Transcription

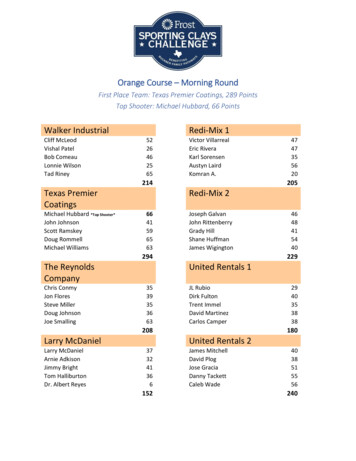

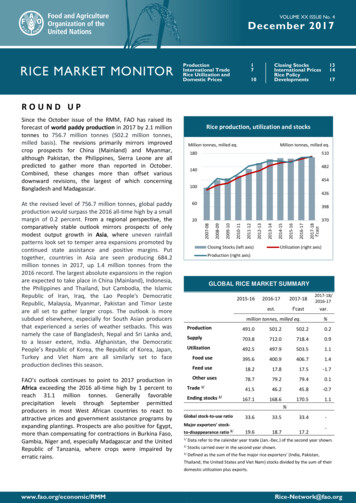

Round baler guideRound baler guideCheck out the specification and price details of round balers and baler-wrapperscurrently available in the UK. Our focus here is on machines capable of producingbales of a fixed diameter suitable for hay, silage and strawCase IHModelRB344 Rotor FeederRB344 Rotor CutterRB545 Rotor CutterRB545 Rotor CutterSilage PackBaleList price List price List price (rotor List price (balerdiameter (fork feed) (rotor feed) feed cutter) wrapper)1.25m— 23,586——1.25m—— 26,320—1.25m—— 41,493—1.25m——— 73,568Weight Ptodrive540rpm540rpm540rpm4,500kg Tandem 560/45 Pick-up RB344 — 2.00m (DIN), four-row camtrack, roller wind guard, removable fixed guide wheels; RB545 —2.20m (DIN), five-row camtrack, roller wind guard, removable fixed or castor ( 423) guide wheelsFeed-in RB344 RF — rotor with single tines in spiral formation; RC — twin-tine spiral rotor; RB545 — twin tinesin spiral pattern; Blockage solution RB344 — manual or hydraulic ( 846) rotor and pick-up reverser; RB545 —hydraulic drop floor with automatic knife retraction, optional pick-up de-clutch 508Crop cutting RB344 — 15 spring-loaded serrated knives, in-cab knife engagement, manual knife selection (3, 7 or15); RB545 — 20 spring-loaded serrated knives, in-cab knife engagement, manual knife selection (10, 10 or 20)Bale formation RB344 — base roller plus 34-bar chain and slat mechanism; three-stage bale density by springtensioners and tailgate pressure sensing; RB545 — 18 rollers with 10-notch surface profile, spring tensionersand tailgate pressure sensors, hydraulic in-cab density control; Bale netting RB344 RB545 — automatic netapplication start; front-mounted net roll plus one spare, twine net RB344 770, RB545 not availableBale netting RB545 — automatic net or film application, front-mounted net or film roll plus two spare, twine net not available; Bale ejection Operator-activated tailgate, spring-loaded ramp (delete option - 516)Bale wrapping RB545 — bale transfer mechanism to wrapping table, twin overhead horizontally rotating orbitalarms with 750mm film pre-stretch dispensers, storage for 10 film rolls; Controller RB344 — membrane buttonkeypad and monochrome display; RB545 — AFS Pro 700 ISObus capable display (delete option - 1,413); balersISObus 3 compliant; Lubrication RB344 — auto chain lube, central lubrication (delete option - 465); RB545 —auto chain lube and greasing standardOther options RB545 — tandem axle air brakes 855; 500/55x20 tyres in place of 560/45R22.5 - 2,056ClaasModelRollant 340Rollant 340 RotoFeedRollant 374 RotoFeedRollant 374 Roto CutRollant 375 Roto CutRollant 375 Roto CutUniwrapRollant 454 Roto CutRollant 455 Roto CutBaleList price List price List price (rotor List price (baler Weight Axlediameter (fork feed) (rotor feed) feed cutter) wrapper)1.20m 20,860———2,685kg SingleTyresPto(standard)drive11.5/80-15.3 540rpm1.20m— 23,460——2,685kgSingle15.0/55-17540rpm1.20m— 20m———— 34,280 .0/55-171,000rpm1,000rpm1.20m——— 57,4604,700kgSingle1.20m1.20m———— 40,775 42,625——3,150kg3,150kgSingleSingle500/45 - 22.5 p 340 — 1.85m, 340 RF 374 — 2.10m (1.90m DIN), camtrack, no roller press, non-removable rigid guidewheels; 375 — adds double roller press; 374-455 — removable castor guide wheels; Feed-in Roto Feed — singletines, four per ring, arranged in a spiral; Roto Cut — 8mm double tines, four pairs per ring, arranged in a spiral;Blockage solution 340 — none; 374-455 — hydraulic drop floor automatically lowers up to 30mm in continuoususe, can be fully opened to clear blockages; Crop cutting 374, 375 Roto Cut — 16 spring-loaded serrated knives,in-cab knife engagement; 454-455 Roto Cut — 25 spring-loaded serrated knives, in-cab knife engagement andfour-stage knife selection (0, 12, 13, 25); Bale formation 340-454 — 16 rollers, hydraulic pressure adjustment;455 RC — addition of Maximum Pressure System (MPS) pivoting upper three rollers for added core and outerlayer density; Bale netting Auto net application, front-mounted net roll; 454 455 — tension control by net rollbrake, twine net 1,180- 1,315 (not available on 454 RC, 455 RC); Bale ejection 340-375 — operatoractivated tailgate, spring-loaded ramp; 454 455 — manual or automatic tailgate operation; Bale wrappingTransfer by lift frame to forward-tilting four-belt wrapping platform, twin overhead orbital arms with 67% oroptional 82% ( 235) film pre-stretch dispe nsers, 12-roll storage, bale mat 420, bale tipper 2,060profi 4/201772www.profi.com

ClaasController 340-375 — operator non-ISObus terminal; 375 Uniwrap to 455 RC — ISObus compliant terminalincluding Claas Communicator II (delete option - 925); 375 Uniwrap — app for iPad option 1,045 (tractorrequires ISObus); Lubrication auto chain lube (all except 340); 374 375 — mechanical central lubrication 1,120; 454 455 — electronic auto central lubrication 1,270, standard on 375 Uniwrap (delete option- 1,265); Other options 80mm ball hitch 425; LED lights 510; moisture sensor 635; 375 Uniwrap — dualcircuit air brakes 315John DeereModelBaleList price List price List price (rotor List price (baler Weight AxleTyresdiameter (fork feed) (rotor feed) feed cutter) wrapper)(standard)F441M Multicrop1.25— 34,470——n/aSingle 11.5/80-15.3Rotoflow HC1.35mF441M Multicrop1.25— 37,555——n/aSingle 11.5/80-15.3Maxicut HC 131.35mF441M Silage Special1.25—— 34,470—n/aSingle 11.5/80-15.3Rotoflow HC1.35mF441M Silage Special1.25—— 37,555—n/aSingle 11.5/80-15.3Maxicut HC 131.35mF441R Maxicut HC1.25— 46,048 46,048—n/aSingle15.0/70-18131.35mF441R Maxicut HC1.25— 48,433 48,433—n/aSingle15.0/70-18251.35mC440R Maxicut HC1.25Single or— 86,904— 86,904n/a600/55R22.5131.35mtandemC440R Maxicut HC1.25Single or— 89,457— rpm540rpm540rpm540 or1,000rpm1,000rpm1,000rpm1,000rpmPick-up 2.00m or 2.20m, four-row camtrack, compressor shield or roller ( 590) baffle, fixed or castor ( 322)guide wheels; Feed-in Rotor with double-tine spiral centre section and integrated gathering augers at each end;Blockage solution Hydraulic parallel-action drop floor; optional on F441M Rotoflow ( 1,001), standard on allothers; Crop cutting F441R Maxicut — 13 spring-loaded serrated knives, in-cab knife engagement, no knifeselection; F441R C440R — 13 or 25 spring-loaded serrated knives, in-cab knife engagement, manualknife selection with Maxicut 25 (0, 12, 13, 25); Bale formation F441M Multicrop — seven ribbed steel rollersplus 32-bar chain and slat mechanism; F441M Silage Special — 17 ribbed rollers; F441R C440R — 18rollers with 12-rib profile; density control by tailgate hydraulic cylindersBale netting Manual or auto density triggered net application; net stretch regulated by roll brake; frontmounted net roll plus one spare; twine and net option — F441M, F441R C441R not available; twine only byspecial requestBale ejection F441M F441R — manual or automatic tailgate operation, optional spring-loaded ramp (n/a);C440R — automatic tailgate operation, bale drops on to four-belt wrapping table that moves clear oftailgate; Bale wrapping C440R — two overhead orbital arms carrying 750mm film dispensers; storage for 10spare film rolls; optional bale tipper ( 1,301); Controller F441M — BaleTrak Easy (net control) or BaleTrak (net, bale diameter etc), no ISObus; F441R C440R — any ISObus virtual terminal, including JD ImplementDisplay 1100 and Greenstar 1800; Lubrication F441M — auto chain lubrication optional 181; no centralised orauto greasing; F441R — auto chain lubrication and auto greasing by cartridge (standard) or reservoir with ISObuscontrol ( 1,500); Other options Hydraulic brakes 1,927, air brakes 2,653 C440R — bale drop mat ( 547)KroneModelBellima F 130Comprima F 125Comprima F 125 XC17Comprima F 125 XC26Comprima F 155Comprima F 155 XC17Comprima F 155 XC26Comprima CF 155 XC17 XtremeComprima CF 155 XC26 Xtremeprofi 4/2017BaleList pricediameter (no rotor)1.20m 1.251.50m*1.251.50m*1.251.50m*———List price List price (rotor List price (baler Weight AxleTyres(rotor feed) feed cutter) wrapper)(standard)———1,730kg Single11.5/55-17Single orpoa——n/a500/50-17tandemSingle or— 41,305—3,200kg500/50-17tandemSingle or—poa—3,259kg500/50-17tandemSingle orpoa——n/a500/50-17tandemSingle or— 43,080—3,450kg500/50-17tandemSingle rpm540rpm540rpm540rpm540rpm540rpm——— 80,6156,100kg Tandem500/50-20540rpm———poa6,100kg Tandem500/50-20540rpm73www.profi.com

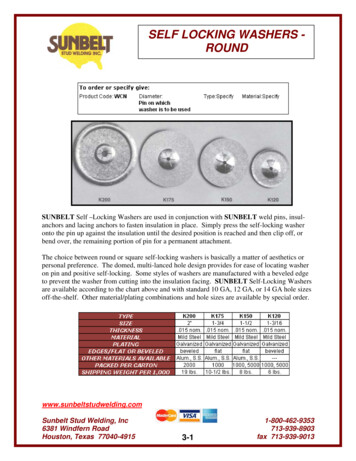

Round baler guideKronePick-up Bellima — 1.80m (DIN), four-row camtrack, tine wind guard with baffle, rigid steel or tyre guide wheels;Comprima — 2.15m (DIN), five-row camless, roller plus baffle tined crop guard, fixed guide wheelsFeed-in Bellima — underfloor feed tines, side augers; Comprima — side gathering augers, 415mm diameter tworow spiral tine rotor; Comprima XCut — side augers, 415mm diameter three-row twin-knife chevron spiral rotorBlockage solution Bellima — none; Comprima — hydraulic drop floorCrop cutting Comprima XC — spring-loaded auto reset single-side serrated knives, manual or hydraulic ( 1,420)knife engagement and selection — 17 knives (0, 8, 9, 17) or 26 knives (0, 13, 13, 26)Bale formation Bellima — ribbed base roller plus continuous chain and slat elevator, mechanically lockedtailgate, mechanical bale pressure indicators for side-to-side guidance or optional audible/visual indicators;Comprima — ribbed base and two profiled rollers over intake plus continuous rubber belt and slat elevator, coilspring density control, mechanical bale pressure indicators for side-to-side guidance; F 155 — bale diameterfixed at one of six sizes in 5cm increments between 1.25m and 1.50mBale netting Bellima — manual net application or twine tying start, net stretch by tensioning bar and net rollbrake, front-mounted net roll plus one spare, net twine standard; Comprima — net or stretch film ( 3,970including camera), automatic application start, net stretch by tensioning bar and net roll brake, front-mountednet or film roll plus two spare, no twine option; Bale ejection Bellima — manual open/close; Comprima —manual or automatic tailgate open; both — spring-loaded plate bale ramp collects incoming material beforetailgate closedBale wrapping CF 155 XC — pivoting frame transfers bale to chain and slat wrapping table, two overheadorbital arms carry 500mm or 750mm 50% or 70% pre-stretch film dispensers; bale drops on rubber mat,optional bale turner 1,060, storage for 10 film rolls; Controller Bellima — manual operation; Comprima —Comfort electronics and Delta II membrane switch and display terminal or any ISObus terminal including KroneCCI 200; Lubrication Bellima — manual (single chain drive); Comprima — auto chain oilingOther options Comprima — Tractor Implement Management — full automation of baler and tractor except forwardpower shuttle engage 550, hydraulic or air brakes 1,865, tandem axles unbraked 4,390 or braked 7,125KubotaModelBF 3255 RBF 3255 SC-14BaleList price List price List price (rotor List price (baler Weight Axlediameter (fork feed) (rotor feed) feed cutter) wrapper)1.25m— 31,499——2,620kg Single1.25m—— 33,305—2,900kg 40rpm540rpmPick-up 2.20m with inboard chain drive, five-row dual camtrack, roller crop press wind guard, fixed guidewheels within baler widthFeed-in R — spiral rotor with two rows of single tines; SC — double-tine spiral rotorBlockage solution Floor section opens front and rear hydraulically on parallelogram linkageCrop cutting SC — 14 spring-loaded serrated knives, in-cab knife engagement, no knife selectionBale formation Ribbed steel rollers hydraulic density controlBale netting Manual or auto net application; stretch regulated by net roll brake, front-mounted (chest height)net roll plus two spares, twine and net not availableBale ejection Manual or automatic tailgate open, manual close, spring-loaded bale rampBale wrapping NoneController Focus 3 non-ISObus terminalLubrication Auto chain lubricationOther options Hydraulic brakes 1,288, air brakes 1,733; 22.5in tyres in place of 17in 1,067- 1,733KuhnModelFB 3130 OptiFeedFB 3130 OptiCut 14FB 3135 OptiCut 14FB 3135 OptiCut 23FB 3135 AutomateOptiCut 14FB 3135 AutomateOptiCut 23BaleList price List price List price (rotor List price (balerdiameter (fork feed) (rotor feed) feed cutter) wrapper)1.25m— 31,312——1.25m—— 33,880—1.25m—— 38,222—1.25m—— 40,775—Weight 5m—— 40,650—3,300kgSingle400/60-22.5540rpm1.25m—— 43,203—3,400kgSingle400/60-22.5540rpm

KuhnFBP 3135 AutomateBalePack OptiCut 14FBP 3135 AutomateBalePack OptiCut 23i-BIO OptiCut 14i-BIO OptiCut 231.25m— 65,971— 65,9715,600kg Tandem400/60-22.5540rpm1.25m——— 68,5245,600kg � 54,906 0rpmSingleSinglePick-up 2.30m, five-row camtrack, short crop roller wind guard, fixed or castor pneumatic guide wheels FB — 203, FBP i-BIO 236; Feed-in Rotor with double-tine spiral centre section and integrated gathering augersat each end; Blockage solution OptiFeed — hydraulic drop floor and rotor disengagement; OptiCut — hydraulicdrop floor, auto knife retraction and rotor disengagement; FB 3135 Automate — automatic drop floor operationCrop cutting FB 3130 — 14 spring-loaded serrated knives, in-cab knife engagement, no knife selection; FB 3135 FBP 3135 i-BIO — 14 or 23 spring-loaded serrated knives, in-cab knife engagement, manual knife selection(0, 4, 7, 7, 14 or 0, 7, 11, 12, 23); Bale formation 18 ribbed steel rollers; density control by tailgate hydrauliccylinders; Bale netting FB FBP — manual or auto density triggered net application; i-BIO — auto densitytriggered net application; net stretch regulated by roll geared to 90% of bale rotation speed; front-mounted netroll plus one spare; twine binding FB FBP — 1,790; stretch film binding i-BIO 5,002; Bale ejection FB 3130 FB 3135 — operator-activated tailgate, spring-loaded ramp; FB 3135 Automate — automatic tailgate open/closewith tailgate lift height regulated by spring-loaded ramp; FB 3135 Automate BalePack — automatic tailgate open/close, bale moved to four-belt wrapping table by two transfer/anti roll-back forks; i-BIO — bales wrapped onbottom rollers in bale chamber, auto tailgate operation, optional bale turner; Bale wrapping FBP — two overheadorbital arms carrying 750mm film dispensers providing conventional wrapping or optional 3D wrapping ofcylindrical surface then across the ends; storage for five spare film rolls; i-BIO — horizontal ring carrying two70% pre-stretch 750mm film dispensers; storage for six spare film rolls; Controller FB 3130 — membrane buttonhand control with mono display, no ISObus; FB 3135 FBP 3135 i-BIO — Kuhn VT50 145mm colour displayterminal or any ISObus virtual display including Kuhn CCI 200; Lubrication Auto chain lubrication; auto rollergreasing optional 1,651 Other options Hydraulic brakes FB/FBP — 1,753, iBIO 1,517; air brakes iBIO 2,553, camera kits from 770. Note: Automate features, including automatic knife cleaning, available withmanual, semi-automatic and fully automatic modesTough timesask for anew kind ofreliability.MGX-III: Theclever all-rounderThe Kubota MGX-III has many talents– but the most impressive one is itsuncompromising reliabilityHighly efficient 4-cylinder engines with provenKubota reliabilityExceptionally versatile with intelligent and userfriendly 8-speed power shift transmissionExceptional levels of comfort are provided by thelarge cab and clear arrangement of all controlsPerfectly matched with all Kubota implements andretrofit ISOBUS terminalswww.kubota.co.ukprofi 4/201775T: 01844 873156www.profi.com

Round baler guideLely WelgerModelBaleList price List price List price (rotor List price (balerdiameter (fork feed) (rotor feed) feed cutter) wrapper)RP 2051.25m— 24,245——RP 245 MasterCut 13 1.25m—— 29,535—RP 245 XtraCut 171.25m—— 31,515—RP 245 Profi XtraCut1.25m—— 34,270—25RPC 245 Tornado1.25m——— 65,695XtraCut 25Weight o(standard)drive11.5/80-15.3 540rpm11.5/80-15.3 540rpm11.5/80-15.3 710/40-22.5540rpmPick-up RP205 — 2.00m or 2.25m ( 750), five-row camless, tine wind guard with optional crop press roller(2.00m 457, 2.25m 399), fixed or castor ( 530) guide wheels; RP245 — 2.25m, five-row camless, crop pressroller wind guard, fixed or castor ( 530) guide wheelsFeed-in RP205 — undershot feed rotor with single tines in a spiral; RP245 — twin-tine spiral rotorBlockage solution RP205 — none; RP245 — flexible floor beneath intake rotor plus hydraulic floor opening withauto knife retractionCrop cutting Hydraulically-protected spring-loaded serrated knives, hydraulic knife engagement; manual orhydraulic knife selection — MasterCut 13 knives (0, 13), XtraCut 17 knives (0, 8, 9, 17), XtraCut 25 knives (0, 12,13, 25)Bale formation 18 steel rollers with 10-rib surface profile, tailgate mechanical locks, electronic densitymonitoring; Balercontrol E — on-baler adjustment; E-link — remote adjustmentsBale netting Manual or with E-Link controller selectable manual/automatic net application start; front-mountednet roll plus one spare; twine net RP205 2080, RP245 2070, not available on RP245 TornadoBale ejection RP205 — operator-activated tailgate, spring-loaded ramp 380; RP245 — ramp standardBale wrapping RP245 Tornado — gravity bale transfer to wrapping table, horizontal rubber roller-driven ringwith two film pre-stretch dispensers, storage for 12 film rollsController RP205 RP245 MasterCut — Balercontrol E membrane button keypad and info display; RP245XtraCut — E-link Balercontrol; RP245 Tornado — E-link Pro membrane button keypad info, set-up and operation;balers non-ISObusLubrication RP205 — auto chain lube; RP245 — auto chain lube, central bearing lubrication standard, automaticbearing lubrication option 1,559, standard on RP245 TornadoOther options RP245 — hydraulic brakes 1,210; RP245 Tornado — hydraulic brakes standard,air brakes 850Metal-Fach (Zetor UK)ModelBaleList price List price List price (rotor List price (balerdiameter (fork feed) (rotor feed) feed cutter) wrapper)Metal-Fach Z562-01.20m 12,959———Metal-Fach Z562-11.20m— 13,771——RotorMetal-Fach Z562-21.20m—— 14,630—Rotor CutterMetal-Fach Z562-401.20m—— 15,489—Rotor CutterWeight k-up 1.80m, four-row camtrack, tine wind guard, fixed guide wheelsFeed-in Z562-0 — reciprocating forks; Z562-1 Z562-2 — twin-blade spiral rotorBlockage solution NoneCrop cutting Z562-1 — 13 spring-loaded serrated knives, manual knife engagementBale formation Z562-0/1/2 — 16 ribbed steel rollers; Z562-40 — 18 ribbed steel rollers. Hydraulic bale densitycontrol with on-baler adjustmentBale netting Twine standard, net application optional 1,030; manual net application trigger, net stretch bytensioning bar and net roll brakeBale ejection Manual tailgate operation, spring-loaded bale rampBale wrapping NoneController Metal-Fach LP-02 membrane button controller for netting start, pick-up drive, tailgate open, balecounter, etc), no ISObus; Lubrication Optional chain central lubrication 458Other options Forage treatment liquid applicator 1,059McHaleModelF5400F5500F5600F5600 PlusFusion 3Fusion 3 Plusprofi 4/2017BaleList price List price List price (rotor List price (balerdiameter (fork feed) (rotor feed) feed cutter) wrapper)1.2

orbital arms carry 500mm or 750mm 50% or 70% pre-stretch film dispensers; bale drops on rubber mat, optional bale turner 1,060, storage for 10 film rolls; Controller Bellima — manual operation; Comprima — Comfort electronics and Delta II membrane switch and display te