Transcription

Overview and Comparison ofGlobal Method Validation SchemesPresented By: Pat Bird and Christopher HaneySponsored by Q Laboratories, Inc. and Clear LabsOrganized by IAFP’s Applied Laboratory MethodsProfessional Development Group

Webinar Housekeeping For best viewing of the presentation material, please click on‘maximize’ in the upper right corner of the ‘Slide’ window,then ‘restore’ to return to normal view. Audio is being transmitted over the computer, so please haveyour speakers ‘on’ and volume turned up in order to hear. Atelephone connection is not available. Questions should be submitted to the presenters during thepresentation via the Questions section at the right of thescreen.2

Webinar Housekeeping It is important to note that all opinions and statementsare those of the individual making the presentation andnot necessarily the opinion or view of IAFP. This webinar is being recorded and will be available foraccess by IAFP members at www.foodprotection.orgwithin one week.3

Patrick Bird Microbiology R&D Supervisor for Q Laboratories Managed dozens of validations for AOAC PTM, AOACOMA, AFNOR and MicroVAL submission Active member of the ISO WG3 for method validation Serves on the AOAC Research Institute Board ofDirectors Co-project leader for the AOAC ISPAM working group onMicrobiological Quantitative Statistical Analysis4

Christopher Haney Senior Scientist on Clear Labs’ Microbiology Team Manages validation pipeline for novel NGS basedmethods for pathogen detection Experience as a Microbiologist at U.S. Food and DrugAdministration, GenMark Diagnostics, and RokaBiosciences, where he managed the validationlaboratory5

Method Validation : IndependentLaboratory Perspective

Method Validation: Independent Laboratory PerspectiveObjective Overview of References/Certification Bodies Study Design: AOAC PTM AOAC OMA ISO 16410-2 Harmonization7

Certification Overview8

Overview of Reference/Certification Bodies Appendix J: AOAC INTERNATIONAL Methods Committee Guidelines forValidation of Microbiological Methods for Food and EnvironmentalSurfaces (2012); or ISO 16140:2003. Performance Tested MethodsSM (PTM) Official Methods of AnalysisSM (OMA) Appendix D: AOAC INTERNATIONAL Guidelines for Collaborative StudyProcedures To Validate Characteristics of a Method of Analysis9

Overview of Reference/Certification Bodies ISO 16140 Series ISO 16140-1 (2016): Microbiology of the food chain — Method validation— Part 1: Vocabulary ISO 16140-2 (2016): Microbiology of the food chain — Method validation— Part 2: Protocol for the validation of alternative (proprietary) methodsagainst a reference method ISO/DIS 16140-6 (2018): Microbiology of the food chain — Methodvalidation — Part 6: Protocol for the validation of alternative (proprietary)methods for Microbial Confirmation and Typing Procedures Certification Bodies: MicroVal, AFNOR, NordVal10

Study Design –AOAC11

AOAC Validation12 AOAC Research Institute usesguidelines and referencesdeveloped by AOACINTERNATIONAL and AOACvolunteer subject matter expertsfor its testing protocols and dataevaluation Ruggedness/Robustness, Productperformance consistency, productperformance stability andinstrument performance variationare all certification requirements;technical criteria are developedwithin the Research Institute withguidance from AOAC volunteers.

AOAC ValidationMethod DeveloperResponsibilities and SLV Inclusivity Exclusivity Matrix Study Claim-dependent POD and dPOD13Independent LaboratoryResponsibilities Matrix StudyCollaborative Study 1 Food per 5 FoodsValidated 1 Surface per 5Surfaces ValidatedMatrix Study Robustness(PTM only) Stability (PTM only) Instrument Variation(PTM Only) Lot-to-Lot Variation(PTM only)MICROBIOLOGICAL METHODSTECHNICAL REQUIREMENTS (AOAC) 10 labs forqualitativemethods POD acrosscollaborators 8 labs forquantitativemethods 1 Food

AOAC Validation – Single Lab Validation Inclusivity/Exclusivity Evaluated using pure isolates; no food matrices Inclusivity (Range of target analytes detected by method) 50 Target Strains (100 for Salmonella spp.) Will define scope of method(ex. Non-lactose fermenting Salmonella, 6 common Listeria spp.) Exclusivity (Range of non-target analytes excluded) 30 Non-target strains Closely related to target strainsVALIDATIONPerformance Characteristics of Microbiological Methods14

AOAC Validation – Single Lab Validation15Robustness Evaluate performance of the assay with small changes inTable 3: Robustness parameterskey parametersTable 4: Robustness Experimental Design (incubation time/temperature; volumes of lysis buffer,reagents, etc)ParameterLow valueSample VolumeLow valueLysis TimeReagent VolumeLow valueLow valueNominal ValueNominal valueNominal valueNominal valueHigh valueHigh ValueHigh valueHigh value Conducted using inoculated food matrix at fractional range Factorial Design to minimize number of test portionsTreatment Combination123456789Enrichment Time45 mL45 mL45 mL45 mL55 mL55 mL55 mL55 mL50 mL1st Lysis TimeLow ValueLow ValueHigh ValueHigh ValueLow ValueLow ValueHigh ValueHigh ValueNominal Value2nd Lysis TimeLow ValueHigh ValueLow ValueHigh ValueLow ValueHigh ValueLow ValueHigh ValueNominal Value

AOAC Validation – Single Lab Validation16Stability Can be conducted in real-time and/or accelerated study. Accelerated data can provide immediate information onshelf-life, but must submit data for real-time (ex.provided below) Can be submitted during certificate renewalCandidate MethodReal timeAcceleratedStorageTemperatureTime Points(from the date of production)2-8 1 C1 mo., 2.5 mos., 5 mos., 6 mos25 2 C4 days, 9 days, 17 days, 20days

17 Lot-to-Lot Variation 3 Lots of Assays Target/non-target strains Can be combined with stability and or instrument variation Instrument Variation 3 Instruments Target/non-target strains

AOAC – Independent Laboratory Study Method comparison Choice of matrix· The number of matrices chosen determines theclaim18

AOAC – Independent Laboratory Study19Raw milk and dairy productsFood CategoriesEggs andderivativesDried cereals, fruits, nuts,seeds and vegetablesHeat processed milk and dairyproductsRaw and ready-to-cook fishand seafood (unprocessed)Chocolate, bakery productsand confectionaryRaw meat and ready-to-cookmeat products (exceptpoultry)Ready-to-eat, ready-to-reheatfishery productsMulti-component foods ormeal ComponentsReady-to-eat, ready-to-reheatmeat productsFresh produces and fruitsPet food and animal feedRaw poultry and ready-tocook poultry productsProcessed fruits andvegetablesEnvironmental samples (foodor feed production)Ready-to-eat, ready-to-reheatmeat poultry productsInfant formula and infantcerealsPrimary production samples(PPS)ANNEX A (informative)Table A.1 — Classification of samples and their relevance fortesting for various microorganisms

AOAC – Independent Laboratory Study Method comparison Choice of matrix Choice of organism Inoculum level Equilibration period20

AOAC – Independent Laboratory Study21Table 1: Study SummaryMatrix/Test PortionFresh RawGround BeefInoculationOrganismE. coli O157:H7ATCC 43895Inoculation Levelper OrganismReplicatesper method0 cfu /test portion50.2–2 cfu/test portion202-5 cfu/test portion5Inoculating is TimePointsFresh culture4 C, 48-72 hMLG 5.09,5B.05,4.09 and8.1022 hoursVALIDATIONPerformance Characteristics of Microbiological Methods

AOAC – Independent Laboratory Study Method comparison Choice of matrix Choice of organism Inoculum level Equilibration period AlternativeConfirmations/Reference Method22

AOAC ValidationIn Addition:Any modification to a method, including extension to a newmatrix or target organism requires revalidation/verification(Note: The degree of verification willdepend on nature/extent of the modifications)Level 1 – Minor (do not require additional validation work) –software upgrade, etc.Level 2- Will require validation data (requirement forindependent lab depends on modification)Level 3- Will require validation data from method developerand independent laboratory.VALIDATION-METHOD MODIFICATIONS23

AOAC – OMA Collaborative Study: Qualitative Selection of Matrix 10 Collaborators 36 Test portions Shipment of test portions Performance of method/reference method Collection of Data/Statistical Analysis Submission of Report and Presentation to the ERP24

AOAC – OMA Collaborative Study: Qualitative Selection of Matrix 8 Collaborators 8 Test portions Shipment of test portions Performance of method/reference method Collection of Data/Statistical Analysis Submission of Report and Presentation to the ERP25

Study Design –ISO 16140-226

ISO 16140-2 Combines aspects of AOAC PTM and AOAC OMAprograms Entire study must be completed by Expert Lab Qualitative: Sensitivity, RLOD, Inclusivity/Exclusivity, ILS Quantitative: Trueness, Accuracy, Inclusivity/Exclusivity, ILS Other performance requirements (Stability, lot-tolot) covered under manufacturing standard27

ISO 16140-2: Qualitative Sensitivity Selection of Categories· 3 Types per category· 20 individual samples per type RLOD 1 Matrix per category validated Inclusivity/Exclusivity 50 (100)/30 ILS 10 collaborators 24 total test portions28

ISO 16140-2: Quantitative Relative Trueness Selection of Categories· 3 Types per category· 5 individual samples per type Accuracy 1 Matrix evaluated in duplicate or 2 different matrices percategory validated Inclusivity/Exclusivity 50 (100)/30 ILS 8 collaborators 8 total test portions29

Harmonization30

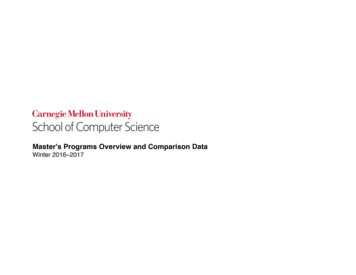

31 Programs harmonized with PTM Official Methods of AnalysisSM Antibiotic drug residues in milk· US Food & Drug Administration Center for VeterinaryMedicine and the National Conference on Interstate MilkShipments Health Canada – Bureau of Chemical Safety (Food Allergens) MicroVal AFNOR (in progress) NordVal (in progress) The goal is to achieve optimal efficiency and avoid duplicationof efforts in order to meet regulatory and product safety testingrequirements.HARMONIZATION-PROGRAM TOPROGRAM

AOAC Research InstitutePerformance Tested MethodsTypes of MethodsProprietary MethodsReference MethodsAOACI, FDA, USDA, ISO, HealthCanadaClaimVariety-10 matrices/5 groupsSelected-5 matrices/2 groupsGroup-5 matrices/1 groupAOAC INTERNATIONALOfficial MethodsProprietary and NoncommercialAOACI, FDA, USDA, ISO,Health CanadaPer matrix basis- allmatrices in MethodDeveloper ClaimMicroValISO 16140-2:201532Proprietary and Non-commercialISO, CEN, Other ReferenceMethodsBroad Range of Foods-5categoriesCategory-3 typesRestricted Foods- SpecificCategories- 3 types per categoryAdditional CategoriesPrimary production,FeedEnvironmentalsApprox. 12 months dependingon complexityRLOD(POD may be analyzedadditionally)EL is ISO 17025 for referencemethodTime to ValidationAs little as six months12 months minimumStatistical CalculationsProbability of Detection (POD)Probability of Detection(POD)Laboratory AccreditationN/AN/AValidated MethodsReviewedRequired yearlyFirst Action for 2 yearsFinal Action vote by OMBRequiredMethods PublishedILM, Journal of AOACJournal of AOAC, OfficialMethods of AnalysisMicroVal website/Organizationdependent

Expectations and planning for dual expert review of final study33

Overview andComparison of GlobalMethod ValidationSchemes: MethodDeveloper PerspectiveChristopher Haney, Senior ScientistClear Labs

Choosing aValidationSchemeI.Launch GeographyII.Launch HorizonIII.CostIV. Customer Acceptance35

I. Launch Geography Generally: ISO 16140 (AFNOR, NordVal, MicroVal) : EU,Asia (Taiwan), Africa (Tunisia)Choosing aValidationScheme Mandated in EU by EC 2073/2005 Country-by-country acceptance outside EU EU members may have additional requirementsThe use of alternative analytical methods isacceptable whenthe methods are validated against the referencemethod in accordance with ISO standard 16140or other internationally accepted similarprotocols - EC 2073/2005; Article 5 § 536

I. Launch Geography Generally: ISO 16140 (AFNOR, NordVal, MicroVal) : EU,Asia (Taiwan), Africa (Tunisia)Choosing aValidationScheme Mandated in EU by EC 2073/2005 Country-by-country acceptance outside EU EU members may have additional requirements AOAC PTM/OMA: USA, Latin America, Asia,Oceania Validation not mandated for industry use37

I. Launch Geography Generally: ISO 16140 (AFNOR, NordVal, MicroVal) : EU,Asia (Taiwan), Africa (Tunisia)Choosing aValidationScheme Mandated in EU by EC 2073/2005 Country-by-country acceptance outside EU EU members may have additional requirements AOAC PTM/OMA: USA, Latin America, Asia,Oceania Validation not mandated for industry use Less Generally: Country-specific schemes Commonalities with AOAC/ISO 16140 eg. Health Canada’s “Microbiology FoodLaboratory Procedure” (MFLP) and “HealthProtection Branch” (HMB) certifications38

II. Launch Horizon / Marketing Expediency AOAC PTM No application/acceptance windows Study scope customizationChoosing aValidationScheme39

II. Launch Horizon / Marketing Expediency AOAC PTM No application/acceptance windows Study scope customizationChoosing aValidationScheme AOAC OMA 2 Phases First Action; Final Action 2 Year Minimum40

II. Launch Horizon / Marketing Expediency AOAC PTM No application/acceptance windows Study scope customizationChoosing aValidationScheme AOAC OMA 2 Phases First Action; Final Action 2 Year Minimum ISO 16140 (AFNOR) Regimented phases Phase approvals at meetings41

III. Cost Hardware and ScaleChoosing aValidationScheme AOAC PTM: 2 laboratories involved AOAC OMA: 10 laboratories involvedsimultaneously ISO 16140: 10 laboratories involvedsimultaneously At least 3 countries EU-centric Expert Laboratory42

III. Cost Hardware and ScaleChoosing aValidationScheme AOAC PTM: 2 laboratories involved AOAC OMA: 10 laboratories involvedsimultaneously ISO 16140: 10 laboratories involvedsimultaneously At least 3 countries EU-centric Expert Laboratory Study Performance AOAC PTM: can be 80% in-house, but In-house expertise: fractional inoculation Laboratory scale: 100L media 26kg matrixper matrix study attempt Strain library: 50,000 (Salmonella enterica, viaATCC) ISO 16140 Primarily done by Expert Laboratory43

IV. Customer Acceptance In markets without a mandate (eg. USA),customers mayChoosing aValidationScheme Prefer ISO 16140Accept PTMRequire OMAReject Certification bodies in lieu of internalmethods44

How to BeReadyI.ConsultantsII.HomeworkIII.Exit R&DIV. Operations ActivatedV.Expectation Management45

I. Consultants – Get one Built into AOAC PTM/OMA Numerous options for ISO 16140How to BeReady46

I. Consultants – Get one Built into AOAC PTM/OMA Numerous options for ISO 16140How to BeReadyII. Homework Target markets? What do your target customers prefer? Country/Matrix/Target-specific schemes (eg.Nat’l Poultry Improvement Plan; NPIP)47

I. Consultants – Get one Built into AOAC PTM/OMA Numerous options for ISO 16140How to BeReadyII. Homework Target markets? What do your target customers prefer? Country/Matrix/Target-specific schemes (eg.Nat’l Poultry Improvement Plan; NPIP)III. Exit R&D Know the result before you start validation48

I. Consultants – Get one Built into AOAC PTM/OMA Numerous options for ISO 16140How to BeReadyII. Homework Target markets? What do your target customers prefer? Country/Matrix/Target-specific schemes (eg.Nat’l Poultry Improvement Plan; NPIP)III. Exit R&D Know the result before you start validationIV. Operations Activated Quality System online ISO 16140 requires an on-site audit Product/Method is in a sellable format –bottles, labels, etc in final form Multiple production lots on-hand49

V. Expectation Management Validation is not an end-pointHow to BeReady50

Questions?51

Method comparison Choice of matrix . Submission of Report and Presentation to the ERP . 25 . Study Design – ISO 16140-2 . 26 . ISO 16140-2 Combines aspects of AOAC PTM and AOAC OMA programs