YR-4 x 112Z9A-YR-4 x 2Z9A-YR-4 x 3Z9A-YR-6 x 2Z9A-YR-6 x 3Z9A-YR-6 x 42 [51]3 [76]3 [76]4 [102]4 [102]4 [102]6 [152]6 [152]6 [152]2 x 1-1/2 [51 x 38]3 x 1-1/2 [76 x 38]3 x 2 [76 x 51]4 x 1-1/2 [102 x 38]4 x 2 [102 x 51]4 x 3 [102 x 76]6 x 2 [152 x 51]6 x 3 [152 x 76]6 x 4 [152 x 102]4-1/2 [114]7-1/4 [184]7-1/4 [184]9-1/16 [230]9-1/16 [230]9-1/16 [230]11-1/8 [283]11-1/8 [283]11-1/8 [283]13/16 [21]1-5/8 [41]1-5/8 [41]1-5/8 [41]1-5/8 [41]1-5/8 [41]1-3/4 [44]1-3/4 [44]1-3/4 [44]5-5/8 [143]8-5/32 [207]8-9/32 [210]10-3/32 [256]10-3/32 [256]9-1/8 [232]15-25/32 [401]16-3/4 [425]13-11/16 [348]7-7/8 [200]12-9/16 [319]12-9/16 [319]14-11/16 [373]14-11/16 [373]14-11/16 [373]17-3/16 [437]17-3/16 [437]17-3/16 [437]*One-piece molded.Z9A-YB COMBINATION WYE and 45 ELBOWAEngineering Specification:ASTM-F1412, F.R.P.P. - 210ZURN Z9A-YB COMBINATION WYE and 45 ELBOW –Flame-retardant polypropylene combination wye and1/8 bend fitting assembly.Options:-F Fusion Lock; -M Mechanical Seal; -S Stab Lock SealBFLCDimensions in Inches [mm]Model No.Nom. Pipe 61-1/2 [38]2 [51]3 [76]4 [102]6 [152]4-5/32 [106]5-3/32 [129]8-23/32 [221]10-5/32 [258]12-13/16 [325]3-13/16 [97]4-1/2 [114]7-1/4 [184]9-1/16 [230]11-1/8 [283]21/32 [17]13/16 [21]1-5/8 [41]1-5/8 [41]1-3/4 [44]4-1/8 [105]5-1/8 [130]8-19/32 [218]9-7/8 [251]12-9/16 [319]6-9/16 [167]7-7/8 [200]12-9/16 [319]14-11/16 [373]17-3/16 [437]13

Z9A-YRB REDUCING COMBINATION WYEand 45 ELBOWAPolypropyleneEngineering Specification:ASTM-F1412, F.R.P.P. - 210ZURN Z9A-YRB REDUCING COMBINATION WYEand 45 ELBOW – Flame-retardant polypropylenereducing combination wye and 1/8 bend fittingassembly.Options:-F Fusion Lock; -M Mechanical Seal; -S Stab Lock SealBLFCDimensions in Inches [mm]Model No.Nom.Pipe SizeReducer SizeABCFLZ9A-YRB-2 x 112Z9A-YRB-3 x 112Z9A-YRB-3 x 2Z9A-YRB-4 x 112Z9A-YRB-4 x 2Z9A-YRB-4 x 3Z9A-YRB-6 x 2Z9A-YRB-6 x 3Z9A-YRB-6 x 42 [51]3 [76]3 [76]4 [102]4 [102]4 [102]6 [152]6 [152]6 [152]2 x 1-1/2 [51 x 38]3 x 1-1/2 [76 x 38]3 x 2 [76 x 51]4 x 1-1/2 [102 x 38]4 x 2 [102 x 51]4 x 3 [102 x 76]6 x 2 [152 x 51]6 x 3 [152 x 76]6 x 4 [152 x 102]5-15/16 [135]7-23/32 [196]8-3/32 [206]9-1/16 [230]9-11/32 [237]10-15/16 [278]16-3/8 [416]17-1/32 [433]14-7/8 [378]4-1/2 [114]7-1/4 [184]7-1/4 [184]9-1/16 [230]9-1/16 [230]9-1/16 [230]11-1/8 [283]11-1/8 [283]11-1/8 [283]13/16 [21]1-5/8 [41]1-5/8 [41]1-7/8 [48]1-7/8 [48]1-7/8 [48]1-3/4 [44]1-3/4 [44]1-3/4 [44]8-15/16 [227]8-11/16 [221]8-15/16 [227]10-9/32 [261]10-1/2 [267]11-1/16 [281]15-7/8 [403]16-17/32 [419]14-3/8 [365]7-25/32 [198]12-27/32 [326]12-27/32 [326]14-15/16 [379]14-15/16 [379]14-15/16 [379]17-3/16 [437]17-3/16 [437]17-3/16 [437]Z9A-YY 45 DOUBLE WYEEngineering Specification:ASTM-F1412, F.R.P.P. - 210ZURN Z9A-YY 45 DOUBLE WYE – Flame-retardantpolypropylene double wye fitting assembly.Options:-F Fusion Lock; -M Mechanical Seal; -S Stab Lock SealBLE ACDimensions in Inches [mm]14Model No.Nom. Pipe 61-1/2 [38]2 [51]3 [76]4 [102]6 [152]3-1/8 [79]4-1/16 [103]6 [152]7 [178]11-1/8 [283]3-3/16 [81]4-1/2 [114]7-1/4 [184]9-1/16 [230]11-1/8 [283]21/32 [17]13/16 [21]1-5/8 [41]1-5/8 [41]1-3/4 [44]4-3/13

The Zurn Plumbing Products Group offers a century-old tradition of high-quality products and customer service. Zurn Industries was founded in 1900 in Erie, Pennsylvania. Created initially to manufacture a patented backwater valve, Zurn has worked faithfully throughout the past century to expand its product offering. Today, Zurn now manufactures