Transcription

DYLAN MECHANICAL CONSTRUCTIONSERVICES, INCHVAC COMMISSIONINGCHECKLISTSBT COLLINS HIGH TECH RTS, SACRAMENTO, CAHarold Cullick PEMay 24, 2010

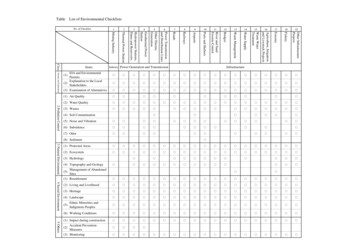

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010TABLE OF CONTENTSHVAC PRE COMMISSIONING CHECKLISTSPageChilled Water Piping System3Hot Water Piping System4Refrigerant Piping System5Ductwork Air Handling Unit #16Variable Air Volume Air Handling Unit #17Variable Air Volume Units9-30Air Cooled Condensing Unit and DX Fan Coil31Pumps32-37Packaged Air Cooled Chiller38Hot Water Boiler39-40Demarc Room Vent Fan41Exhaust Fan Restroom Exhaust42HVAC System Controls43HVAC FUNCTIONAL PERFORMANCE TEST COMMISSIONING PumpsVariable Air Volume UnitsVariable Air Volume Air Handling Unit #1Packaged Air Cooled ChillerAir Cooled Condensing Unit and DX Fan CoilHot Water BoilerHVAC System ControlsBT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning checklist – PipingFor Chilled Water Piping SystemChecklist ItemQA QC CAInstallationa. Piping complete.b. As-built shop drawings submitted.c. Piping flushed and cleaned.d. Strainers cleaned.e. Valves installed as required.f. Piping insulated as required.g. Thermometers and gauges installed as required.h. Verify operation of valves.i. Air vents installed as specified.j. Flexible connectors installed as specifiedk. Verify that piping has been labeled and valves identified as specified.Testing, Adjusting, and Balancing (TAB)b. TAB operation complete.Page3a. Hydrostatic test complete.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning checklist – PipingFor Hot Water Piping SystemChecklist ItemQA QC CAInstallationa. Piping complete.b. As-built shop drawings submitted.c. Piping flushed and cleaned.d. Strainers cleaned.e. Valves installed as required.f. Piping insulated as required.g. Thermometers and gauges installed as required.h. Verify operation of valves.i. Air vents installed as specified.j. Flexible connectors installed as specifiedk. Verify that piping has been labeled and valves identified as specified.Testing, Adjusting, and Balancing (TAB)b. TAB operation complete.Page4a. Hydrostatic test complete.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning checklist – PipingFor Refrigerant Piping SystemChecklist ItemQA QC CAInstallationa. Piping complete.b. As-built shop drawings submitted.c. Piping flushed and cleaned.d. Strainers cleaned.e. Valves installed as required.f. Piping insulated as required.g. Thermometers and gauges installed as required.h. Verify operation of valves.i. Air vents installed as specified.j. Flexible connectors installed as specifiedk. Verify that piping has been labeled and valves identified as specified.Testing, Adjusting, and Balancing (TAB)b. TAB operation complete.Page5a. Hydrostatic test complete.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist – DuctworkFor Air Handler: AHU #1Checklist ItemInstallationQAQCCAa. Ductwork complete.b. As-built shop drawings submitted.c. Ductwork leak test complete.d. Fire dampers, smoke dampers, andaccess doors installed as required.e. Ductwork insulated as required.f. Thermometers and gauges installed as required.g. Verify open/closed status of dampers.h. Verify smoke dampers operation.i. Flexible connectors installed as specifiedTesting, Adjusting, and Balancing (TAB)Page6a. TAB operation complete.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VariableVolume Air Handling UnitFor Air Handling Unit: AHU #1Checklist ItemQA QC CAInstallationa. Vibration isolation devices installed.b. Inspection and access doors are operable and sealed.c. Casing undamaged.d. Insulation undamaged.e. Condensate drainage is unobstructed.(Visually verify drainage by pouring acup of water into drain pan.)f. Fan belt adjusted.g. Manufacturer's required maintenance clearance provided.Electricala. Power available to unit disconnect.b. Power available to unit control panel.c. Proper motor rotation verified.d. Verify that power disconnect is locatedwithin sight of the unit it controls.e. Power available to humidifier.Coilsa. Chilled water piping properly connected.b. Chilled water piping pressure tested.c. Hot water piping properly connected.d. Hot water piping pressure tested.e. Air vents installed on water coils withshutoff valves as specified.f. Any damage to coil fins has been repaired.BT Collins High Tech RTS, Sacramento, CAPagea. Controls operable.b. Power connected and rotation check.7Heat Recovery Unit

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010c. Bypass dampers operable.Controlsa. Control valves/actuators properly installed.b. Control valves/actuators operable.c. Dampers/actuators properly installed.d. Dampers/actuators operable.e. Verify proper location, installation andcalibration of duct static pressure sensor.f. Fan air volume controller operable.g. Air handler controls system operational.Testing, Adjusting, and Balancing (TAB)Page8a. Construction filters removed and replaced.b. TAB report submitted.c. TAB results within 10%/-0% of L/scfm shown on drawingsd. TAB results for outside air intake within 10%/-0% of both the minimum and maximumL/s cfms shown on drawings.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 1Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)a. Verify terminal maximum air flow set.b. Verify terminal minimum air flow set.c. TAB operation completeFor VAV Terminal: 2BT Collins High Tech RTS, Sacramento, CAPage9Pre-commissioning Checklist - VAV Terminal

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page10a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 3Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page11a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 4Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page12a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 5Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page13a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 6Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page14a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 7Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page15a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 8Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page16a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 9Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page17a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 10Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page18a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 11Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page19a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 12Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page20a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 13Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page21a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 14Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page22a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 15Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page23a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 16Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page24a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 17Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page25a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 18Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page26a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 19Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page27a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 20Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page28a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 21Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VAV terminal controls set.b. Reheat terminal/coil controls verified.Testing, Adjusting, and Balancing (TAB)b. Verify terminal minimum air flow set.c. TAB operation complete.Page29a. Verify terminal maximum air flow set.BT Collins High Tech RTS, Sacramento, CA

Dylan Mechanical Construction Services, IncCommission Agent: Harold Cullick, PEMay 24, 2010Pre-commissioning Checklist - VAV TerminalFor VAV Terminal: 22Checklist ItemQA QC CAInstallationa. VAV terminal in place.b. VAV terminal ducted.c. VAV terminal connected to controls.d. Reheat coil connected to hot water pipe.e. Manufacturer's required maintenanceclearance provided.Controlsa. Reheat VA

HVAC System Controls 64-65 . Dylan Mechanical Construction Services, Inc Commission Agent: Harold Cullick, PE May 24, 2010 BT Collins High Tech RTS, Sacramento, CA Page 3 Pre-commissioning checklist