Transcription

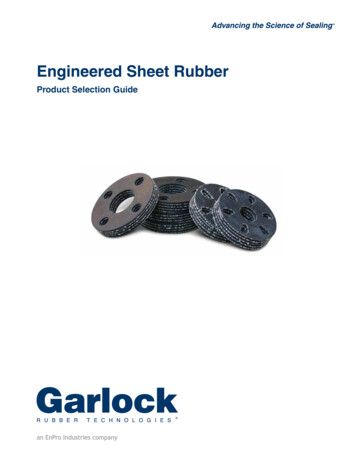

Engineered Sheet RubberProduct Selection Guide

Garlock RubberGarlock Rubber Technologies offers the most extensiveline of sheet rubber in the industry. Our top quality products are made with pride at our state of the art facility inParagould, Arkansas.Garlock Rubber Technologies success is founded onexperience, innovation, state of the art technology anddedication to quality. For nearly 120 years, we've been aleader in the rubber industry with many technical 'firsts'. First to use the alkali reclaim process which curesrubber more efficiently and makes it easier to handle. First to develop and patent the Rotocure VulcanizationProcess, for uniform continuous process curing. First to use the Bierer Davis Oxygen Bomb to acceler ate rubber aging tests.Garlock Rubber Technologies also maintains one ofthe industry's most advanced technical labs, where wetest the physical, chemical and component properties ofmaterials and finished products. Our computer controlledmanufacturing equipment ensures the tightest possiblegauge tolerances and highest quality control. That technology, combined with extensive employee training andexperience, means our quality is guaranteed.Our experienced engineering and field support staff areavailable to help you decide which products are best foryour job requirements. And we have a wide range of madeto order capabilities so we can customize a product tomeet your special needs.Call Garlock Rubber Technologies for unsurpassed quality and service, including: Everything in rubber sheeting including SBR, natural,nitrile, neoprene, EPDM, butyl, CPE, and VITON .Available in custom made colors and finishes with orwithout fiber reinforcement. Complete line of slit to width skirtboard and chutelining and protecting products for the construction,aggregate and conveyor belting markets. Complete line of cushioning products for the road andbridge construction, building construction andvibration isolation markets. Gauge thicknesses from 1/32" to 2" (0.8 mm to 50.8mm) 1/32" to 1/4" (0.8 mm to 6.4 mm) thicknesses avail able up to 72" (1828 mm) in width. 1/4" to 1/2" (6.4 mm to 12.7 mm) thicknesses availableup to 72" (1828 mm) in width. 1/2" to 3" (12.7 mm to 76.2 mm) thicknesses availableup to 48" (1219 mm) in width. Heavy gauge over 3/8" (9.5 mm) available up to 50'(15.24 m) lengths.VITON is a registered trademark of DuPont Dow Elastomers.ContentsSafety Information.2Product Selection Guide . .3Non Oil Resistant Sheet .5Commercial Grade Neoprene Sheet .6Neoprene Oil and Ozone Resistant Sheet .7Nitrile Oil Resistant Sheet .8Neoprene Diaphragm Sheet . .9Food Grade Sheet .10Cloth Inserted Sheet . .11Chute Lining and Extruded Skirtboard .12VIBLONTM Cushioning Pads .13Neoprene Bearing Pads .14High Performance Sheet Rubber-500 Series .15Chemical Resistance Guidelines . .16Chemical Resistance Charts .17Elastomers and Performance Characteristics .22Custom Items .24Ordering and Service Information .25ANSI /ASTM Information .25Metric Conversion Charts.261

Safety InformationREAD THIS PAGE BEFORE USING ANY OF THEINFORMATION IN THIS CATALOGThis catalog is intended as a guide to selecting the propersheet rubber for the applications listed herein. It containsimportant cautions, warnings, guidelines and directions forthe safe and proper use of Garlock sheet rubber. All thesedirections and footnotes should be read and understood before specifying or using any of these sheet rubber products.Symbols, boxes, boldface type, etc. are used to call attentionto these instructions. Be sure to read and understand thembefore proceeding further with this information.WARNING Certain sheet rubber applications are dangerous, suchas those involving high temperatures, fuels andflammables, high pressures or chemical exposure. An in-service failure of sheet rubber can result inserious bodily injury or property damage. Do not usethe sheet rubber products above the temperaturesrecommended by the manufacturer. All operators must be thoroughly trained to inspect forleakage and other signs of gasket wear.2 Failure or misapplication of a seal, gasket or sheetrubber could cause the release of poisonous, corrosiveor flammable material resulting in serious bodily injury,such as buns to the skin, eyes or respiratory systemthrough coming in contact with the escaping fluid vapor. Personnel located in areas close to systems containingthese dangerous materials must be properly equippedwith protective clothing, facial protection and emergencybreathing equipment. SERVICE LIFE: The service life of a sheet rubber willdecrease as the application approaches the uppertemperature limit. The service life of sheet rubberproducts in high temperature applications depends onthe specific details of the application, including chemicalsand/or oils in contact with the rubber.CONSULT THE CHEMICAL RESISTANCE GUIDELINESBEGINNING ON PAGE 17 OF THIS CATALOG FOR VITON , CPE, AND BUTYL PRODUCTS. CALL GARLOCKAT (800) 643.0134 OR FAX (800) 325.0506 FOR ADDITIONAL APPLICATION GUIDELINES AND CHEMICALCOMPATIBILITY INFORMATION ON OTHER SHEETPRODUCTS.

Product Selection GuideTypical Tensile*(minimum)psi (bar)SpecificationsPageNo.70-851,000 (700)69 (48)ASTM D-1330 Gr. I & II5Red70-85800 (400)55 (28)ASTM D-1330 Gr. II5NaturalTan35-453,400 (3,000)235 (207)ASTM D2000-AA-4305, 12Style 563EPDMBlack55-651,700 (1,500)117 (104)ASTM D2000-3BA-615-B13-C125Style 564EPDMBlack55-651,200 (1,000)83 (69)ASTM D2000-2BA-610-C125Style 244Blended CR/NBR/SBRBlack35-45900 (800)62 (55)ASTM D2000-BC-4086Style 254Blended CR/NBR/SBRBlack55-651,000 (800)69 (55)ASTM D2000-BC-5086Style 264Blended CR/NBR/SBRBlack55-651,100 (800)76 (55)ASTM D2000-BC-6086Style 274Blended CR/NBR/SBRBlack65-751,200 (1,000)83 (69)ASTM D2000-BC-7106Style 284Blended CR/NBR/SBRBlack75-851,400 (1,000)97 (69)ASTM D2000-BC-8106Style 5240NeopreneBlack35-451,700 (1,500)117 (104)ASTM D2000-5BC-413-A14-B14-E0347Style 5260NeopreneBlack55-651,800 (1,500)124 (104)ASTM D2000-2BE-615-A14-B14-C12E014-F17-Z17Style 5280NeopreneBlack75-851,800 (1,500)124 (104)ASTM D2000-2BE-815-A14-B14-C12E014-F177Style 361NitrileBlack55-652,000 (1,800)138 (124)ASTM D2000-BF-6188Style 363NitrileBlack55-651,200 (1,000)83 (69)ASTM D2000-BF-6108DiaphragmStyle 3205,3206, 3210NeopreneBlack65-751,500 (1,400)104 (97)ASTM D2000-BC-7149ProductElastomerColorBay State22NAT/SBRRedStyle 50NAT/SBRStyle 135* Figures are for rubber compound without fabric.Durometer*(Shore A)NOTE: Stock items appear in BOLD type. For items and sizes not listed,contact Customer Service at 800.643.0134.NOTE: The chart on pages 3 and 4 lists the basic physical properties ofeach Garlock sheet rubber style, making it easier to match your specifications and requirements to a Garlock material.Since each application is unique, when trying to match a sheet rubber toa specific application various criteria should be considered including thelist on page 26 under "Information Necessary for Custom Manufacturing".Further information regarding the use of Garlock sheet rubber is available by calling Garlock Customer Service at 800.643.0134.3

Typical Tensile*(minimum)psi (bar)SpecificationsPageNo.55-651,700 (1,500)104 (83)ASTM D-200-2BF-615-E03410Black70-801,300 (1,000)90 (69)ASTM D2000-BC-810-Z111SBR/NBRPolyester FabricBlack70-801,300 (1,000)90 (69)ASTM D2000-BC-810-Z111Style 2264Blended SBR/CR/NBR PolyesterFabricBlack55-651,100 (800)76 (55)ASTM D2000-BC-60811SuperRINOHIDE SBRBlack55-652,800 (2,500)193 (173)ASTM D2000-BA-62512RINOBACK SBR/CottonbackBlack55-652,800 (2,500)193 (173)ASTM D2000-BA-62512Tan GumStyle 135NaturalTan35-453,400 (3,000)235 (207)ASTM D2000-AA-43012Style 7164SBRBlack55-652,400 (2,000)166 (138)ASTM TM D2000-AA-61012VIBLON NitrileTan-N/ADesigned to meet MIL-C-822Especifications13BearingPadsNeoprene & NaturalBlack45-552,600 (2,250)179 (155)Designed to meet AASHTOspecifications1455-652,800 (2,250)193 (155)65-753,000 (2,250)207 (155)ProductElastomerColorStyle 362NitrileWhiteMulti-Ply2103SBR/NBRPolyester FabricStyle 2102Durometer*(Shore A)Style 501BrandedVITON Black70-801,300 (1,000)90 (69)ASTM D2000-2HK-710-B37-Z115Style 505BrandedCPEBlack65-752,000 (1,800)138 (124)ASTM D2000-BA-61515Style 509BrandedButylBlack55-651,800 (1,500)124 (104)ASTM D2000-BA-61515* Figures are for rubber compound without fabric.VITON is a registered trademark of DuPon Dow Elastomers.NOTE: Stock items appear in BOLD type. For items and sizesnot listed, contact Customer Service at 800.643.0134.4WARNINGExposure to chemicals, fuels, oils or heat can affect the performance ofsheet rubber and cause the product to lose its ability to maintain a seal,causing leakage or other failure which could result in property damage,serious injury or death. Since each application is unique, consult Customer Service at 800.643.0134 or fax 800.325.0506 for further information.

Non-Oil Resistant SheetExcellent general purpose gasket materials for air, hot andcold water, saturated steam and exterior service.Style 564Bay State 22Has the same general characteristics as Style #563, but itis a commercial quality sheet.(Branded) has a smooth, rotocured finish. It is a blendof natural and SBR rubber, specially compounded to bequick sealing, non hardening and heat resistant. It conformseasily to uneven flange surfaces. ASTM D2000-2BA-610-C12 ASTM D 1330 Gr. IStyle 50A cloth finish, drum cured sheet. It is an excellent, low cost,flange gasket material. ASTM D 1 330 Gr. IIStyle 135A full floating, natural rubber. It resists most organic salts,ammonia, acids and alkalies. It is non marking. ASTM D2000-AA-430Style 563An EDPM sheet that provides outstanding resistance toweathering, ozone and UV expo sure. It provides excellentchemical resistance and dynamic properties. ASTM D2000-3BA-615-B13-C12Typical Tensile*(minimum)psi (bar)FinishUltimateElongation(% min)Approx. Wt.Lbs/Yd2[kg/m2]1/16" atureRangeProductElastomerColorDurometer*(Shore A)Bay State22 BrandedNatural/SBRRed70-851,000 (700)69 (48)Smooth2004.7 [2.5]up to 72(1829)1/16, 1/8,1/4 (1.6, 3.2,6.4)-20ºF to 180ºF(-29ºC to 82ºC)Style 50Natural/SBRRed70-85800 (400)55 (28)ClothImpression1505.0 [2.7]36, 48(914,1219)1/16 thru 1/4(1.6 thru 6.4)-20ºF to 180ºF(-29ºC to 82ºC)Style 135NaturalTan35-453,400 (3,000)235 (207)Smooth6002.9 [1.6]36, 48(914,1219)1/16 thru 1(1.6 thru25.4)-20ºF to 180ºF(-29ºC to 82ºC)Style 563EPDMBlack55-651,700 (1,500)117 (104)Smooth4003.3 [1.8]36 (914)1/16 thru 1/4(1.6 thru 6.4)-40ºF to 275ºF(-40ºC to 135ºC)Style 564EPDMBlack55-651,200 (1,000)83 (69)Smooth3503.6 [2.0]36, 48(914,1219)1/16 thru 1/2(1.6 thru12.7)-20ºF to 250ºF(-29ºC to 121ºC)* Refer to "Sheet Rubber Tolerances", page 265

Commercial Grade Neoprene SheetThese products are blends of neoprene, nitrile and SBR rubbers. They are moderately oil-resistant, for use as bumpers,pads and in sealing and general gasket applications.Style 284Style 244 ASTM D2000-BC-810A hard, good quality, blended CR/NBR/SBR sheet.A soft, good quality, blended CR/NBR/SBR sheet. ASTM D2000-BC-408Style 254A medium soft, good quality, blended CR/NBR/SBR sheet. ASTM D2000-BC-508Style 264A medium hard, good quality, blended CR/NBR/SBR sheet. ASTM D2000-BC-608Style 274A hard, good quality, blended CR/NBR/SBR sheet. ASTM D2000-BC-710ProductElastomerColorDurometer*(Shore A)Typical Tensile*(minimum)psi (bar)FinishUltimateElongation(% min)Approx. Wt.Lbs/Yd2[kg/m2]1/16" atureRangeStyle 244BlendedCR/NBR/SBRBlack35-45900 (800)62 (55)Smooth3503.7 [2.0]up to 72(1829)1/16 thru 1(1.6 thru25.4)-20ºF to 190ºF(-29ºC to 88ºC)Style 254BlendedCR/NBR/SBRBlack45-551,000 (800)69 (55)Smooth3004.0 [2.2]up to 72(1829)1/16 thru 1(1.6 thru25.4)-20ºF to 190ºF(-29ºC to 88ºC)Style 264BlendedCR/NBR/SBRBlack55-651,100 (800)76 (55)Smooth3003.9 [2.1]up to 72(1829)1/32 thru 2(0.8 thru50.8)-20ºF to 190ºF(-29ºC to 88ºC)Style 274BlendedCR/NBR/SBRBlack65-751,200 (1,000)83 (69)Smooth2004.0 [2.2]up to 72(1829)1/16 thru 1(1.6 thru25.4)-20ºF to 190ºF(-29ºC to 88ºC)Style 284BlendedCR/NBR/SBRBlack75-851,400 (1,000)97 (69)Smooth2004.1 [2.2]up to 72(1829)1/16 thru 1(1.6 thru25.4)-20ºF to 190ºF(-29ºC to 88ºC)* Refer to "Sheet Rubber Tolerances", page 266

Neoprene Oil and Ozone Resistant SheetThis blended neoprene sheet is used where good oil,petroleum, ozone and weathering resistance is needed. It isvery popular due to the broad range of applications in whichit may be used.Style 5240A soft, premium grade, neoprene sheet with good resistanceto oil, weathering and ozone exposure. ASTM D2000-5BC-413-A14-B14-E034Style 5260A medium hard, premium grade, neoprene sheet. ASTM D2000-2BE-615-A14-B14-C12-E014-F17-Z1(Z1 Equals 300% Elongation)Style 5280A hard, premium grade, neoprene sheet with good oilresistance. ASTM ColorDurometer*(Shore A)Typical Tensile*(minimum)psi (bar)FinishUltimateElongation(% min)Approx. Wt.Lbs/Yd2[kg/m2]1/16" atureRangeStyle 5240NeopreneBlack35-451,700 (1,500)117 (104)Smooth5003.9 [2.1]36 (914)MTO**-40ºF to 200ºF(-40ºC to 93ºC)Style 5260NeopreneBlack55-651,800 (1,500)124 (104)Smooth3004.0 [2.2]36 (914)1/16, 1/8, 1/4(1.6, 3.2, 6.4)-40ºF to 200ºF(-40ºC to 93ºC))Style 5240NeopreneB

ASTM D2000-AA-430 Style 563 An EDPM sheet that provides outstanding resistance to weathering, ozone and UV expo sure. It provides excellent chemical resistance and dynamic properties. ASTM D2000-3BA-615-B13-C12 * Refer to "Sheet Rubber Tolerances", page 26 Style 564 Has the same general characteristics as Style #563, but it is a commercial quality sheet. ASTM D2000-2BA-610