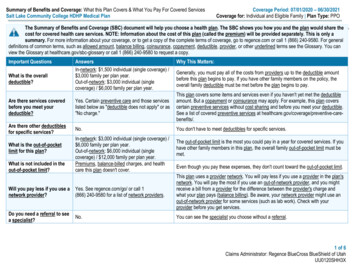

Transcription

The Benefits andImplementation ofModular Data CentersJames Alvers, HP CFS / November 20, 2013 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Agenda: Modular Data Center ConceptsIT EvolutionHP IT Infrastructure StrategyDeployment Process & ExampleThe ResultModular Components OverviewApplication PotentialComments and Q&A Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Data Center Design DemandsDriving Levels of Modularity: Custom to Appliance Meets the “Business Needs” Reliable and available Resource & space and efficient Converged & “Integrated” Scalable, modular and elastic A Shared resource pool, dynamicallyprovision Fully automated Speed of design, procurement & deployment Self-regulating Standardized processes & policies Fully available and resilient Monitoring & control Fully service-oriented Adaptable to future IT Lowest OpEx & CapEx3 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Monolithic Brick & MortarUnique or with Modular Template 4Custom-built onsite.Typical design cycle: 1 yearTypical construction cycle: 1-2 yearsNot very scalableHighest CapEx and OpExBuilt now for all future eventualitiesDoes offer high customization andcreature comforts Copyright 2012 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Flexible Data CenterThe Industrialized Data Center 5Efficient tilt-up, precast, or prefabricatedconstruction for core & whitespaceExternal power and cooling modulesfactory built and tested.Start with 1 Quad, capability of addingcapacity as necessaryBroad turnkey options: menu-drivenselection, quads can have different usescases, density, tiers etc.Standardized set of design, constructionmaterials and prefabricated componentsfrom established supply chainReduced design cycleVariety of cooling designed for minimumpossible energy consumption IntegratedCopyright 2012 Hewlett-PackardDevelopmentCompany,L.P. The information contained herein is subject to change without notice.securityand fireprotection

Flexible Data CenterThe Industrialized Data Center 6Efficient electrical power supply chain withvariety of uninterruptable power supply(UPS) systems with minimum conversionsExcellent operational efficiencydemonstrated by PUEs of 1.2 or lower thatsignal OpEx cost savingsConcurrent maintainability and faulttolerance eliminating single points of failureand providing capability for maintenanceproceduresReduced onsite installation, startup andcommissioning cyclePossible 1 year deployment Copyright 2012 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Saving on CapExModular Construction can cut capital cost by 40%7 Copyright 2012 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Data Center Site Infrastructure Tier StandardsModular designs can be configured to any tier rating (Uptime Institute)8 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Premanufactured DC’sContainerized DC’s Many types and configurations: All in ones IT/data only Power and UPS equipment Cooling modules Can conform to ISO standards for sizeand transport: 10-, 20-, 40-, and 53-ft lengths standard 9.5-ft width typically 9Non ISO: Can be any size Can be occupied Can meet IFB/IFC codesLowest CapexVery Scalable Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Premanufactured DC’sContainerized DC’s Usually built to UL 2755; not occupied 10Code officials often unfamiliarScalableUp to 20 conventional IT racks3 kW to 40 kW per rack and higherMaybe built to IFB/IFC codesFactory built and testedRapid deployment for emergency,incremental capacity, specific use case(density, HPC), short term needs etc.usually 6 months.Installed outside, inside and oftenrelocatableHP POD 20cHP POD 40cStd densityLength with clearance24ft (20ft)41.5ft (40ft)Max weight50,000lbs100,000lbsMax non-redundant powercapacityMax redundant power capacity290kW450kW145kW291kWPower busways2 x 225A4 x 225ARack capacity10 50U racks20 50U racksTotal U-space500U1000UEquivalent traditonal DC2000 sqft4000 sqftDensity960 Servers or 1920 Servers orFlow rate of required chilledwater Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.5400 HDs12,000 HDs120 gpm240 gpm

UL CertificationUL2755To answer the needs from the information technology industrystakeholders such as equipment manufacturers, users and authoritieshaving jurisdiction (AHJs), UL developed the world’s first safety standardfor modular data centers – UL subject 2755 outline of investigation (OOI).The subject not only covers the installation of servers in a CDC, but alsoaddresses the safety of power distribution, cooling systems andsmoke/fire protection systems – basically all of these being used togetheras a system in one "container" and then viewed as a product that onlyneeds to be evaluated for proper installation in the field.11 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Container Datacenter Market ForecastVolume( B)300Americas 7.0EuropeAsia 6.0 0.9 0.8 4.0 0.6 3.0 2.0 1.0 0.0 6.6 1.1 5.0 1.9 0.4 0.6 0.9 0.5 1.3 2.0 1.8 2.4150100 1.1 1.8250200 1.5 0.9Overall Data Center (Millions of Sq. ft) 3.0 3.52012 2013 2014 2015 2016 20175002012 2013 2014 2015 2016 2017Containers Increasing 37% CAGR , Overall Data Center Market increasing 9.5% CAGR12 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.Sources: IHS Research, “World Market for Containerized Data Centers, 2012”Frost & Sullivan, “Data Center Market Update 2012”

IT Evolution Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

14 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

The changing IT worldAdditional business driversContinuous connectivity Mobile apps Social networking On demand servicesAdvanced analytics Big data HPCNew revenue opportunities Business expansion15The Compute CloudIs real and maturingHas advantages for everyoneBenefits will drive adoptionObject storage (data cloud)Business and consumerAnything, (almost) anywhere,anytimeNothing ever goes awayPreconfigured solutionsIntegrated deployments ofhardware & software Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

The Changing IT WorldOn the other hand, New and Enhanced Types of IT EquipmentMoonshot and future servers Moonshot: 89% less energy in 80% less space for 77% cost Future servers will provide similar value in other ways Next generation servers will offer significant economy as wellStorage evolution and revolution Density and power savings continue Memristor will be a game changerAdvanced networking and SDN Optimized flexibilitySecurity, backup 16 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

What is the impact?Benefits to the IT infrastructure organizationData center power consumption shrinks, dramatically (to perform thesame work)Specific examples from several real world scenarios: 89% (9.1X) reduction from current traditional servers to Moonshot– 34X (or more) reduction from older servers to Moonshot 87% (7.7X) reduction in watts per TB of enterprise storage, over four years 96% (20X) reduction moving four year old servers into our Compute CloudSimilarly, a small fraction of data center physical space is requiredR&D engineers are really good at getting more work done per watt They are even better at putting things in smaller packages! 17Power densities, especially for servers, continue to riseFor many new server deployments, very high density space is desirable Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

What is the impact?An couple of interesting – and key – effectsThe TCO of a unit of IT work continues to decrease rapidlyThe cost to do the same work is a tiny fraction of what it cost a couple years agoThe cost to do the same work tomorrow will be a tiny fraction of today The IT TCO is much much less – other than network bandwidth The facility TCO to run the IT is much much lessEfficiency Breeds DemandDriving down the cost increases demandThe lower the cost, the higher the demand 18New use cases have a positive ROIIncremental deployments achieve revenue and profit growthLong desired capabilities become possible and bring value Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

The Rebound EffectJevons Paradox“Technological progress that increases the efficiency with which aresource is used tends to increase (rather than decrease) the rate ofconsumption of that resource”– Wikipedia quote of Blake Alcott, Ecological Ergonomics, 200519 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

HP IT Infrastructure Strategy Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

What’s in an HP Data Center?HP IT for HP Internal OperationsHP networkingHP software HP Intelligent ManagementCenterHP Universal CMDBConfiguration Manager HP Network Automation HP Network Node ManagerHP SiteScope HP Networking Switches andRouters HP Tipping Point IntrusionPrevention Systems HP Server Automation HP Operations Orchestration HP servers HP Moonshot HP ProLiant BL-series Blades HP ProLiant DL-series HP ProLiant SL-seriesHP data centers HP 240a EcoPOD Conventional Brick & Mortar21 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.HP storage HP 3PAR P10000 HP XP P9500 HP SAN Switches

Why additional capacity?What is driving the demand for more data center space?We have six really really good Brick and Mortar Data CentersConsolidated all business applications into new Next Generation Data Centers in 20072009 The data centers remain excellent enterprise class facilities and we will continue to fully utilize themWe continually transform applications and the underlying IT infrastructureFocus on Company TCO of the business solution Normally, Continual IT Transformation would result in more than enough data center capacity forgrowthHowever, efficiency breeds demand!Incremental deployments grow revenue and profit22 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Capacity options consideredWe fully reviewed multiple options to determine the best strategyTraditional brick and mortarBuild an advanced energy efficient but still conventional brick and mortar data center Known entity, high initial cost for significant capacity, lengthy funding to IT production cycleBuild a “Flex-DC” using a brick and mortar whitespace with modularinfrastructureLeverage the quality and savings inherent in pre-configured factory built facilityinfrastructure Similar timeline to brick and mortar, new to everyoneUtilize a fully Containerized Modular Data Center approachDeploy the HP 240a EcoPOD with third party containerized facility infrastructure frompartners 23 Rapid& deployment,rackedconfiguredIT,notice.likely most efficient, new to Copyright construction2013 Hewlett-Packard DevelopmentCompany, L.P. Thefactoryinformation containedherein&is subjectto change withouteveryone

Selection criteriaSelected HP IT requirements for data center space – in random orderContinuously available100.00% available (or as close to it as humanly possible) Meets all HP IT and Real Estate requirements for concurrent maintainability and fault toleranceOptimally accommodate current and next generation ITUltra density space, flexible enough for different types of IT equipment Must be capable of supporting our current and future BL-series Blade Enclosures, Moonshot, andfuture serversZero changes to IT or facility support modelsExisting processes, policies, and procedures applicable without compromise Applies to both deployment and support24 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Selection CriteriaSelected HP IT goals for any data center space – in random orderLow TCOLow initial cost, low operating costHighly efficient facilityIncorporate industry leading energy efficiency practices – low yearly continuous PUEaverage“Right sized” units of capacityAvoid overbuilding expensive data center capacity that may never be usedRapid timeline (from funding to IT production)“Just in time” data center capacity25 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Modular is Not a New ConceptBackup generators have been modular for decades26 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Making the SelectionAnalyzing all factors and weighting, the HP 240a EcoPOD was top in allcategoriesUnbiased and independent choiceHP IT choose to deploy EcoPODs because it was and is the optimal solution to meetbusiness needs Met or exceeded all requirements and schedule, no other option met all Did not receive pressure to deploy In some cases, education on solution, alternatives, and true costs was necessary gain approvalFactory installation and configuration of IT equipment was and is a greatbenefitInitially, we didn’t comprehend the benefits of Factory Express and POD Works Installation and cabling in the factory saved weeks of schedule and more expensive on-site labor Configuration and validation in the factory had similar benefits27 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Why PODs?The EcoPOD was the optimal match for all HP IT requirementsKey factors made the HP 240a EcoPOD the clear winnerThe EcoPOD met all “must-have” and all “strongly desired” requirements Highly available configuration – met or exceeded fault tolerant and continuously maintainablerequirements No changes in IT or facility processes – looks and supported like a brick and mortar Lower cost per kW of usable IT capacity than conventional brick and mortar builds Much faster timeline from funded project to production IT – compared to conventional brick andmortar builds. Very short design and construction cycle. Efficiency, as measured in year round PUE, exceeded all other candidates Perfectly right-sized units of capacity – we choose both 674kW and 1150kW models28 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

IT capacity examplesHow much IT fits in an EcoPOD?An EcoPOD full of HP IT equipment is a incredible amount of IT capabilityAn HP IT configured EcoPOD solution can support: Over 115,000 cloud serversOr over 3,000 BL G8 Physical BladesOr almost 550 Moonshot chassis with nearly 25,000 server cartridges – or close to100,000 CPUsOr any combination of the above or other IT technologyThe above is with today’s IT technology; tomorrow 29 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

HP IT POD strategyA summaryUtilize EcoPODs as the foundation of incremental capacity in a hybridmanner Continue to deploy low density IT equipment, such as storage arrays, in existing very good datacenters Utilize EcoPODs for high or very high density IT equipment– Cloud deployments– Other virtual and physical servers– Existing application transformation and new demand 1/3 factory populate EcoPODs; add incremental IT equipment as the initial is consumed Match incremental deployments insuring additional capacity is on line just before existing capacityfully utilizedWe may utilize PODs or EcoPODs for any future deployment anywhere30 At existing data center sites or anywhere significant quantities of high density capacity is needed Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Deployment Process &Example Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

HP IT EcoPOD deployment #132 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Sketch of an HP240a EcoPOD33 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Breakout of major EcoPOD components3412 ACunitsAC Service12 ACunits22 Racks ITIT Hot Aisle22 Racks IT Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

35 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

POD 240A Technical SpecificationsStructureNorth AmericaPOD length45 ftPOD width21.5 ft (base), 32 ft (total with DX units)POD height21 ft (with DX cooling units)Hot and cold aisle width(2) 39.5 in cold aisles; (1) 8.5 ft hot aisleWeight (approximated with IT)257,000 lbsEnclosure ratingNEMA 3RPowerPower distribution(16) 200 A BuswaysPOD input voltage415 V, 3Ø for IT & 480 V, 3Ø for HVAC, 50–60 HzRack power distribution330 A or 60 A Metered rack mounted power distribution unitsRack power output voltage240 V, 1ØPUE1.05 (Economizer mode) to 1.4 (DX closed loop mode)CoolingCooling technologyAdaptive cooling: Modular direct expansion (DX) with air-side EconomizerCooling redundancy options5N; N 1; 2NPOD IT capacity61,347 kW (N); 1,150 kW (N 1); 674 kW (2N)Cooling capacity per rack30 kW (N); 26 kW (N 1); 15 kW (2N)CFM per rack3,545 (N); 3,250 (N 1); 1,772 (2N) CFMLimited to two power distribution units (PDUs) per rack. 30A PDU Capacity is 17 kW, 60A PDU capacity is 34 kW36 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

POD 240A IT Specifications IT Capacity 2,200U of available rack space, (44) 50U racks Average rack densities up to 30kW , and peak racks up to69kW Offers the equivalent of 10,000 sq ft of traditional data centerspace, housing over 7,000 server nodes or 24,000 hard drives IT Flexibility Racks are standard 19" universal RETMA rails Supports HP and third-party industry-standard hardware withfront-to-back air flow Racks can be fully integrated, tested and installed throughFactory Express Full cable management and integrated structured cabling canbe provided as part of your POD order37 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

Looks and supported like a data center38 Copyright 2013 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

“Overview” of t

What’s in an HP Data Center? HP Server Automation HP Operations Orchestration HP Universal CMDB Configuration Manager HP SiteScope . HP networking HP Moonshot HP ProLiant BL-series Blades HP ProLiant DL-series HP ProLiant SL-series . HP storage .