Transcription

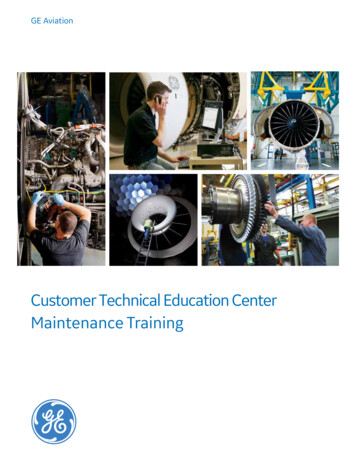

GE AviationCustomer Technical Education CenterMaintenance Training

TRAININGHistory of GEFrom the first turbosuperchargerto the world’s most powerfulcommercial jet engine, GE’shistory of powering aircraft spansnearly a century of innovation.GE Aviation is a world-leadingprovider of commercial and militaryjet engines and components as wellas integrated digital, electric power,and mechanical systems for aircraft.GE Aviation also has a global servicenetwork to support these offerings.Technological excellence, supportedby continued investments inresearch and development, hasbeen the foundation of GE Aviation’sgrowth and helps to ensure qualityproducts for customers well intothe future.Technology Innovation 2First U.S. Jet EngineFirst Turboprop EngineFirst Variable Stator EngineFirst Mach 2 EngineFirst High-Bypass Engine First Variable CycleTurbofan Engine First Unducted Fan Engine First 30:1 Pressure Ratio Engine GE90-115B World RecordSteady-State Thrust: 122,965 lbs

TRAININGTable of ContentsGE Customer Training Services 4Global Footprint 5ATA 104 Specifications 6Services Offered 7Course and Service Matrix 8GENX Courses 10GE90 Courses 12CF6 Courses 14CF34 Courses 16CFM56 and LEAP Courses 18CT7/T700 Courses 20F404/F414 Courses 22F110 Courses HF120 Courses M601/H80 Courses Powerplant Engineering Diagnostics GE Advanced Technology& Research Center Systems E-Learning/Digital Training Class Costs Innovative Global CustomerTraining Solutions 242627282930334142433

TRAININGGE CustomerTraining ServicesAt the Customer Technical Education Center, our visionand goals focus on fulfilling the training needs of eachcustomer by providing world-class training instructorsand facilities to ensure that the most current technicalinformation is available for each of our products. Westrive to quickly respond to training needs on time andas expected—all with the end goal of improving enginereliability through state-of-the-art maintenanceinstruction.Our promise is to continue to employ the most modernteaching methods using hands-on applications andinstructions on products and tooling while offering newand innovative digitized solutions to you —our customer.4

TRAININGGlobal FootprintCTECAEMTCGE ATRCThe Customer Technical EducationCenter (CTEC), located just outsideCincinnati, Ohio, provides technicaltraining to customer mechanics,powerplant engineers, GE employeesand other representatives on a dailybasis to help ensure fleet reliability.More than 4,000 customer studentspass through the doors of CTECeach year.The Aero Engine Maintenance TrainingCenter (AEMTC)—a cooperativetraining institute comprised ofChinese partners, Safran AircraftEngines, CFM International, and GEAviation—specializes in maintenancetraining for GE and CFM commercialaircraft engines.The GE Advanced Technology& Research Center (GE ATRC) islocated in Doha, Qatar, in the MiddleEast. This GE Aviation technicalcustomer training facility is part of theQatar Science & Technology Parkwithin Education City.CTEC employs a staff of world-classengine training experts who deliver notonly technical training, but also realworld application instructions for eachof the GE and CFM engine programs.CTEC also provides regular customertours of the training facility as partof its support for customers. Inaddition, monthly “Voice of theCustomer” lunches are held tobetter understand customertraining and technical needs.On-site classes are also availableto customers who desire a privatecourse for a large number oftheir mechanics.Since 1996, the center has trainedmore than 6,000 students fromairlines throughout Asia. Located onthe campus of the Civil AviationFlight University of China (CAFUC),AEMTC is a two-story buildingcontaining six classrooms and a shopwith six training engines. There arefour instructors who conducttraining classes for CFM56-3, CFM565B, CFM56-7B, and CF6-80C2 linemaintenance, borescope inspectionand advanced engine systems.AEMTC keeps close ties with theCFM training facilities at GE Aviation(CTEC) and Safran Aircraft Engines(CTC) by sharing the same trainingmaterials, quality controlmeasurements and instructor bestpractices. AEMTC also keeps closecontact with the GE/CFM FieldService team in China in order totailor special training and seminars toan airline’s requirements.The 13,400-square-meter(144,238-square-foot) facility includessix digital classrooms, as well as14 engine/tooling bays for the “handson” portion of the technical learningofferings. In addition, GE Oil & Gas,GE Healthcare and the GE GlobalResearch Center is located withinthe facility.The facility opened in 2010 andfeatures a full assortment of trainingon various engine models. Popularclass offerings such as LineMaintenance, Borescope andEngine Change are available toqualified customers.Additional facility highlights: 490 square meters (5,260 squarefeet) of lab space 150-seat auditorium 465-square-meter (5,000-squarefoot) product display lobby5

TRAININGATA 104 SpecificationsAll GE courses comply with ATA 104 Specifications.Level I General FamiliarizationPersonnel must be familiar with current equipmentand have a general knowledge of turbine-poweredtransport aircraft. Level I provides a brief overviewof the airframe, systems, and powerplant as outlinedin the Systems Description Section of the AircraftMaintenance Manual.Level II Ramp and TransitPersonnel must be familiar with turbine-poweredtransport aircraft, digital electronic equipment, andhave experience in ramp, transit and turnaroundactivity. Level II provides a basic system overview—a description of controls, indicators, and principalcomponents, including their locations and practicaltraining on servicing and minor troubleshooting.Level III Line and Base Maintenance TrainingIn addition to requirements for levels I and II, personnelattending level III training should possess the knowledgeand experience required to maintain turbine-poweredtransport aircraft. Level III provides a detailed description,operation, component location, removal/installation,BITE and troubleshooting procedures to maintenancemanual level.6Level IV Specialized TrainingPersonnel must have considerable experience in thefield in which training will be received. Level IV providesa detailed description, component location, in-depthtroubleshooting, adjustment, test procedures, rigging,engine run-up, in-depth use of wiring diagrams,schematics and engineering data. Entry level isdefined by subject matter.Level V Component Overhaul TrainingPersonnel must meet prerequisites established by thevendor. Specialized maintenance/overhaul training isconducted by airframe/engine/avionics manufacturersand/or their suppliers and/or airlines to a componentmaintenance manual level. Entry level is defined bysubject matter.

TRAININGServices OfferedGE Aviation’s Customer Training Services Team isconstantly studying flight data and adapting our classesto best suit our customers’ needs—your needs. Our teamis committed to providing quality training to our customersto help reduce maintenance errors and improve fleetreliability. That’s why we offer a complete curriculum oftechnical training courses on our products. Ourphilosophy is simple: Better maintenance practicesreduce operation disruptions. So it’s no surprise thatour courses are designed to simulate the environmentin which you work and the real-world problemsyou encounter.TranslationsAll classes and training material are presented inEnglish. Additional class time may be required if atranslator is needed; please discuss during classscheduling. Customers are responsible forsupplying their own translators.Mobile Training ProgramUnder this program, a CTEC instructor provides trainingand support beyond what is achievable in the classroomat the customer’s facility. This program is especiallybeneficial to customers introducing a new enginetype into their fleet, as a GE expert can work withtechnicians on the flight line, answering questions andproviding education on issues as they occur. Althoughthe Mobile Training Program is primarily focused on linemaintenance, CTEC instructors can also provide guidanceduring engine changes and certain repairs.Contact cts.scheduling@ae.ge.com for programavailability and specific offerings.Distance EducationDistance education allows customers to receive theacademic portions of a traditional instructor-led classwithout the expense of traveling to one of our trainingcenters or paying for an instructor to come to theirsite. Individual students can log into a standard onlinecollaborative meeting format and call into the class.They will receive the same information and have thesame level of participation as if they attended theclass in person.TroubleshootingThis two-day class will focus on the engine faultindications and troubleshooting logic using currentfleet data to highlight the issues customers see most.Dedicated Troubleshooting classes are available onmost engine lines. See course description for details.7

TRAININGCourse and Service /F108CFM56-3CFM56-7 LEAP-1ALEAP-1B CF34-3A1/3B B/J R/JCF34-8CCF34-8ECF34-10E CF6-80ECF6-80C2 PMCCF6-80C2 FADECCF6-80C2/K1F/L1F Engine Model(s) Flight LineTrouble-shootingBorescopefor InspectorsBorescopeBlade BlendEngine Removal& Installation GE90-115BGE90-94B GENX-1BGENX-2B GE Honda HF120 GE M601/H80 T700 CT7 F404/F414 F110 8

TRAININGCourse and Service MatrixDiagnostics/TrendInterpretationEngine Top CaseCFM56-2/F108CFM56-3CFM56-7 LEAP-1ALEAP-1B CF34-3A1/3B B/J R/JCF34-8CCF34-8ECF34-10E CF6-80ECF6-80C2 PMCCF6-80C2 FADECCF6-80C2/K1F/L1F Engine Model(s)Fan Stator Removal& InstallationEngine Fan Split GE90-115BGE90-94B GENX-1BGENX-2B IntermediateMaintenanceMinorRefurbishmentGE Honda HF120GE M601/H80T700CT7 F404/F414F1109

TRAININGGENX A culmination of more than 60 years ofinspired engine design, the GEnx turbofanengine refines the best technologies andsystems of our most successful familymembers, the GE90 and CF6 engines.Designed to power a new generation ofaircraft, the GEnx has evolved from a strongheritage of ingenuity, commitment anddedication to excellence. The engine of thefuture is here, ready to make its mark in ourproud legacy of aviation history.10

TRAININGGENX CoursesGEnx-1B/-2B General FamiliarizationGEnx-1B/-2B Borescope Blade Blend*This ATA 104 level I course is available on CD and is a prerequisite, to becompleted at the student’s home base, before attending Line Maintenance.This course is an academic training session designed for personnel whorequire a general knowledge of the basic engine construction features,airflows, engine systems and accessories.1 dayClass size: 4This ATA 104 level III course is an academic and practical training sessiondesigned for line maintenance technicians and supervisory personnel.Subject matters will include blade blend procedures, use of borescopeblend equipment and application of the maintenance manual for theGEnx series engine.Normal time to complete the CD GEnx General Familiarization Courseis approximately 4.0 hours.Prerequisite: Borescope Inspection Course or experience withborescope inspection.GEnx-1B/-2B Line Maintenance5 daysClass size: 6-12This ATA 104 level III course is an academic and practical trainingsession designed for line maintenance mechanics and supervisorypersonnel with glass cockpit, high-bypass engine and Englishlanguage experience.GEnx-1B/-2B Borescope for Inspectors1 dayClass size: 3-6This ATA 104 level III course is an academic and practical trainingsession designed for line or shop personnel responsible forborescoping the GEnx-1B engine.GEnx-1B/-2B Engine Removal & Installation2 daysClass size: 6-12This ATA 104 level IV course is an academic and practical trainingsession designed to provide the information necessary to removeand install a GEnx engine. The course also provides hands-on practicefor GEnx-1B engine removal and installation.GEnx-1B/-2B Fan Stator Removal & Installation3 daysClass size: 6-12This ATA 104 level III course is an academic and practical trainingsession designed for line or shop personnel. This class is only 13.0hours (2 days) when combined with the Line Maintenance Coursedue to courseware overlap.* This course must be purchased at the current training rate, or training entitlements may be used at a three times (3X) rate if trainingentitlements are available to the customer.11

TRAININGGE90 GE90 General FamiliarizationAdvanced, reliable and efficient, theThis ATA 104 level I course is available on CD and is a prerequisite,to be completed at the student’s home base, before attendingLine Maintenance. This course is an academic training session, designedfor personnel who require a general knowledge of the basic engineconstruction features, airflows, engine systems and accessories.GE90 is the most powerful commercialNormal time to complete the CD GE90 General Familiarization Courseis approximately 4.0 hours.jet engine in the world—holding theAvailable for GE90-94B and GE90-115B engine models.records for steady-state thrust andGE90 Line Maintenancefor powering the longest non-stop5 daysClass size: 6-12This ATA 104 level III course is an academic and practical training session,designed for line maintenance mechanics and supervisory personnelwith glass cockpit, high-bypass engine and English language experience.Course length can be adjusted for personnel who do not meet theserequirements.commercial flight in history. With highlydeveloped propulsion technologyinfused in every feature

maintenance, borescope inspection and advanced engine systems. AEMTC keeps close ties with the CFM training facilities at GE Aviation (CTEC) and Safran Aircraft Engines (CTC) by sharing the same training materials, quality control measurements and instructor best practices. AEMTC also keeps close contact with the GE/CFM Field