Transcription

SHEETMETALWORKING1. Cutting Operation2. Bending Operation3. Drawing4. Other Sheet-metal Forming5. Dies and Presses6. Sheet-metal Operation7. Bending of Tube Stock1

Introduction Cutting and forming thin sheets of metal usuallyperformed as cold working Sheet metal 0.4 (1/64) to 6 mm (1/4in) thick Plate stock 6 mm thick Advantage - High strength, good dimensionalaccuracy, good surface finish, economical massproduction (low cost). Cutting, bending, drawingε1γLocalized neckingθ 55 Because ν 0.5 in plasticity,ε1 -2ε2 -2ε3ε2ε3,ε22θ ε1ε2

Sheet Metalworking Terminology “Punch-and-die”– Tooling to perform cutting, bending, anddrawing “Stamping press”– Machine tool that performs most sheet metaloperations “Stampings”– Sheet metal products3

Sheet-metal Characteristics Elongation – the capability of the sheet metal tostretch without necking and failure. Yield-point elongation– Lüeder’s bands on Low-carbon steels and Al-Mg alloys.Lüder’s bands can be eliminated by cold-rolling thethickness by 0.5-1.5%.YupperYlower Anisotropy– Crystallographic and mechanical fibering anisotropy Grain Size effect on mechanical properties Residual Stress, Springback and Wrinkling Testing method– Cupping test– Forming Limit Diagram4

1. Cutting Operation Cutting operation– Plastic deformation– Penetration (1/3 thickness)– Fracture Shearing using a machine called powershear or square shear. Blanking – shearing a closed outlinepart(desired part called blank) Punching – sheared part is slag (or scrap)and remaining stock is a desired partpart5

Cutting OperationPunchtDiecRolloverBurnishFracture zoneBurr6

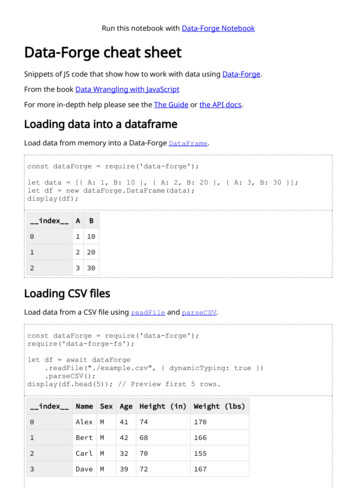

Analysis Clearance - 4-8% but sometime 1% of thickness– Too small – fracture does not occur requiring more force.– Too large – Get pinched and cause an excessive burr Clearance: c a*t– Metal group– 1100S and 5052S aluminum alloys, all tempers– 2024ST and 6061ST aluminum alloys;brass, soft cold rolled steel, soft stainless steel– Cold rolled steel, half hard; stainless steel,half hard and full harda0.0450.0600.0757

Die, blank and punch sizecDhDbcFor a round blank,Blank punch diameter Db-2cBlank die diameter DbFor a round hole,Hole punch diameter DhHole die diameter Dh 2cAngular clearance of 0.25o to 1.5oCutting forces: F S*t*L 0.7*TS*t*Lwhere S Shear strengtht thicknessL length of cutting edgeTS Ultimate tensile strengthAngular clearance8

Other Cutting Operations Cutoff and Partingpartpartpartscrap Slotting, Perforating and Notching Trimming, Shaving and Fine BlankingTrimmingShavingFine Blanking9

2. Bending Operations V-bending Edge Bending10

Other Bending Operation FlangingHemmingSeamingCurlingChannel,U-bendingAir bending,Offset bending,Corrugating andTube forming11

3. Drawing Basic drawing operation – a cup-shapepartFFhDpccFhDpDb12

Detail Steps of DrawingvFvFvFvFvvvFvFv1. Initial ContactFvv2. BendingFvFvvFv3. Straightening4. Friction &Compression5. Final Shape13

Analysis of Drawing Measure of DrawingDb– Drawing ratio: DR feasible if DR 2DpDb D p– Reduction: r feasible if r 0.5Db– Crude measures of the severity of a deepdrawing operation D F πDp t (TS ) b 0.7 Dp Drawing Forces:Max at 1/3 length2 2 Holding Force: Fh 0.015Yπ Db (Dp 2.2t 2Rd ) 14

Other Drawing Operation RedrawingDrawing without a BlankholderNot cylindrical cupsDefects–––––Wrinkling in the flangeWrinkling in the wallTearingEaring – Anistropy in sheet metalSurface scratch15

Forming-Limit Diagram A grid pattern of circles, typically 2.5 to 5mm in diameter,produced by electrochemical or photoprinting. After drawing, the circles are observed for failure. The major strain is on the major direction and magnitudeof strainMajor AxisMinor AxisMajor AxisMinor AxisMajor strain120FailureLow Carbon SteelHigh Strength Steel60SimpleTensionPureshear0-6080Al alloySafeEqualbiaxial0Minor strain8016

4. Other Sheet-Metal Operations With Metal Tooling– Ironing– Coining and Embossing– Lancing Using hydrostatic pressure– Guerin Process – Rubber pad– Hydroforming - Hydraulic fluid17

5. Dies and Presses Stamping Die– Punch– Die– StripperPunch HolderPunch Types– Simple– Compound– Progressive Press– Hydraulic– MechanicalStripperStrip stockGuide pindieDie holderPress baseBlank18

– Too small – fracture does not occur requiring more force. – Too large – Get pinched and cause an excessive burr Clearance: c a*t – Metal group a – 1100S and 5052S aluminum alloys, all tempers