Transcription

DESIGN REFERENCE FORELEVATOR INSTALLATIONSNexWay

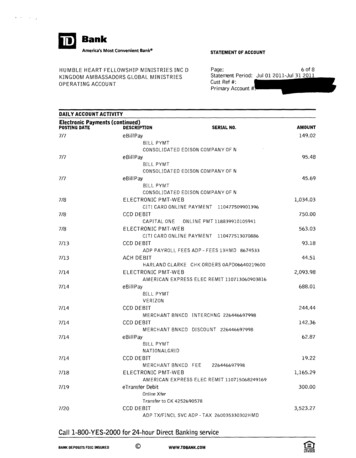

BASIC SPECIFICATIONS OF THE NexWay Capacity and Speed 1200161350 Control, Door and Operation SystemsRated speed (m/sec)EN81-12.02.53.03.54.05.06.0 18 160021 180024 200026 2250302500333000407.08.09.010.0Number ofelevatorsin a bankRated speed (m/sec)2.02.5Maximum number of stops1050kg3.03.54.05.08.09.010.0Please consult our local agents.641507.0Please consult our local agents.2501350kgMaximum travel (m) *21600kg1800kg200250Please consult our local agents.2000kgMinimum floor height (mm)2500 *3Door systemΣAI-2200C groupcontrol system(option)1 car (1C-2BC)———2 cars— (2C-2BC)———— (3C-ΣAI-22) (3C-ΣAI-2200C)—— (4C-ΣAI-22) (4C-ΣAI-2200C)——— (5C-ΣAI-2200C)——— (6C-ΣAI-2200C)7 cars——— (7C-ΣAI-2200C)8 cars——— (8C-ΣAI-2200C)6 cars6.0Control systemΣAI-22 groupcontrol system(option)5 cars Specifications *1Operation system2-car groupcontrol system(optional)4 cars).—: Not applicable1-car selectivecollective(Standard)3 carsNotes:*1: The symbol shown in the table indicates that a technical inquiry is required.The symbol shown in the table indicates that a technical inquiry is required depending on conditions.*2: Refer to page 5 to 12 for the hoistway and machine room layout plans for the models with specifications marked in gray (For the layouts for models with other specifications, please consult our local agents. : ApplicableVVVF control withmicroprocessor,VVVF control and2-panel centerData Networkopening CO (Standard),System2-panel sidewith multipleopening 2S microprocessor(option),modules4-panel center(VFGH)opening 2CO (option)Selective collective (2BC) AI-22 & AI-2200C Group Control SystemsThe system consists of call buttons in the car, and ariser of up and down destination floor buttons installedat each elevator hall (single button at terminal floors),which connect electrically with microprocessorssupervising floor selection and direction of travel. A carwill respond to those car and hall calls that comply withits direction of service.When there are no more calls registered for the car’sdirection of travel, the car’s service direction isreversed.The systems, which employ an intelligent expertsystem and fuzzy logic, are specially designed forgroup control of 3 to 8 elevators (as described above).Practical information required for group control isstored in the system's memory as a “KnowledgeDatabase”. Drawing from this database, various trafficconditions are monitored and analyzed applyingIF-THEN decision rules to maximize the effectivenessof each elevator operation.The systems perform assignments to the most-usedlocations, and thereby provide superb efficiency andservice.In addition to the above, Σ AI-2200C system performsoptimal car allocation using Dynamic Rule-setOptimizer.Notes:*1: Please consult our local agents if the maximum travel exceeds the values specified in the above table.*2: For the rated capacity 2250kg to 3000kg, please consult our local agents for maximum travel.*3: For some elevator specifications, the floor height (distance between floors) must be a minimum of 2500mm.Please consult our local agents if the floor height is less than “Entrance height HH 700mm”.12

REFERENCE DATA FOR ELEVATOR PLANNINGSelecting the Elevator SpeedElevator traffic reaches a peak when people employedin the building arrive for work in the morning, whenthey break for lunch at midday, and when they leavefor home in the evening. Obviously, the elevators mustbe capable of handling the increased traffic duringthese peaks. And during actual business hours, theelevators must be able to respond promptly to servethe people who are on the move inside the building aswell as those who arrive at or leave the building. Sothat the elevators best suited to the conditions andenvironment at hand can be selected, MitsubishiElectric applies computer simulation, trafficcomputation, and other techniques based on its wealthof experience in this field to offer a wide range ofelevator consulting services. Given below are referencedata useful for general planning.The maximum number of floors served in a buildingserves as the criterion for selecting the speed at whichthe elevators should travel. To select elevators usingthe chart below, if the building has 23 floors, selectelevators with a speed of 3.5m/sec or 4.0m/sec.Note: The following chart shows the recommended elevatorspeed per maximum number of service floors. The bestsuited speed varies depending on the following factors:*Building usage;*Single-tenant building or multi-tenant building;*Floor heights;*Population in the building;*Number of elevators in the group; or*Capacity of the elevator.Please consult our local agents for details.Recommended elevator speed9.0 m/sec60 floors6.0 m/sec45 floors4.0 m/sec35 floors3.0 m/sec25 floors5 floors2.0m/sec1.5m/sec1.0 m/sec10 floors1.75m/sec15 floors2.5 m/sec20 floors3.5 m/sec30 floors5.0 m/sec40 floors7.0 m/sec50 floors8.0 m/sec55 floors10.0 m/secMax. no. of floors servedSTANDARD INSTALLATION Notes on Installation PlanningPoints Relating to theHoistwayElevator ArrangementElevator installations should be properlyplanned according to such factors as thesize and nature or kind of the building,the traffic flow and peak traffic demandor conditions, the location of publictransportation facilities and stores. Dispersing elevators in different areas ofa building adversely affects theirpassenger-carrying efficiency. Therefore,elevators should, as far as possible, beconcentrated in the center of thebuilding. When two groups of elevators face eachother, ample space should be leftbetween the groups. The number of elevators in each groupshould be decided on the basis of thephysical arrangement of the elevatorsand the floors served. As much as possible, all the floorsserved by one group of elevators shouldbe functionally and structurally similar.Dissimilarity among the floors served willresult in a drop in service level. In residential buildings, hotels, and thelike, it is not desirable for the elevatorhall to be located farther than 50 metersfrom any apartment or room. In steel-reinforced concretebuildings, design the hoistways sothat concrete walls are at least120mm thick. Hoistways must be no more than30mm out of plumb. No wiring or distribution panelsshould be built into or mounted onhoistway walls. It is forbidden under most buildingcodes to install any conduit work orpiping in hoistways except asrequired for the elevator itself. Pit-depth and overhead-heightdimensions must always be at leastthe minimum shown in the drawings. If it proves necessary to make use ofspace below the pit, contact ourlocal subcontractor. When the building is to be of steelconstruction, our localsubcontractor should be broughtinto the discussion at the earliestpossible moment. Points Relating to theMachine RoomProvide the recommended widthand height to assure that there willbe sufficient room for inspection andmaintenance. Since the elevator drive equipmentgenerates considerable heat,sufficient ventilation and or airconditioning capacity must beprovided to assure that themachine-room temperature doesnot exceed 40 C.Refer to elevator site requirementsat page 18 for details. When occupied areas of the buildingare in close proximity to themachine room, such as in the caseof elevators for the low and middlefloors of a high-rise building, it maybe desirable to provide additionalsoundproofing or intervening walls. Some Examples of Bank ArrangementsDesirable Plans Selecting the Operation SystemLarge-scale office buildingScale of buildingNumber ofMedium-scale office buildingelevaOperation systemtors121-car selective collective (2BC)2-car group control system (2BC)345678Undesirable Plans AI-22 group control system AI-2200C group control systemApplicable system3Recommended system4

RATED SPEED OF 2.0 3.0 m/sec Machine-room height (HM)R12.02.53.0Ventilator(by owner)2500Power outlet(by owner)Power receiving panelwith a lockable device(by owner)Power receiving panelfor lighting(by owner)TC10501350TR 1002.0Machine room100 Dimension table of car, hoistway and machine mberofpersonsEntrancewidthJJ (mm)Carinternaldimensions(mm)Width DepthAA BB2.02.53.0Minimum hoistwaydimensions(mm)Minimummachine roomdimensions(mm)3.0 Highestfloor53605290100 TR 1505440TR 200 5440TR 1005640100 TR 2505790Note: The dimensions OH are calculated when the car frame height(HB) is 3450mm.In-line arrangementHoistwaywidth/unitAU (mm)*12-unitinstallation*22-unitinstallationWidth DepthAH BHWidth DepthAM BMP141050149001600 150021004300 23004700 3605P1813501811002000 150025005100 23005100 3605P2116002111002000 170025005100 25005100 3805P2418002411002100 175026005300 25505400 4100P2620002611002100 195026005300 27505400 4300Lowestfloor Top clearance (TC)[Terms of the tables] The dimensional information herein is based on the requirements of EN81-1. This dimensions herein are standard specifications without the fireproof landing door and counterweight safety. Please consult our localagents for details. The minimum hoistway dimensions (AH and BH) shown in the table are after waterproofing of the pit and do not include plumb tolerance.(Unit: mm)Travel (TR) (m)Rated speed(m/sec)Notes:*1: The hoistway width per unit (AU) is for reference. A single-unit installation is not recommended.*2: The hoistway width (AH) for 3- or 4-unit in-line installation can be calculated as follows:AH Hoistway width per unit (AU) x Number of car units in the shaft Separator beam width 100mm x (Number of car units –1)TR 100100 TR 2502.0176019102.5184019903.021902340 Pit-depth (PD)Ratedspeed(m/sec)TravelTR(m)2.0100 TR 150150 TR 200TR 1003.0100 TR 150150 TR 200200 TR 250160018002080280028002950 TR 1002.5135030502080295028403100 2000 Reaction loads in machine room and pitRated evationRated capacity (kg)1050100 TR 150150 TR 200P1(Unit: mm)TR 100520005360150 TR 200150 18005210TR 150TR 1002.51600HLHoistway(Unit: mm)Rated capacity (kg)OH (min.)ControlpanelTravelTR(m)Entrance height:HH 2100ControlpanelRatedspeed(m/sec)PD (min.)Attachmentpanel Overhead-height (OH)Travel (TR)R2Total heightAccess doorWidth: 1000Height: 2000(by owner)Ventilation window(by owner)AHCinder-concrete finish(by owner)BM (min)BBBHJJAAAUEN81-1HB 3450100Hoisting hook or trolley beam (by owner)RegulationRated speed(m/sec)AM (min)(Unit: mm)HM (min.)Layout example of in-line arrangement3.0(Unit: kN)Rated capacity 1802102306

RATED SPEED OF 3.5, 4.0 m/sec Machine-room height (HM)Machine J (mm)Width DepthAA BB3.54.0TravelTR(m)Rated capacity (kg)1050135016003.5TR 1005970100 TR 25061204.0TR 250652018002000HighestfloorMinimum hoistwaydimensions(mm)Minimummachine roomdimensions(mm)In-line arrangementHoistwaywidth/unitAU (mm)*12-unitinstallation*22-unitinstallationWidth DepthAH BHWidth DepthAM BMP141050149001600 150021504400 23004750 3605P1813501811002000 150025505200 23005200 3605P2116002111002000 170025505200 25005200 3805P2418002411002100 175026505400 25505400 4100 Top clearance (TC)(Unit: mm)Travel (TR) (m)Rated speed(m/sec)100 TR 150TR 10025203.5150 TR 2504.0P1P1P2Elevation3070 Reaction loads in machine room and pit Pit-depth (PD)Ratedspeed(m/sec)3.5TravelTR(m)4.0(Unit: mm)Rated speed(m/sec)Rated capacity (kg)1050135016001800TR 10030203660100 TR 15033703660150 TR 2003660200 3760TR 2507P226705400 430026502100 19505400 27501100262000P26Notes:*1: The hoistway width per unit (AU) is for reference. A single-unit installation is not recommended.*2: The hoistway width (AH) for 3- or 4-unit in-line installation can be calculated as follows:AH Hoistway width per unit (AU) x Number of car units in the shaft Separator beam width 100mm x (Number of car units –1)[Terms of the tables] The dimensional information herein is based on the requirements of EN81-1. This dimensions herein are standard specifications without the fireproof landing door and counterweight safety. Please consult our localagents for details. The minimum hoistway dimensions (AH and BH) shown in the table are after waterproofing of the pit and do not include plumb tolerance.HB 3450LowestfloorPD (min.)CodenumberRatedspeed(m/sec)(Unit: mm)Note: The dimensions OH are calculated when the car frameheight (HB) is 3450mm. Dimension table of car, hoistway and machine roomRatedspeed(m/sec) Overhead-height (OH)HLBHPower receiving panelfor lighting(by owner)Carinternaldimensions(mm)Cinder-concrete finish(by owner)OH (min.)Power outlet(by owner)Power receiving panelwith a lockable device(by owner)Hoistway2500EN81-1Entrance height:HH 2100Groupcontrol panel3.54.0Hoisting hook or trolley beam (by owner)Travel (TR)Control panelRegulationTotal heightVentilation window(by owner)Attachment panelRated speed(m/sec)BM (min) Lobby width 2BHElevator lobbyR2Access doorWidth: 1000Height: 2000(by owner)AHLobby width:3500-4500JJAAAUVentilator(by owner)BHBBR1TCAM (min)100(Unit: mm)HM (min.)Layout example of facing arrangementTR 2003920200 TR 250402020003.54.0(Unit: kN)Rated capacity 52002152358

RATED SPEED OF 5.0 m/sec Machine-room height (HM)Power outlet(by owner)Power receiving panelwith a lockable device(by owner)Power receiving panelfor lighting(by Cinder-concrete finish(by owner)(Unit: mm)Rated capacity (kg)135016001800TR 1506650150 TR 25070502000HighestfloorTotal heightNote: The dimensions OH are calculated when the car frameheight (HB) is 3450mm. Dimension table of car, hoistway and machine ancewidthJJ (mm)Width DepthAA BB5.0Minimummachine roomdimensions(mm)LowestfloorIn-line arrangementHoistwaywidth/unitAU (mm)*12-unitinstallation*22-unitinstallationWidth DepthAH BHWidth DepthAM BMP1813501811002000 145027005500 22505500 3850P2116002111002000 170027005500 25005500 4050P2418002411002100 175028005700 26005700 4150P2620002611002100 195028005700 28005700 4350 Top clearance (TC)Rated speed(m/sec)5.0(Unit: mm)Travel (TR) (m)TR 150150 TR 25032003600P1P1P2 Reaction loads in machine room and pit Pit-depth (PD)Ratedspeed(m/sec)5.09P2ElevationNotes:*1: The hoistway width per unit (AU) is for reference. A single-unit installation is not recommended.*2: The hoistway width (AH) for 3- or 4-unit in-line installation can be calculated as follows:AH Hoistway width per unit (AU) x Number of car units in the shaft Separator beam width 100mm x (Number of car units –1)[Terms of the tables] The dimensional information herein is based on the requirements of EN81-1. This dimensions herein are standard specifications without the fireproof landing door and counterweight safety. Please consult our localagents for details. The minimum hoistway dimensions (AH and BH) shown in the table are after waterproofing of the pit and do not include plumb tolerance.PD nimum hoistwaydimensions(mm)TC2500 Overhead-height (OH)5.0Machine room1800HB 34505.01600HLGroupcontrol panel1350OH (min.)Control panelDistribution panelHoisting hook or trolley beam (by owner)Rated capacity (kg)Entrance height:HH 2100Ventilation window(by owner)Reactor panelAccess doorWidth: 1400Height: 2000(by owner)Lobby width:3500-4500R2BHElevator lobbyRatedspeed(m/sec)AM (min)Travel (TR)JJAAAUAHVentilator(by owner)BHBBR1BM (min) Lobby width 2BH100(Unit: mm)HM (min.)Layout example of facing arrangementTravelTR(m)(Unit: mm)Rated capacity (kg)135016001800TR 1504050150 TR 2004350200 TR 2504450Rated speed(m/sec)20005.0(Unit: kN)Rated capacity 215235240240P221023022022010

RATED SPEED OF 6.0 m/sec Machine-room height (HM)2000Cinder-concrete finish(by owner)Machine room Overhead-height (OH)Ratedspeed(m/sec)6.0TravelTR(m)(Unit: mm)Rated capacity (kg)135016001800TR 1506650150 TR 25070502000HighestfloorTotal heightNote: The dimensions OH are calculated when the car frameheight (HB) is 3450mm. Dimension table of car, hoistway and machine ancewidthJJ (mm)Width DepthAA BBP186.013501811002000 1450Minimummachine roomdimensions(mm)LowestfloorIn-line arrangementHoistwaywidth/unitAU dth DepthAH BHWidth DepthAM BM5500 22505550 3900P2116002111002000 170027005500 25505550 4100P2418002411002100 175028005700 26005700 4150P2620002611002100 195028005700 28005700 4350 Top clearance (TC)(Unit: mm)Travel (TR) (m)Rated speed(m/sec)6.0TR 150150 TR 25032003600P1P1P2 Reaction loads in machine room and pit Pit-depth (PD)Ratedspeed(m/sec)TravelTR(m)TR 1506.011P2ElevationNotes:*1: The hoistway width per unit (AU) is for reference. A single-unit installation is not recommended.*2: The hoistway width (AH) for 3- or 4-unit in-line installation can be calculated as follows:AH Hoistway width per unit (AU) x Number of car units in the shaft Separator beam width 100mm x (Number of car units –1)[Terms of the tables] The dimensional information herein is based on the requirements of EN81-1. This dimensions herein are standard specifications without the fireproof landing door and counterweight safety. Please consult our localagents for details. The minimum hoistway dimensions (AH and BH) shown in the table are after waterproofing of the pit and do not include plumb tolerance.PD (min.)Ratedspeed(m/sec)Minimum hoistwaydimensions(mm)HB 3450Power outlet(by owner)Power receiving panelfor lighting(by owner)Carinternaldimensions(mm)TC28006.0Power receiving panelwith a lockable device(by owner)Hoistway1800HLGroupcontrol panel1600OH (min.)Control panel1350Entrance height:HH 2100Distribution panelAccess doorWidth: 1400Height: 2000(by owner)Lobby width:3500-4500Reactor panelBHElevator lobbyR2Hoisting hook or trolley beam (by owner)Rated capacity (kg)Travel (TR)JJAAAUAHVentilation window(by owner)BHBBR1Ratedspeed(m/sec)AM (min)BM (min) Lobby width 2BH100Ventilator(by owner)(Unit: mm)HM (min.)Layout example of facing arrangement(Unit: mm)Rated capacity (kg)135016004050TR 200150 4350200 TR 25044501800Rated speed(m/sec)20006.0(Unit: kN)Rated capacity 215230240245P220521522523012

ENTRANCE LAYOUT DRAWINGSType E-302, E-312 (Option)Center-Open doorsCenter-Open doorsE-302: Min. 130, Max. 600E-312: Min. 160, Max. 500Type E-102 (Standard)(Min. clearance)Door plan (section B-B)Key hole a: 100Key hole b: 115Door plan (section B-B)Key hole a: 100Key hole b: 115(Min. clearance)Key hole a: 120Key hole b: 145(Min. clearance)Max. 1500mmMin. 160mm without indicatorMin. 200mm when PID-D417 indicator is providedKey hole a: 100Key hole b: 115Key hole a: 120Key hole b: 14520Key hole a: 120Key hole b: 145Hoistway entranceType E-302Hoistway entranceDoor elevation(section A-A)Hoistway entranceType E-312Door elevation(section A-A)Door elevation(section A-A)Building structure(by owner)Wall and floor finishing(by owner)13Building structure(by owner)Notes: 1. A triangular key hole is required under EN81-1.2. Sections A-A and B-B shows dimensionswithout a fireproof landing door.Wall and floor finishing(by owner)Notes: 1. A triangular key hole is required under EN81-1.2. Sections A-A and B-B shows dimensionswithout a fireproof landing door.14

ELECTRICAL INSTALLATION Power Feeder Data *1Speed(m/

Since the elevator drive equipment generates considerable heat, sufficient ventilation and or air-conditioning capacity must be provided to assure that the machine-room temperature does not exceed 40 C. Refer to elevator site requirements at page 18 for details. When occ

![FLOW TEMP. CONTROLLER [MASTER] (Cased) - mitsubishi-les.info](/img/6/im-ib-bh79d499h02-pac-if061-62-63b-e.jpg)