Transcription

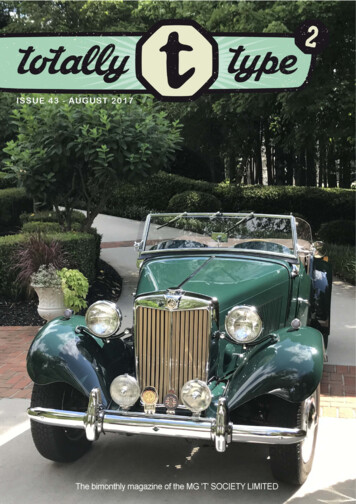

THE EDITORJohn JamesWelcome to Issue 43, August 2017!“Volvo calls time on combustion engine withpledge to electrify all cars by 2019.” was theheadline in a recent Financial Times (Businesssection) issue. Coming as it does on the back ofthe editorial in the June TTT 2, it’s all getting a bitscary. There seems to be a headlong rush toswitch (sorry, couldn’t think of another word!) toelectric vehicles and none of the manufacturersappear to want to be left behind.Volvo is owned by Geely, the Chinese carmaker,so it is not hard to see where the impetus iscoming from as China is already the world leaderin pure-electric vehicles with a reported 265,000sold in its home market last year. It has beensuggested that the Volvo agenda may putpressure on Tesla, the US electric start-up, whosemarket capitalisation has soared ionalism about newspaper headlines, forwhen you read the above article, it states that after2019 there will still be Volvo cars made with asmall petrol engine with a large battery. Butchange is definitely coming with Jaguar saying thatits all-electric five-seater sports car, the I-Pace, isto go on sale next year and Audi and MercedesBenz vowing to begin selling electrics from 2019.The copy for the road books is shortly being sentto Hagerty International Classic Car Insurance andI must thank this company and NTG MotorServices, who have sponsored the road books andthe rally plates for this tour and for the last four.We really do value their support.Looking ahead to 2018, the MG Octagon Car Club‘Founders Weekend’ is being held over theweekend of the 11th to 13th May in the Peak Districtof Derbyshire. Full details are given in the JulyBulletin.The sixth Totally T-Type 2 Tour is being held overthe weekend of the 17th to 19th August in theCotswolds. Full details will be given in the editorialof the next issue. Additionally, for those attendingthis year’s tour, I have obtained 50 copies of thehotel brochure which I will distribute, along with anaide-memoire detailing the booking arrangements.In the ‘Suck, Squeeze, Bang and Blow’ article,published in the last issue, the term “MicroPinking” was incorrectly attributed to JohnSaunders. It should have been attributed to ChrisMorgans. Apologies are due to John.Back in May I met up with Steve Poteet from SouthCarolina and his son, James. Through the goodoffices of Pete Neal, the MGCC Archivist, we spentthe best part of a day in Abingdon, including lunchat the Boundary House.Is it too much to hope that the price of petrol willplummet as the world will be awash with the stuff?I hardly think so!The arrangements for the 5th Totally T-Type 2 Tour(Tour of West Sussex and East Hampshire) whichis being held from the 18th to 20th August are bangon schedule with the rally plates now prepared,courtesy of the combined efforts of Peter Cole inhis ‘Bognor Regis design studio’ and BrianRainbow in his ‘Harbury workshop’.Steve’s 1953 TD (TD27602) is on the front coverand he also sent me this picture.It looks as though we are going to have a recordentry of around 50 cars with guests from Australiaand France joining us.Steve purchased the car from Ed Seagrave in2000. Steve was working with Ed on a completerestoration of the TD and one day he asked whatEd’s plans were for the finished car. Ed said thathe would probably sell it, so Steve bought it.Unfortunately, a year after Steve and Ed hadcompleted the car Ed passed away. So, the car isvery important to Steve.He also has a TC under restoration.

Interleaf Pads on TD/TF(and Y) Rear SpringsAt the suggestion of Barrie Jones, MGCC TRegister Technical Specialist for the TD and TFmodels, I have had some of these interleaf padsmade from Nylatron.The Service Parts List for the TF Midget lists theseas:Nylatron is said to have high mechanical strength,stiffness, hardness and toughness, good fatigueresistance, high mechanical damping ability, goodsliding properties and excellent wear resistance.The cost is 2.07 per pad, which is less expensivethan commercially available rubber pads and theyshould last a lot longer!Rubber pad – interleaf ACG5232Twenty four (24) are required.As far as I know, this part number is common tothe TD and Y-type.As can be seen from the illustration in the YBWorkshop Manual (the TD/TF manual has thesame illustration) the pads were originally square,but the caption to the illustration pointed out thaton some models the leaf rubber pad is circular andnot square in shape as shown.The picture below shows the 4th leaf down (the onewith the clip) from an original TF spring and youcan see that the pad is part circular but withsquared off ends.Although the Parts List specifies the quantity as24, some people only order 20 because, as can beseen from the picture of the 4th leaf down, the holein this leaf cannot be drilled right through,otherwise it wouldn’t be possible to attach the clip.I don’t know what was done originally (I suspectnothing) but there should be enough of a recess tofit an interleaf pad which has had its ‘nipple’shortened.I am aware that these pads are also fitted to therear springs of MG ZA/ZB and no doubt theWolseley 4/44.JOHN JAMES jj(at)ttypes.org {Please substitute @for (at)}. 85, Bath Road, Keynsham, BRISTOLBS31 1SR.DISCLAIMER BY THE EDITORThe following picture shows (a) how the rubberpads can wear and distort and (b) shows the holesdrilled in each leaf to accept the pads (the secondand third leafs are missing their pads).‘Totally T-Type 2’ is produced totally on avoluntary basis and is available on the websitewww.ttypes.org on a totally FREE basis. Itsprimary purpose is to help T-Type ownersthrough articles of a technical nature and pointthem in the direction of recommended serviceand spares suppliers.Articles are published in good faith but neither Inor the authors can accept responsibility orlegal liability and in respect of contents, liabilityis expressly disclaimed.Before doing anything that could affect thesafety of your car seek professional advice.JOHN JAMES, EDITOR TTT 24

SUPPLY OF T-TYPE ASH FRAMES(INCLUDING TIMBER PARTS)If you want a complete ash frame, or just a fewtimbers if you are keeping your original frame andyou need to replace some rotted sections of it,there is plenty of choice of suppliers.MOSS, NTG, Andy King (who has bought thestock and machinery from Rique Llinares – nowretired), the Hutson Motor Company, Steve Gilbert(for a panelled body), will all be pleased to supplyyou.I have recently received the following from AndyDenton, who served a five-year apprenticeship asa pattern maker.“I started making Ash frames and parts in 1988when I became an apprentice at Holroyd & HallPattern Makers in Clayton, Bradford, under thetuition of Mr Philip Robinson. He had taught myfather pattern making when he went there 33 yearsprevious. However, I didn't go to work for my fatheras he wanted me to be taught by Mr Robinson,who would ensure that I would learn the tradecorrectly. Philip didn't retire until I had completedmy apprenticeship.Holroyd & Hall supplied ash parts to Moss, NaylorBros and Hutson Motor Company. Sadly, whenNaylor Brothers got into difficulties over the NaylorTF1700 it affected Holroyd & Hall. Hutsons boughtNaylor Cars but soon realised that the brains of theoperation were at Holroyd & Hall, so PhilipRobinson was bought out and we became part ofthe Hutson Motor Co.At 22 I left Hutsons for a change of career but Ikept my hand in at pattern making by doing jobs atmy father’s pattern shop. Philip Robinson wentthere for a short time, to bring the standard ofpattern making back up to how it should be.In 2001 my father retired and Airedale Pattern Coshut down. I would still see Philip Robinsonregularly as he had started building a 1955 TFfrom scratch; new chassis, bulkhead, everythingmade brand new.I spoke with Philip a couple of years ago aboutstarting with the T-Types again, but at 85 he saidhe was too old. However, he said that he wouldhelp me in whatever way he could. So, over thelast 18 months I have set up a full working PatternShop; we have re-done all the drawings,templates, all the jigs and tooling has been madeand from next month the adverts will be in the MGOwners Club magazine.I intend to make replacement chassis andbulkheads in the future, all the tooling has beendone for the 54/55 TF - just the other models totool up for.”Andy sent me the following examples of his work:Andy’s address is:57 Main Road,Drax,SELBYNorthYorkshire,YO8 8NTTel: 01757 617455Totally T-Type 2, August 2017 5

Mention was made in the last issue of a rebuilt TFgearbox by Classic & Sports Cars Essex.This family run business has been established formany years, and over that time has built up anexcellent reputation for high quality service.The technicians are headed by father and sonteam, Michael and Jason Waller, who have awealth of experience in the motor industry.Before opening their premises in Essex, they ran ahistoric Formula One team and regularly took partin the Cam-Am championships .winning a fewalong the way.That’s better!As will be seen from their website, this companyhas experience on a wide selection of marquesand focusses on servicing, restoration andbespoke finishing work. Customers are welcome tovisit the workshop to view progress throughout allstages of their project.Jason Waller sent me a selection of photographsof work done on T-Types and I’ve reproducedsome of these for readers of TTT 2.That’s even better!Not untypical of how some arrive.Horrible mess!6All ship-shape and Bristol fashion!

Pictures below show T-Types in various stagesof construction (TC, TD {frame}, TD & TF1500).Pictures below show carb side of XPAGengine, TC9935, TF8576 and TC3984.Totally T-Type 2, August 2017 7

XPAG COOLINGEric Worpe delivered another of his superbtechnical presentations to the attendees at theMGCC T Register’s ‘Rebuild’ seminar back inthe Spring. I’m most grateful to Eric for takingtime to write up his presentation and for takingphotographs of those wonderfully explicitdrawings of his which help to make the subjectmatter ‘live’.It’s probably as well that we choose not to agoniseabout the lack of efficiency of an internalcombustion engine as we strive to improve theperformance of our T-Types. The realisation thatsome 75% of the fuel’s energy is wasted as lostheat would be quite dispiriting.By way of an example, even running the engine atits greatest efficiency (coinciding with its peaktorque output at around 2,800 rpm) which gives auseful power output of about 34 BHP, theequivalent of 100 BHP is generated as heat; some50 BHP through the exhaust and 50 BHP throughcooling. That’s sufficient energy to enable one tomake a cup of tea every second.heat expands the incoming air and thus reducesthe density of air available for combustion. Drivingon cold mornings usually generates a muchbroader grin, not so much from clenched teeth dueto the cold, but from the enhanced performance ofthe engine. At the same time, heat from theexhaust ports and valves also needs to beremoved, so most of the coolant flow is directedthrough the cylinder head.Engines can be subject to external temperaturesranging from -10 to 40 degrees centigrade andhave to cope with widely varying engine loads fromidling to full power. Trying to maintain a suitablystable engine temperature, despite such diverseoperating conditions, has resulted in someingenious ideas from temperature controlledradiator grill slats to the ubiquitous thermostat.The skirted thermostat in the XPAG is quitesophisticated, compared with everything else,Figure, 1.Internal combustion engines burn fuel attemperatures that can melt cast iron, which ratherfocuses the mind on finding ways to dissipatewaste heat. Removing high levels of heat from aconcentrated source would need massive coolingfins radiating out from the cylinder head if direct aircooling were to be used, plus a generous flow ofcool air. Not a problem with a propeller stuck infront of an aircraft engine.The alternative is to use a high specific heatcapacity liquid to remove heat from the confinedsource and then dump the heat in an efficientlydesigned device for dissipating heat into an airstream. Water, which is usually used as the liquidmedium, boils only slightly higher than theoptimum temperature for engines to run at. Thisleaves little head room for overheating beforesteam is produced.However, although generating steam absorbsconsiderable heat energy for a very small rise intemperature, the steam once generated is unableto absorb much heat, causing a rapid rise in thetemperature of the engine block. Any sudden risein the temperature of the block may not initially beapparent as the steam condenses when in contactwith the coolant in the radiator’s header tank andescapes as water vapour through the overflowpipe under the car.Fortunately, the XPAG’s cooling system wasdesigned with a generous cooling capacity, able tocope with most situations. The design of thecooling system should prioritise the inlet ports andvalves; these need to be as cool as possible as8Figure 1 – Original skirted thermostat.When the engine is cold and the thermostat’svalve closed, all the coolant is directed through theby-pass loop. This maintains sufficient flow toscavenge out any hot-spots in the cylinder headand helps even out any temperature variationswithin the engine block. Differential temperaturesand hence expansion effects, stress the cast ironblock which is weak in tension and thus prone tocracking.As the by-pass loop coolant flowing through thehead reaches the operating temperature of thethermostat, the valve starts to open and at thesame time, an attached skirt begins to shut downthe by-pass loop. Ultimately when the engine isgenerating sufficient heat, the thermostat valve willbe fully open and the by-pass loop closed off sothat all the coolant is pumped through the radiator.However, before reaching this stage, thethermostat apportions what coolant flows throughthe radiator and what portion flows through the bypass loop so as to maintain a constant enginetemperature whilst achieving the maximum flowrate. This is a feature not provided by substituting“modern” thermostats for the skirted type. Figure 2.

directed through two narrow vertical slits behindthe pump, to cool the front of the cylinder walls.This area would otherwise be exposed to theaccumulated heat picked up by the coolant as itflows forwards through the head and on to thethermostat.Figure 2 - Modern thermostats in originalhousing.The need for skirted thermostats in modernengines is obviated by the use of Nodular cast ironin the engine blocks. Nodular iron differs from greycast iron in that the free graphite is present ascompact, isolated nodules rather than as flakesdispersed throughout the cast iron. This reducedpotential cracks propagating along the fault linescreated by the alignment of graphite flakes.This improvement in casting during the mid-1950swas due to the addition of Magnesium and specialheat treatment of the cast iron. Consequently, fullflow through a by-pass loop was no longeressential due to the increased strength andductility of Nodular cast iron.The heat generated within the block is carriedaway by a thermo-syphon action in such a waythat both head and the upper block end up runningat a similar temperature, leading to reduceddifferential expansion and thus less stress withinthe whole head and block, enabling it to be madelighter.This may seem over-protective, but experiencegained with early air- cooled aero engines, showedthat rapid cooling of just part of the engine during anon-powered dive, could lead to fractures in thecylinder head.Figure 3 shows a schematic of the coolant flow.The temperature differences are exaggerated toindicate the problems due to low flow rates.An absence of turbulence in the coolant flow couldencourage wide temperature differences within theengine, so a high flow rate is desirable, confirmingthe need for an effective by-pass loop duringwarming up when the thermostat valve is closed.The thermostat isn’t just there to allow the engineto warm up quickly, but to stabilize the enginerunning temperature at an optimum level and thusreduce stresses within the cast iron block.Original skirted type thermostats are nowavailable, but I’ve discovered that their assemblylacks the correct adjustment that synchronises theopening of the valve with the closing of the bypass loop. Looking through the by-pass portshould reveal the skirt’s top sitting level with theopening. However, the skirt on some appears to sitsome 4mm below the opening, which ultimatelyprevents it completely closing off the by-pass portat the correct operating temperature. The actualthermostat bellows may soon be available as aseparate item for self-assembly in existinghousings.Coolant Flow PathsMuch credit is due to Claude Bailey, designer ofthe X-Series engines. He paid particular attentionto having full flow filtered lubrication and a pumpedcooling system that prioritised the cylinder head,whilst also cooling the area of the bores swept bythe piston rings.Coolant flow is “assisted” by the water pump’simpeller to flow along a duct under the manifold tothe rear of the block, where it rises up to the backof the cylinder head through an elongated hole inthe gasket, if fitted correctly. Some coolant is alsoFigure 3 – XPAG coolant flow.Pumped Flow RatesIt’s at this point that I admit to indulging in somehome spun theory concerning coolant flow rates.Consider the radiator in a near maximum heatgenerating situation, powering uphill on a hot day.Totally T-Type 2, August 2017 9

The thermostat would be almost fully open ataround 74 deg. C. A fast coolant flow would resultin a reduced temperature difference across bothengine and radiator. What heat the coolantabsorbed whilst flowing quickly through the blockwould have little chance to cool down during itsbrief period in the radiator. The whole radiatorwould sit at an elevated average temperature, withits maximum temperature of 74 deg. C. beingdefined by the thermostat.Such a situation actually enhances the coolingability of the radiator as Newton’s law of coolingstates that the degree of cooling depends on thetemperature excess.A slow flow rate would result in any specificvolume of coolant absorbing more heat in theengine and conversely would also allow theradiator to dissipate more heat from the samespecific volume, resulting in a greater temperaturedifferential.As mentioned, large temperaturedifferentials within the engine increase expansionstress levels.Fig. 4 illustrates the benefits of high flow rateswhen the engine is working hard (thermostat fullyopen). It seems six bladed impellers could offerimprovements in cooling.average air displacement of the fan would beabout 5,300 ft/min. In effect, the fan is onlydisplacing air at around 1,300 ft/min.(*) The air velocity through the radiator is anunknown, any air flowing through the radiator finsexpands due to the absorbed heat, resulting in anincreased velocity of the air leaving the radiator.An added bonus is the forward thrust generatedwhich can, with careful design, equal the drag ofthe radiator. This is known as the Meredith Effect.Somehow, I doubt if Morris Radiators would haveconsidered such an issue in their design.Over Heating1. Loss of coolant: leakage or evaporationdue to open vented system.2. Furred-up radiator: Is this due to calciumor rust deposits in the narrow brass tubes?For a thorough de-scale, the radiator wouldneed to be removed and a pumped recirculating flushing loop set up.For rust deposits, mix Phosphoric or Oxalicacid (available as powder) with hot water.For calcium deposits, mix Citric acid(available as a powder) with hot water. Analternative is Muriatic acid or Spirits of Salt,which is a dilute form of hydrochloric acidand therefore hazardous.After flushing with acids, use a neutraliserflushing solution with Baking Soda andthen follow up with several plain waterflushes. The final

to Hagerty International Classic Car Insurance and I must thank this company and NTG Motor Services, who have sponsored the road books and the rally plates for this tour and for the last four. We really do value their support. Loo