Transcription

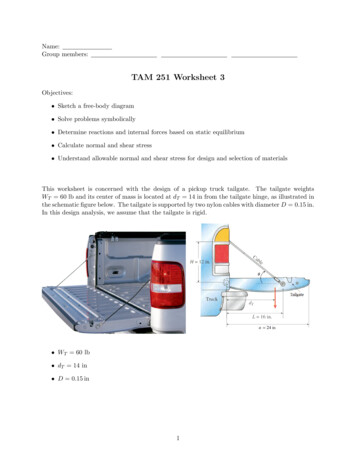

Name:Group members:TAM 251 Worksheet 3Objectives: Sketch a free-body diagram Solve problems symbolically Determine reactions and internal forces based on static equilibrium Calculate normal and shear stress Understand allowable normal and shear stress for design and selection of materialsThis worksheet is concerned with the design of a pickup truck tailgate. The tailgate weightsWT 60 lb and its center of mass is located at dT 14 in from the tailgate hinge, as illustrated inthe schematic figure below. The tailgate is supported by two nylon cables with diameter D 0.15 in.In this design analysis, we assume that the tailgate is rigid. WT 60 lb dT 14 in D 0.15 in1

1) Sketch a free-body diagram that includes the reaction force at each tailgate hinge (componentsRx and Ry ), the internal force in each cable Fc and the tailgate weight WT . Remember that, dueto symmetry, each cable will hold half of the weight of the tailgate. Label the free body diagramwith variable names and not numerical values.2) Use equilibrium to determine a symbolic expression for the internal force at each cable, Fc , dueto the weight of the tailgate WT .3) Obtain an expression for the normal stress in each cable, σc . Use the numerical values givenabove to evaluate σc .2

4) Consider the situation below, where you load the tailgate with several 12 ounces beer cans (totalweight is denoted as Wcans ). Assume that you can arrange all the cans such that its center of massis located at distance dT from each tailgate hinge. Modify the free-body diagram from part (1) sothat includes the weight of the cans, Wcans . Neglect the weight of the aluminum in each can, suchthat each full beer can weighs 0.75 lb.5) Use equilibrium to determine an expression for the internal force at each cable, Fc , due to theweight of the tailgate plus cans.6) How many cans can you load in your tailgate before failure of the nylon cables? The failurestress of the nylon is σf ail 11 ksi.3

7) What is the corresponding resultant reaction force R at each hinge (weight of the tailgate plusthe weight of the cans)?8) The picture below shows an example of a tailgate hinge. Assume that the hinge pin is made ofsteel, is loaded in single shear, and has a diameter dp 0.5 in. What is the corresponding value ofthe average shear stress (τave ) in the pin (self-weight of the tailgate plus cans)?9) The allowable shear stress for the steel pin is given by τall 6 ksi. Is this design safe?4

Consider the picture below. The weight of the ramp plus the four-wheeler can be modeled by avertical force Fm 300 lb applied at the end of the tailgate, as illustrated in the schematic figure.For now, neglect the contact force between the tailgate and the truck bumper due to the rigidrotation of the tailgate (we will include this force in a future assignment).10) What is the normal stress σm in each cable due to the weight of the tailgate WT plus appliedforce Fm ?11) Can we continue to use the nylon cables for this loading condition?5

12) Assume that for a given loading condition and the geometry depicted in question 10), thetailgate experiences a small rigid rotation φ 0.5 degrees. Use small rotation approximation todetermine the strain in the cable.13) Compare the approximated small strain with the exact geometric value.6

TAM 251 Worksheet 3 Objectives: Sketch a free-body diagram Solve problems symbolically Determine reactions and internal forces based on static equilibrium Calculate normal and shear stress Understand allowable normal and shear stress for design and selection of materials This worksheet is concerned with the design of a pickup truck tailgate.