Transcription

Cognizant 20-20 InsightsUsing Mobility to Elevate WarehouseManagementEnterprise mobility promises to infuse warehouses with greater agilityand nimbleness, but getting there requires that manufacturers take aphased approach, dissecting every operational function and identifyingkey imperatives and process enhancements along the way.Executive SummaryWithout a proper dose of automation, warehousemanagers are unable to achieve the operationalperformance and cost efficiencies needed tocontribute to the greater good of the manufacturing enterprise. This is particularly importantin materials handling, where the slightest inefficiency can lead to operational slowdowns andreputational damage with business partners andcustomers. To meet the requirements of increasingly demanding customers — where doing morewith less is a business imperative — warehousemanagers are laser focused on IT-enabled processchanges that drive operational nimbleness andflexibility, with continuous focus on improvingefficiency and productivity in significant warehousing tasks such as picking, put away, shipping,cross-docking, etc.Enterprise mobility, according to both IDC1 andGartner,2 is among the “four forces” shaping business-IT transformational decisions by deliveringexponential productivity gains and incrementalcognizant 20-20 insights march 2013business value. It is a key enabler of warehouseefficiency, flexibility and nimbleness, allowingmanufacturers to live the future of work, today.This white paper explores areas where mobilitycan be utilized and the key considerations fordeploying mobility in a typical warehouse.Mobility in Warehouse ManagementAdopting mobility can boost the number of ordersand packages processed daily by facilitating thewhole range of warehouse functions from picking,put away, packaging, labelling and shipping,through receiving and cross-docking. For example,in the receiving area a warehouse operator canscan and identify incoming shipments and thenreroute, inspect or relabel them. Similarly, in theshipping area an operator can scan outgoingpackages to ensure order accuracy and can routethem accordingly to the correct dock door orcarry out any required value-added services asprompted on the mobile device.

Enabling the Mobile WarehouseManagement & Supervisory FunctionsReal-Time ApprovalsBI and ReportingSystem AdministrationAd-hoc Label ntoryManagementInventory TransactionsDirected Put AwayPurchase RequisitionMaterial InspectionOn-Demand Stock InformationMaterial ReceivingCycle CountingInbound SchedulingFleet ManagementPhysical Inventory CountingEPOD/EPOCStock ManagementShipment TrackingJob SchedulingPacking, Loading and ShippingReplenishment TransactionsDispatch PlanningConsigned Inventory / VMIMaterial ocessingDirected PickingFigure 1Figure 1 offers a high-level overview of thefunctions that mobility can support in a typicalwarehouse.organizational needs (which are beyond the scopeof discussion here).Once the contours of where mobility can help inwarehouse operations are defined, warehousemanagers can delve deeply to obtain a detailedunderstanding of how ground-level functionscan actually be mobile-enabled and explore thebenefits that can and should be derived fromsuch initiatives.Inbound Materials ProcessingThe functions outlined in Figure 1 can be executedusing different types of handheld mobile devices,including scanners, mobile computers and vehicle-mounted devices, or a combination of these.The selection of these devices for each functiondepends on parameters ranging from the warehouse’s physical environment, the materials itdeals with, Cap-Ex availability and other specificcognizant 20-20 insightsCore FunctionsThe processes involving the receipt of goods intothe warehouse can greatly benefit from the useof mobility. Figure 2 (on page 3) illustrates howmobility can be integrated with inbound materialsprocessing along with the benefits of doing so.Inventory ManagementInventory management is a core area withinwarehouse management where mobility canbring high levels of efficiency. Figure 3 (on page4) shows how mobility can be integrated withinventory management functions along with theassociated benefits.2

Mobility’s Inbound Materials Processing BenefitsFunctionHow to Enable MobilityInboundSchedulingReal-time updates can be exchanged using mobile devicesbetween incoming shipments and the warehouse to facilitateefficient inbound scheduling. Based on these updates, thedock door assignments can be created and altered on areal-time basis.Reduction in waiting time forvehicles at the receiving dock.MaterialsReceivingInbound materials can be scanned, verified and receivedin the warehouse using a mobile device. The mobile devicecan be used to update the receipt status in the enterprisesystem in real time or in batches.Flexibility at the floor levelalong with real-time updates.MaterialsInspectionBased on preconfigured quality plans within the enterprisesystem, inbound materials inspection can be carriedout and the data can be entered for comparison againstapproved specifications using mobile devices. This candirect the warehouse worker to take the necessary actionfor inspection results based on pre-configured rules in theenterprise system.Reduction in overall time andhence cost of quality assuranceactivities.Mobile devices can provide real-time visibility to ordersrequiring cross-docking and suggest suitable inboundCross-Docking shipments for fulfilment. Material can be allocated to theseSuggestions orders on the mobile device and shipped directly withouthaving to be routed through the warehouse’s inventory.Reduction in time and effortneeded to match inbounds andoutbounds for cross-docking.Possibility for enabling crossdocking in warehouses that areunable to use this best practice.Directed PutAwaySpot suggestions of locations for put away of materials canbe displayed on mobile devices based on custom logic andrules depending on warehouse layout, location of existingitems, item type and other parameters. Suggestion-basedput away using mobility will enable easy consolidation ofmaterial in the warehouse based on any chosen parameter.In addition, mobility can enable scanning as opposed tomanual key-in and real-time update of inventory records.BenefitSaves time and effort formaterial consolidation whileimproving concurrent information availability.Figure 2Outbound Material ProcessingIn many businesses, a warehouse’s efficacy isdetermined by how well it is able to processoutbound orders. Figure 4 (on page 5) highlightshow mobility can be integrated with functionsof outbound material processing along with theassociated benefits.Management and SupervisoryFunctionsBesides the core warehousing functions, thereare various management and supervisoryfunctions performed by warehouse managersand shop floor supervisors that mobility can beneficially transform. Figure 5 (on page 6) revealshow mobility can help such functions along withthe benefits.Mobility Deployment Considerationsin a WarehouseDeploying mobility in a warehouse requires a disciplined approach to achieve its full potential. Thedeployment can either be a part of the organization’s overall IT strategy or a warehouse-focusedcognizant 20-20 insightsengagement. Irrespective of the approach taken,deploying mobility in a warehouse requires specialcare across numerous aspects due to its processintensive nature, coupled with the fact that it isa core component of the manufacturing valuedelivery mechanism. Thus, it is imperative that thedeployment blends in smoothly with day-to-dayactivities and causes minimal disruption. Figure6 (on page 6) lays out our recommendations fora seamless deployment of mobility across thewarehouse functions.Objective DefinitionIn this stage, the general approach will involveidentifying the strategic or tactical objectives thatdrive the introduction of mobility in warehouse(s).For example, the objectives can be improvinginventory management, bringing down costswithout impacting service, improving workersafety and/or achieving regulatory compliance.Balance Top Floor and Shop Floor GoalsManagement buy-in for the mobility program willensure tight alignment of the technology with3

Mobility’s Inventory Management BenefitsFunctionHow to Enable MobilityBenefitPurchase requisitions can be raised right at the point ofsource of demand in shop floors and warehouses usingmobile devices.Reduction of purchase leadtime.InventoryTransactionsBasic inventory transactions such as issue, receipt,transfer of goods, etc. can be carried out using mobiledevices. The mobile application can provide informationabout the current location of materials, destination ofmaterials, handling instructions and all other related dataso the user can carry out the specific transaction.Improving concurrent information availability and eliminatingadditional effort for maintainingupdated information.On-DemandStock InformationReal-time information regarding availability of stock andother stock-specific information can be made available onmobile devices from anywhere, anytime. Information canbe queried via different methods (e.g., item-based inquiry,location-based inquiry, etc.).Improving concurrent information availability for fasterdecision-making.Cycle CountingCycle count orders can be executed by scanning itemsplanned for count at any location using a mobile device.The mobile application can keep track of the count andpending items while it can also require users to verify itemand lot information.Reduction in counting effortand enforcement of betteroperational discipline.PhysicalInventoryCountingPhysical counting of all items in particular inventorylocations can be handled using a mobile device. The application can keep track of the counts and also allow entryof items which did not have system records and hence forcounts that were not generated.Reduction in counting effortand concurrent update ofinformationStockManagementMobile applications can be used for stock managementincluding updating the stock quantities, stock condition,location, pack details, registering stock relocations, etc.Reduction in stock managementeffort with concurrent information availability.Job SchedulingReal-time notification of job and flow scheduling canbe sent to shop floor workers on mobile devices. Also,dynamic status updates on work orders and assemblycompletion can be propagated using mobile applications.Better availability of entory levels can be managed using the enterprisesystem’s planning and replenishment features (e.g.,min-max, Kanban, etc.) that includes generating preapproved move orders. These move orders can be effectivelytracked and transacted using a mobile device on the shopfloor.Reduction in time and effort forcarrying out replenishments,thus increasing material availability.MaterialsAllocationRule-based material allocations created by the enterprisesystem for different kinds of move orders such asoutbound orders, issues to shop floor, inventory transfers,etc. can be viewed and managed using mobile devices. Incases where these need modification, such requests canbe initiated, reviewed and approved by appropriate usersbased on configured workflow using their mobile devices.Time savings by providingground level flexibility inhandling material allocations.Consigned or vendor-managed inventory can be receivedon a mobile device using a single receipt transaction tocreate the order line and receive the goods in a singlestep by pre-configuring the rules for order and linecreation.Effort reduction in consignmentinventory gementInventoryReceiptFigure 3cognizant 20-20 insights4

Mobility’s Outbound Materials BenefitsFunctionHow to Enable MobilityDirectedPickingPick lists generated by the enterprise system and assigned tospecific users based on business rules can be viewed by warehouseworkers on their mobile devices. These tasks are then executed bythe user, based on directions provided by the mobile applicationthat optimizes the task at every point based on material availability, route and other variables. The mobile application can alsoupdate the system concurrently with the current task status.Time and hence costsavings in one of themost significant warehousing processes —order picking.Packing,Loading andShippingTasks related to containerization, labeling, loading and shippingcan be administered and executed using mobile devices. Specificinstructions can be transmitted to workers carrying out these tasksin the form of mobile notifications. Additional information such ascost items for shipping charges, outside service tracking numbers,etc. can be captured at this level using a mobile device.Time and cost savingsthrough efficientexecution of packingand shipping process.DispatchPlanningDispatches can be prioritized and hence accelerated by providingthe dispatch planning system, real-time mobile updates on thereadiness of shipments and other delivery requirements. Predispatch tasks can be tracked through mobile devices and theinformation can be constantly fed to the dispatch planning systemin real time to enable this.Time savings andaccuracy of dispatchesby priority and e-kittingTasks for value-added transactions such as packing material asper delivery requirements, gift wrapping, etc. along with specificinstructions can be dispatched through mobile devices based onrequirements recorded in the system. Tasks such as kitting andde-kitting before dispatch can also be administered and executedthrough mobile devices.Increased efficiency andaccuracy in executingvalue-added services.Real-time information can be effectively tracked on delivery, stops,diversions and breakdowns by shipment handlers using mobiledevices to provide updates and even request service. Trackinginformation at this level can help by providing customers withexact information on the status of shipments, which is importantfor B2C companies.Enhanced trackingefficiency and greatercustomer satisfaction.Dynamic optimization can be achieved in fleet utilization byreceiving location and status updates of vehicles in real timeusing mobile devices. Also, dispatches can be consolidated andoptimized based on concurrent information. Route optimizationcan be achieved based on real-time information being receivedfrom mobile-enabled vehicles to enable traffic updates, weatherconditions and other geo-relevant information.Cost reduction throughefficient fleet utilizationand management.Electronic proof of delivery/collection along with signature capturecan be implemented using mobile devices. The delivery person canuse a specialized mobile device to record the acknowledgementfrom customer and to concurrently update status.Time savings inobtaining proof ofdelivery and updatingdelivery oof ofDelivery/Collection(EPOD/EPOC)BenefitFigure 4the organization’s overall strategic objectives.This approach will help ensure the organizationachieves synergistic benefits over the long term.On the other hand, it is also imperative thatthese objectives address key and significant painpoints of the warehouse workforce, as well as thefunction. This will drive active participation andwholehearted adoption of mobility solutions bykey stakeholders.cognizant 20-20 insightsPut Numbers to ObjectivesIt is a good practice to calibrate objectives withnumerical targets where quantitative measurements are feasible. This will help justify the investments needed for the deployment as well as makeit easy to measure the results post-deployment.It may be difficult to assign exact numericaltargets in most cases, so ballpark objectives canbe set. For example, if inventory reduction is an5

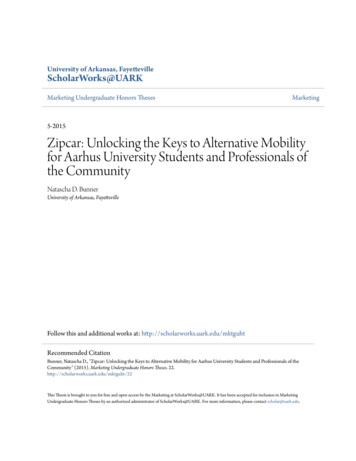

Mobility’s Supervisory BenefitsFunctionHow to Enable MobilityBenefitReal-time approvals can be provided by supervisors andadministrators for all warehouse processes using mobileapplications. When an activity requiring approval isrecorded, notifications are received by the supervisor(s)(based on pre-configured workflows), who can review andapprove/reject the request concurrently from his device.Time savings leading tocost savings through fasterexecution of processes.Business Intelligence andReportingBusiness intelligence and analytical tools can be used togenerate ad hoc reports with interactive charts and layoutson mobile devices that can be accessed from anywhere,anytime. This can take advantage of information updatesprovided through mobile devices in near-real time, thusgiving scope to execute and track key warehousing aspectssuch as predictive replenishments, hours accounting, etc.Faster and effective accessto intelligent information andanalysis leading to efficientdecision-making.Time savings through ease ofconfiguration management.System AdministrationSome basic system administration functions such as useradministration, device administration and parametersadministration can be made accessible through mobiledevices to administrators who work in distributed environments (e.g., modifying user access to specific functions,changing device configurations, changing parameter valuesof system parameters, etc.).Ad Hoc LabelPrintingAd hoc label printing requests can be made through mobiledevices from any point in the warehouse whenever neededby any user who has access to the specific function.Time savings through ease ofmaking print requests fromanywhere.Real-TimeApprovalsFigure 5objective, then mobility deployment can target a7% to 10% reduction in inventory.Process EvaluationThis requires an intensive evaluation of thewarehouse processes in light of the objectivesdefined in the previous stage. Evaluation andanalysis of key processes should result in reengineering for improved execution efficiency interms of cost reduction, speed, error reduction,productivity improvement, agility of informationflow and the other objectives already defined.The underlying focus will be to integrate mobilityinto the host of activities needed to maximizedeployment benefits.Mobility for Business Goals, Not Vice VersaIt is important to keep in mind that the objectivesof deploying mobility, which were identified inthe first stage, were to help attain business goalsrather than deployment of a mobility strategyand devices. For example, suppose the existingKey Considerations for Successful Warehouse Mobility utionDesigningBalance Top Floor& Shop Floor Goals.Put Numbers toObjectives.Mobility forBusiness Goals.Evaluate WarehouseEnvironment &Usability.Keep the TechnoFunctional View.Design for aPhase-WiseImplementation.Take the “App-Way.”Involve End Users.Minimize DesignComplexities.BuildPilot TestingChoose Vendorsfor Solution.Follow IterativeBuilds.Measure theBusiness, Not Justthe System.Choose the RightWarehouse forPilot.Figure 6cognizant 20-20 insights6DeploymentDeploy Warehouseby Warehouse.Train Optimally.Evaluate a RemoteSetup Option.Support &Scale-upSet Up aCentralizedand Remote.ManagementInfrastructure.

way of working involves inbound material putaway and inventory consolidation as two separateprocesses and one of the objectives is to optimizeinventory handling costs. The reengineeredprocess should involve mobility-enabled directedput away which handles consolidation automatically rather than keeping put away and consolidation as two separate processes and mobileenabling each process individually.Evaluate Warehouse Environment and UsabilityIt will be comparatively easier to assess theenvironmental conditions in this stage whileevaluating the processes. Detailed notes can bemade here regarding circumstances such as dustexposure, extreme temperatures, possibility ofcontact with liquids and chemicals, possibility ofdrops and wash-downs and other such conditionsexperienced across variou

deploying mobility in a warehouse requires special care across numerous aspects due to its process-intensive nature, coupled with the fact that it is a core component of the manufacturing value- . Improving concurrent infor-matio