Transcription

QualityManagementSystem (QMS)CertificationUnderstanding Medical Device QMSCertificationMedical device manufacturing is one of the most regulated sectors in which significant qualitysystems and product requirements must be satisfied. The regulatory requirements are intended toensure that manufacturers consistently design, produce and place onto the market medical devicesthat are safe and fit for their intended purpose.“Successfully certified organizations are able to demonstrate the effectiveinterconnectivity of their processes. It is essential to be able to demonstrate howoutputs from complaints, for example, feed into management review, improvementprocesses, Technical Documentation and risk management updates, to name a few.”Teresa PerryGlobal Quality and Accreditation Manager – Medical Devices.making excellence a habit.

Introduction to a medical device QMSThe ISO 13485 standard is an effective solution to meet the comprehensive requirementsfor a QMS. Adopting ISO 13485 provides a practical foundation for manufacturers toaddress the regulations and responsibilities as well as demonstrating a commitment tothe safety and quality of medical devices.What is ISO 13485?BSI's approach to excellenceISO 13485 is a stand-alone QMS standard, derived from theinternationally recognized and accepted ISO 9000 qualitymanagement standard series. ISO 13485 adapts the previousversion of ISO 9001, ISO 9000:2008 process-based model for aregulated medical device manufacturing environment. While ISO13485 is based on the ISO 9001 process model concepts of Plan,Do, Check, Act, it is designed for regulatory compliance; thereforeit is more prescriptive in nature and requires a more thoroughlydocumented QMS.BSI selects and recruits professionals to conduct ISO 13485audits. Candidates must have design, manufacturing or processknowledge in addition to general knowledge on use of medicaldevices. Our assessment staff come to BSI with exceptional realindustry experience. They then go through rigorous internaltraining and BSI qualification processes including best practicequality systems auditing techniques, understanding criticalmanufacturing processes and interpretation of regulatorycompliance expectations.ISO 13485 was written to support medical devicemanufacturers in designing a QMS that establishes andmaintains the effectiveness of their processes. It ensures theconsistent design, development, production, installation anddelivery through to disposal of medical devices that are safefor their intended purpose.BSI auditors are experts in current state-of-the-art and areconstantly trained on new requirements and future changes.BSI is always looking ahead to ensure that our clients areprepared and well placed for future changes to compliance andthe regulatory landscape“As I look over the 20 years that 3M Unitekand BSI have worked together, it has beena very satisfying part of my career. Theprofessional and collegial atmosphereBSI brings to these audits stronglyencourages us to want to continuallyimprove our quality managementsystem. Please convey my greatappreciation to you and yourcolleagues for this.”Jerry Horn, PhDManager, Quality and Regulatory3M Orthodontic ProductsCall us now on 44 345 080 90002

A medical device manufacturer’s quality management system is the foundation formaintaining regulatory compliance, driving improvement and effectiveness, andachieving stakeholder confidence in the manufacturer and their products.High performing organizations expect ISO 13485 auditingto be thorough, competent, relevant and challenging of themanufacturers' QMS. Effective auditing provides significantbenefits for the manufacturer.The beneficial outputs of an effective audit include: Meaningful feedback on the effectiveness of the qualitymanagement system Confidence in compliance with regulationsIdentification of areas requiring attentionDetection of areas of non-compliance and riskReporting and certification that is valuable and recognizedRisk Management ISO 14971Risk management is a key component and requirement forISO 13485 certification. ISO 14971 is a risk management systemstandard, which was designed to be compatible with ISO 13485.It helps manufacturers meet the increasing global requirementsand expectations to implement not only quality, but full riskmanagement systems throughout the entire life cycle of themedical devices they manufacture.ISO 14971 satisfies the risk management requirement forIEC 60601-1 for medical electrical equipment and systems. It isa helpful tool for manufacturers in identifying and controllingthe risks associated with their medical devices, but alsoevaluating interactions with other devices. Increasingly,ISO 14971, in the footsteps of ISO 13485, is becoming aninternational requirement for medical device manufacturersto meet regulatory expectations globally.Medical Device Single Audit ProgramThe Medical Device Single Audit Program (MDSAP) allows asingle audit of a medical device manufacturer's QMS whichsatisfies the requirements of multiple regulatory jurisdictions.Audits are conducted by Auditing Organizations (AO), such asBSI, authorized by the participating Regulatory Authorities (RA)to audit under MDSAP requirements.MDSAP is a way that medical device manufacturers can beaudited once for compliance with the standard and regulatoryrequirements of up to five different medical device markets:Australia, Brazil, Canada, Japan and the United States.A BSI MDSAP Audit can also be combined with assessment forCE and ISO 13485.MDSAP audits can be performed by a recognized MDSAP AO,such as BSI, which has performed MDSAP audits worldwideand issued a significant number of global sites with MDSAPcertifications; we are currently processing many more.bsigroup.com/mdsapVisit bsigroup.com/medical3

The importance of ISO 13485ISO 13485 is important to designers, manufacturers, anddistributors of medical devices. In addition, suppliersand service providers can enhance an organization'smarketability as more and more manufacturers requirecertification in order to do business with a vendor.with a higher level of confidence in the ability to consistentlyachieve and maintain compliance with regulatoryrequirements. It can also help to minimize surprises andfailures which might adversely affect patient safety anddamage a manufacturer's reputation.When it comes to medical device manufacturing, patientsafety greatly depends on the quality and consistencyof medical products, and ensuring effectiveness, controland maintenance of your QMS is critical to customers,stakeholders, patients and users, and regulatory agencies.The value of ISO 13485 is not just in the implementation,but also in providing a tool for a thorough audit to test theeffectiveness of the system. It provides the manufacturerWhen it comes to medical device manufacturing, patient safety greatlydepends on the quality and consistency of medical products.ISO 13485 and CE markingISO 13485 is the best internationally-accepted modela medical device organization can implement to helpdemonstrate compliance to laws and regulations ofthe medical device industry. ISO 13485 is the qualitymanagement system standard accepted as the basis forCE marking medical devices under European Directivesand Regulations.Although ISO 13485 certification is not mandatory forCE marking medical devices under the European MedicalDevice Directives (AIMDD, MDD, IVDD), it is harmonized,which allows the presumption of conformity to theDirectives.ISO 13485 is also not mandatory for CE marking underthe European Medical Device Regulations (MDR, IVDR).Although there are currently no standards harmonized tothe Regulations, ISO 13485:2016 remains a state-of-theart document. BSI, as one of the leading Notified Bodiesfor CE marking, can verify medical device manufacturers’selection of the most efficient conformity assessmentroutes to achieve CE marking.Where to find moreinformationBSI has developed a suite ofmaterials, including webinars,whitepapers and training coursesto help you understand ISO 13485.bsigroup.com/ISO-13485Call us now on 44 345 080 90004

Your path to certificationBSI provides a full range of services to support your path to certification. BSI's businessdevelopment team can help you and your organization fully understand the ISO 13485certification process and its available guidelines. We provide training courses that cansupport you in developing you develop a thorough understanding of the complexities ofcomplying with the standard, as well as the laws and regulations the standard helpsto address.Once a medical device QMS has been developed andimplemented, a BSI Client Manager can conduct a rigorousassessment of the system against the requirements. Uponsatisfactory completion, BSI will issue a certificate to thestandard, which you can then use to promote your businessand accredited products, providing globally-recognizedevidence of your company's commitment to quality systemsand maintaining patient safety.Key activities for ISO 13485Get top management involvedTop management involvement is a requirement for ISO 13485.Involvement must be demonstrated by providing evidenceof its commitment to the standard by determining customerrequirements, establishing a quality policy, and ensuringrelevant, useful, and measurable objectives. Top managementneeds to focus on responsibility, representation, communication,and review of medical devices.The third revision of ISO 13485 doesNOT align with the revised structure ofISO 9001:2015. For those medical devicemanufacturers who hold dual certification,you will need to be aware and plan yourinternal procedures to take into account thedifferences.Inputs such as the following could be considered: Regulatory requirementsInternational or national standardsCustomer product or service requirements including:-usability requirementscustomer complaintsfeedbackbenchmarkingmarket trends, statistics and forecast informationExamples of activities to process these inputs include: Design and development processRisk managementManagement reviewComplaint investigationsCorrective action or preventive actionAdopt the process modelAs an output, your organization can consider such things asdecisions and actions related to:Rather than focusing on each individual clause of the standard,read the requirements in terms of inputs and outputs. ISO13485 uses the Plan, Do, Check, Act methodology; each keyarea of the standard, such as quality system, managementresponsibility, resource management, product realization,and measurement, must be read in terms of inputs to therequirement (i.e. resource requirements) and outputs to therequirement (i.e. measurements). Only through careful studyand understanding of the process model can you achieve thiseffective thinking approach. Design and development of new productExisting product redesignNew or revised labellingAdvisory notices or other actionsRisk management reports/filesImprovementQuality planningPolicy, process or procedure revisionVisit bsigroup.com/medical5

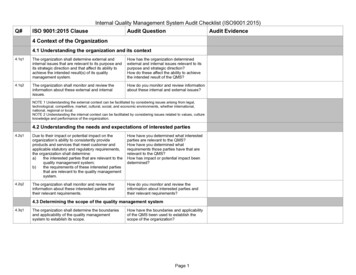

Conducting an internal auditWhen an organization adopts ISO 13485, it commits to establishing, documenting,implementing, and maintaining a QMS, which includes a commitment to an effectiveinternal audit program. There are four steps to conducting a complete and effectiveinternal audit.PlanPlanning is an important component to the ISO 13485standard. Organizations must consider product realization,ISO 13485 in its entirety, and QMS requirements establishedby the organization. This is in addition to all of the activitiesrelated to the product, such as planning of the product,customer requirements, design, purchasing, production,storage, and measuring, and any additional requirements.DoConducting internal audits is one of the biggest areas of nonconformity seen in support of the ongoing process over time.As costs rise and enthusiasm for an effective system fades,organizations begin to falter. However, in order to maintainan effective quality management system, an organizationmust press on and conduct its internal audit plan.13ISO485 Management SystemSupport evaluationCheckImprovementCheckOnce an internal audit is conducted, the results are reported, andactions to correct deficiencies must be processed immediately.Any causes for non-conformities must be eliminated.Questions to consider are: Have deficiencies been corrected?Were they corrected effectively and in a timely manner?Were the causes well understood and eliminated?Were there any trends noted in the process or inthe product?ActThe final step in conducting an effective internal auditfocuses on understanding and measuring the effectivenessof the actions taken, and understanding and measuring theeffectiveness of the internal audit process.Questions to consider here are: Do we need more people?Do we have the right people?Are the people trained effectively?Are we seeing and understanding the right areas of theorganization to detect the issues and corrections that willmake our devices safer and prevent defects from gettingon the market?Call us now on 44 345 080 90006

ISO 13485 training coursesISO 13485 Clause by ClauseThis course has been designed to provide an in depthunderstanding of ISO 13485. On completion participants willbe able to apply knowledge of the ISO 13485 standard to thedevelopment an ISO 13485 compliant quality managementsystem and to maintain on going certification of theirorganization.Course duration: 2 daysImplementing ISO 13485 Medical DevicesBSI’s Implementing ISO 13485 course provides you with theknowledge and process steps to effectively implement aQuality Management System in line with the requirements forISO 13485 certification. The course introduces the conceptsneeded to understand, develop, and implement a qualitymanagement system.Course duration: 2 daysInternal Auditor ISO 13485 Medical DevicesBSI’s Internal Auditor ISO 13485 course is intended for medicaldevice quality professionals aiming to build on their currentknowledge of ISO 13485 and evaluate the effectiveness of thequality management system in their organization. This intensivecourse teaches the principles and practices of effective qualitymanagement systems process audits in accordance withthe ISO 13485 and ISO 19011 “Guidelines for Quality and/orEnvironmental Management Systems Auditing.” The tutor guidesstudents through the internal audit process, from planningan audit to reporting on audit results and following up oncorrective actions.Course duration: 2 daysISO 13485:2016 TransitionThis comprehensive course introduces you to the newrequirements and explores the changes between ISO13485:2003/EN ISO 13485:2012 and the latest standard.With greater attention on the organization’s ability to meetapplicable customer and regulatory requirements, ISO13485:2016 focuses on the entire supply chain of the medicaldevice industry, with added emphasis on risk management.You’ll be able to identify the gaps in your current QualityManagement System (QMS) and start planning your transitionand certification to comply with ISO 13485:2016.Course duration: half day.ISO 13485:2016 Auditor RefresherAre you an existing auditor with knowledge of ISO 13485wishing to update your audit programme in line with ISO13485:2016? This course will refresh your auditingtechniques and help you prepare to audit againstrequirements.With a transition period of 3 years, it’s important to get upto speed so you can ensure your organization is ready tocomply with new requirements. Through audit scenarios,you’ll identify opportunities for improvement and build onyour reporting skills.Course duration: half day.To book your course visit:bsigroup.com/trainingor call us on: 44 345 086 9000Lead Auditor ISO 13485 Medical DevicesBSI’s Lead Auditor ISO 13485 course teaches the principles andpractices of effective quality management systems and processaudits in accordance with ISO 13485 and ISO 19011. Tutorsguide students through the entire audit process, from managingan audit programme to reporting on audit results.Course duration: 5 daysVisit bsigroup.com/medical7

Five reasons to make BSI your Notified BodyExperience and product expertiseGlobal market accessThe benefits of having experienced, professional and wellqualified technical specialists cannot be overstated in thecomplex and ever-changing medical device industry. BSIMedical Devices has a team of over 700; within that team areour technical experts with experience encompassing the fullrange of medical devices and management system standards.BSI Group is a global network of over:We are a global organization, trusted and recognized around theworld. BSI has two Notified Bodies, one in the UK (0086) andone in the Netherlands (2797), both of which have full scopedesignations to the IVDR and MDR.supported by5,000peoplein more than12,000industry experts193countriesFocus on serviceClients work with us because we understand the challengesmedical device manufacturers face in bringing compliantproducts to market efficiently and safely. We offer a range offlexible product review services providing you with efficientStandardDedicatedOnsitepathways to bring your product to fidence and robust reviewsOur comprehensive review process combined with our worldleading experience as a Notified Body will ensure that yourconformity assessment process is both efficient and robust.Passion for patient safetyOur mission is to ensure patient safety while supporting timelyaccess to global medical device technology. We strive to setthe global standard in thorough, responsive, robust conformityassessments, evaluations and certifications.OnsiteHow can BSI support your product launch?Be preparedCertification support and additional servicesIn the competitive medical device marketplace, ensuring thatproduct development meets all regulatory requirements isessential. We provide guidance and training to support youthrough the application process.We offer continual support throughout the certification processand beyond; we also offer:products, as well as online guidance documents expert training delivered online or face-to-face, either in-Worldwide accesshouse or through our public training coursesSeamless transfer to BSIWe can offer a seamless service with comprehensive supportand the absolute minimum level of disruption.industry changes, helping you to plan for the future webinars delivered by our experts on complex regulatoryissues comprehensive whitepapers providing the latest insightson key industry topicsTalk to our experts todayCall: 44 345 080 9000Visit: bsigroup.com/medicalBSI Notified Body (0086)Kitemark Court, Davy AvenueKnowlhillMilton Keynes MK5 8PPUnited KingdomBSI Netherlands Notified Body (2797)Say BuildingJohn M. Keynesplein 91066 EP AmsterdamThe NetherlandsT:7 44 345 080 9000E:7 eu.medicaldevices@bsigroup.comT: 31 20 346 0780E: eu.medicaldevices@bsigroup.comThe trademarks in this material (for example the BSI logoor the word “KITEMARK”) are registered and unregisteredtrademarks owned by the British Standards Institution inUnited Kingdom and certain other countries throughoutthe world.BSI/UK/084/MD/0920/en/BLDWe are a recognized Certification Body in Hong Kong,Japan, Malaysia, Singapore and Taiwan, and a recognizedMDSAP Auditing Organization for all participatingRegulatory Authorities. regulatory updates and a newsletter service focusing onCopyright 2020, The British Standards Institution. All rights reserved.We offer a wide range of proven regulatory and qualitymanagement programs that work together for fullinternational compliance. Our Quality Management System(QMS) solutions include ISO 13485, ISO 9001, ISO 14001and many more.bsigroup.com access to more than 34,000 standards and related

The ISO 13485 standard is an effective solution to meet the comprehensive requirements . 3M Orthodontic Products 2. High performing organizations expect ISO 13485 auditing to be thorough, competent, relevant and challenging of the . BSI will issue a certificate to the