Transcription

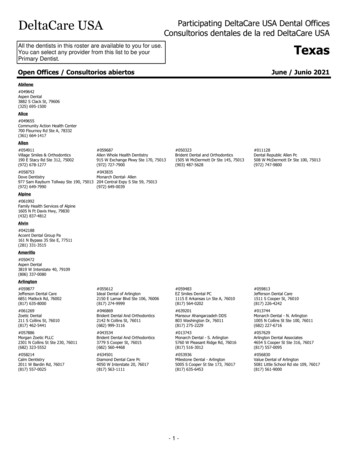

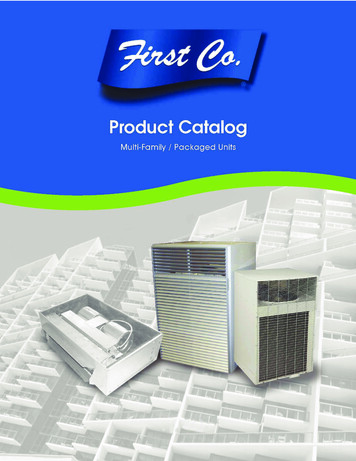

INSTALLATIONINSTRUCTIONSE2005 Lennox Industries Inc.Dallas, Texas, USACB29M & CB30MElite Series UnitsMULTI POSITION BLOWER COILS504,719M09/05Supersedes 04/05Litho U.S.A.RETAIN THESE INSTRUCTIONSFOR FUTURE REFERENCETable of ContentsIMPORTANTFor downflow application, kit number 83M57(LB 109844A) is required. Kit is not provided withcoil blower; order separately.IMPORTANTThe Clean Air Act of 1990 bans the intentional venting of refrigerant (CFC’s and HCFC’s) as of July 1,1992. Approved methods of recovery, recycling orreclaiming must be followed. Fines and/or incarceration may be levied for noncompliance.WARNINGProduct contains fiberglass wool.Disturbing the insulation in this product duringinstallation, maintenance, or repair will expose youto fiberglass wool. Breathing this may cause lungcancer. (Fiberglass wool is known to the State ofCalifornia to cause cancer.)Fiberglass wool may also cause respiratory, skin,and eye irritation.To reduce exposure to this substance or for furtherinformation, consult material safety data sheetsavailable from address shown below, or contactyour supervisor.Lennox Industries Inc.P.O. Box 799900Dallas, TX 75379 990009/05*2P0905*CB29M & CB30M Series Units . . . . . . . . . . . . . . . . . .General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Shipping & Packing List . . . . . . . . . . . . . . . . . . . . . . . .CB29M Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . .CB30M Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . .Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Field Piping Connections . . . . . . . . . . . . . . . . . . . . . . .Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sealing the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Blower Speed Adjustments . . . . . . . . . . . . . . . . . . . . .Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .System Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . .11124558999101617CB29M & CB30M Series UnitsThe Lennox CB29M and CB30M Elite series blower coilunits are designed for installation with a matched remoteoutdoor unit and optional field installed electric heat. Theblower coil units are for indoor installation only.The CB29M and CB30M units, designed for multi positional installations, are completely assembled at the factoryand shipped ready for upflow or horizontal right hand discharge installation.GeneralThese instructions are intended as a general guide and donot supersede local codes in any way. Consult authoritieshaving jurisdiction before installing the unitCheck equipment for shipping damage; if found, immediately contact the last carrier.Shipping and Packing ListEach CB29M and CB30M unit package contains:1 Assembled blower coil unitPage 1504,719M*P504719M*

CB29M Upflow and Downflow Unit Dimensions inches (mm)3/4(19)PIPING PLATE DETAIL(For upflow and downflow positions)SUPPLYAIR OPENINGD1-1/8 (29)3/4(19)4-3/8 (111)2(51)LINE VOLTAGEINLETS (TOP &LEFT SIDE)LOW VOLTAGEINLETS (TOP &RIGHT SIDE)Top View5/8(16)CONDENSATEDRAINS (2)(UPFLOW ANDDOWNFLOW)2-3/4(70)E3-1/2 (89)RETURNAIROPENING1 (25)1-3/4 (44)5/8(16)B5/8(16)FLIQUID LINE11-1/16(281)5-3/8(137)5/8 (16)SUCTION LINECONDENSATEDRAINS (2)(HORIZONTAL)Top ICHEAT(FIELD ELD INSTALLED)ASUCTIONLINERETURN AIRFILTERACCESSCOILFront ViewLIQUIDLINEFILTERBLOWERRETURN AIRSUPPLYAIRE5/8(16)AAIR FLOWLOW VOLTAGE(RIGHT SIDE)LINE VOLTAGE(LEFT SIDE)F5/8(16)COILBLOWER1(25)Side ViewSUPPLY AIR11-1/16 (281)5/8(16)Side ViewUpflow Position5/8(16)D5/8(16)Front View5/8 (16)Downflow Position(Kit number 83M57 (LB 909844A) required to convertunit to downflow applications.)Model No.DimensionABCDEFCB29M-21/26 & 51948315351CB29M-41 & 21948320508Page 2504719M 09/05CB29M-51 & 22153320508

CB29M Horizontal Left and Right Hand Unit Dimensions inches ENSATEDRAINS (2)(UPFLOW ANDDOWNFLOW)COILBLOWERCFor dimensions A"through F", seechart on Page 2.1-1/8(29)CONDENSATEDRAINS )1-3/4(44)LIQUIDLINESUCTIONLINETop View1-1/2(38)5/8(16)5/8(16)11-1/16 3/4(281) (19)AE5/8(16)OPTIONAL ELECTRICHEAT (FIELD INSTALLED)FRETURNAIROPENING1(25)LINE VOLTAGEINLETS (TOP &RIGHT SIDE)AIRFLOW3/4(19)SUPPLYAIROPENINGBLOW VOLTAGEINLETS (BOTTOM& RIGHT SIDE)5/8(16)End ViewFront ViewFILTER ACCESSD3/4(19)End ViewHorizontal Position (Right-Hand Air LTEROPTIONAL ELECTRICHEAT (FIELD INSTALLED)3/4LOW VOLTAGE(19) 11-1/16 INLETS (TOP &LEFT SIDE)(281)Top ViewSUPPLYAIROPENINGLINE VOLTAGE INLETS(BOTTOM & LEFT SIDE)End ViewLIQUIDLINE2(51)FILTERACCESSAIRFLOWCONDENSATE DRAINS (2)(HORIZONTAL)Front (44)5-3/4(146)E1(25)5/8(16)FRETURNAIR OPENING5/8(16)End ViewHorizontal Position (Left-Hand Air Discharge)Page 3CB29M/CB30M SERIES

CB30M Upflow and Downflow Unit Dimensions inches (mm)3/4(19)PIPING PLATE DETAIL(For upflow and downflow positions)SUPPLYAIR OPENINGD1-1/8 (29)3/4(19)4-3/8 (111)2(51)LINE VOLTAGEINLETS (TOP &LEFT SIDE)LOW VOLTAGEINLETS (TOP &RIGHT SIDE)Top View5/8(16)FCONDENSATEDRAINS (2)(UPFLOW ANDDOWNFLOW)2-3/4(70)E3-1/2 (89)RETURNAIROPENING1 (25)1-3/4 (44)5/8(16)B5/8(16)LIQUID LINE11-1/16(281)5-3/8(137)5/8 (16)SUCTION LINECONDENSATEDRAINS (2)(HORIZONTAL)Top LD EOPTIONALELECTRICHEAT(FIELD INSTALLED)COILLIQUIDLINEFILTERFront ViewBLOWERGRETURN AIRSUPPLYAIRE5/8(16)AAIR FLOWLOW VOLTAGE(RIGHT SIDE)LINE VOLTAGE(LEFT SIDE)F5/8(16)COILBLOWERARETURN AIRHSUCTIONLINE1(25)Side ViewSUPPLY AIR11-1/16 (281)5/8(16)Side ViewUpflow Position5/8(16)D5/8(16)5/8 (16)Front ViewDownflow Position(Kit number 83M57 (LB 909844A) required to convertunit to downflow applications.)Model 5/8625Page 4504719M 3/4502215332050827-7/870824-5/8625CB30M-51 & 2235842050827-7/870830-5/8778

CB30M Horizontal Left and Right Hand Unit Dimensions inches ENSATEDRAINS (2)(UPFLOW ANDDOWNFLOW)COILBLOWERCFor dimensions A"through H", seechart on Page 4.1-1/8(29)CONDENSATEDRAINS )1-3/4(44)LIQUIDLINEOPTIONAL ELECTRICHEAT (FIELD INSTALLED)Top (16)SUCTIONLINEG1(25)11-1/16 3/4(281) (19)LINE VOLTAGEINLETS (TOP &RIGHT SIDE)AIRFLOW3/4(19)SUPPLYAIROPENINGBLOW VOLTAGEINLETS (BOTTOM& RIGHT SIDE)5/8(16)End ViewFront ViewFILTER ACCESSD3/4(19)End ViewHorizontal Position (Right-Hand Air LTEROPTIONAL ELECTRICHEAT (FIELD INSTALLED)3/4LOW VOLTAGE(19) 11-1/16 INLETS (TOP &LEFT SIDE)(281)Top ViewSUCTION LIQUIDLINE LINESUCTIONLINELIQUIDLINEA5/8 GB3/4(19)LINE VOLTAGE INLETS(BOTTOM & LEFT TE DRAINS (2)(HORIZONTAL)Front ViewEnd View5-3/8(137)E1(25)5/8(16)FRETURNAIR OPENING5/8(16)5-3/4(146)End ViewHorizontal Position (Left-Hand Air Discharge)RequirementsInstallationInstallation of Lennox blower coil units with or without optional electric heat must conform with standards in the National Fire Protection Association (NFPA) Standard forInstallation of Air Conditioning and Ventilation SystemsNFPA No. 90A," and Standard for Installation of Residence Type Warm Air Heating and Air Conditioning Systems NFPA No. 90B," manufacturer’s installation instructions and local municipal building codes.This unit is certified for installation clearances to combustible material as listed on the unit rating plate. Accessibilityand service clearances must take precedence over combustible material clearances.WARNINGImproper installation, adjustment, alteration, service or maintenance can cause property damage,personal injury or loss of life. Installation and service must be performed by a qualified installer orservice agency.The CB29M and CB30M units are factory configured forupflow or horizontal right hand discharge installation. Fordownflow or horizontal left hand discharge, some fieldmodification is required.Page 5CB29M/CB30M SERIES

2. No further adjustment is necessary. Set unit so that it issloped 1/4 inch toward the drain pan end of the unit.IMPORTANTKit number 83M57 (LB 109844A) must be installedfor downflow application.NOTE For horizontal applications, an auxiliary drainpan is recommended. Refer to local codes.Disassembling CB30M Blower Coil UnitThese units are shipped from the factory fully assembled.The CB30M blower coil unit’s sections may be separatedto facilitate movement at some installation sites. If required, disassemble the unit as follows:1. Remove access panels from both blower and coil assemblies. This will lighten the cabinet for lifting.2. Remove one screw from the left and right posts insidethe unit. Remove one screw from each side on theback of the unit. Unit sections will now separate.3. To reassemble, align cabinet sections and reinstallscrews. Replace access panels.NOTE For horizontal applications in high humidityareas, seal around the exiting drain pipe, liquid line,and suction line to prevent infiltration of humid air.Right Hand Discharge ConfigurationUpflow/DownflowDrain PanHorizontal Drip ShieldHorizontalDrain PanNo Adjustmentis NecessaryFigure 2Upflow Application1. Remove access panels. Remove corrugated paddingfrom the space between the blower and coil assemblies.2. To ensure proper operation, remove the horizontaldrain pan from units in upflow configurations (see figure 1).3. Place unit in desired location. Make sure that unit islevel. Connect return and supply air plenums as required using sheet metal screws.4. Install units that have no return air plenum on a mounting stand at least 14" from the floor for proper air return. Lennox offers an optional upflow unit stand.(45K31 for CB29M 21, 26, and 31; 45K32 forCB29M 41 through 65.)3. If the unit is to be suspended, it must be supportedalong the entire length of the cabinet (see figure 3). Ifusing a chain or strap, attach a piece of angle iron orsheet metal to the unit (either above or below the unit),so that the full length of the cabinet is supported. Usesecuring screws which are no longer than 1/2 inch toavoid damaging the coil or filter. Use sheet metalscrews to connect the return and supply air plenums.Suspending Horizontal UnitAngle Iron orSheet MetalElectrical Inlet Clearance4 in. (102 mm)1/2 IN.SCREWSMAX.Upflow ConfigurationFRONT VIEWEND VIEWFigure 3Upflow/DownflowDrain PanHorizontal Drain Pan(Remove for Optimum Performance)CAUTIONFigure 1Horizontal Right Hand Discharge Application1. Remove access panels. Remove corrugated paddingfrom the space between the blower and coil assembly.Page 6504719M 09/05When removing the coil, there is possible danger ofequipment damage and personal injury. Be carefulwhen removing the coil assembly from a unitinstalled in right or left hand applications. The coilmay tip into the drain pan once it is clear of the cabinet. Support the coil when removing it.

4. (See Detail B and C in figure 4.) Remove screws fromtop cap. Remove horizontal drip shield screw locatedin the center of the back coil end seal.5. Rotate horizontal drip shield 180 front to back.6. Remove plastic plug from left hole on coil front endseal and re install plug in back hole. Re install horizontal drip shield screw in front coil end seal. Drip shieldshould drain downward into horizontal drain pan insidecoil.7. Rotate top cap 180 front to back and align with unused screw holes. Holes must align with front and backcoil end plates. Note that top cap has a 45 bend onone side and 90 bend on the other. The 90 bendmust be on the same side as the horizontal drainpan. See figure 4.Horizontal Left Hand Discharge ApplicationNOTE For horizontal applications, an auxiliary drain panis recommended. Refer to local codes.Remove the access panels and the corrugated paddingfrom the space between the blower and coil assembly before operation. Make the following modifications:1. (See Detail A in figure 4.) Pull coil assembly from unit.Pull off the horizontal drain pan.2. Remove drain plugs from back drain holes on horizontal drain pan and re install them on front holes.3. Rotate drain pan 180 front to back and install it on theopposite side of coil.Left-Hand Discharge ModificationsCoil shown in upflow position for easy conversionNOTE Use extreme care when re installing screwsinto coil end plate engaging holes. Misaligned screwsmay damage coil.8. (See figure 5.) From the upflow position, flip cabinet90 to the left and set into place. Replace coil assembly. Secure coil in place by bending down tab on cabinet support rail.Detail A(DRAINPAN)PLUGGEDENDCOILASSEMBLYOPEN END FORCONDENSATIONDRAINORIGINALPLUGLOCATIONLeft Hand Discharge ConfigurationSecuring Tab onCabinet Support RailHorizontalDrip ShieldNEW PLUGLOCATIONTOP CAP ROTATED TOCORRECT POSITIONTOP CAPSCREWSDetail B(TOP CAP)HorizontalDrain PanCABINETSUPPORTFigure 590BEND9.Detail CALIGN HOLESWITH HOLESIN COIL ENDPLATE.TOPCAP90BEND10.11.12.BACK COILEND SEALDRAIN PANFigure 4NOTE For horizontal applications in high humidityareas, seal around the exiting drain pipe, liquid lineand suction line to prevent infiltration of humid air.Knock out drain seal plate from access door. Secureplate to cabinet front flange with screw provided.Flip access door and replace it on the unit.Set unit so that it is sloped 1/4 inch toward the drainpan end of the unit. Connect return and supply air plenums as required using sheet metal screws.If the unit is to be suspended, it must be supportedalong the entire length of the cabinet (see figure 3). Ifusing a chain or strap, attach a piece of angle iron orsheet metal to the unit (either above or below the unit),so that the full length of the cabinet is supported. Usesecuring screws which are no longer than 1/2 inch toavoid damaging the coil or filter. Use sheet metalscrews to connect the return and supply air plenums.Page 7CB29M/CB30M SERIES

Downflow ApplicationNOTE If downflow application is required, separately order kit number 83M57 and install per kit’s instructions.Also, use metal or class I supply and return air plenums.If the homeowner reports water dripping from supply air diffusers, check the shields and tape. Make sure the tape iscompletely attached to the edges of the drip shield, andthat the drip shield is wedged firmly in place.Field Piping ConnectionsWARNINGAll CB29M/CB30M coils are equipped with a factory installed, internally mounted expansion valve. Use LennoxL15 (sweat) series line sets as shown in Table 1 or usefield fabricated refrigerant lines. L10 (flare) line sets maybe used by cutting off flare nut. Refer to the piping sectionof the Lennox Unit Information Service Manual for propersize, type and application of field fabricated lines.If electric heat section with circuit breakers (ECB29)are applied to downflow CB29M or CB30M unit, circuit breakers must be rotated 180 to the UP position. See ECB29 installation instructions for moredetails.Combustible Flooring Additive BaseTable 1Refrigerant Line SetsBLOWERCOIL UNITCB29MCB29MUnitCombustibleFloor AdditiveBaseProperly SizedFloor OpeningFigure 6On combustible flooring, use an additive base (figure 6).Cut an appropriately sized opening for combustible base(see dimensions in figure 7). Set the additive base intoopening. Connect supply air plenum to the additive base.Set the unit on the additive base so flanges of the unit dropinto the base opening and seal against the insulation strips.The unit is now locked in place. Install return air plenumand secure with sheet metal screws.inches(mm)20 (508)CB29M 41 to 65CB30M 31 to 6518 1/4 (464)CB29M 21/26 & 31CB30M 21/2623 1/4 (591)CB29M 41 to 65CB30M 31 to 653/8 in(8 mm)5/8 in(16 mm)L10 2620 ft. 50 ft.(6 m 15 m)L15 2620 ft. 50 ft.(6 m 15 m) 31 413/8 in(10 mm)3/4 in.(19 mmL10 4120 ft. 50 ft.(6 m 15 m)L15 4120 ft. 50 ft.(6 m 15 m) 46 513/8 in(10 mm)7/8 in.(22 mm)L10 6530 ft. 50 ft.(9 m 15 m)L15 6530 ft. 50 ft.(9 m 15 m) 653/8 in(10 mm)1 1/8 in.(29 mm)FIELDFABRICATEDFIELDFABRICATED4. With heat shield in place, sweat in suction line elbow,provided, and line set. After procedure is completed,remove heat shield.TOP VIEW22-1/8 (562)13-3/8 (340)5. Place heat shield against piping plate and around theliquid line connection. Sweat in the liquid line elbow(provided) and the line set.OPENING2 (51)SIDE VIEW6. Refer to instructions provided with outdoor unit for leaktesting, evacuating and charging procedures.Figure 7Page 8504719M 09/05 21/263. Place heat shield (damp rag) against piping plate andaround the suction line connection. Heat shield mustbe in place to guard against damage to the paint.1-5/8 (41)5/8 (16)L15Line Sets2. Be aware of filter access panel when connecting lines.Filter must be accessible.1-5/8 (41)SUPPLYAIROPENINGL10Line Sets1. Use a wet rag to protect TXV bulb (or remove it) whenbrazing suction line.11-3/8(289)15 (381)CB29M 21/26 & 31CB30M 21/26Vapor/Suction LineNOTE CB29M/CB30M series evaporators use nitrogen or dry air as a holding charge. If there is no pressurewhen the rubber plugs are removed, check the coil or lineset for leaks before installing. After installation, pull avacuum on the line set and coil before releasing the unitcharge into the system.Downflow Combustible Base Dimensions1-5/8 (41)LiquidLine No.

Condensate DrainFiltersConnect main condensate drain and route downward to anopen drain or sump. Do not connect drain to a closed wastesystem. Refer to figure 8 for typical condensate trap configuration.IMPORTANTFilter access panel must be in place during unit operation. Excessive warm air entering the unit may result in water blow off problems.Typical Condensate Drain ConnectionMinimum 1 inch (25 mm) pitchper 10 feet (3048mm) of lineTrap must be deep enough tooffset maximum static difference(generally, 2" [51mm] minimum).Pipe diameter differenceEach unit includes a factory installed filter. Note that filteraccess door fits over access panel. Air leakage will occur ifaccess panel is placed over filter door.CoildrainpanFigure 8It is recommended that the auxiliary drain be connected toa drain line for all units. If auxiliary drain is not connected, itmust be plugged with provided cap. For downflow units,the auxiliary drain MUST be connected and routed to adrain. See figure 9 for auxiliary and main drain locations.Left HandDischargeUpflow orDownflowRight HandDischargeFilters should be inspected monthly and must be cleanedor replaced when dirty to assure proper furnace operation.Reusable filters supplied with some units can be washedwith water and mild detergent. Some units are equippedwith standard throw away type filters which should be replaced when dirty.To remove filter, loosen the thumbscrews holding the filterpanel in place. Slide filter out of the guides on either side ofcabinet, insert new filter and replace panel. See Table 2 forreplacement filter sizes.Table 2Filter DimensionsMain drain on rightAuxiliary drain on leftFigure 9The f

The Lennox CB29M and CB30M Elite series blower coil units are designed for installation with a matched remote outdoor unit and optional field installed electric heat. The blower coil units are for indoor installation only. The CB29M and CB30M units, designed for multi position-al installations, are completely assembled at the factoryFile Size: 366KBPage Count: 20People also search forlennox cb29m 41 1p partslennox wiring diagram for Heating units-ele filer for cb30m-31-4plennox cb30m power board accesslennox cb30m 41 2p specificationsLENNOX CB30M-21/26/2P PARTS