Transcription

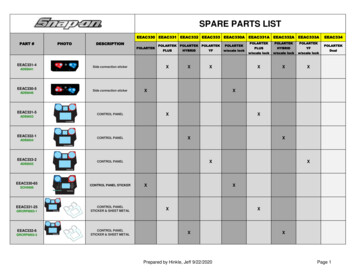

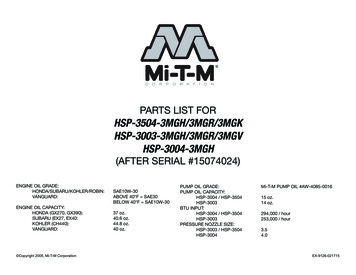

PARTS LIST SP-3004-3MGH(AFTER SERIAL #15074024)ENGINE OIL GRADE:HONDA/SUBARU/KOHLER/ROBIN:SAE10W-30VANGUARD: ABOVE 40 F SAE30BELOW 40 F SAE10W-30ENGINE OIL CAPACITY:HONDA (GX270, GX390):37 oz.SUBARU (EX27, EX40:40.6 oz.KOHLER (CH440): 44.8 oz.VANGUARD: 40 oz. Copyright 2005, Mi-T-M Corporation1PUMP OIL GRADE:Mi-T-M PUMP OIL #AW-4085-0016PUMP OIL CAPACITY:HSP-3004 / HSP-350415 oz.HSP-3003 14 oz.BTU INPUT:HSP-3004 / HSP-3504294,000 / hourHSP-3003 253,000 / hourPRESSURE NOZZLE SIZE:HSP-3003 / HSP-35043.5HSP-3004 4.0EX-9126-021715

This Parts Listing has been compiled for your benefit. You can be assured your hot water pressure washer was constructed and designed with quality andperformance in mind. Each component has been rigorously tested to insure the highest level of quality.The contents of this Parts Listing are based on the latest product information available at the time of publication. The manufacturer reserves the right to makechanges in price, color, materials, equipment, specifications or models at any time without notice.WARNINGTHIS IS A PROFESSIONAL HIGH PRESSURE, HOT WATER PRESSURE WASHER. CAUTION SHOULD BE OBSERVED WHEN USINGOR REPAIRING THIS UNIT! READ AND FOLLOW THE SAFETY WARNINGS LISTED BELOW BEFORE ATTEMPTING ANY REPAIRS ONTHIS PRESSURE WASHER!SAFETY WARNINGS1.NEVER alter or modify the equipment. Be sure any accessory items and system components being used will withstand the pressure developed.Use only genuine manufacturer parts for repair of your pressure washer. Failure to do so can cause hazardous operating conditions and will VOIDwarranty.2.NEVER make adjustments on machinery while the unit is connected to the engine without first removing the ignition cable from the spark plug.Turning over the machinery by hand during adjustment or cleaning might start the engine and machinery with it, causing serious injury to the operator.3.Know how to stop and bleed pressures quickly. Be thoroughly familiar with controls.4.Before servicing the unit, turn unit off, relieve the water pressure and allow the unit to cool down. Do not make repairs while the unit is running.Service in a clean, dry, flat area. Block the wheels to prevent the unit from moving. Be especially careful to properly dispose of any flammablematerials.5.After testing the machine, DO NOT leave the pressurized unit unattended. Shut off the unit and release trapped pressure before leaving. Copyright 2005, Mi-T-M Corporation2EX-9126-021715

Table of NS.7FLOW CHART.8EMF SYSTEM.8GENERAL THEORY OF OPERATION.9DECAL PLACEMENT.10FRAME (AFTER SERIAL #15010743).12ENGINE/ PUMP ASSEMBLY (HSP-3004, 3504).14ENGINE/ PUMP ASSEMBLY (HSP-3003).16HIGH PRESSURE PUMP (3-0194).18HIGH PRESSURE PUMP (3-0241).20UNLOADER/MANIFOLD ASSEMBLY.22UNLOADER (850-0252).24PRESSURE SWITCH (22-0171).26DETERGENT INJECTOR (50-0052).28COIL DRAIN PLUG (850-0218).29HEAT EXCHANGER/EMF SYSTEM (AFTER SERIAL #15070469).30BOILER ASSEMBLY (850-0226) AFTER SERIAL #15048210.32ELECTRODE GAP SETTINGS.32GUN / WAND / HOSE ASSEMBLY.34DUAL LANCE ASSEMBLY (16-0417) .36FUEL TANK (850-0248).38FUEL PUMP (3-0020) & FUEL SOLENOID (44-0100) .39EMF SYSTEM (850-0403) (AFTER SERIAL #15074024).40ELECTRIC BOX .42WIRING SCHEMATIC (AFTER SERIAL #15070469).44WIRING DIAGRAM (AFTER SERIAL #15070469).45 Copyright 2005, Mi-T-M Corporation3EX-9126-021715

NOTESDATE SERIAL NUMBER REASON2/15/2012 #15070469 ADDED KOHLER ENGINE10/07/2009 #15048210 ELECTRODE PLATE CHANGE4/30/2012#15074024IGNITION COIL ASSEMBLY UPDATE Copyright 2005, Mi-T-M Corporation4EX-9126-021715

NOTES Copyright 2005, Mi-T-M Corporation5EX-9126-021715

SPECIFICATIONSMODEL NUMBERHSP-3504-3MGHOperating Pressure (PSI/Bar):Water Volume (GPM/lpm):Outlet Water Temperature (F/C):Engine:ModelHSP-3504-3MGR3.3/12.5 ( /- 5%)3.5/13.3 ( /- 5%)GX390EX40SAE10W-3040.6/1.244.8/1.337/1.1Oil AlertTMOil GuardTMOil SentryTMOil AlertTMUnleaded Gasoline 86 Octane Minimum1.72/6.51.85/7.0Starting1.72/6.5Recoil RopeMaximum No Load RPM3600 ( /- 100)High Pressure Pump:Direct Driven, Oil Bath, Triplex PistonOil TypeMi-T-M Pump Oil #AW-4085-0016Oil Capacity (oz./liters)15/.44PlungersCeramicManifoldForged BrassValvesStainless SteelUnloaderInlet Water StrainerGX39037/1.1Fuel TypeFuel Capacity (gal./ liter)CH440Four Stroke, Overhead Valve, Single CylinderOil TypeLow Oil ProtectionHSP-3004-3MGH3000/207 ( /- 5%)140 F/78 C ( /- 20 F) rise above inlet ambient (210 F/ 99 C maximum)HondaHondaRobin SubaruKohlerEngine TypeOil Capacity (oz./ liter)HSP-3504-3MGK3500/241 ( /- 5%)PresetAdjustableRemovable Clear Bowl for inspection and cleaning of Stainless Steel ScreenHeat Dump ValveRelieves heated water during unloader bypass stageDetergent Injector:Adjustable Low Pressure downstream from pumpBurner Fuel System:Fuel TypeNo.1 or No.2 Fuel Oil, Diesel or KeroseneFuel Capacity (gal./liters)5.5/21Fuel Filter/ Water SeparatorSpin on (10 micron) filter/ E-Z water drainFuel PumpTwo Line, Single StageFuel Pressure (PSI/ BAR)145/10Fuel Nozzle1.75 60 B DelavanFuel Consumption (GPH/ LPH)2.1 GPH Continous BurningElectro Magnetic Firing (EMF) System:Belt Driven (Patent # 5,954,494)IgnitionTransistorized MagnetoControl Voltage12 Volt DCBlowerForced AirHeat Exchanger:Vertical, Top fired, Dual Spiral CoilBTU Input294,000Efficiency86% with #2 Fuel Oil/ DieselSmoke Density0-3 per ASTM D2156Controls:On/ Off SwitchIndustrial grade rocker switchPressure SwitchHigh Limit SwitchShuts off burner fuel supply upon trigger releaseShuts off burner fuel supply when outlet water temp. exceeds 210 F/ 99 CFuel Solenoid:12 VoltSafety Relief:Relieves excess system pressureUnit Net Weight (Lbs/kg):428/194430/195434/197428/194Unit Shipping Weight (Lbs/kg):551/250553/251557/253551/250Unit Net Dimension (In/cm):Unit Shipping Dimension (In/cm):43Lx 30Wx 41H/109L x 76W x 104H46.5L x 31.5W x 48.5H/118L x 80W x 123H Copyright 2005, Mi-T-M Corporation6EX-9126-021715

SPECIFICATIONSMODEL NUMBERHSP-3003-3MGHHSP-3003-3MGROperating Pressure (PSI/Bar):Water Volume (GPM/lpm):2.90/11.0 ( /- 5%))Outlet Water Temperature (F/C):Engine:Model130 F/ 72 C ( /- 20 F) rise above inlet ambient (210 F/ 99 C maximum)HondaRobinVanguardGX270EX279 HorseEngine TypeFour Stroke, Overhead Valve, Single CylinderOil TypeSAE10W-30Oil Capacity (oz./liter)Low Oil ProtectionAbove 40 F SAE30 / Below 40 F SAE10W-3037/1.140 oz.Oil SensorOil AlertTMFuel TypeFuel Capacity (gal./liter)Oil Guard Unleaded Gasoline 86 Octane Minimum1.6/6.0Starting2.0/7.6Recoil RopeMaximum No Load RPM3600 ( /- 100)High Pressure Pump:Direct Driven, Oil Bath, Triplex PistonOil TypeSAE30W Non-DetergentOil Capacity (oz./liters)14/.41PlungersCeramicManifoldForged BrassValvesStainless SteelUnloaderInlet Water StrainerHSP-3003-3MGV3000/207 ( /- 5%)AdjustableRemovable Clear Bowl for inspection and cleaning of Stainless Steel ScreenThermal Relief ValveRelieves heated water during unloader bypass stageDetergent Injector:Adjustable Low Pressure downstream from pumpBurner Fuel System:Fuel TypeNo.1 or No.2 Fuel Oil, Diesel or KeroseneFuel Capacity (gal./liters)5.5/21Fuel Filter/ Water SeparatorSpin on (10 micron) filter/ E-Z water drainFuel PumpTwo Line, Single StageFuel Pressure (PSI/ BAR)145/10Fuel Nozzle1.50 60 A DelavanFuel Consumption (GPH/ LPH)1.81 GPH Continous BurningElectro Magnetic Firing (EMF) System:Belt Driven (Patent # 5,954,494)IgnitionTransistorized MagnetoControl Voltage12 Volt DCBlowerForced AirHeat Exchanger:Vertical, Top fired, Dual Spiral CoilBTU Input253,000Efficiency83% with #2 Fuel Oil/ DieselSmoke Density0-3 per ASTM D2156Controls:On/ Off SwitchIndustrial grade rocker switchPressure SwitchShuts off burner fuel supply upon trigger releaseHigh Limit SwitchShuts off burner fuel supply when outlet water temp. exceeds 210 F/ 99 CFuel Solenoid:Safety Relief:Unit Net Weight (Lbs/kg):Unit Shipping Weight (Lbs/kg):Unit Net Dimension (In/cm):Unit Shipping Dimension (In/cm): Copyright 2005, Mi-T-M Corporation712 VoltRelieves excess system pressure428/194551/25043Lx30Wx41H/109 1715

EMF SYSTEMOMHSP046-072996-BAROMHSP090-040705-RZFLOW CHART Copyright 2005, Mi-T-M Corporation8EX-9126-021715

GENERAL THEORY OF OPERATIONWATER FLOW: Connect a pressurized water source to the INLET GARDEN HOSE CONNECTION (1) and turn on the watersupply. The water will flow through a WATER STRAINER (2) which has a clear inspection bowl.The water then travels into the TRIPLEX HIGH PRESSURE PUMP (3) which has an UNLOADER (4) that bypasses the waterwhen the trigger gun is closed. To protect the pump from heated water during this bypass stage, a HEAT DUMP VALVE (5) willopen at 140 F/60 C allowing the heated water to escape. The Heat Dump Valve automatically resets when the water cools. thePRESSURE SWITCH (6) controls the fuel supply to the burner.When using detergents, the solution passes through the DETERGENT STRAINER (7) located on the DETERGENT HOSE (8).The detergent solution then travels into the ADJUSTABLE LOW PRESSURE DETERGENT INJECTOR (9).From there, the water may be allowed to flow out of the DRAIN PLUG (10) or through the heat EXCHANGER INLET (11) whereit is heated when the burner is on. As the water exits the HEAT EXCHANGER OUTLET (12), it enters a safety system whichprotects the operator from danger. The safety system contains a HIGH TEMPERATURE LIMIT SWITCH (13) which senses thewater temperature and shuts off the fuel supply to the burner if it gets too hot. If the unloader fails to by pass the water or theburner remains on when the trigger gun is closed, the SAFETY RELIEF (14) will relieve and allow water to exit safely.The heated water then flows through the HIGH PRESSURE HOSE (15) and to the TRIGGER GUN ASSEMBLY (16) which allowsthe operator to control the water spray. When the trigger gun is open, the water flows through the ADJUSTABLE PRESSUREDUAL LANCE (17) and exits the NOZZLE (18).FUEL FLOW: The Fuel Pump draws fuel from the Fuel Tank (19) through a replaceable FUEL FILTER/WATER SEPARATOR(20) and into the Fuel Pump (21). Fuel exits the fuel pump, into a FUEL SOLENOID VALVE (22) which controls fuel flow to theFuel Nozzle (23) where it ignites and burns in the heat exchanger.EMF SYSTEM: The patented Electro Magnetic Firing (EMF) System is an integrated system which gives all the requirements forcombustion.The BELT (1) from the power source turns the HUB (2) which has two EXTERIOR MAGNETS (3) attached. As these magnetsspin past the IGNITION MODULE (4), a magnetic flux is created from which the ignition module produces a high voltage. Thisvoltage arcs across the electrodes giving the spark that is needed for ignition.This hub has an Internally MOUNTED MAGNET (5) which spins past a STATOR (6) that produces the voltage that controls thefuel supply to the heat exchanger. In addition to this, the hub also spins the BLOWER FAN (7) that forces the air into and throughthe heat exchanger.The FUEL PUMP (8) is also connected the hub by means of a flexible coupler. Copyright 2005, Mi-T-M Corporation9EX-9126-021715

HSP LG DECAL PLACEMENT - MITM 071913DECAL PLACEMENT Copyright 2005, Mi-T-M Corporation10EX-9126-021715

HSP LG DECAL PLACEMENT MITM 071913 CHDECAL PLACEMENTITEM1DESCRIPTIONPART #DECAL - RISK OF FIRE (SEE 71-0010)QTYN/A12DECAL - RISK OF BURNS (SEE 71-0010)N/A13DECAL - CAUTION: RISK OF FIRE (SEE 71-0010)N/A14DECAL - WARNING/CAUTION/OPERATION (SEE 71-0010)N/A15DECAL - BURNER ON/OFF (SEE 71-0010)N/A16DECAL - Mi-T-M STRIPE34-219227DECAL - HOT SURFACES (SEE 71-0010)N/A18DECAL - Mi-T-M34-217019DECAL - 14” STRIPE34-25651-DECAL - 14” STRIPE W/3500PSI34-2569110DECAL - DATA PLATEN/A111DECAL - WARNING: RISK OF EXPLOSION (SEE 71-0010)N/A171-00101-DECAL SET Copyright 2005, Mi-T-M Corporation11EX-9126-021715

HSP099 011215 KMDFRAME (AFTER SERIAL #15010743) Copyright 2005, Mi-T-M Corporation12EX-9126-021715

HSP099 011215 KMDFRAME ASSEMBLYITEMDESCRIPTIONMi-T-M GING *(ONE FOOT REQUIRED)33-002015HEAT EXCHANGER / EMF -006849LOCKNUT30-0155210BRAKE 13BOLT27-9550114NUT30-0004115PUSH/PULL TOGGLE CLAMP33-0400116BOLT27-0015217ENGINE/ PUMP ASSEMBLYN/A118NUT30-3023819ENGINE SHIM33-0169420BOLT27-9529621NOZZLE HOLDER20-1198A01122GROMMET33-0001423FUEL TANK ASSEMBLY850-0193124FUEL HOSE15-0147225FRAME5-0120A01126ELECTRIC BOX ASSEMBLYN/A127NUT30-6001128STAR WASHER28-1009129BRIDGE RECTIFIER32-1114130BOLT27-8807131UNLOADER/ MANIFOLD ASSEMBLYN/A1*MUST ORDER IN ONE FOOT LENGTHS Copyright 2005, Mi-T-M Corporation13EX-9126-021715

HSP100-070113-CHENGINE/ PUMP ASSEMBLY (HSP-3004, 3504) Copyright 2005, Mi-T-M Corporation14EX-9126-021715

HSP100 070113 CHENGINE/PUMP ASSEMBLYITEMDESCRIPTIONPART #QTY1ENGINE - HONDA1-00861-ENGINE - HONDA 13.0 HP RECOIL - RED1-02051-ENGINE - KOHLER 429CC RECOIL1-02081-ENGINE - ROBIN 14.0HP RECOIL1-0176112WASHER28-0605-WASHER-ALUM .533 X .800 X .07028-060613OIL DRAIN24-01431-OIL DRAIN EXTENSION24-014214ADAPTER 003718KEY43-008819BOLT27-8434410ADAPTER PLATE38-0051111HIGH PRESSURE HOSE15-0194112ELBOW23-0034113RELIEF VALVE22-0005114PRESSURE SWITCH22-0171115PLUG23-0244116WATER FILTER19-0096117ELBOW23-0119118HOSE CLAMP42-0011119HOSE *(TWO FEET GUARD20-0384A011*MUST ORDER IN ONE FOOT LENGTHS Copyright 2005, Mi-T-M Corporation15EX-9126-021715

HSP134 072213 CHENGINE/ PUMP ASSEMBLY (HSP-3003) Copyright 2005, Mi-T-M Corporation16EX-9126-021715

HSP134 072213 CHENGINE/PUMP ASSEMBLYITEMDESCRIPTIONMi-T-M #QTY1ENGINE - HONDA1-01621-ENGINE - SUBARU1-013412WASHER - HONDA28-060513OIL DRAIN - HONDA24-01431-OIL DRAIN - SUBARU70-038014ADAPTER 003718KEY43-008819BOLT27-8434410ADAPTER PLATE38-0051111HIGH PRESSURE HOSE15-0194112ELBOW23-0034113RELIEF VALVE22-0005114PRESSURE SWITCH22-0171115ELBOW24-0004116WATER FILTER19-0096117ELBOW23-0119118HOSE CLAMP42-0011119HOSE *(TWO FEET GUARD20-0384A011*MUST ORDER IN ONE FOOT LENGTHS Copyright 2005, Mi-T-M Corporation17EX-9126-021715

3-0194 070214 ALCHIGH PRESSURE PUMP (3-0194) Copyright 2005, Mi-T-M Corporation18EX-9126-021715

3-0194-070214 ALCPUMP ASSEMBLYREF.PART #QTY.REF.PART #QTY.1BOLT27-8884829SHIM- 0.1MM (QTY. VARIES 1-3)46-0704-2SHAFT COVER46-07131-SHIM- 0.2MM (QTY. VARIES 1-3)46-0705-3OIL SEAL(SEE KIT 70-0337)26-0194130O-RING25-038014O-RING(SEE KIT 70-0337)25-0397131BEARING (AFTER SERIAL #28511)48-007215BEARING48-00621-BEARING (BEFORE SERIAL #2

Oil Type Mi-T-M Pump Oil #AW-4085-0016 Oil Capacity (oz./liters) 15/.44 Plungers Ceramic Manifold Forged Brass Valves Stainless Steel Unloader Preset Adjustable Inlet Water Strainer Removable Clear Bowl for inspection and cleaning of Stainless Steel Screen Heat Dump