Transcription

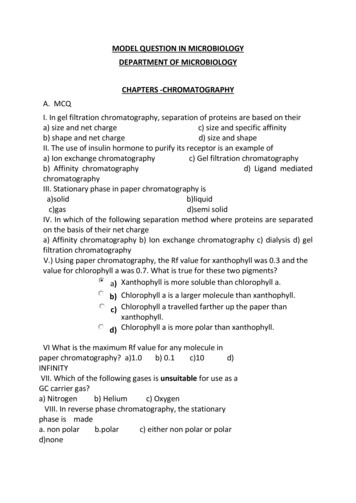

Microbiology/Industrial ApplicationsResearch Biotechnology YeastBacteria Viruses Particle DetectionLeading in High Sensitivity Detection and Analysis

01INTRODUCTIONMicrobiology Industrial Applications* Biotechnology and Cell Culture* Research* Food and Beverage IndustryThe microorganisms are the most successful group of allliving species occupying each habitat in water, soil, plantsand animals including humans with enormous success.This leads to a fundamental impact on all research areas inmodern biology and medicine.

MAIN BENEFITSPrecision High sensitivity flow cytometersfor low signal intensity applicationsVersatility Any microbial FCM applicationcan be performed on Partec instrumentsComfort Quick enumeration of total cellcount within minutesSafety Any cell type can be detected andidentified by our flow cytometersCosts Optimization of large scale productionprocesses saves time and money* Industrial ApplicationsBiotechnologically designed and employed microorganismsfor applications in food industry, chemistry and pharmacysignificantly increase the importance. Because of their smallsize sophisticated technology is required for detection andcharacterization. Partec offers dedicated instruments andreagents for the analysis of microorganisms.

02OVERVIEWWide Range of ApplicationsPartec provides the complete range of flow cytometrytechnology for characterization of microorganismsResearchMicroorganisms have desirable properties which make them analyzed on flow cytometers. Due to an instrument set-uppredominant model organisms for genome analysis, detec- being optimized for low signal intensity applications thetion of regulatory and metabolic pathways, cell division and Partec instruments are commonly preferred for viralcell-cycle studies and many others. Easy handling and culti- detection and characterization.vation procedures thereby reaching an unlimited number ofapproaches are major benefits when working with thesecells. Flow cytometry as the major methodology for cellularanalysis supports all research oriented applications by itshigh potential of analysing cellular properties.Not only cells but also virus particles are successfully beingImage: Dennis Kunkel Microscopy, Inc.cells as well as highly developed cell biological and geneticBiotechnology and Cell CultureWith increasing knowledge about the functionality of A novel approach uses the susceptibility of cells to toxicmicroorganisms it became more common to employ them substances to set-up a bio-monitoring assay to assess thefor biotechnological processes. A new industry developed on toxic potential of various substances.the principle of using microorganisms as bioreactors – thefor the production of pharmaceuticals, nutrition additives,bio-fuels and chemical components. Flow cytometersthereby play a valuable role for monitoring the cultivationof cells, establishing cellular assays or optimizing yield ofprotein expression cultures.Image: Dennis Kunkel Microscopy, Inc.“White Biotechnology“. Microorganisms are commonly used

Food and Beverage IndustryThe utilization of microorganisms for food production hasQuality control of food products is an issue with growingbeen part of the cultural evolution of humans for centuries.importance. Partec provides valuable support becauseAlthough the same organisms are still employed for fermen-virtually any cellular contamination can be detected on ourtation processes in a large scale nowadays, the food andflow cytometers. Protocols for general detection of anybeverage production is a highly engineered industrialcontaminant or individual species detection based onprocess. Large fermenters require constant monitoring toDNA specific probes are available.prevent a break-down directly coupled to loss of money andtime. Beer, wine and whiskey production are based upon thefor alcohol production. Partec offers dedicated instrumentsand reagent kits for monitoring the yeast growth parameters.Controlling the desired organisms is one feature of theprocess, however not less important is the immediatedetection of contaminating and very often spoiling organisms.Image: Dennis Kunkel Microscopy, Inc.fermentation of sugar by the yeast Saccharomyces cerevisiaeIndustrial ApplicationsIndustrial production steps often include the removal ofoccur during the process or further downstream duringwaste water treatment. Partec flow cytometers allow thedetection and hence quantification of virtually any particlewith a size smaller than 200 μm and therefore function asvaluable tools for process optimization.Image: Dennis Kunkel Microscopy, Inc.particles by filtering or chemical treatment. This can either

03OVERVIEWMicrobiology Industrial ApplicationsThe high potential of flow cytometry for microbial analysisconditions the nearly endless versatility. A range of applications is displayed on the following pages, designatedPartec instruments and reagents can be found in section 14.Research04 Research in Biology and Medicine05 Virus detectionBiotechnology and Cell Culture06 Cell Counting in Biotechnology and Cell Culture07 Toxicology and BiomonitoringFood and Beverage industry08 Quality control of Food products09 Yeast in Brewery, Destillery, Wine production10 Fermentation control, Food industry, Process optimization11 BrettanomycesIndustrial Applications12 Particle counting, Paper industry

04APPLICATIONSResearchRESEARCH IN BIOLOGY AND MEDICINEMAIN BENEFITSSuperior sensitivity and resolutionLarge selection of excitation lightSurprisingly enough an estimated 99% ofPartec offers the strongest (for flowall living microorganisms have not evencytometry available) laser models for abeen discovered although (or maybemaximum excitation of the selectedbecause) they colonise any habitat withfluorochromes. This also makes the lowgreat success. From an evolutionary pointsignal intensity microorganisms an easyof view the microbes show a large degreeto approach object of analysis. The choiceSuitable instrumentsof biodiversity, commonly being unified byfrom a large number of light sources andfor this application:the feature of their small size. This featurethe modular design of all our instrumentsCyFlow SLmakes the microbes to a group which isallows the usage of the whole range ofCyFlow spacemost privileged for analysis by flowavailable test reagents. Cell enumeration,CyFlow MLcytometry: the cells usually occur ascell cycle analysis, viability analysis andFor details please seeindividuals and as a consequence samplemany other fluorescence measurementssection 14.preparation is pretty much facilitated.are easy to perform applications onHowever, signal intensities are usuallyPartec flow cytometers.sourcesModular design of Partecinstruments for highest flexibilitylow due to small cell size and hence, lowcellular content of stainable molecules.Fig. 1Lactobacillus spec.Staphylococcus spec.FSCFL3-mitochondrial activityFL1-viable cellsFL1-stainSSCFL3-dead cellsSaccharomyces cerevisiaFSCSeperation of differently sized organisms during a single measurement in a scatter plot: Staphylococcus spec. – Lactobacillus spec. – Saccharomyces cerevisiae.Subsequent analysis: Mitochondrial activity measurement of Staphylococcus, DNA stain of Lactobacillus, Viability measurement of Saccharomyces.FL1

05APPLICATIONSResearchVIRUS DETECTIONMAIN BENEFITSHighest sensitivity by advanced laserpowerDetection of virus particles is verytechnologies for the modern line ofdemanding for both the sensitivity of thePartec instrumentation. Consequently,instrument and the sample preparationPartec was the first developer andconditions because low sensitivities canmanufacturer of flow cytometers offeringbe expected for both scatter and fluo-laser excitation power far beyond therescence signals. Therefore, technicalwell – established standards. In addition,Suitable instrumentsspecifications of the instrument need toPartec flow cytometers can be optimizedfor this application:be pushed to a limit. Partec has alwaysfor low signal intensity measurements.CyFlow SLbeen working on the leading edge ofVirus particles in most cases can onlyCyFlow spaceFCM technology and incorporated thebe detected by staining of the viralCyFlow MLlatest developments of available lasernucleic acids.For details please seeMeasurements at the leading edge oftechnologysection 14.Detection of Bacteriophage MS2 on a Partec flow cytometerSSCFig. 3SSCFig. 2FSCFSCFSC – SSC plot of pure buffer (Fig. 2) and virus particles diluted in the same buffer (Fig. 3). Under the preparation conditions phages tend to form aggregates , thus explaining theelongated tail of virus particles in the gated region.

06APPLICATIONSBiotechnology and Cell CultureCELL COUNTING IN BIOTECHNOLOGYAND CELL CULTUREMAIN BENEFITSCell counting within minutesStraight forward and simple stainingproceduresMeasurement of functional assaysAn accurate determination of the actual cellthe total number of cells being present.content is a necessary step in monitoringBy FCM technology cells can easily bethe growth of microorganisms. Conventionalidentified by their size and structure. Intechniques include counting in a chambercase a more specific detection method isor cultivation on agar plates. Especiallyrequired cells can be stained with aSuitable instrumentsthe plating techniques are time-demandingspecific DNA binding dye. Results arefor this application:because results are not available beforeobtained within minutes by this method.CyFlow SLgrowth of cells has been observed macro-Additional information (viability, speciesCyFlow spacescopically. The obtained count reflectsidentification) may be obtained by slightCyFlow MLthe cultivable cell number only undermodifications of the staining protocol.For details please seesection 14.certain growth conditions, not necessarilyComparison of cell counting technologies: flow cytometry against conventional methodsFLOW CYTOMETRYResult: Cultivable cell countResult: Total cell countViable cell countIdentification of speciesPhysiological parametersFig. 4SSCCONVENTIONAL METHODSCell concentration:795 cells /μlFSCFig. 5StainingCountPlating on agarCell concentration:782 cells / μlDNA-stainCell GrowthAnalysis by FCMTypical flow cytometric result of cell counting:cells can easily be identified based on their scattersignals (Fig. 4) or after DNA staining (Fig. 5).PARTEC FLOW CYTOMETRY – MORE THAN 120 TIMES FASTER THAN CONVENTIONAL METHODS12 – 48 hoursConventional methodsFlow Cytometry10 minutes

07APPLICATIONSBiotechnology and Cell CultureTOXICOLOGY AND BIOMONITORINGMAIN BENEFITSCell counting within minutesModern technology creates and producesis the green algae Desmodesmus spec.an overwhelming number of chemicalCultures of virtually any cell type can becomponents which are ubiquitarillyanalyzed in the same way and maypresent as food additives, colouringreduce tests on whole organisms.Assessing biological hazardpotential of chemical substancesReplacement of animal testproceduresagents, etc. The biological effect of thesesubstances on cellular functionality hasGrowth kinetics of treated cultures yieldSuitable instrumentsonly been tested in few cases. The toxicthe LC50 value for an investigated com-for this application:potential of chemicals though has to bepound by exactly counting the cellCyFlow SLtested more carefully due to morenumber. This kind of analysis can easilyCyFlow spacerestrictive regulations. In vitro toxicitybe done on Partec flow cyometers whichCyFlow MLassays can easily be developed based onare all equiped with the unique TrueFor details please seeflow cytometry detection techniques. TheAbsolute Volumetric Counting (pleasesection 14.most common phytoplankton organismsee section 15) feature.employed for toxicity monitoring assaysDetermination of cell number in toxicology assaysFig. 6Fig. 7123Replicates – 123Growth of monitor organisms in multi-well plates at time point 72 hours (Fig. 6) without testing component (upper row) or after addition of the testing component at variousconcentrations (bottom rows). Samples can directly be analyzed from the incubation plates by using the Multi-well plate autoloader Robby Well. Cell count versus time yieldsthe LC50 for each compound (Fig. 7).

08APPLICATIONSFood and Beverage IndustryDNA SPECIFIC DETECTION, QUALITYCONTROL OF FOOD PRODUCTSMAIN BENEFITSSequence specific detection ofcontaminantsEasy quantification of contaminantsQuality control of food productsMicroorganisms are indispensable forniques are available (FISH technology)many production processes in food andwhich can be applied on Partec flowbeverage industry. However they maycytometry systems. In this way contami-also be amongst the most unwantednations of growing cultures with spoilingcontaminants in the same reactors.bacteria (e.g. Lactobacillus brevis orSuitable instrumentsControlling and protecting the goodPectinatus spec.) can easily be detected.for this application:ones, detecting and abolishing the badThe method does not require time-CyFlow SLones: this challenging task can only beconsuming plating of samples and sub-CyFlow spacereached by employing the proper cellsequent day-long incubation timesCyFlow MLanalyzing instruments. Due to their highbefore receiving the final result. TheFor details please seesensitivity, the easy instrument handlingmobile technology of Partec's flowsection 14.and many available reagents Partec scytometers allows the monitoring offlow cytometers make applications as cellseveral fermenters even at differentenumeration, measurement of total viablelocations thereby reducing investmentcell count and many others accessible forinto technical equipment to a minimum.any quality check facility. For species-Of course, the same technique can alsospecific detection of microorganismsbe applied for classical taxonomy studiesnewly developed DNA hybridization tech-using species specific DNA probes.Identification of Lactobacillus by a DNA probeFig. 9Fig. 10FL1Fig. 11FL1Detection of Lactobacillus acidophilus cells with a labelled RNA specific probe (detectablein the green fluorescence channel). Histogram of green fluorescence of a control sample(Fig. 8) and a hybridized sample (Fig. 9). Cells labelled with the fluorescent probe show astrong signal in FL1.SSCSSCCountCountFig. 8FSCFSCTwo FSC-SSC plots of the hybridized samples. Labelled cells in RN 1 of Fig. 9 arebackgated to Fig. 11 (highlighted in green).

09APPLICATIONSFood and Beverage IndustryYEAST IN BREWERY, DESTILLERY,WINE PRODUCTION AND FOODINDUSTRYSaccharomyces cerevisiae (baker s yeast)MAIN BENEFITSMonitoring of fermentationRapid measurement of cell viabilityPhysiological growth parameterson Partec flow cytometry instruments.is without any doubt the most employedmicroorganism in food and beverageThe Trehalose content of Saccharomycesproduction. A fact which emphasizes itscerevisiae is commonly believed to conferimportance for human nutrition on astress tolerance to growing yeast cells andglobal scale. Controlling the cell growthenables the cells to survive stages ofstatus requires both, long experienceanhydrobiosis.and the right technical equipment. Thestrains of baker s yeast for fermentationfirst is not commercially available - youpurposes normally contain more thanhave already proven your qualities anyway.10% Trehalose of the dry weight. TheFor the latter we provide the dedicatedTrehalose content varies significantly ininstruments for monitoring cell density,dependence of nutrition content and growthviability, contaminants and other growthrate and is an important indicator forparameters in order to prevent dramaticcellular physiology. With Partec FCM unitsfermentation crashes. Due to its modularand staining kits the level of Trehaloseoptical design, almost every fluorescence-content can easily be determined.CommerciallySuitable instrumentsfor this application:CyFlow SLCyFlow spaceappliedCyFlow MLFor details please seesection 14.based detection reagent can be analyzedAnalysis of physiological growth parameters of yeast cellsFig. 12Fig. 13Fig. 14Mean Fluorescence intensityCells / μlFL3-dead cellsTrehalose content of yeast cellsGrowth (hours)FL1 -viable cellsSaccharomyces cerevisiae stained with the Partec“Yeast Control –Viability“ kit. The ratio of living anddead cells can be obtained 10 minutes after takingthe sample from the fermenter (Fig. 12).FL1 -trehaloseFL1 -trehaloseFluorescence measurement of yeast Trehalose content. Staining withPartec “ Yeast Control – Trehalose“ at time points 0 (left) and 12 hours(right) after inoculation (Fig. 13).Trehalose content of growing yeast cells at various stagesafter inoculation (Fig. 14).

10APPLICATIONSFood and Beverage Industry Industrial ApplicationsFERMENTATION CONTROL, FOODINDUSTRY, PROCESS OPTIMIZATIONMAIN BENEFITSMonitoring of fermentationRapid measurement of cell viabilityPhysiological growth parametersThe major area of application is theindustry. Fermentation success directlymicrobial quality control in food, foodinfluences product quality becauseadditives and beverage production, inslightest variations in taste, colour,the pharmaceutical industry and in pro-smell or stability of the final product areduction of drinking water and in wasterecognized by the consumer. Year-longwater treatment. Process control inconstancy of the product can only bebioreactors cultivating bacteria, yeast orreached by experience and sophisticatedhigher cells require constant control ofdetection methods. Partec instrumentsfermentation conditions.contribute significantly by providingessential information of cell count,Lactobacillus spec. is the most com-viability and other physiological growthmonly employed bacteria in foodparameters.Suitable instrumentsfor this application:CyFlow SLCyFlow spaceCyFlow MLFor details please seesection 14.Quick determination of total cell number of Lactobacillus directly taken from the fermenterFig. 16SSCFL1-viable cellsFig. 15Cell concentration:985 cells / μlFSCIdentification and counting of Lactobacillus can easily be done in the FSC – SSC plot (Fig. 15).Viablecell concentration:938 cells / μlFSCA simple DNA stain allows discrimination of living and dead cells (Fig. 16, living cells inQ2, dead cells in Q4).

11APPLICATIONSFood and Beverage IndustryBRETTANOMYCES DETECTION –QUALITY CONTROL OF WINEMAIN BENEFITSQuality control of expensive wineproductsFast detection and quantification ofcontaminantsA major problem in red wine productionpresence of sulphur. Sulphur dioxidewith high economical impact is thetreatment itself influences the winesappearance of off-flavours caused bybuquet and reduces sales prices signifi-Brettanomyces sp. yeasts during winecantly. Therefore, after finishing thematuration. Unwanted taste componentsalcoholic fermentation by SaccharomycesSuitable instrumentslike ”antispetic“, ”bretty“, ”cheese“,yeast, early detection and quantificationfor this application:”rancidity“, ”horse sweat“ and, ”animalicof Brettanomyces in maturating wine isCyFlow SLnote“ cause wine spoilage and reducerequired to ensure absence of thisCyFlow spacewine quality and price. Brettanomycesorganism or to initiate sulphur or otherCyFlow MLspoilage can be prevented by addingtreatments. Partec flow cytometry solu-For details please seesulphur dioxide at an early stage oftions are now replacing conventionalsection 14.maturation before Brettanomyces developmethods which have been too expensivein reasonable numbers. Yeast proliferationand time consuming to prevent winereacts in particular sensitive on thespoilage by Brettanomces on a wide scale.New developed, economic detectionmethodEnumeration of Brettanomyces sp. in red wineFig. 17Cell sizCountConcentration ofBrettanomyces:17.710 cells / mlViable BrettanomycesViable BrettanomycesFluorescence staining of Brettanomyces allows fast quantification of spoiling yeast cellsSmooth hills in Southern France

12APPLICATIONSIndustrial ApplicationsPARTICLE DETECTION IN PA

Partec instrumentation. Consequently, Partec was the first developer and manufacturer of flow cytometers offering laser excitation power far beyond the well – established standards. In addition, Partec flow cytometers can be optimized for low signal intensity measurements. Virus particles